EP0123671B1 - Machine de forage - Google Patents

Machine de forage Download PDFInfo

- Publication number

- EP0123671B1 EP0123671B1 EP19840890067 EP84890067A EP0123671B1 EP 0123671 B1 EP0123671 B1 EP 0123671B1 EP 19840890067 EP19840890067 EP 19840890067 EP 84890067 A EP84890067 A EP 84890067A EP 0123671 B1 EP0123671 B1 EP 0123671B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotor

- drill column

- drill

- drilling device

- drilling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000005553 drilling Methods 0.000 title claims description 31

- 239000011435 rock Substances 0.000 claims description 4

- 238000009527 percussion Methods 0.000 claims description 2

- 239000012530 fluid Substances 0.000 claims 1

- 238000000034 method Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B19/00—Handling rods, casings, tubes or the like outside the borehole, e.g. in the derrick; Apparatus for feeding the rods or cables

- E21B19/16—Connecting or disconnecting pipe couplings or joints

Definitions

- the invention relates to a device for drilling, in particular for rotary drilling of rock or the like, with a device for loosening the drill pipe.

- a multi-part drill pipe is used, which is gradually extended with a further drill rod.

- the process is such that the boring bar, including the drill bit, is advanced until the connection point between the stub and the boring bar comes close to the borehole.

- the drill pipe e.g. with a wrench or the like. Rotationally held and the stub is rotated in the opposite direction for drilling or rotary impact drilling, be it via the rotating assembly or its own motor.

- the rod before loosening the connection, it can be advantageous for the rod to be pulled a short distance out of the borehole, whereupon so-called blows occur on the stub, which makes the threaded connection more easily detachable.

- the drilling unit is arranged on a carriage and is moved backwards after loosening the threaded connection, whereupon a new boring bar is inserted, which is connected to the drill pipe, which is still held in place, and the plug-in connector using the normal rotary movement.

- the fork wrench is then disengaged and the drill pipe is ready for further use. If the drill hole has now been made to the desired depth, the individual drill rods must be pulled out of the drill hole again.

- the connections of the boring bars are loosened step by step.

- boring bars are usually used which have an external thread at one end and an internal thread at the other end, with both the external and the internal thread having the same diameter. With rotary impact drilling, the sleeves, which have the internal thread, are subject to a particularly high load, so that the sleeves break prematurely.

- the boring bars have external threads at their two ends, each of which can be connected via a sleeve which has a corresponding internal thread, which can either be continuous or divided into two and in the same direction.

- a device for drilling with multi-part drill pipe is known, the parts of which can be connected to one another via internal and external threads, a drive being provided for releasing the drill pipe, which holds the drill pipe via cam-shaped gripper elements.

- the cam-shaped grippers are moved via gear wheels which engage in an internal ring gear.

- the internal ring gear is moved by a drive motor via another spur gear.

- a disengageable driver solves the problem of a quick connection between the drilling device and the drill pipe, i.e. it is an advantage if there is a frictional connection without a long start-up time.

- the present invention had for its object to provide a device for drilling, which allows the gripper elements to be engaged in a particularly simple manner by rotating the rotor.

- the aim is achieved in that a ring, which has drivers for the gripper elements, is mounted in the rotor and can be held by a housing surrounding the rotor.

- the production of boreholes and in particular the pulling of the drill pipe can be carried out particularly quickly, since the gripping elements can be engaged and quickly applied by rotating the rotor in a particularly simple manner.

- the gripping elements can easily be pivoted out by rotating in the opposite direction.

- Accurate centric guidance of the drill pipe which is advantageous for fast clamping of the drill pipe in the device, can be achieved by providing at least one, preferably two, guides centrally to the rotor, in particular with a truncated cone and a cylindrical surface for the drill pipe .

- a particularly simple constructive solution which at the same time allows the work surface to be easily adapted to the circumstances, consists in that at least three cam-shaped gripping elements are mounted on the rotor, the respective working surfaces being partially cylindrical, and the axis of the cylinder being outside the pivot axis of the gripping elements.

- the gripping elements can be replaced particularly quickly, which is particularly important when a gripping element breaks or when the device is changed over for a drill pipe with a different diameter Meaning is.

- the rotor has an external toothing into which a drive pinion meshes.

- the rotor has a hollow axis through which the drill pipe can be guided, this results in a particularly simple and trouble-free construction.

- a ring which has drivers for the gripping elements, is mounted in the rotor and can be held in place by a housing surrounding the rotor, the gripping elements can be engaged in a particularly simple manner by rotating the rotor.

- the gripping elements can easily be pivoted out by rotating in the opposite direction.

- Accurate centric guidance of the drill pipe which is advantageous for fast clamping of the drill pipe in the device, can be achieved by providing at least one, preferably two, guides centrally to the rotor, in particular with a truncated cone and a cylindrical surface for the drill pipe (are).

- the relative movement between the drill pipe and the device according to the invention when solving the object according to the invention is taken into account in a particularly favorable manner in that the rotor, preferably together with the further drive on the mount, can be moved in the axial direction of the drill pipe, and optionally via resilient elements, cylinders or the like . is movable into a rest position.

- FIG. 1 shows a mobile drilling device with drilling arm and drill carriage

- FIG. 2 shows a drilling arm

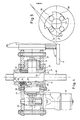

- FIGS. 3 and 4 show a clamping device with cam-like gripping elements

- FIG. 5 shows the schematic representation of a clamping device with rollers.

- a vehicle 2 is provided on the vehicle 1 shown in FIG. 1, which is calculated for the operator. Furthermore, a hydraulic unit 3, which serves to drive the drilling arm 4 and the rotary impact unit 5 and the clamping and turning device 6 and the key 7, is provided. The percussion device lowers along the carriage 8 during drilling until the stub 9 comes close to the clamping and rotating device. Then the threaded connection between the drill pipe and the stub is released and the rotary impact device is brought into the starting position shown in the drawing. Furthermore, a new boring bar is inserted into the mount, the drill string located in the borehole is held in place by key 7, connected to the new boring bar and at the same time screwed into the stub. This process is repeated until the desired drilling depth is reached. Then the drill pipe is gradually raised and one drill rod is separated from the rest of the drill pipe, the drill pipe located in the borehole being held in place by the key 7, and the connection being released via the clamping and rotating device.

- the drilling arm shown in FIG. 2 is connected to the tracked vehicle via a bracket 10.

- the console 10 has flanges 11 which carry a telescopic boom 12 which can be adjusted in height and in the sides via the cylinders 13, 14.

- the boom carries a swivel head 15, which in turn carries the mount holder 16, pivotably via a cylinder 16a.

- the carriage 8 has at one end longitudinally displaceable the impact rotary drilling device 5 and at the other end the clamping and rotating device 6. In the position shown in Fig. A substantially horizontally aligned borehole is drilled.

- FIG. 3 shows a clamping and rotating device, partly in section and in plan view, whereas in FIG. 4 the section along line 4/4 according to FIG. 1 is shown.

- the housing 17 is guided on the carriage 8 via a slide shoe 18. 4, a rotary motor 19 is fastened in the housing.

- This rotary motor 19 drives the rotor 21 via a pinion 20.

- This rotor has an external toothing 22.

- the rotor has a hollow axis 23, which is mounted in the housing 17.

- Guides 24, which are frustoconical, engage in the hollow axis on both sides have surface 25 and a cylindrical guide surface 26.

- cam-like gripping elements 28 are mounted in the rotor via axes.

- the self-locking angle should not be greater than three degrees if the gripping elements and the drill pipe are made of steel.

- the self-locking angle in this case is given by the sum of the angles ⁇ i and a 2 , which is defined by the connection of the axis of the drill pipe 30 and the axis of rotation 27 of the gripping element.

- the second leg of these two angles is defined by the line of contact 37 between the gripping element and the sleeve.

- this angle is equal to or less than the angle of the self-locking, the gripping elements come to the immovable engagement on the smooth surface of the drill string, whereby effortless loosening is given, while at the same time a high moment arises over the relatively large diameter of the rotor 21 the sleeve can be applied so that trouble-free loosening is easily possible.

- FIG. 5 which can be installed in the device according to FIGS. 3 and 4, it has inner wedge surfaces 38, which cooperate with rollers 39, these rollers being able to be brought back into contact with the drill sleeve.

- the angle a of the self-locking is defined here by the tangents on the roller 39, which is given in each case by the points of contact on the sleeve 31 or on the wedge-shaped surface 38.

- the clamping and rotating device is moved from its position along the carriage when unscrewing the sleeve.

- the device is returned to its starting position by means of the spring 40.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Geology (AREA)

- Mining & Mineral Resources (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Earth Drilling (AREA)

- Drilling And Exploitation, And Mining Machines And Methods (AREA)

Claims (5)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0123383A AT382682B (de) | 1983-04-07 | 1983-04-07 | Vorrichtung zum bohren |

| AT1233/83 | 1983-04-07 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0123671A2 EP0123671A2 (fr) | 1984-10-31 |

| EP0123671A3 EP0123671A3 (en) | 1985-04-03 |

| EP0123671B1 true EP0123671B1 (fr) | 1988-09-14 |

Family

ID=3509481

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19840890067 Expired EP0123671B1 (fr) | 1983-04-07 | 1984-04-05 | Machine de forage |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0123671B1 (fr) |

| JP (1) | JPS59187991A (fr) |

| AT (1) | AT382682B (fr) |

| AU (1) | AU566591B2 (fr) |

| DE (1) | DE3474050D1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6125791U (ja) * | 1984-07-23 | 1986-02-15 | 石垣食品株式会社 | 板付き切りかまぼこ |

| FI854120L (fi) * | 1985-10-22 | 1987-04-23 | Tampella Oy Ab | Oeppningsanordning foer borrstaenger foer en skarvstaongsborrningsutrustning. |

| FI78340C (fi) * | 1985-10-22 | 1989-07-10 | Tampella Oy Ab | Oeppningsanordning foer en utrustning foer skarvstaongsborrning. |

| DE3819537A1 (de) * | 1988-06-08 | 1989-12-14 | Bauer Spezialtiefbau | Ankerbohrgeraet |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA876536A (en) * | 1969-05-22 | 1971-07-27 | W. Becker Floyd | Tong assembly for drill pipes |

| US3662867A (en) * | 1970-03-13 | 1972-05-16 | Robert B Kinzbach | Force transmitting coupling |

| US3760658A (en) * | 1971-01-08 | 1973-09-25 | W Guier | Apparatus for supporting pipe tongs |

| US4372026A (en) * | 1980-09-16 | 1983-02-08 | Mosing Donald E | Method and apparatus for connecting and disconnecting tubular members |

-

1983

- 1983-04-07 AT AT0123383A patent/AT382682B/de not_active IP Right Cessation

-

1984

- 1984-04-02 JP JP6346984A patent/JPS59187991A/ja active Pending

- 1984-04-02 AU AU26333/84A patent/AU566591B2/en not_active Ceased

- 1984-04-05 DE DE8484890067T patent/DE3474050D1/de not_active Expired

- 1984-04-05 EP EP19840890067 patent/EP0123671B1/fr not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| EP0123671A3 (en) | 1985-04-03 |

| AU566591B2 (en) | 1987-10-22 |

| AT382682B (de) | 1987-03-25 |

| DE3474050D1 (en) | 1988-10-20 |

| ATA123383A (de) | 1986-08-15 |

| JPS59187991A (ja) | 1984-10-25 |

| EP0123671A2 (fr) | 1984-10-31 |

| AU2633384A (en) | 1984-10-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2461112C3 (de) | Drehbohrkopf | |

| EP0886034B1 (fr) | Dispositif de forage | |

| DE3438478A1 (de) | Zusatzhandgriff fuer handbediente maschinen | |

| DE1944988B2 (fr) | ||

| DE1203199B (de) | Bohrgeraet | |

| EP0123671B1 (fr) | Machine de forage | |

| EP0860580B1 (fr) | Appareil pour la manutention de tiges de forage | |

| EP0510416B1 (fr) | Mécanisme à coup pour colonne de forage | |

| DE3612762A1 (de) | Teleskopierbares bohrgeraet | |

| DE2505986A1 (de) | Vorrichtung zum auseinanderschrauben von bohrgestaengerohren in einer bohrmaschine | |

| DE19918530B4 (de) | Kupplung zum Verbinden zweier Abschnitte eines Bohrgestänges | |

| EP0518114B1 (fr) | Dispositif pour raccorder de manière amovible un tube de forage avec un appareil d'entrâinement rotatif | |

| AT390124B (de) | Oeffnungsanordnung zum loesen eines aus verschraubten bohrstangen bestehenden bohrgestaenges einer ausruestung fuer langlochbohrung | |

| DE3408246C2 (de) | Vortriebseinrichtung zum Herstellen unterirdischer Hohlräume nach dem Rohrvorpreßverfahren | |

| DE1188014B (de) | Gesteinsbohrgeraet mit exzentrisch arbeitendem Bohrwerkzeug | |

| EP0439600B1 (fr) | Engin de forage | |

| DE10218407B4 (de) | Vorrichtung zum Lösen von Gestängegewindeverbindungen | |

| DE1187566B (de) | Bohrwerkzeug fuer das Schlagbohren mit einem sich drehenden Bohrer | |

| DE1220360B (de) | Gesteinsbohreinrichtung | |

| DE2706940A1 (de) | Bohrgeraet mit hydraulischem antrieb | |

| EP0119375B1 (fr) | Dispositif de forage et de mise en place des boulons d'ancrage, notamment pour le minage | |

| DE1188529B (de) | Bohrmeissel | |

| DE19629211A1 (de) | Ankerbohrmaschine | |

| DE202020004924U1 (de) | Vorrichtung und Verwendung zum Lösen oder Festziehen von Langkörpern | |

| DE3514030A1 (de) | Bohrvorrichtung, insbesondere zum rammbohren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850418 |

|

| 17Q | First examination report despatched |

Effective date: 19870319 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR GB IT LI LU NL SE |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3474050 Country of ref document: DE Date of ref document: 19881020 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930315 Year of fee payment: 10 Ref country code: CH Payment date: 19930315 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19930316 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930317 Year of fee payment: 10 Ref country code: DE Payment date: 19930317 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930318 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930322 Year of fee payment: 10 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19930430 Year of fee payment: 10 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940405 Ref country code: GB Effective date: 19940405 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19940406 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19940430 Ref country code: CH Effective date: 19940430 Ref country code: BE Effective date: 19940430 |

|

| BERE | Be: lapsed |

Owner name: VEREINIGTE EDELSTAHLWERKE A.G. VEW Effective date: 19940430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19941101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940405 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941229 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950103 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84890067.6 Effective date: 19941110 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |