EP0104176B1 - Verfahren zum verschliessen von nicht-starren tragetaschen und so enthaltene tragetaschen - Google Patents

Verfahren zum verschliessen von nicht-starren tragetaschen und so enthaltene tragetaschen Download PDFInfo

- Publication number

- EP0104176B1 EP0104176B1 EP82903049A EP82903049A EP0104176B1 EP 0104176 B1 EP0104176 B1 EP 0104176B1 EP 82903049 A EP82903049 A EP 82903049A EP 82903049 A EP82903049 A EP 82903049A EP 0104176 B1 EP0104176 B1 EP 0104176B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bag

- folded

- handle

- rigid element

- bags

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims abstract description 12

- 239000000463 material Substances 0.000 claims abstract description 18

- 239000004033 plastic Substances 0.000 claims description 18

- 229920003023 plastic Polymers 0.000 claims description 18

- 238000003466 welding Methods 0.000 claims description 10

- 239000003351 stiffener Substances 0.000 description 13

- 239000010408 film Substances 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 239000000123 paper Substances 0.000 description 4

- -1 polyethylene Polymers 0.000 description 4

- 239000004698 Polyethylene Substances 0.000 description 3

- 238000004026 adhesive bonding Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 229920000573 polyethylene Polymers 0.000 description 3

- 238000001746 injection moulding Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000002985 plastic film Substances 0.000 description 2

- 230000000717 retained effect Effects 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 1

- 241000826860 Trapezium Species 0.000 description 1

- 240000008042 Zea mays Species 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 210000002445 nipple Anatomy 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 235000020004 porter Nutrition 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 229920003002 synthetic resin Polymers 0.000 description 1

- 239000000057 synthetic resin Substances 0.000 description 1

- 238000003856 thermoforming Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/24—End- or aperture-closing arrangements or devices using self-locking integral or attached closure elements, e.g. flaps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/1658—Elements for flattening or folding the mouth portion

- B65D33/1666—Slitted tubes with or without a core; U-shaped clips made of one piece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/16—End- or aperture-closing arrangements or devices

- B65D33/18—End- or aperture-closing arrangements or devices using adhesive applied to integral parts, e.g. to flaps

- B65D33/20—End- or aperture-closing arrangements or devices using adhesive applied to integral parts, e.g. to flaps using pressure-sensitive adhesive

Definitions

- the former have the advantage, in the absence of being rigid, of being stiff and of being able to be reinforced by folding, gluing, but they involve still fairly elaborate manufacturing processes.

- the bags made of plastic sheets certainly have the drawback of being extremely devoid of "hold” (they fall in on themselves and have no stiffness in their plan).

- the plastic film having good tensile and tear strength extremely thin films are used (of the order of a few hundredths of a millimeter, or even a hundredth of a millimeter) in order to limit their cost.

- these sheets can be produced in films or sheaths which are easy to manufacture in feature films and it is possible to shape them (closure and association with other elements themselves made of plastic) by simple welding or gluing. But, with some extremely rare exceptions as we will see below, these bags are made entirely of plastic.

- the Applicant has sought to design a simple means making it possible to give a bag in the form of a pocket made of a flexible material, in particular plastic, a certain hold, while ensuring a tight closure of the bag.

- the invention relates to a method for ensuring the closure of bags, of flexible material, in particular of thin plastic, in which successively is applied, on at least one of the upper edges of the bag, a flat rigid element whose length substantially corresponds to the width of the bag, said element is fixed permanently by welding said element to said upper edge, and the assembly is folded, after the two walls are brought together, against the bag and which is characterized in that that a handle is fixed on the closure thus produced, by engagement of a movable rigid element on the folded part of the bag, said element having an upper part forming a handle handle and a lower part shaped so as to form a housing retaining the flap and whose length is less than the width of the bag.

- the present invention also relates to a bag in the form of a plastic bag, with two walls and a bottom, and a closure system on the upper edge of the bag, characterized in that it is provided with a closure system such as above defined.

- the rigid element intended to be applied against one of the upper edges of the bag is constituted by a simple flat ruler whose length corresponds substantially to the width of the bag on which it is mounted.

- the length of the rigid element will correspond to the width of the bag.

- the rigid element will have a length slightly less than the width of the bag, so as not to hinder the introduction of objects inside the bag.

- the rigid element can be made of any material having a certain rigidity, such as plain cardboard, cardboard impregnated with a plastic material or plastic material.

- Its attachment to the wall of the bag can be obtained by any suitable means: gluing, stapling, riveting, welding.

- the rigid element will advantageously be made of cardboard impregnated with a synthetic resin (for example polyethylene). It is attached to the wall of the plastic bag (which can be polyethylene, polypropylene, polyester or a complex) by heat sealing or by high frequency welding or the like.

- a synthetic resin for example polyethylene

- the bag will be supplied by the manufacturer generally with the rigid rigid element 'on the upper part of one of the walls of the bag.

- the rigid element can also be delivered separately and mounted on the bag at the time of use.

- this stiffening element gives to the plastic bag on which it is mounted is to stretch the wall on the upper part of which it is fixed, which facilitates the introduction of objects inside the bag, the 'one of the walls being stiffened while the other remains flexible.

- the stiffening element makes it possible to ensure the closure of the bag by bringing the two walls closer and folding it against the free wall of the bag.

- the closure thus produced is completely hermetic since it extends over the entire width of the bag.

- the stiffening element also ensures excellent support of the bag which, even under the effect of a large load, does not deform, the rigid element working like a beam over the entire width of the bag.

- the mobile rigid element is in the form of a removable handle which is placed on a bag at least one of the edges of which has been stiffened by fixing a rigid band, after loading the bag and folding from the upper part, to ensure proper closure and to carry the bag more easily.

- the removable handle according to the invention has this particularity of being able to be instantly mounted on the bag by simple transverse sliding on the flap and to ensure, after engagement on said flap, its connection with the bag.

- the handle according to the invention which is of a particularly simple design, will advantageously be made of plastic by injection molding.

- the lower part of the handle by which the latter is secured to the bag has a section in the shape of an inverted U, the branches of which have different heights, the highest branch having its lower part folded towards the inside of the U, the branches of the U overlapping the folded upper part of the bag, while the folded branch forms a housing in which the flap engages.

- the length formed by the branch of the folded U preferably has a width slightly greater than the thickness of the flap, so that the latter, once introduced into the housing, is immobilized.

- the housing will have a height corresponding to that of the flap so that after engagement of the flap in said housing, the lower edge of the rigid strip is substantially at the same level as the end of the branch of the folded U.

- the latter is separated from the horizontal branch of the U by a sufficient distance to allow the engagement of the folded upper part of the bag.

- the folded part of the branch of the U determines with the branch of the U not folded a longitudinal passage in which is engaged the upper part of the bag located immediately below the folded part.

- the flap After placing the handle on the bag, the flap is retained in its housing and is pressed against the upper part of the bag which is itself between the folded part of the U-branch and the other branch of the U .

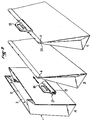

- FIG 1 a bag 1 of thin plastic material provided with a stiffener 2 according to the invention.

- the bag shown in this figure has lateral bellows 3, but it could not include such bellows and be simply constituted by two walls welded on their edges.

- the stiffener 2 has a length which corresponds to the width of the bag and is fixed inside the bag against the upper part of one of the walls.

- This stiffener is advantageously constituted by a sheet of cardboard impregnated with polyethylene of which it will suffice to fix by heat welding its upper edge against the upper edge of the wall of the bag.

- stiffener 2 makes it possible to make the wall rigid on the upper edge of which it is fixed, facilitating the introduction of objects inside the bag when the latter placed flat, simple lifting of the unstiffened edge.

- FIGS. 2A, 2B and 2C illustrate the process of closing a bag and fitting a handle according to the invention.

- the bag 1 is shown in the open position provided with its stiffener 2 (FIG. 2A), consisting of a rigid strip made of a heat-weldable material and fixed by welding to the upper edge of the bag.

- stiffener 2 consisting of a rigid strip made of a heat-weldable material and fixed by welding to the upper edge of the bag.

- Said handle is placed on the bag by simple transverse sliding on the flap 4 (FIG. 2C).

- the handle 17 ensures by its lower part the closure of the bag at the same time as its attachment to the bag.

- the handle 17 has at its upper part a handle 18 while its lower part is shaped so as to form a housing 19 in which the flap 4 engages.

- FIG. 3 shows a front view of a handle according to the invention and, in FIG. 4, a cross section of this handle along the line 4--4 of FIG. 3.

- the lower handle part has a section in the shape of an inverted U whose branches 20 and 21 have different heights, the highest branch 20 being folded inwards of the U to form the housing 19 in which the flap 4 engages.

- the housing 19 has a width slightly greater than the thickness of the flap to allow the engagement of the flap 4 but in such a way that the latter is maintained in a substantially vertical position in its housing.

- the folded part 22 of the branch 20 household with the other branch 21 of the U a longitudinal passage 23 in which is engaged the upper part 26 of the bag located immediately below the flap 4 ( Figure 2C).

- the end 24 of the folded part 22 is spaced a sufficient distance from the horizontal branch 25 of the U to allow the engagement of the folded upper part of the bag.

- the vertical side walls 20, 21 and 22 are given which delimit, on the one hand, the housing 19 in which the flap is retained and, on the other hand, the passage longitudinal 23 in which the upper part 26 of the bag is engaged, a shape and dimensions such that said walls engage one after the other on the folded upper part of the bag.

- Figure 5 shows the development of the lower part of the handle.

- the wall 22 which corresponds to the folded part of the branch of the U, has its ends 27 in the form of an arc of a circle while the walls 20 and 21 which correspond to the two branches of the U have a substantially trapezoidal shape.

- the outer wall 21 which is applied against the face of the bag opposite to that against which the upper part 4 of the bag has been folded down, has the shape of a trapezium whose vertices 28 have been rounded.

- the height of the wall 22 must correspond substantially to the height of the flap 4 so that after engagement of the handle on the flap, the edge 12 of the rigid strip and the upper longitudinal edge 29 of the wall 22 is substantially at the same level. This edge 29 determines a line along which the folding of the bag takes place.

- the handle has, in its upper part, a handle 18 having in its grip zone a rounded edge 30 which makes the carrying of the bag more comfortable.

- the present invention provides a particularly elegant solution to this problem by proposing a closure system with a very simple design and with great efficiency, at the same time that it allows these bags to be carried easily.

- the handle according to the invention which is used in association with the stiffener has a lower cost price than the conventional closure system which is most often encountered on bags made of the most common materials.

- closure system specified by the applicant ensures a perfectly hermetic closure of the bag which happens to be closed over its entire width regardless of the size of the load contained in the bag.

- stiffener according to the invention can be advantageously used in association with the flat cardboard bottom described in the patent in question.

- FIG. 6 shows a bag fitted with a flat cardboard bottom 16 such as that described in patent No. 2,338,854.

- a bag the upper part of which is made in accordance with the present invention and the lower part of which in accordance with patent No. 2,338,854, has an excellent hold and which can be pulled on the handle or on the bottom like and much better than if it were a very rigid paper bag whose cost would be at least twice as expensive.

- the handle instead of being obtained by molding in one piece with the rest of the handle, could be attached to the lower part of the handle.

- the handle could be produced by other methods than by injection molding, for example by thermoforming.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Purses, Travelling Bags, Baskets, Or Suitcases (AREA)

Claims (4)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8119539A FR2514730B1 (fr) | 1981-10-16 | 1981-10-16 | Procede permettant d'assurer la fermeture de sacs non rigides et sacs obtenus par ledit procede |

| FR8119539 | 1981-10-16 | ||

| FR8123099 | 1981-12-10 | ||

| FR8123099A FR2518059B2 (fr) | 1981-12-10 | 1981-12-10 | Procede permettant d'assurer la fermeture de sacs non rigides et sacs obtenus par ledit procede |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0104176A1 EP0104176A1 (de) | 1984-04-04 |

| EP0104176B1 true EP0104176B1 (de) | 1987-01-07 |

Family

ID=26222578

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82903049A Expired EP0104176B1 (de) | 1981-10-16 | 1982-10-13 | Verfahren zum verschliessen von nicht-starren tragetaschen und so enthaltene tragetaschen |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0104176B1 (de) |

| AU (1) | AU8994982A (de) |

| DE (1) | DE3274968D1 (de) |

| IT (1) | IT1191032B (de) |

| WO (1) | WO1983001430A1 (de) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1572548B1 (de) * | 2002-11-13 | 2012-04-11 | Sehyang Industrial Co.,Ltd. | Verfahren und vorrichtung zum versiegeln einer packung |

| US20240239558A1 (en) * | 2021-05-12 | 2024-07-18 | Holweg Group | Flexible bag having a convertible bottom, method and machine for manufacturing same |

| FR3122847B1 (fr) * | 2021-05-12 | 2023-05-12 | Holweg Group | Procédé et machine de fabrication de sac flexible du type enveloppe, notamment avec renfort |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1043277A (fr) * | 1951-09-25 | 1953-11-09 | Poignée fixe fixe ou amovible pour sacs en papier, cellophane ou autre matière | |

| US3026017A (en) * | 1959-05-11 | 1962-03-20 | Bemis Bro Bag Co | Bag top closure with carrying handle |

| US3442437A (en) * | 1968-02-19 | 1969-05-06 | Charles R Mann | Bag construction with closure carrier |

| GB1365924A (en) * | 1972-02-16 | 1974-09-04 | British Visqueen Ltd | Plastics film articles |

| CH630862A5 (en) * | 1979-02-21 | 1982-07-15 | Walter Monn | Device for clamping together the overlapping and folded back edges of sheets, bags or packets, also designed to support them |

-

1982

- 1982-10-13 EP EP82903049A patent/EP0104176B1/de not_active Expired

- 1982-10-13 AU AU89949/82A patent/AU8994982A/en not_active Abandoned

- 1982-10-13 DE DE8282903049T patent/DE3274968D1/de not_active Expired

- 1982-10-13 WO PCT/FR1982/000168 patent/WO1983001430A1/fr active IP Right Grant

- 1982-10-15 IT IT23758/82A patent/IT1191032B/it active

Also Published As

| Publication number | Publication date |

|---|---|

| WO1983001430A1 (fr) | 1983-04-28 |

| IT1191032B (it) | 1988-02-24 |

| DE3274968D1 (en) | 1987-02-12 |

| AU8994982A (en) | 1983-05-05 |

| IT8223758A0 (it) | 1982-10-15 |

| EP0104176A1 (de) | 1984-04-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2035288B1 (de) | Plastikbeutel mit öffnungen für lebensmittelprodukte und verfahren zu seiner herstellung | |

| EP1675789B1 (de) | Beutel mit elastischem band und verfahren zu dessen herstellung | |

| FR2588246A1 (fr) | Sac comportant sur une bande de paroi une fermeture a glissiere en matiere plastique, les matieres de la fermeture et de la bande etant incompatibles sur le plan de la fusion, et procede de realisation dudit sac | |

| EP0746507A1 (de) | Dichtes behältnis, verfahren zu seiner herstellung, verfahren zu seiner befüllung mit einer flüssigkeit | |

| EP2125537A1 (de) | Dehnbarer behälter für flaschen oder ähnliches | |

| FR2501645A1 (fr) | Recipient pour photographies | |

| EP0104176B1 (de) | Verfahren zum verschliessen von nicht-starren tragetaschen und so enthaltene tragetaschen | |

| EP1654172B1 (de) | Beutel mit elastischem und nicht elastischem gleitendem doppelband und herstellungsverfahren dafür | |

| FR2858754A1 (fr) | Sac a dos equipe d'un ensemble ceinture a pivotement angulaire | |

| FR2643046A1 (fr) | Recipient etanche a usage notamment alimentaire | |

| FR2907428A1 (fr) | Poignee pour sac obtenu dans une matiere plastique souple | |

| WO2006064045A1 (fr) | Sac de transport de marchandises | |

| BE1008390A6 (fr) | Sac souple et procede de realisation de celui-ci. | |

| FR2518059A2 (fr) | Procede permettant d'assurer la fermeture de sacs non rigides et sacs obtenus par ledit procede | |

| FR2858807A1 (fr) | Sac a lien coulissant a fermeture amelioree | |

| FR2697507A1 (fr) | Sac souple d'emballage équipé d'une poignée de fermeture et de portage. | |

| CH410306A (fr) | Dispositif de préhension et de fermeture destiné à être adapté sur un sachet en matière thermoplastique | |

| FR2479149A1 (fr) | Sac refermable en matiere plastique et procede pour le fabriquer | |

| EP2444329B1 (de) | Schließvorrichtung und Beutel, der diese Vorrichtung verwendet | |

| EP1508526A1 (de) | Zugbeutel mit zweiteiligen Zugband | |

| FR2481090A1 (fr) | Poignee pour sac, notamment pour sac cabas, et procede de fabrication de ladite poignee | |

| FR2514730A1 (fr) | Procede permettant d'assurer la fermeture de sacs non rigides et sacs obtenus par ledit procede | |

| FR2821585A1 (fr) | Procede de fabrication d'emballage a poignee simple | |

| EP0560654A1 (de) | Tasche | |

| FR2885118A1 (fr) | Charniere de liaison entre un receptacle et un couvercle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19831021 |

|

| AK | Designated contracting states |

Designated state(s): DE GB |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB |

|

| REF | Corresponds to: |

Ref document number: 3274968 Country of ref document: DE Date of ref document: 19870212 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19881013 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19890701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |