EP0088731B1 - Soupape pour l'évacuation de la vapeur d'un contenant - Google Patents

Soupape pour l'évacuation de la vapeur d'un contenant Download PDFInfo

- Publication number

- EP0088731B1 EP0088731B1 EP83810089A EP83810089A EP0088731B1 EP 0088731 B1 EP0088731 B1 EP 0088731B1 EP 83810089 A EP83810089 A EP 83810089A EP 83810089 A EP83810089 A EP 83810089A EP 0088731 B1 EP0088731 B1 EP 0088731B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- cover sheet

- container

- water

- valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/24—Adaptations for preventing deterioration or decay of contents; Applications to the container or packaging material of food preservatives, fungicides, pesticides or animal repellants

Definitions

- the subject of the invention is a semi-rigid container intended for heating its contents, in particular a prepared dish, by immersion in hot water and comprising a detachable cover sheet, a portion of the internal face of which is covered with a microporous film.

- Patent application DE-A-2,318,028 describes a food container consisting of a rigid part and a cover sheet: comprising an external film secured to an internal film by means of an adhesive layer .

- the outer film of the cover sheet is detached, the inner film is then exposed to the atmosphere in order to allow the passage of gases or vapors. If such a container can allow the heating of its contents while avoiding an overpressure due to the production of gases or vapors, it cannot on the other hand solve the problem posed during the heating by immersion in hot water.

- the invention advantageously solves this problem by proposing a semi-rigid container, the cover sheet of which is designed in such a way that a small portion of microporous film is put into working condition just before the container and its contents are heated, for immersion in hot water.

- the container according to the invention is characterized in that the film is hermetically sealed on a portion of the internal face of the cover sheet, that said cover sheet is arranged so that a small portion of it is detached according to a pre-established rupture line to discover a corresponding surface of the film, and in that the film is made of a material making it water-resistant and at the same time permeable to gases and vapors and impermeable to liquids and colloids.

- the object of the invention described below comprises a thin porous film which allows the vapors formed during the heating of the contents to escape, and which prevents the medium used for the heating (usually water) from entering the container.

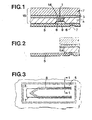

- Fig. 1 is a transverse view of the cover sheet of the container according to the invention, describing in particular the detail of the sheet portion covered by the film.

- Fig. 2 is a transverse view of the system shown in FIG. 1 after removal of the protective sheet.

- Fig.3 is a top view of the portion of cover sheet comprising the film.

- Fig. 4 is an example of a container provided with a detachable cover sheet.

- a tear line (1) which is completely independent of the tear line along which the container is opened makes it possible to lift a portion of the cover sheet (15) thus creating an opening which remains however closed by a film. (5) welded to the inner surface of the cover sheet.

- the cover sheet comprises three main components: an external film with low elasticity (2) covered with a plastic layer (3), this plastic layer (3) being sealed to a film (4) having the same composition.

- the film (4) is a composite film with several layers, it is essential that the outer layer of this film has the same composition as the plastic layer (3).

- the film (5) is made of the same material as the film (4), or the inner layer of the film (4), and it is hermetically sealed to this film by welding at the area (7) characterized by a hollow ( 6).

- the weld path is represented by the dotted area (8).

- the film (5) is made from well known microporous films resistant to the penetration of water.

- an incision (1) constituting the pre-established rupture line is made inside the zone delimited by the line (7) which corresponds to the weld line of the film (5).

- the weld line (8) along which the film (2) is welded to the film (4) via the plastic layer (3) -this weld line (8) corresponds to the weld zone (14) and in the hollow (8) of the transverse view shown in FIG. 1 -coincides with most of the course of the incision (1), except for the opening tab, where the weld line (8) ends in a point at which the tearing begins.

- the film (5) is exposed just before the container and its contents are reheated.

- the film (5) allows the vapor produced inside the container during heating to exit, while preventing the liquid from escaping, or the water used for heating to return.

- the pressure normally produced during heating is thus reduced, and the container can be opened without splashing of hot liquid.

- the outer film (2) is made of a material with low elasticity such as aluminum, paper, certain plastics or other materials with low elasticity.

- the film (2) is provided with a thin adhesive layer (3) made of the same thermoplastic substance as the internal film (4). In a preliminary operation, an incision is made in the film (2) and the adhesive layer (3), the outline of which corresponds to the predetermined breaking line (1) along which the sheet will be torn.

- the film (2) is welded to the film (4) via the adhesive layer (3).

- the film has a biaxial molecular orientation.

- the thermoplastic film is melted, which largely destroys the molecular orientation to which the film essentially owes its breaking strength.

- the welding area is further weakened by the hollow formed under the effect of the pressure exerted during the welding operation. Notches produced for example by edges or by other patterns of the welding tool can further increase the weakness of the weld line.

- the tab of the cover sheet is detached by gripping it with your fingers.

- the tear begins at the tip formed by the weld line (8) and then propagates along the pre-established rupture line (1) until the entire portion of sheet surrounded by this line is detached.

- the object of the invention is to prevent digestion due to overpressure in containers, and in particular those filled with food products which must be reheated before consumption, generally by immersion in boiling water.

- the film (5) hermetically welded to the cover sheet before use; before or after the container has been reheated, the cover sheet is detached, thereby exposing the film (5) made of a microporous or porous thermoplastic film welded to the internal surface of the cover sheet.

- the film (5) is permeable to water vapor, but impermeable to water. This prevents the warming water from mixing with the contents of the container, and that this content gushes out upon opening.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Self-Closing Valves And Venting Or Aerating Valves (AREA)

- Temperature-Responsive Valves (AREA)

- Separation Using Semi-Permeable Membranes (AREA)

- Manufacture, Treatment Of Glass Fibers (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Cookers (AREA)

- Closures For Containers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83810089T ATE23837T1 (de) | 1982-03-05 | 1983-03-04 | Dampfablassventil fuer verpackungen. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH1340/82 | 1982-03-05 | ||

| CH134082 | 1982-03-05 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0088731A1 EP0088731A1 (fr) | 1983-09-14 |

| EP0088731B1 true EP0088731B1 (fr) | 1986-11-26 |

Family

ID=4208190

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83810089A Expired EP0088731B1 (fr) | 1982-03-05 | 1983-03-04 | Soupape pour l'évacuation de la vapeur d'un contenant |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US4461420A (enExample) |

| EP (1) | EP0088731B1 (enExample) |

| JP (1) | JPS58171362A (enExample) |

| AT (1) | ATE23837T1 (enExample) |

| CA (1) | CA1193512A (enExample) |

| DE (1) | DE3367895D1 (enExample) |

| DK (1) | DK104083A (enExample) |

| FI (1) | FI830712L (enExample) |

| GR (1) | GR77954B (enExample) |

| NO (1) | NO830724L (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8663188B2 (en) | 2007-12-28 | 2014-03-04 | Aktivpak, Inc. | Dispenser and therapeutic package suitable for administering a therapeutic substance to a subject, along with method relating to same |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0825583B2 (ja) * | 1986-03-27 | 1996-03-13 | ハウス食品株式会社 | 加熱調理用密封容器 |

| JPS63152638A (ja) * | 1986-10-06 | 1988-06-25 | アプライド・エクストルージョン・テクノロジーズ・インコーポレーテッド | 調整雰囲気の包装用フィルム |

| DE3726162A1 (de) * | 1987-08-06 | 1989-02-16 | Bosch Gmbh Robert | Verpackungsbehaelter mit aufreisseinrichtung |

| JPH0272828A (ja) * | 1988-03-10 | 1990-03-13 | Isamu Miya | 珈琲豆の簡易焙煎方法 |

| US4923703A (en) * | 1988-03-14 | 1990-05-08 | Hercules Incorporated | Container comprising uniaxial polyolefin/filler films for controlled atmosphere packaging |

| US4910032A (en) * | 1988-11-16 | 1990-03-20 | Hercules Incorporated | Water-permeable controlled atmosphere packaging device from cellophane and microporous film |

| US5407087A (en) * | 1992-12-30 | 1995-04-18 | Lever Brothers Company, Division Of Conopco, Inc. | Venting closure |

| US5547694A (en) * | 1993-03-23 | 1996-08-20 | The Pillsbury Company | Container for refrigeratable yeast-leavened doughs |

| AU5950196A (en) | 1995-05-30 | 1996-12-18 | Landec Corporation | Gas-permeable membrane |

| US6013293A (en) * | 1997-09-10 | 2000-01-11 | Landec Corporation | Packing respiring biological materials with atmosphere control member |

| US6548132B1 (en) | 1998-07-23 | 2003-04-15 | Landec Corporation | Packaging biological materials |

| GB2353986A (en) * | 1999-09-10 | 2001-03-14 | Tecksom Internat Ltd | Openable sealing of container mouth |

| US8110232B2 (en) | 2000-09-26 | 2012-02-07 | Apio, Inc. | Packaging of bananas |

| US7601374B2 (en) * | 2000-09-26 | 2009-10-13 | Landec Corporation | Packaging of respiring biological materials |

| US7004632B2 (en) * | 2003-03-31 | 2006-02-28 | The Glad Products Company | Ventable storage bag |

| US20040213956A1 (en) * | 2003-04-25 | 2004-10-28 | Rutherford Sales & Recovery Co., Inc. | Perforated film with liquid retention and gas/vapor venting characteristics for packaging |

| US20080176036A1 (en) * | 2003-04-25 | 2008-07-24 | Mitchell Melvin G | Micro-perforated laminae and method |

| SE527398C2 (sv) * | 2003-05-30 | 2006-02-28 | Micvac Ab | Envägsventil för livsmedelsförpackning |

| US7160590B2 (en) * | 2003-08-18 | 2007-01-09 | Advanced Technology Materials, Inc. | Packaging including a composite web comprising porous layer |

| US20050050854A1 (en) * | 2003-09-09 | 2005-03-10 | Jean-Pascal Zambaux | Sterile, pyrogen-free, polymeric film-based heating bag |

| DE102006017834A1 (de) * | 2006-04-13 | 2007-10-18 | Cfs Kempten Gmbh | Eine mikrowellengeeignete Verpackung |

| EP2104525A4 (en) | 2006-12-29 | 2010-12-29 | Amir Genosar | HYPODERMIC RESERVOIR AND APPARATUS FOR DRUG DELIVERY |

| US20100108671A1 (en) * | 2008-11-04 | 2010-05-06 | William Cho | Pressure Relief System |

| US20100175850A1 (en) * | 2009-01-09 | 2010-07-15 | Kaucic Edward M | Relief Vent for a Hot Fill Fluid Container |

| WO2013112636A1 (en) | 2012-01-23 | 2013-08-01 | Apio, Inc. | Atmosphere control around respiring biological materials |

| US9427710B2 (en) * | 2013-03-15 | 2016-08-30 | Bemis Company, Inc. | Radial filtration vent and medical device packaging |

| EP3377319B1 (en) | 2015-11-17 | 2022-01-05 | Amcor Flexibles France SAS | Method for ripening or heat treating packaged food |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3083861A (en) * | 1960-05-27 | 1963-04-02 | Lily Tulip Cup Corp | Vented container closure lids |

| FR1333994A (fr) * | 1962-07-17 | 1963-08-02 | Hermorion Ltd | Emballage appelé à contenir du lait stérilisé |

| US3158491A (en) * | 1963-02-26 | 1964-11-24 | American Can Co | Food container |

| US3298505A (en) * | 1965-02-12 | 1967-01-17 | Brown Co | Laminated closure for food trays and trays closed with same |

| US3432087A (en) * | 1966-09-01 | 1969-03-11 | Alfred P Costello | Package valve |

| US3410395A (en) * | 1967-07-14 | 1968-11-12 | Gen Binding Corp | Steam sterilizable package and method of making the same |

| US3547257A (en) * | 1968-01-22 | 1970-12-15 | American Hospital Supply Corp | Package for sterile article |

| DE2109940A1 (en) * | 1970-03-26 | 1971-10-14 | Fa J Plaut, Wien | Anti dirt, water and atmospheric corrosion coating |

| US3716180A (en) * | 1970-06-01 | 1973-02-13 | Robalex Inc | Packaging |

| US3806618A (en) * | 1971-02-21 | 1974-04-23 | Robalex Inc | Method of heating a package of food |

| DE2209393C2 (de) * | 1971-02-26 | 1984-06-28 | Christenssons Maskiner & Patenter AB, 16130 Stockholm | Deckfolie zum dichten Verschließen gefüllter becherartiger Behälter |

| SE350945B (enExample) * | 1971-03-01 | 1972-11-13 | Christenssons Maskiner | |

| GB1392580A (en) * | 1972-04-10 | 1975-04-30 | Standard Packaging Corp | Controlled atmosphere package |

| US4055672A (en) * | 1972-04-10 | 1977-10-25 | Standard Packaging Corporation | Controlled atmosphere package |

| US3946780A (en) * | 1973-01-04 | 1976-03-30 | Sellers John C | Fermentation container |

| US4136796A (en) * | 1974-04-11 | 1979-01-30 | Greif Bros. Corporation | Vented closure |

| GB1520511A (en) * | 1975-04-18 | 1978-08-09 | Heinz Co H J | Production of mushroom spawn |

| DE2539351A1 (de) * | 1975-09-04 | 1977-03-10 | Mardon Flexible Packaging Ltd | Verpackungskonstruktion |

| US4096948A (en) * | 1977-03-18 | 1978-06-27 | American Can Company | Cook-in carton with integral removable section and blank therefor |

| FR2428583B1 (fr) * | 1978-06-16 | 1985-07-12 | Somycel Sa | Sac sterilisable realise dans une feuille de matiere plastique et destine a la production de blanc de champignon |

-

1982

- 1982-10-22 US US06/436,181 patent/US4461420A/en not_active Expired - Fee Related

-

1983

- 1983-02-28 DK DK104083A patent/DK104083A/da not_active Application Discontinuation

- 1983-03-02 FI FI830712A patent/FI830712L/fi not_active Application Discontinuation

- 1983-03-03 NO NO830724A patent/NO830724L/no unknown

- 1983-03-04 GR GR70677A patent/GR77954B/el unknown

- 1983-03-04 JP JP58036522A patent/JPS58171362A/ja active Pending

- 1983-03-04 AT AT83810089T patent/ATE23837T1/de not_active IP Right Cessation

- 1983-03-04 CA CA000422885A patent/CA1193512A/en not_active Expired

- 1983-03-04 EP EP83810089A patent/EP0088731B1/fr not_active Expired

- 1983-03-04 DE DE8383810089T patent/DE3367895D1/de not_active Expired

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8663188B2 (en) | 2007-12-28 | 2014-03-04 | Aktivpak, Inc. | Dispenser and therapeutic package suitable for administering a therapeutic substance to a subject, along with method relating to same |

Also Published As

| Publication number | Publication date |

|---|---|

| FI830712A7 (fi) | 1983-09-06 |

| NO830724L (no) | 1983-09-06 |

| US4461420A (en) | 1984-07-24 |

| ATE23837T1 (de) | 1986-12-15 |

| GR77954B (enExample) | 1984-09-25 |

| FI830712A0 (fi) | 1983-03-02 |

| JPS58171362A (ja) | 1983-10-08 |

| DK104083A (da) | 1983-09-06 |

| EP0088731A1 (fr) | 1983-09-14 |

| FI830712L (fi) | 1983-09-06 |

| DE3367895D1 (en) | 1987-01-15 |

| CA1193512A (en) | 1985-09-17 |

| DK104083D0 (da) | 1983-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0088731B1 (fr) | Soupape pour l'évacuation de la vapeur d'un contenant | |

| EP0088730B1 (fr) | Feuille de couverture scellée sur des contenants par soudure pour constituer un couvercle détachable | |

| EP0597741B1 (fr) | Récipient étanche au gaz | |

| EP1544127B1 (fr) | Emballage à opercule perforable | |

| EP0252791B1 (fr) | Plateau-présentoir perfectionné formant emballage | |

| FR2676715A1 (fr) | Capsule de bouchage a vis a impermeabilite aux gaz amelioree. | |

| EP0547941B1 (fr) | Récipient et son procédé de fabrication | |

| FR2551031A1 (fr) | Recipient a ouverture par pelage et procede de production des elements de fermeture de tels recipients | |

| FR2649071A1 (enExample) | ||

| FR2596366A1 (fr) | Recipient scelle utilisable a des fins de cuisson | |

| FR2600631A1 (fr) | Ensemble verseur et capsule de bouchage inviolable | |

| EP0197073A1 (fr) | Emballage etanche, procede de fabrication et utilisation de cet emballage. | |

| FR2695108A1 (fr) | Emballage, procédé et dispositif de conditionnement pour produit liquide, solide ou pâteux pasteurisé ou stérilisé. | |

| EP0961732A1 (fr) | Verseur a bouchage pour des recipients, notamment pour des boites de conditionnement de liquides | |

| FR2627158A1 (fr) | Fermeture d'extremite pour recipient d'emballage | |

| WO2004113184A2 (fr) | Dispositif de liberation d'une matiere liquide ou pulverulente dans un emballage etanche et conditionnement comportant un tel dispositif | |

| FR2666078A1 (fr) | Recipient pour boisson avec un nouveau moyen de distribution. | |

| FR2618411A1 (fr) | Recipient pour emballage de denrees alimentaires, ferme par opercule arrachable et reutilisable comme couvercle | |

| FR2781460A1 (fr) | Conditionnement pour produit alimentaire multi-composants | |

| FR2767123A1 (fr) | Nouvelle structure de recipient et procede de conditionnement d'un produit au moyen de ce recipient | |

| FR2761348A1 (fr) | Conditionnement pour produit alimentaire destine a etre rechauffe par micro-ondes | |

| EP0915013B1 (fr) | Procédé pour l'operculage de récipients, feuille d'operculage pour la mise en oeuvre de ce procédé et produit industriel obtenu | |

| LU88112A1 (fr) | Opercule flottant | |

| WO2007039676A1 (fr) | Procédé et dispositif pour la cuisson de produits alimentaires aux micro-ondes, dans un emballage du type barquette, et conditionnement obtenu par leur mise en oeuvre | |

| WO2001068478A1 (fr) | Emballage distributeur d'un produit alimentaire comportant un recipient externe autoportant et un recipient interne deformable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19840206 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| ITF | It: translation for a ep patent filed | ||

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 23837 Country of ref document: AT Date of ref document: 19861215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3367895 Country of ref document: DE Date of ref document: 19870115 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19870331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Free format text: 5204,PAGE 3645 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19890215 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19890217 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19890220 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19890228 Year of fee payment: 7 Ref country code: BE Payment date: 19890228 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19890317 Year of fee payment: 7 Ref country code: CH Payment date: 19890317 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19890331 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19890531 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19900304 Ref country code: AT Effective date: 19900304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19900305 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19900331 Ref country code: CH Effective date: 19900331 Ref country code: BE Effective date: 19900331 |

|

| BERE | Be: lapsed |

Owner name: C O D INTER TECHNIQUES S.A. Effective date: 19900331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19901001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19901130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19901201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83810089.9 Effective date: 19910110 |