EP0056780A2 - Disposition de pompes à chaleur - Google Patents

Disposition de pompes à chaleur Download PDFInfo

- Publication number

- EP0056780A2 EP0056780A2 EP82730005A EP82730005A EP0056780A2 EP 0056780 A2 EP0056780 A2 EP 0056780A2 EP 82730005 A EP82730005 A EP 82730005A EP 82730005 A EP82730005 A EP 82730005A EP 0056780 A2 EP0056780 A2 EP 0056780A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat pump

- heat

- arrangement according

- compressor

- pump arrangement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B7/00—Compression machines, plants or systems, with cascade operation, i.e. with two or more circuits, the heat from the condenser of one circuit being absorbed by the evaporator of the next circuit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B29/00—Combined heating and refrigeration systems, e.g. operating alternately or simultaneously

- F25B29/003—Combined heating and refrigeration systems, e.g. operating alternately or simultaneously of the compression type system

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B1/00—Compression machines, plants or systems with non-reversible cycle

- F25B1/04—Compression machines, plants or systems with non-reversible cycle with compressor of rotary type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/06—Several compression cycles arranged in parallel

- F25B2400/061—Several compression cycles arranged in parallel the capacity of the first system being different from the second

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/07—Details of compressors or related parts

- F25B2400/075—Details of compressors or related parts with parallel compressors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/07—Details of compressors or related parts

- F25B2400/075—Details of compressors or related parts with parallel compressors

- F25B2400/0751—Details of compressors or related parts with parallel compressors the compressors having different capacities

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/13—Economisers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B40/00—Subcoolers, desuperheaters or superheaters

- F25B40/02—Subcoolers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B41/00—Fluid-circulation arrangements

- F25B41/20—Disposition of valves, e.g. of on-off valves or flow control valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B49/00—Arrangement or mounting of control or safety devices

- F25B49/02—Arrangement or mounting of control or safety devices for compression type machines, plants or systems

- F25B49/022—Compressor control arrangements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B9/00—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point

- F25B9/002—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point characterised by the refrigerant

- F25B9/006—Compression machines, plants or systems, in which the refrigerant is air or other gas of low boiling point characterised by the refrigerant the refrigerant containing more than one component

Definitions

- the invention relates to a heat pump arrangement in which the subcooling enthalpy is used by means of a second heat pump and the heat obtained and raised to a higher temperature level can also be dissipated as useful heat in addition to that of the first heat pump.

- the liquid working fluid is cooled before expansion in heat pumps and the heat energy generated is thus made usable.

- the object of the invention is to increase the improvement in effectiveness achieved by supercooling in a heat pump arrangement of the type specified at the outset, that is to say in particular to stabilize the output by varying the condensation temperature and / or to improve the coefficient of performance.

- This object is achieved in that a second heat pump is inserted into the circuit of the working fluid of a first heat pump in such a way that it directly cools down the liquid working fluid.

- the liquefied working fluid (refrigerant) that emerges from the condenser and flows to the expansion valve has a temperature that is higher than the return temperature that can be achieved for heat use due to the necessary thermal contact resistance due to the heat exchanger properties of the condenser (when used for a Hot water heating is the temperature of the water delivered by the heat distribution system to the heat pump).

- the liquid working medium If the liquid working medium is cooled before expansion, its enthalpy decreases, so that less liquid has to evaporate during expansion and thus the proportion of the energy to be supplied by the heat source is increased.

- the use of the enthalpy to be obtained from the liquid subcooling is particularly problematic because the temperature level is lower than that during the condensation.

- this enthalpy for example for heating water, is made possible by the use of a second heat pump, which accordingly consists of an evaporator, compressor, condenser and expansion valve.

- the evaporator of the second heat pump is inserted directly into the working fluid circuit of the first heat pump. So that the evaporation temperature of the second heat pump is a function of K on- densationstemperatur the first heat pump, so that higher condensation temperatures higher vaporization temperatures and thus lead to the intended improvement in the coefficient of performance of the entire heat pump arrangement. Due to the existence of only a single heat exchange process, the heat "quality" is almost retained.

- the first and second heat pumps are designed very differently - even in the case of a shared heat utilization system.

- the ratio of the nominal power consumption of the first heat pump and the second heat pump is approximately With this design, both heat pumps can be operated together over the entire operating time and an optimal increase in the coefficient of performance and positive change in the performance behavior is achieved.

- a smaller numerical value of the ratio leads to a reduced improvement in the coefficient of performance with a more constant heating output with increasing condensation temperature during an increase in the ratio has the opposite effect.

- the first and second heat pumps in the case of shared heat-use systems preferably have approximately the same switch-on times, so that the improvement achieved can be used optimally.

- the components of the heat pump arrangement are designed overall so that the evaporation temperature in the evaporator of the additional heat pump is (significantly) higher than the temperature in the evaporator of the first (basic) heat pump. This results in a noticeably higher coefficient of performance for the additional heat pump (based on approximately identical condensation temperatures) than for the basic heat pump. The coefficient of performance resulting for the entire heat pump arrangement is considerably improved.

- the additional heat pump Due to the liquid subcooling by means of an additional heat pump, the more enthalpy can be taken from the heat source and used for heating, the higher the condensation temperature, i.e. the additional heat pump largely compensates for the system-related decrease in output of the basic heat pump towards higher condensation temperatures and thus has a stabilizing effect visibly the available performance - based on the overall arrangement.

- This stabilizing property is of particular importance because the decrease in output due to higher condensation temperatures in heat pumps used to supply hot water heaters goes hand in hand with the higher hot water supply temperatures required at lower outside temperatures.

- the invention makes it possible, despite the initially associated with the presence of an additional heat pump Magni- ß augmentation of the expense with respect to the number of elements to be provided not only in operation, a substantial energy savings.

- There are also advantages in production since instead of a heat pump consisting of relatively large and expensive components, two smaller heat pumps are used, the components of which are cheaper overall. Increasing the output of a heat pump for low condensation temperatures requires a considerable amount of extra work in higher output ranges, while the additionally required medium-output heat pump for relatively high condensation temperatures can be produced inexpensively in an encapsulated form with a relatively small size.

- the entire arrangement consisting of two heat pumps can be manufactured as a compact unit and installed completely prefabricated.

- both heat pumps can also be used optimally to supply separate consumers. If, for example, a relatively small amount of heat with the highest possible temperature is required for heating domestic water, it is advantageous if only 25 to 33% of its enthalpy is withdrawn from the liquid working medium of the first heat pump by the second heat pump.

- the condensers of the two heat pumps are connected in series.

- the high condensation temperatures that can be achieved thereby enable effective utilization of the improvement in performance of a heat pump arrangement achieved by the invention by particularly effective increase in performance, particularly when there is a high demand for power.

- the second heat pump is preferably operated with a non-azeotropic mixture of refrigerants, because the liquid working medium of the first heat pump, from which the useful heat for the second heat pump is extracted, experiences a much greater change in temperature during cooling than the carrier of the useful heat of the first heat pump.

- the evaporator of the second heat pump assumes a locally different, ie decreasing, temperature distribution in the flow direction of the working medium of the first pump. Due to the different evaporation temperatures of the components of the non-azeotropic K älteffengemisches and the resulting spatial distribution of the evaporation spaces of the individual components within the evaporator results in improved heat transfer and a homogenization of the distribution of heat transfer across the evaporator surface.

- the evaporator of the second heat pump is operated using the parallel flow method (ie the working media of the two heat pumps flow in the same direction during heat exchange), excessive suction gas overheating with the resulting risk of excessive pressure gas overheating can be prevented.

- the parallel flow method ensures that the second heat pump is defective even if the expansion valve is defective the working medium emerging from the evaporator of this heat pump has essentially the same temperature as the working medium emerging from the heat exchanger belonging to the evaporator of the first heat pump.

- the ratio of the power consumption of the compressors of the two heat pumps is chosen to be particularly favorable if the second heat pump, together with the first one, can remain in permanent operation under the operating conditions to be regarded as normal, because the maximum improvement achieved - based on the operating time of the heat pump arrangement comes into effect.

- An exception to this is a short switch-on delay of the compressor of one of the two heat pumps - preferably the second heat pump - in order to limit the starting current of the arrangement.

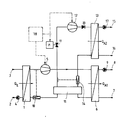

- the single figure shows a schematic representation of a heat pump arrangement according to the invention.

- the heat pump arrangement shown in the figure initially contains the known working medium circuit of a compression heat pump components in a conventional arrangement.

- the working fluid evaporates at a temperature T o and extracts the heat of vaporization from the medium flowing through the evaporator 1 in a separate circuit.

- the heat of vaporization Q E is extracted from a brine flowing through the pipes 2 and 3 in the direction of the arrow, which is circulated by means of a pump 4.

- the brine in turn flows through, for example - heat exchanger (not shown) placed in the ground and is thereby heated. Accordingly, heat absorption from the ambient air etc. is also possible.

- a compressor 5 draws in the vaporous working medium at a pressure p o and compresses it to the pressure p.

- the condenser 6 which also forms a heat exchanger, the compressed, gaseous working medium liquefies at a temperature T and, in the process, emits the heat Q A1 as useful heat to a heating circuit which contains a feed line 7 and a discharge line 8 and which contains a further circulation pump 9.

- the liquid working medium flows from the condenser 6 back to the evaporator 1, where the circuit closes.

- the medium to be used in the working circuit is selected according to the expected temperatures and pressures.

- the known refrigerants (mixtures) are available.

- An additional compressor 12 which can be of a small design because of the relatively high evaporator temperatures, a condenser 13 serving as a heat exchanger and an expansion valve 14 complete the working medium circuit of the second heat pump.

- the useful heat Q A2 is discharged into the lines 15 and 16, which are separated from the useful heat lines 7 and 8 of the first heat pump, in a circuit provided with a circulating pump 17.

- This is the system for domestic water heating, the heating system of which is supplied by the first heat pump.

- the condenser 13 can be included in a hot water tank.

- Lines 15 and 16 form the process water supply and return,

- the arrangement of the evaporator 11 of the second heat pump in the vicinity of the condenser 6 of the first heat pump and the combination of the condenser 13 of the second heat pump with the condenser 6 of the first heat pump enable a particularly compact design, since the components of the second heat pump take up relatively little space, so that they can be installed in a housing with the condenser of the second heat pump, possibly with its compressor, without requiring a substantial additional space.

- the largest component of such a heat pump arrangement, the evaporator of the first heat pump, which is the base load, can be arranged spatially independently of the other components, but is preferably accommodated within the same housing.

- the heat exchangers forming the condensers 6 and 13 of the two heat pumps can, depending on the requirements - according to the considerations made at the outset - either be combined or arranged separately in order to supply useful heat for different consumers, the base load-providing heat pump in the domestic energy area advantageously being used for the heating supply is used, while the second heat pump is preferably used for domestic water heating.

- the heat exchangers 6 and 13 can be operated both in parallel and in series according to the requirements, with the combination into a single structural unit also being advantageous here.

- the arrangement is in the flow direction of the medium that transports the useful heat in such a way that the Useful heat is first dissipated from the condenser of the first heat pump and then from the condenser of the second heat pump, since in this way a maximum heat flow is ensured due to the temperature conditions that arise.

- a control part 18 is provided which, together with the switching on of the compressor 12, opens a solenoid valve 19 and keeps it open during the operation of the compressor.

- a backflow preventer 20 also ensures that no refrigerant liquefied in the condenser 13 flows back into the compressor 12 in the event of interruptions in operation. In this way, the additional heat pump can be switched on and off during operation.

- Such a backflow preventer 20 including solenoid valve 19 is unnecessary if the compressor 5 of the second heat pump is designed as a rotary piston compressor, such a rotary piston compressor being further distinguished on the one hand by the fact that it survives wet starts without damage and on the other hand there is an inherent protection against overload in that if the evaporation temperature is too high, the power consumption decreases.

- the control part 18 in the figure is also designed so that it turns on when both Ver the activation of the compressor 12 of the additional heat pump is delayed slightly (ie by one or more seconds), so that the sudden load on the power supply network is reduced when the arrangement is started up.

- the delay effect can be achieved by known electromechanical or electronic delay switching means.

- the presence of two compressors can thus easily meet the demand of many electricity supply companies for limiting the surge load increase when switching on heat pump systems.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Heat-Pump Type And Storage Water Heaters (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3102247 | 1981-01-19 | ||

| DE3102247 | 1981-01-19 | ||

| DE19813106152 DE3106152A1 (de) | 1981-01-19 | 1981-02-16 | "waermepumpenanordnung" |

| DE3106152 | 1981-02-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0056780A2 true EP0056780A2 (fr) | 1982-07-28 |

| EP0056780A3 EP0056780A3 (fr) | 1982-08-25 |

Family

ID=25790761

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82730005A Pending EP0056780A3 (fr) | 1981-01-19 | 1982-01-19 | Disposition de pompes à chaleur |

| EP82900346A Expired EP0069756B1 (fr) | 1981-01-19 | 1982-01-19 | Agencement de pompes a chaleur |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82900346A Expired EP0069756B1 (fr) | 1981-01-19 | 1982-01-19 | Agencement de pompes a chaleur |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP0056780A3 (fr) |

| DE (2) | DE3106152A1 (fr) |

| DK (1) | DK410582A (fr) |

| WO (1) | WO1982002588A1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2006057594A1 (fr) * | 2004-11-26 | 2006-06-01 | Första Närvärmeverket Ab | Installation et procede de chauffage |

| WO2006099378A1 (fr) * | 2005-03-14 | 2006-09-21 | York International Corporation | Systeme cvc equipe d'un sous-refroidisseur mecanique |

| EP2211125A1 (fr) * | 2009-01-27 | 2010-07-28 | Zanotti S.p.A. | Installation et procédé de production d'eau chaude et froide devant alimenter un ou plusieurs utilisateurs thermiques |

| WO2013088356A1 (fr) * | 2011-12-12 | 2013-06-20 | Innovation Factory S.R.L. | Unité de pompe à chaleur à hautes performances |

| WO2014184184A1 (fr) * | 2013-05-14 | 2014-11-20 | Energy Machines S.A. | Installation de chauffage |

| CN106524539A (zh) * | 2016-12-22 | 2017-03-22 | 广东高而美制冷设备有限公司 | 利用冷热水自然对流进行过冷的太阳能空气能换热系统 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19935550A1 (de) * | 1999-07-30 | 2001-02-08 | B K T Bonnet Kaeltetechnik Gmb | Kälteanlage |

| DE10103150B4 (de) * | 2001-01-24 | 2015-12-10 | Stiebel Eltron Gmbh & Co. Kg | Lüftungsanlage |

| JP4788766B2 (ja) | 2006-04-14 | 2011-10-05 | 三菱電機株式会社 | 熱交換器及び冷凍空調装置 |

| FR2934890B1 (fr) * | 2008-08-06 | 2010-09-17 | Cb Froid | Installation de pompe a chaleur pour le chauffage d'un fluide. |

| DE102010056370A1 (de) * | 2010-05-02 | 2012-06-06 | KLK Klima Lüftung Kälte GmbH | Vorrichtung zur Steigerung der Effizienz einer Wärmepumpe bei der Brauchwassererzeugung |

| JP5054180B2 (ja) | 2010-11-04 | 2012-10-24 | サンデン株式会社 | ヒートポンプ式暖房装置 |

| FR2973863B1 (fr) | 2011-04-11 | 2014-12-26 | Aj Tech | Pompe a chaleur bi-etagee a hautes performances |

Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE330378C (de) * | 1919-12-14 | 1920-12-13 | Edmund Altenkirch | Heizung |

| GB494996A (en) * | 1937-08-03 | 1938-11-04 | Teves Kg Alfred | Improvements in or relating to refrigerating machines |

| CH225518A (de) * | 1942-02-06 | 1943-02-15 | Escher Wyss Maschf Ag | Wärmepumpenanlage. |

| CH234315A (de) * | 1943-07-13 | 1944-09-30 | Escher Wyss Maschf Ag | Wärmepumpe. |

| US2717765A (en) * | 1953-06-05 | 1955-09-13 | Jr Paul Lawler | Viscosimeter bath refrigeration unit |

| US2782350A (en) * | 1953-08-06 | 1957-02-19 | Whirlpool Seeger Corp | Electrical circuit for multiple motor system |

| US2919558A (en) * | 1957-04-24 | 1960-01-05 | Borg Warner | Air conditioning system |

| US3733845A (en) * | 1972-01-19 | 1973-05-22 | D Lieberman | Cascaded multicircuit,multirefrigerant refrigeration system |

| US3852974A (en) * | 1971-12-03 | 1974-12-10 | T Brown | Refrigeration system with subcooler |

| DE2516560A1 (de) * | 1974-04-18 | 1975-10-30 | Projectus Ind Produkter Ab | Waermepumpenanlage |

| DE2520226A1 (de) * | 1975-05-07 | 1976-11-25 | Gerhard Heeren | Mehrstufige waermepumpe |

| US4000626A (en) * | 1975-02-27 | 1977-01-04 | Webber Robert C | Liquid convection fluid heat exchanger for refrigeration circuit |

| US4028079A (en) * | 1976-02-23 | 1977-06-07 | Suntech, Inc. | Cascade refrigeration system |

| DE2907982A1 (de) * | 1979-03-01 | 1980-09-11 | Lawrence E Lush | Vorrichtung zur leistungsregelung von kuehlgeraetekompressoren |

| US4227380A (en) * | 1979-11-09 | 1980-10-14 | Frick Company | Single casing, multiple duty valve |

| DE2922119A1 (de) * | 1979-05-31 | 1980-12-11 | Kmn Beratung Beratungsbuero Fu | Kombination von kaeltemaschinen und waermepumpen zur kaelte- und waermeerzeugung unter ausnutzung der naturwaerme |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH239501A (de) * | 1944-02-19 | 1945-10-31 | Bbc Brown Boveri & Cie | Wärmepumpen-Anlage mit mindestens zwei mit verschiedenen Wärmemitteln betriebenen Wärmepumpensystemen. |

| DE7908625U1 (de) * | 1979-03-27 | 1979-07-19 | Lindner, Helmut, 4600 Dortmund | Modulwaermepumpe zur erwaermung von heiz- und brauchwasser aus umweltwaerme |

| DE2919824A1 (de) * | 1979-05-16 | 1980-11-20 | Siemens Ag | Waermepumpe |

-

1981

- 1981-02-16 DE DE19813106152 patent/DE3106152A1/de not_active Withdrawn

-

1982

- 1982-01-19 DE DE8282900346T patent/DE3264958D1/de not_active Expired

- 1982-01-19 EP EP82730005A patent/EP0056780A3/fr active Pending

- 1982-01-19 WO PCT/DE1982/000014 patent/WO1982002588A1/fr active IP Right Grant

- 1982-01-19 EP EP82900346A patent/EP0069756B1/fr not_active Expired

- 1982-09-14 DK DK410582A patent/DK410582A/da not_active Application Discontinuation

Patent Citations (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE330378C (de) * | 1919-12-14 | 1920-12-13 | Edmund Altenkirch | Heizung |

| GB494996A (en) * | 1937-08-03 | 1938-11-04 | Teves Kg Alfred | Improvements in or relating to refrigerating machines |

| CH225518A (de) * | 1942-02-06 | 1943-02-15 | Escher Wyss Maschf Ag | Wärmepumpenanlage. |

| CH234315A (de) * | 1943-07-13 | 1944-09-30 | Escher Wyss Maschf Ag | Wärmepumpe. |

| US2717765A (en) * | 1953-06-05 | 1955-09-13 | Jr Paul Lawler | Viscosimeter bath refrigeration unit |

| US2782350A (en) * | 1953-08-06 | 1957-02-19 | Whirlpool Seeger Corp | Electrical circuit for multiple motor system |

| US2919558A (en) * | 1957-04-24 | 1960-01-05 | Borg Warner | Air conditioning system |

| US3852974A (en) * | 1971-12-03 | 1974-12-10 | T Brown | Refrigeration system with subcooler |

| US3733845A (en) * | 1972-01-19 | 1973-05-22 | D Lieberman | Cascaded multicircuit,multirefrigerant refrigeration system |

| DE2516560A1 (de) * | 1974-04-18 | 1975-10-30 | Projectus Ind Produkter Ab | Waermepumpenanlage |

| FR2268232A1 (fr) * | 1974-04-18 | 1975-11-14 | Projectus Ind Produkter Ab | |

| US4000626A (en) * | 1975-02-27 | 1977-01-04 | Webber Robert C | Liquid convection fluid heat exchanger for refrigeration circuit |

| DE2520226A1 (de) * | 1975-05-07 | 1976-11-25 | Gerhard Heeren | Mehrstufige waermepumpe |

| US4028079A (en) * | 1976-02-23 | 1977-06-07 | Suntech, Inc. | Cascade refrigeration system |

| DE2907982A1 (de) * | 1979-03-01 | 1980-09-11 | Lawrence E Lush | Vorrichtung zur leistungsregelung von kuehlgeraetekompressoren |

| DE2922119A1 (de) * | 1979-05-31 | 1980-12-11 | Kmn Beratung Beratungsbuero Fu | Kombination von kaeltemaschinen und waermepumpen zur kaelte- und waermeerzeugung unter ausnutzung der naturwaerme |

| US4227380A (en) * | 1979-11-09 | 1980-10-14 | Frick Company | Single casing, multiple duty valve |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8904815B2 (en) | 2004-11-26 | 2014-12-09 | Energy Machines S.A. | Heating installation and heating method |

| CN101095015B (zh) * | 2004-11-26 | 2010-12-08 | 第一近热工厂股份公司 | 加热设备和加热方法 |

| WO2006057594A1 (fr) * | 2004-11-26 | 2006-06-01 | Första Närvärmeverket Ab | Installation et procede de chauffage |

| WO2006099378A1 (fr) * | 2005-03-14 | 2006-09-21 | York International Corporation | Systeme cvc equipe d'un sous-refroidisseur mecanique |

| US7908881B2 (en) | 2005-03-14 | 2011-03-22 | York International Corporation | HVAC system with powered subcooler |

| EP2211125A1 (fr) * | 2009-01-27 | 2010-07-28 | Zanotti S.p.A. | Installation et procédé de production d'eau chaude et froide devant alimenter un ou plusieurs utilisateurs thermiques |

| WO2013088356A1 (fr) * | 2011-12-12 | 2013-06-20 | Innovation Factory S.R.L. | Unité de pompe à chaleur à hautes performances |

| WO2014184184A1 (fr) * | 2013-05-14 | 2014-11-20 | Energy Machines S.A. | Installation de chauffage |

| CN105229380A (zh) * | 2013-05-14 | 2016-01-06 | 能源机器公司 | 加热设备 |

| CN105229380B (zh) * | 2013-05-14 | 2017-12-15 | 能源机器公司 | 加热设备 |

| US10274207B2 (en) | 2013-05-14 | 2019-04-30 | Energy Machines Aps | Heating installation |

| CN106524539A (zh) * | 2016-12-22 | 2017-03-22 | 广东高而美制冷设备有限公司 | 利用冷热水自然对流进行过冷的太阳能空气能换热系统 |

| CN106524539B (zh) * | 2016-12-22 | 2018-08-10 | 广东高而美制冷设备有限公司 | 利用冷热水自然对流进行过冷的太阳能空气能换热系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| DK410582A (da) | 1982-09-14 |

| DE3264958D1 (en) | 1985-09-05 |

| EP0056780A3 (fr) | 1982-08-25 |

| EP0069756A1 (fr) | 1983-01-19 |

| DE3106152A1 (de) | 1982-08-26 |

| WO1982002588A1 (fr) | 1982-08-05 |

| EP0069756B1 (fr) | 1985-07-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69827110T2 (de) | Klimaanlage | |

| DE3805987C2 (fr) | ||

| DE2915979A1 (de) | Fuer kuehlbetrieb eingerichtete waermepumpenanlage | |

| EP0056780A2 (fr) | Disposition de pompes à chaleur | |

| DE2908989A1 (de) | Waermepumpe | |

| DE3209761A1 (de) | Waermepumpenanlage | |

| DE3215141A1 (de) | Klimaanlage | |

| DE3109843C1 (de) | Heizungsanlage mit einem Heizkessel und einer Waermepumpe | |

| WO2014180749A1 (fr) | Dispositif muni d'un composant électronique et d'une machine frigorifique servant à refroidir le composant électronique, et procédé servant à refroidir un composant électronique | |

| DE2700123A1 (de) | Klimaanlage mit waermepumpe | |

| DE69004009T2 (de) | Kühlanlage mit Zusatzwärmespeicher. | |

| DE60033261T2 (de) | Klimaanlage | |

| DE2711144C2 (fr) | ||

| DE3313429A1 (de) | Waermepumpenvorrichtung | |

| DE102008043807B4 (de) | Kälteanlage | |

| EP2215412A1 (fr) | Installation pour le refroidissement, le chauffage ou la climatisation, en particulier installations frigorifiques | |

| EP0593495B1 (fr) | Dispositif frigorifique | |

| DE102008043823B4 (de) | Wärmepumpenanlage | |

| WO2004030957A1 (fr) | Systeme de regulation de la temperature pour vehicule automobile | |

| DE2424693A1 (de) | Kuehlanlage | |

| EP3810999B1 (fr) | Procédé de fonctionnement d'une pompe à chaleur et machine frigorifique | |

| EP1620684B1 (fr) | Procede de regulation d'un cycle de carnot et installation appropriee pour sa mise en oeuvre | |

| DE112021007291T5 (de) | Wärmequellenmaschine einer Kühlvorrichtung und Kühlvorrichtung einschließlich derselben | |

| DE20216324U1 (de) | Wärmepumpe mit Kühlfunktion | |

| DE102010008408B4 (de) | Verfahren zum Betreiben eines Rückkühlkreislaufes mit einem Hybridkühler für eine Anlage mit einer diskontinuierlichen Wärmeabgabe und Vorrichtung hierfür |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): IT |

|

| AK | Designated contracting states |

Designated state(s): IT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 19830210 |

|

| XX | Miscellaneous |

Free format text: VERFAHREN ABGESCHLOSSEN INFOLGE VERBINDUNG MIT 82900346.6 (EUROPAEISCHE ANMELDENUMMER) DURCH ENTSCHEIDUNG VOM 28.06.83. |