CN214930928U - Boxing device and picking machine suitable for strawberry picking machine - Google Patents

Boxing device and picking machine suitable for strawberry picking machine Download PDFInfo

- Publication number

- CN214930928U CN214930928U CN202121222073.7U CN202121222073U CN214930928U CN 214930928 U CN214930928 U CN 214930928U CN 202121222073 U CN202121222073 U CN 202121222073U CN 214930928 U CN214930928 U CN 214930928U

- Authority

- CN

- China

- Prior art keywords

- rocker

- strawberry

- seat

- boxing

- guide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Abstract

The utility model discloses a boxing device and picking machine suitable for strawberry picking machine, including supply box mechanism, boxing controller, transport mechanism and elevating system, supply box mechanism, boxing controller and elevating system set gradually along transport direction of transport mechanism, supply box mechanism to set up at transport mechanism's input, be used for storing the packing carton, and supply the packing carton to transport mechanism on, transport mechanism is used for propelling out the packing carton of supply box mechanism bottommost and with its propelling movement direction along the conveyer belt; the boxing controller is used for receiving the strawberries picked by the picking hand and guiding the strawberries to the packaging box running below the strawberry outlet of the boxing controller; the lifting mechanism is arranged below the outer side of the outlet end of the conveying mechanism and used for temporarily storing and transferring the packing boxes after the packing boxes are loaded. The strawberries picked by the picking hands are directly placed in a transportation and sales packaging box by the device, so that personnel do not contact the strawberries, and the strawberry transfer times and the sorting workload are reduced.

Description

Technical Field

The utility model belongs to the technical field of agricultural machine, concretely relates to cartoning device and picking machine suitable for strawberry picking machine.

Background

With the continuous increase of agricultural labor gaps and the sudden rise of agricultural labor cost in China, the development of agricultural picking equipment becomes an important mode for solving the problem of insufficient agricultural labor and is also an important technical means for realizing large-scale and modernization of agriculture. The strawberry picking machine is an important platform for realizing automatic picking of strawberries, while the design of the existing strawberry picking machine is mainly focused on the aspects of an identification system, a picking hand of a tail end actuating mechanism, a carrying platform and the like, and the design of a collecting device after the strawberries are picked is less concerned. The strawberries are picked by picking hands and then temporarily stacked in a collecting container on a picking machine, the collecting container is taken down after the strawberries in the collecting container reach a certain number, and the strawberries are transferred to a turnover box by a planter and are ready for next-stage transportation and sale. In the strawberry collection mode, the strawberries are stacked and placed in the collection container, the strawberries are laminated layer by layer, and the strawberries on the lower layer are easy to crack; the strawberry falling height of the picking hand when the strawberry is placed in the picking hand is consistent as much as possible, the stroke of the picking hand needs to be controlled and adjusted along with the increase of the stacking height, and the complexity of control is increased; strawberry transfer times are more in the whole collection process, the probability of strawberry damage is increased, personnel contact participation is needed in the transfer process, the labor intensity is high, and the efficiency is low.

SUMMERY OF THE UTILITY MODEL

The utility model aims at solving the problem that exists on the above-mentioned prior art, provide a cartoning device and picking machine suitable for strawberry picking machine, the cartoning device of this scheme can set up on the strawberry picking machine, as the partly of picking machine, will pick the strawberry that hand picked and pluck and directly place in the transportation sells the packing carton, makes personnel contactless strawberry, reduces strawberry transfer number of times and letter sorting work load.

The utility model discloses an one of purpose is realized through following technical scheme:

a boxing device suitable for a strawberry picking machine comprises a box supplying mechanism, a boxing controller, a conveying mechanism and a lifting mechanism, wherein the box supplying mechanism, the boxing controller and the lifting mechanism are sequentially arranged along the conveying direction of the conveying mechanism, and the box supplying mechanism and the boxing controller are arranged above the conveying mechanism; the box supplying mechanism is arranged at the input end of the conveying mechanism and used for storing the packaging boxes and supplying the packaging boxes to the conveying mechanism, the box supplying mechanism comprises a packaging box accommodating bin surrounded by four upright posts, the lower parts of the upright posts are fixed on two sides of the conveying mechanism through connecting buckles, and a channel gap for pushing out the packaging boxes is formed between the upright posts and the conveying mechanism; the conveying mechanism is used for pushing the packing boxes and comprises a conveying belt, a plurality of push plates are arranged along the length direction of the outer surface of the conveying belt in a surrounding mode and used for pushing the packing boxes at the bottommost part of the box supplying mechanism out of the channel gaps and pushing the packing boxes along the moving direction of the conveying belt; the boxing controller is used for receiving the strawberries picked by the picking hand and guiding the strawberries into a packaging box below a strawberry outlet of the boxing controller; the lifting mechanism is arranged below the outer side of the output end of the conveying mechanism and used for temporarily storing and transferring the packing boxes after the packing boxes are loaded.

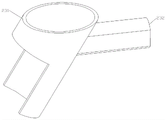

As the preferred scheme, the boxing controller comprises a strawberry collecting table, a plurality of strawberry receiving holes which are sequentially arranged are formed in the strawberry collecting table, and the strawberry collecting holes are of funnel-shaped structures and used for receiving strawberries picked by picking hands and putting the strawberries into the strawberry collecting table.

Preferably, the boxing controller further comprises a guide seat and a control slide seat; the guide seats are arranged below the strawberry collecting table in a butt joint mode, the number of the guide seats is consistent with that of grooves in each row of the packaging box, the guide seats are arranged along the transverse direction of the conveying belt and comprise guide pipes and fixing arms, the fixing arms are arranged on the outer side walls of the guide pipes, the guide pipes are made of hollow cylindrical pipelines and are connected with the strawberry receiving holes, the upper sections of the guide pipes are provided with strawberry storing cavities, and the side walls of the lower sections of the guide pipes are provided with semicircular strawberry outlet openings with notches on one sides; the control slide seat comprises a slide seat end plate, an inclined plane stop block, a slide seat shaft and a reset spring, wherein the inclined plane stop block is arranged on one side end face of the slide seat end plate and is arranged in one-to-one correspondence with the berry outlet of the guide pipe, the slide seat shaft is arranged on the other side end face of the slide seat end plate, the reset spring is arranged on the slide seat shaft in a penetrating mode, the inclined plane stop block is driven by the rocker mechanism to move horizontally so as to open/close the berry outlet.

Preferably, the cartoning controller further comprises a rocker mechanism for driving and controlling the sliding seat to horizontally reciprocate and a cam mechanism for driving the rocker mechanism to swing; the rocker mechanism comprises a rocker shaft, a roller rocker, a sliding seat rocker and a roller bearing, wherein one end of the roller rocker is fixedly connected with the rocker shaft, the other end of the roller rocker is fixedly connected with an inner ring of the roller bearing, one end of the sliding seat rocker is fixedly connected with the rocker shaft, the other end of the sliding seat rocker is connected with the sliding seat shaft, the roller rocker and the sliding column rocker are arranged at a certain included angle, an outer ring of the roller bearing is located on a motion track of a control cam of the cam mechanism, and the control cam is in contact with the outer ring of the roller bearing to drive the rocker mechanism to swing around the rocker shaft, so that the sliding seat is controlled to horizontally reciprocate.

According to a preferable scheme, the boxing controller comprises a base frame, the base frame comprises a cam mounting seat, a rocker mounting seat and a guide mounting seat which are integrally arranged, the cam mounting seat and the guide mounting seat are respectively connected to two sides of the rocker mounting seat, and the rocker mounting seat is horizontally arranged and used for mounting a rocker mechanism; the cam mounting seat is vertically arranged on one side of the rocker mounting seat and is used for mounting the cam mechanism; the guide mounting seat; the adjusting device is used for installing the control sliding seat, a guide seat fixing plate is arranged on the opening side of the guide installation seat, a plurality of installation openings are formed in the guide seat fixing plate along the width direction of the conveying belt, a fixing arm is arranged on the outer side of the guide pipe, the fixing arm is installed in the installation openings through an adjusting bolt, and the relative position of the guide seat and the inclined plane stop block can be adjusted through the adjusting bolt.

Preferably, a slide seat mounting plate for mounting the control slide seat is arranged on the guide mounting seat, the slide seat mounting plate is vertically arranged and is positioned on the inner side of the guide pipe, a slide hole is formed in the slide seat mounting plate, and the slide seat shaft penetrates through the slide hole from one side of the slide seat mounting plate and is connected with a slide seat rocker on the other side of the slide seat mounting plate.

As preferred scheme, the fixed deflector that is provided with in transport mechanism's both sides for can not take place the skew when guaranteeing that the packing carton transports on the conveyer belt, the deflector is including fixed curb plate and direction curb plate, fixed curb plate level sets up, installs on conveyer belt both sides frame through the fastener, and the vertical upwards setting of direction curb plate is in the conveyer belt both sides, and the up end of fixed curb plate contacts with the bottom of packing carton under the push pedal promotes, realizes that the packing carton transports the direction to the conveyer belt one by one on fixed curb plate and removes.

As preferred scheme, elevating system includes bottom plate, location flat band and posting, the posting is located the bottom plate directly over, and the framework of posting suits with the appearance of packing carton, and the posting is close to conveyer belt one side and is formed with the frame mouth that links up mutually with the conveyer belt, and the location flat band is provided with many, and location flat band both ends connect respectively posting and bottom plate for guarantee the stationarity that the packing carton piles up.

As a preferred scheme, elevating system still includes elevator motor, lift lead screw, direction optical axis and goes up and down to place the platform, elevator motor sets up the top at the lift lead screw, and lift lead screw and direction optical axis are located the both sides of the frame mouth department of locating frame respectively, and the upper and lower both ends are connected through fixed connection board respectively, goes up and down to place the platform and is located between the flat area of location, goes up and down to place the both sides of platform and be provided with respectively with lift lead screw complex lifting nut and with direction optical axis complex uide bushing, rotate through elevator motor drive lift lead screw to realize that the lift lead screw drives and goes up and down to place the platform and carry out lift adjustment.

The utility model discloses a second of purpose lies in: the strawberry picking machine comprises the boxing device in any scheme, and the boxing device is mounted on a frame main body of the picking machine.

The utility model discloses possess following beneficial effect at least:

1. the utility model discloses, combine current strawberry picking machine and strawberry cartoning machine to construct organically, the collection problem after the strawberry was picked has been solved, this device is directly packed through cartoning device with the strawberry after picking through picking the hand, need not to set up in addition and collect container and turnover case, need not to be equipped with a set of personnel in addition and pack into the case (need to set up the collection fill that loads the strawberry among the prior art, need set of personnel in addition to carry out the strawberry cartoning simultaneously, furthest has reduced the number of times of transferring of strawberry, it piles up to have avoided the strawberry, the damaged probability of strawberry has been reduced, the control degree of difficulty to picking the hand has been reduced indirectly simultaneously. The transfer process basically does not need manual participation, the labor degree is reduced, and the production efficiency is improved. The boxing device mainly comprises four parts of a box supplying mechanism, a boxing controller, a conveying mechanism, a lifting mechanism and the like, wherein the box supplying mechanism is used for storing the packaging boxes and supplying the packaging boxes to the conveying mechanism; the conveying mechanism firstly conveys the packaging box to a box packing controller, boxes the strawberries, and then conveys the strawberries to the lifting mechanism; the packaging box with the strawberries is temporarily stored by the lifting mechanism, and the working scene that the strawberry packaging box is packed while being picked by a single machine is realized.

2. In the preferred scheme, supply box mechanism through with the push pedal cooperation on the conveyer belt, will be located the packing carton of lowermost end according to the settlement of procedure, release in proper order and move to dress box controller below, for the packing carton controller provides incessant packing carton supply, the device is every packing carton promotes a position forward, and the dress box controller can accurately lead the strawberry to corresponding position in the box, has guaranteed transport mechanism, has supplied the mutual coordination operation between box mechanism and the dress box mechanism. The boxing station number on the boxing controller can be adjusted according to the structure of the packaging box.

3. In the preferred scheme, the position of stand pipe is adjustable, realizes the relative position regulation between inclined plane dog and the guide holder through adjusting bolt, realizes from this that the inclined plane baffle stretches into behind the stand pipe breach department, and the inclined plane dog can effectively control the strawberry and lead and send, and to the strawberry of various sizes, the inclined plane dog homoenergetic is according to position control to the leading of the strawberry of various sizes of adaptation control. The boxing controller is in contact with the roller bearing through the cam, meanwhile, the strip-shaped hole in one end of the sliding seat rocker drives the movable pin to move, so that one-time translational sliding of the control sliding seat is achieved, the device guides strawberry fruits in the guide pipe into the packaging box while the sliding seat rocker is pulled, the reset spring reversely pushes the control sliding seat to reset, and the structure can effectively guarantee control flexibility and transmission smoothness between the control cam and the rocker mechanism.

4. In the preferred scheme, it also plays very key coordination to whole device to go out the box, the frame mouth department and the butt joint of transport mechanism output of posting, when the packing carton by propelling movement to elevating system in the posting, because the push pedal is soft rubber material, can be by packing carton reverse compression after pushing elevating system with the packing carton, treat to pass and reset by self elasticity behind the elevating system, guarantee that the propelling movement is continuous, the reliable operation, every promotion of packing carton is to the posting in the back, the platform descends a packing carton height of placing in the lift, elevating system can guarantee the regularity and the stability that the packing carton piles up, do earlier stage preparation work for subsequent packing carton transfer.

Drawings

In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the drawings used in the description of the embodiments or the prior art will be briefly described below, and it is obvious that the drawings in the following description are only some embodiments of the present invention, and for those skilled in the art, other drawings can be obtained according to these drawings without creative efforts.

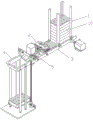

FIG. 1 is a perspective view of the boxing apparatus of the present invention;

fig. 2 is a front view of the boxing apparatus of the present invention;

FIG. 3 is a structural view of a cassette supply mechanism and a transport mechanism;

fig. 4 is a perspective view of a first perspective of the cartoning controller;

fig. 5 is a perspective view of a second perspective of the cartoning controller;

FIG. 6 is a block diagram of the guide housing of FIG. 5;

FIG. 7 is a block diagram of the control slide of FIG. 5;

FIG. 8 is a structural view of the rocker of FIG. 5;

FIG. 9 is a top view of the cartoning controller;

FIG. 10 is a perspective view of the elevating mechanism

FIG. 11 is a diagram showing the operation of the lifting mechanism and the fixed collecting table;

FIG. 12 is a view showing the construction of the elevating platform shown in FIG. 10;

the labels in the figure are: 1. a feeding cassette mechanism, 11, a column, 12, a connector link, 2, a cassette controller, 21, a strawberry collecting table, 22, a strawberry receiving hole, 23, a guide holder, 231, a guide tube, 232, a fixing arm, 24, a control slide holder, 241, a slide holder plate, 242, a slope stopper, 243, a slide holder shaft, 244, a return spring, 245, a movable pin, 25, a rocker mechanism, 251, a rocker shaft, 252, a roller rocker, 253, a slide rocker, 254, a roller bearing, 26, a cam mechanism, 261, a cam holder, 262, a control cam, 263, a cam motor, 264, a coupling, 265, a camshaft, 27, a base frame, 271, a cam mount, 272, a rocker mount, 273, a guide mount, 274, a guide holder fixing plate, 275, an adjusting bolt, 276, a mounting plate, 3, a transmission mechanism, 31, a driving pulley, 32, a driven pulley, 33, a transmission belt, 34, a push plate, 35. guide plate, 36, conveying motor, 4, lifting mechanism, 41, bottom plate, 42, positioning flat belt, 43, positioning frame, 44, lifting motor, 45, lifting screw rod, 46, guiding optical axis, 47, lifting placing table, 471, movable inserting strip, 472, cross bar, 473, guide sleeve, 474, lifting nut, 48, fixed connecting plate, 5, brush mechanism, 51, brush support, 52, correcting brush, 6, fixed collecting table, 61, fixing table, 62, fixed inserting strip, 10 and packaging box.

Detailed Description

The technical solutions in the embodiments of the present invention will be described clearly and completely with reference to the accompanying drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only some embodiments of the present invention, not all embodiments. Based on the embodiments in the present invention, all other embodiments obtained by a person skilled in the art without creative work belong to the protection scope of the present invention.

Hereinafter, preferred embodiments of the present invention will be described in detail.

As shown in fig. 1, 2 and 3, the boxing apparatus includes a box supplying mechanism 1, a boxing controller 2, a conveying mechanism 3 and a lifting mechanism 4, the box supplying mechanism 1, the boxing controller 2 and the lifting mechanism 4 are sequentially arranged along the conveying direction of the conveying mechanism 3, the box supplying mechanism 1 is used for storing the packing boxes 10 and supplying the packing boxes 10 to the conveying mechanism 3; the conveying mechanism 3 firstly conveys the packaging box 10 to the box packing controller 2 for strawberry box packing, and then conveys the strawberry box to the lifting mechanism 4; the boxing controller 2 is arranged above the conveying mechanism 3, 3 boxing stations are arranged on the boxing controller, and 3 strawberries can fall into the packaging box 10 at the same time; the lifting mechanism 4 temporarily holds the package box 10 containing the strawberries. The boxing station number on the boxing controller 2 can be adjusted according to the structure of the packaging box 10, and in the embodiment, the packaging box 10 is internally provided with 3 rows by 5 columns, and 15 grooves are formed in total, and can contain 15 strawberries.

In this embodiment, the cassette supply mechanism 1 is disposed at the input end of the transport mechanism 3; the box supplying mechanism 1 comprises a packaging box containing bin surrounded by four upright posts 11, the lower parts of the upright posts 11 are fixed on a guide side plate of the conveying mechanism 3 through connecting buckles 12, and a channel gap for pushing out the packaging box 10 is formed between the lower ends of the upright posts 11 and the conveying mechanism 3. The cross section of the upright post 11 is L-shaped, so that the four upright posts 11 enclose a cuboid packing box accommodating bin for stacking and storing the packing boxes 10.

In this scheme, transport mechanism 3 is used for the propelling movement of packing carton 10, including driving pulley 31, driven pulley 32, conveyer belt 33, deflector 35 and conveyer motor 36, wherein driving pulley 31 and driven pulley 32 set up respectively at conveyer belt 33 both ends, be used for supporting and driving conveyer belt 33 and rotate, the length direction who follows the conveyer belt 33 surface encircles and is provided with a plurality of push pedals 34, a packing carton 10 for promoting the bottommost of supplying box mechanism 1 is released, and remove along conveyer belt 33 direction of motion on deflector 35, conveyer motor 36 is used for driving pulley 31 and rotates.

Further, the fixed deflector 35 that is provided with in transport mechanism 3's both sides for guarantee that packing carton 10 can not take place to deviate when transporting on conveyer belt 10, the cross section of deflector 35 is L shape, including integrative fixed curb plate and the direction curb plate of connecting, fixed curb plate level sets up, installs on transport mechanism 3 both sides frame through the fastener, is used for supporting packing carton 10 and slides the conveying at fixed curb plate up end, and the direction curb plate sets up in conveyer belt 33 both sides perpendicularly upwards, is used for injecing the traffic direction of packing carton 10.

In particular, the transfer mechanism 3 completes the pushing of the pack 10. After the conveying motor 36 is started, the driving belt wheel 31 rotates to drive the conveying belt 33 to move, the surface of the conveying belt 33 is vertically provided with the push plate 34, the packing box 10 at the bottommost part of the box supplying mechanism 1 is pushed to slide along the moving direction of the conveying belt 33, the packing box 10 is supported by the left and right fixed side plates, and the conveying belt 33 is slightly lower than the inner horizontal plane of the fixed side plates to avoid contacting with the packing box 10. After the bottommost package 10 is completely pushed out by the pushing plate 34, the upper package 10 tightly connected with the bottommost package falls down to wait for the next pushing.

As shown in fig. 3, 4, 5, and 9, the cartoning controller 2 is fixed to the guide side plates on both sides by the auxiliary support plates 28. The boxing controller 2 is used for receiving the strawberries picked by the picking hands and guiding the strawberries into the packaging box 10 below the strawberry outlet of the boxing controller 2, and at the moment, the packaging box 10 is pushed to the boxing controller 2.

The boxing controller 2 comprises a base frame 27, a strawberry collecting table 21, a guide seat 23, a control slide seat 24, a rocker mechanism 25 for driving the control slide seat 24 to horizontally move and a cam mechanism 26 for driving the rocker mechanism 25 to swing; a plurality of strawberry receiving holes 22 arranged in sequence are formed in the strawberry collecting table 21, and the strawberry collecting holes 22 are used for receiving strawberries picked by a picking hand. The number of the guide seats 23 is the same as the number of the grooves of each row of the packing box 10, in this embodiment, the packing box 10 adopts the specification of 3 rows × 5 columns of grooves, so that three guide seats 23 are provided. Three guide holder 23 is along conveyer belt 33's transverse arrangement, guide holder 23 includes stand pipe 231 and fixed arm 232, fixed arm 232 sets up the lateral wall at stand pipe 231, stand pipe 231 is made by a hollow cylindrical pipeline, stand pipe 231 is certain inclination and sets up, it links up with strawberry receiving hole 22 mutually, the upper segment of stand pipe 231 is formed with deposits the berry chamber, be formed with the semicircular play berry mouth that one side has the breach on the lateral wall of stand pipe 231 hypomere.

In this embodiment, the fixing arm 232 is installed in the through hole of the guide seat fixing plate 274 through the adjusting bolt 275, and the position adjustment of the guide tube 231 (that is, the length adjustment of the position where the control slide seat 24 extends into the strawberry outlet of the guide tube 231) can be realized through the adjusting bolt 275, so as to adapt to the guiding and conveying of strawberries with different sizes, for example, when the guide tube 231 is adjusted to the side of the control slide seat 24, the length of the control slide seat 24 extending into the gap is longer, which is suitable for controlling strawberries with smaller sizes, and when the guide tube 231 is adjusted to the side far from the control slide seat 24, the length of the control slide seat 24 extending into the gap is shorter, which is suitable for controlling strawberries with larger sizes, so that the adaptive adjustment can be performed according to the size change caused by different strawberry varieties, harvesting periods and the like, so as to enhance the adaptive capacity of the device. Wherein the guide tube 231 adopts special project organization, is made by cylindrical pipeline, and the neat mouth of port for collecting 21 lower extremes butt joints with the strawberry on the guide tube 231, and the lateral wall of port is cut off under the guide tube 231 to form semicircular breach structure, control slide 24 stretches into breach department, with the dress box of control strawberry.

In the scheme, the control slide seat 24 comprises a slide seat end plate 241, an inclined plane stop block 242 and a slide seat shaft 243, wherein the inclined plane stop block 242 is arranged on one side end surface of the slide seat end plate 241 and is arranged in one-to-one correspondence with the guide pipe 231, the slide seat shaft 243 is arranged on the other side end surface of the slide seat end plate 241, and the inclined plane stop block 242 can horizontally move to open/close a berry outlet under the drive of the rocker mechanism 25; the control sliding seat 24 is installed in a guide hole of the guide installation seat 273, two ends of the sliding seat shaft 243 are planes, the planes are matched with the guide hole to realize linear motion of the control sliding seat 24, one end of the control sliding seat 24 is provided with a groove and a connecting hole for installing and connecting the rocker mechanism 25, the other end of the control sliding seat 24 is provided with a sliding seat end plate 241 and an inclined plane stop block 242, a reset spring 244 is arranged between the sliding seat end plate 241 and the guide installation seat 273, and the reset spring 244 penetrates through the sliding seat shaft 243. The upper end opening of the guide pipe 231 is an inclined round hole, so that strawberries can fall into the receiving hole 22 conveniently, and the lower part of the guide pipe is a semicircular hole, so that the inclined plane stop block 242 is sealed to store the strawberries.

In this embodiment, the strawberry is put into the receiving hole 22 on the strawberry collecting table 21 by the picking hand, the receiving hole 22 is a funnel-shaped structure, 3 receiving holes 22 are arranged on the strawberry collecting table 21, the picking hand puts the strawberry into the receiving hole 22 one by one, the strawberry slides into the guide tube 231 of the guide seat 23 after entering the receiving hole 22, is supported by the inclined plane stopper 242 on the control slide seat 24, and is temporarily kept in the strawberry storage cavity at the upper section of the guide tube 231.

The cartoning controller 2 can adopt the following driving method: the base frame 27 is respectively provided with a rocker mechanism 25 and a cam mechanism 26 for driving the rocker mechanism 25, the rocker mechanism 25 comprises a rocker shaft 251, a roller rocker 252, a sliding seat rocker 253 and a roller bearing 254, wherein one end of the roller rocker 252 is fixedly connected with the rocker shaft 251, the other end of the roller rocker 252 is provided with the roller bearing 254, one end of the sliding seat rocker 253 is fixedly connected with the rocker shaft 251, the other end of the sliding seat rocker 253 is connected with a sliding rod 243, the roller rocker 252 and the sliding column rocker 253 are arranged at an obtuse included angle, the outer annular surface of the roller bearing 254 is positioned on the motion track of the control cam 262, and the control cam 262 is contacted with the roller bearing 254 to drive the rocker mechanism 25 to swing. The inner ring of the roller bearing 254 is connected with one end of a roller rocker 252 through a bolt, the other end of the roller rocker 252 is connected with a rocker shaft 251 in a fastening manner, a sliding seat rocker 253 is also connected with the rocker shaft 251 in a fastening manner, the other end of the sliding seat rocker 253 is provided with a strip-shaped sliding groove hole, the end part of a sliding seat shaft 243 is provided with a shaft fork structure which is arranged at the sliding groove hole through a movable pin 245, the shaft fork structure is clamped at two sides of the sliding seat rocker 253, the movable pin 245 penetrating through the shaft fork structure is arranged in the sliding groove hole, and the movable pin 245 can be movably adjusted in the sliding groove hole. The cam mechanism 26 comprises a cam seat 261, a control cam 262 and a cam motor 263, wherein the control cam 262 is installed on the cam seat 261 through a cam shaft 265, and the cam motor 263 is connected with one end of the cam shaft 265 through a coupler 264 so as to drive the control cam 262 to rotate; camshaft 265 and rocker shaft 251 are mounted to the base via bearing blocks. The cam motor 263 is started, the cam shaft 265 is rotated by a certain angle through the coupling 264, the cam shaft 265 is provided with the control cam 262, and the control cam 262 is contacted with the outer ring of the roller bearing 254.

When the control cam 262 drives the roller rocker 252 to swing downwards, the control cam 262 is in rolling contact with the roller bearing 254, when the control cam 262 is in contact with the outer ring of the roller bearing 254, the outer ring of the roller bearing 254 is in rolling friction with the control cam 262, so that the driving force of the cam motor 263 is transmitted to the rocker mechanism 25, when the control cam 262 rotates once, the control cam 262 is in contact with the roller bearing 254, so that one-time swinging of the roller rocker 252 is realized, the rocker shaft 251 rotates anticlockwise, the slide rocker 253 on the rocker shaft 251 swings anticlockwise, the control slide 24 is driven to move leftwards, the return spring 244 is compressed, the inclined plane stopper 242 moves leftwards to be opened, and the strawberry slides into the packaging box 10 through the guide pipe 23; when the control cam 262 returns, the control slide 24 is reset under the elastic force of the reset spring 244, the inclined plane stop block 242 moves to the right to close the gap of the lower end of the guide tube 23, and the reset spring 244 is the closing spring of the control cam 262 at the same time.

Specifically, the base frame 27 includes a cam mounting seat 271, a rocker mounting seat 272 and a guide mounting seat 273 which are integrally arranged, the cam mounting seat 271 and the guide mounting seat 273 are respectively connected to two sides of the rocker mounting seat 272, and the rocker mounting seat 272 is horizontally arranged and used for mounting the rocker mechanism 25; the cam mounting seat 271 is vertically arranged on one side of the rocker mounting seat 272 and is used for mounting the cam mechanism 26; a guide mount 273; the main body of the sliding seat is of a C-shaped structure, a guide pipe fixing plate 274 is arranged on the opening side of the C-shaped structure, a plurality of mounting openings are formed in the guide pipe fixing plate 274 along the width direction of the conveyor belt 33, a fixing arm 232 on the outer side of the guide pipe 231 is fixed in each mounting opening through an adjusting bolt 275, and the position of the guide pipe can be adjusted through the adjusting bolt 275. The guide mounting seat 273 is provided with a slide mounting plate 276 for mounting the control slide 24, the slide mounting plate 276 is vertically arranged and is positioned on the inner side of the guide pipe 23, a slide hole is formed on the slide mounting plate 276, and the slide shaft 243 passes through the slide hole from one side of the slide mounting plate 276 and is connected with the slide rocker 253 on the other side.

In order to further improve the boxing effect and the automatic correction capability of the lifting device, a brush mechanism 5 is arranged on one side of the outlet of the boxing controller 2, and in consideration of the leading-in position of the strawberries, individual strawberry fruits do not completely fall into the groove of the packaging box 10, so that a correction brush 52 for correcting the positions of the strawberries is arranged, and when the packaging box 10 passes by, the correction brush 52 on the upper side can slightly sweep the strawberries to sweep the strawberries outside the groove of the packaging box 10 into the groove. The brush mechanism 5 comprises a brush support 51 and a correcting brush 52, two sides of the brush support 51 are fixed on the guide plate 35, the correcting brush 52 is fixedly arranged on a beam of the brush support 51, and the correcting brush 52 is used for sweeping strawberries falling out of the groove of the packaging box 10 into the groove.

As described above, when the packing carton 10 pushes to the corresponding position at the bottom of the carton packing controller 2, the conveying motor 36 stops, wait for the strawberry to fall down, after the strawberry falls down, the conveying motor 36 starts a certain step distance to the 2 nd row position, wait for the strawberry to fall down, so repeat until the 5 th row position, after the 5 th row position strawberry falls down, the conveying motor 36 starts, push the packing carton 10 to the lifting mechanism 4, during this period, through the correction brush 52 fixed on the brush support 51, the correction brush 52 sweeps the strawberry gently, can sweep the strawberry that does not fall into the groove of the packing carton 10 into the groove. The pushing plate 34 is made of soft rubber, and can be reversely compressed by the packaging box 10 after the packaging box 10 enters the lifting mechanism 4, and reset by self elasticity after rotating the lifting mechanism 4, so that continuous and reliable operation of pushing motion is ensured.

In this embodiment, as shown in fig. 10, the lifting mechanism 4 includes a bottom plate 41, a positioning flat belt 42, a positioning frame 43, a lifting motor 44, a lifting screw 45, a guiding optical axis 46 and a lifting placing table 47, the positioning frame 43 is located right above the bottom plate 41, an opening for butting with the conveyor belt 33 is formed on one side of the positioning frame 43 close to the conveyor belt 33, two ends of the positioning flat belt 42 are respectively connected with the positioning frame 43 and the bottom plate 41, 4 positioning flat belts 42 are symmetrically arranged on two sides of the lifting placing table 47, 2 positioning flat belts are respectively arranged on each side to ensure the stability of the stacked packing boxes 10, and the positioning flat belts 42 are respectively connected with hooks on the positioning frame 43 and upper and lower hooks of the bottom plate 41 through flat belt holes formed thereon. The lifting motor 44 is arranged at the top end of the lifting screw rod 45, the lifting screw rod 45 and the guide optical axis 46 are respectively positioned at two sides of the opening of the positioning frame 43, the upper end and the lower end of the lifting screw rod 45 are respectively fixedly connected through a fixed connecting plate 48, the lifting placing table 47 is positioned between the positioning flat belts 42, and the lifting placing table 47 is respectively provided with a lifting nut 473 matched with the lifting screw rod 45 and a guide sleeve 474 matched with the guide optical axis 46.

The scheme also provides a picking machine which comprises a main body of the picking machine and the boxing device. In this embodiment, the boxing device is mounted on the picking machine to be a part of the picking machine itself, the boxing device is mounted on the frame of the picking machine by a connecting and fixing member, the conveying direction of the conveying mechanism 3 is made to coincide with the body running direction of the picking machine, for example, the boxing device is mounted at the front end or the rear end of the picking machine so that the lifting mechanism 4 is positioned close to the outer position to be abutted against the fixed collecting table 6, and when the package box of the lifting mechanism 4 is fully collected, the automatic unloading operation of the package box 10 can be realized by the cooperation between the picking machine body and the boxing device.

The box discharging process of the packing box is as follows: after the package box 10 reaches the lifting mechanism 4, it is positioned by the positioning frame 43 and supported by the lifting platform 47, and the positioning frame 43 is mounted on the frame wall board, which is not shown, and is provided with a position switch. When the packaging box 10 reaches the designated position, the position switch is touched, the lifting motor 44 rotates by a certain step distance, and the lifting screw rod 45 rotates to drive the lifting placing platform 47 to move downwards by the height of one packaging box 10 to wait for the next packaging box 10 to be stacked. Wherein the lifting placing table 47 is respectively connected with the lifting screw rod 45 and the guide optical axis 46 and can move up and down.

For facilitating unloading, as shown in fig. 12, the main body of the lifting placing table 47 includes a cross bar 472 and moving insert strips 471, the lifting nuts 473 and the guide sleeves 474 are respectively located at two sides of the cross bar 472, the moving insert strips 471 are provided with a plurality of pieces and are uniformly arranged at one side of the cross bar 472 to form a bearing platform, and a gap is formed between each two adjacent moving insert strips 471.

The unloading mode of the packing box is as follows: as shown in fig. 11, the fixed collecting table 6 includes a fixed table 61 and a plurality of fixed inserts 62 arranged at one side of the fixed table 61, and a gap for accommodating the movable insert 471 is formed between two adjacent fixed inserts 62; after the packing boxes 10 in the lifting mechanism 4 are stacked to reach a preset number, the packing boxes 10 can be automatically unloaded by the strawberry picking machine, the picking machine moves to an unloading station, after the lifting placing table 47 is lowered to the height equal to that of the fixed collecting table 6, the movable inserting strips 471 on the placing table 47 are intersected with the fixed inserting strips 62 on the fixed collecting table 6 in a staggered mode, the lifting placing table 47 continues to descend for a certain distance at the moment, the packing boxes 10 fall on the fixed collecting table, then the picking machine retreats to one side, the lifting placing table 47 ascends to the initial position, and the strawberry packing boxes are automatically transferred and delivered. The picking machine of the embodiment realizes the application of the picking mode of picking and boxing at the same time, improves the utilization efficiency of the picking machine, solves the problem of accumulation of strawberries in the picking process, improves the picking mode and the operation habit that the strawberries can be boxed only after being collected and completed by the picking machine in the prior art, greatly improves the work efficiency, reduces the turnover frequency, and reduces the loss of the strawberries caused in the turnover process for many times.

The above description is only a preferred embodiment of the present invention, and the present invention is not limited to the above embodiments, and although the present invention has been disclosed with the preferred embodiments, it is not limited to the present invention, and any skilled person in the art can make some modifications or equivalent changes without departing from the technical scope of the present invention.

Claims (10)

1. The utility model provides a cartoning device suitable for strawberry picker which characterized in that: the automatic boxing device comprises a box supplying mechanism, a boxing controller, a conveying mechanism and a lifting mechanism, wherein the box supplying mechanism, the boxing controller and the lifting mechanism are sequentially arranged along the conveying direction of the conveying mechanism, and the box supplying mechanism and the boxing controller are arranged above the conveying mechanism;

the box supplying mechanism is arranged at the input end of the conveying mechanism and used for storing the packaging boxes and supplying the packaging boxes to the conveying mechanism, the box supplying mechanism comprises a packaging box accommodating bin surrounded by four upright posts, the lower parts of the upright posts are fixed on two sides of the conveying mechanism through connecting buckles, and a channel gap for pushing out the packaging boxes is formed between the upright posts and the conveying mechanism;

the conveying mechanism is used for pushing the packing boxes and comprises a conveying belt, a plurality of push plates are arranged along the length direction of the outer surface of the conveying belt in a surrounding mode and used for pushing the packing boxes at the bottommost part of the box supplying mechanism out of the channel gaps and pushing the packing boxes along the moving direction of the conveying belt;

the boxing controller is used for receiving the strawberries picked by the picking hand and guiding the strawberries into a packaging box below a strawberry outlet of the boxing controller;

the lifting mechanism is arranged below the outer side of the output end of the conveying mechanism and used for temporarily storing and transferring the packing boxes after the packing boxes are loaded.

2. A boxing device suitable for strawberry picking machines, in accordance with claim 1, wherein: the boxing controller comprises a strawberry collecting table, a plurality of strawberry receiving holes which are sequentially arranged are formed in the strawberry collecting table, and the strawberry collecting holes are of funnel-shaped structures and used for receiving strawberries picked by picking hands and putting the strawberries into the strawberry collecting table.

3. A boxing device suitable for strawberry picking machines, as claimed in claim 2, wherein: the boxing controller also comprises a guide seat and a control sliding seat;

the guide seats are arranged below the strawberry collecting table in a butt joint mode, the number of the guide seats is consistent with that of grooves in each row of the packaging box, the guide seats are arranged along the transverse direction of the conveying belt and comprise guide pipes and fixing arms, the fixing arms are arranged on the outer side walls of the guide pipes, the guide pipes are made of hollow cylindrical pipelines and are connected with the strawberry receiving holes, the upper sections of the guide pipes are provided with strawberry storing cavities, and the side walls of the lower sections of the guide pipes are provided with semicircular strawberry outlet openings with notches on one sides;

the control slide seat comprises a slide seat end plate, an inclined plane stop block, a slide seat shaft and a reset spring, wherein the inclined plane stop block is arranged on one side end face of the slide seat end plate and is arranged in one-to-one correspondence with the berry outlet of the guide pipe, the slide seat shaft is arranged on the other side end face of the slide seat end plate, the reset spring is arranged on the slide seat shaft in a penetrating mode, the inclined plane stop block is driven by the rocker mechanism to move horizontally so as to open/close the berry outlet.

4. A boxing device suitable for strawberry picking machines, in accordance with claim 3, wherein: the boxing controller also comprises a rocker mechanism for driving and controlling the sliding seat to horizontally reciprocate and a cam mechanism for driving the rocker mechanism to swing; the rocker mechanism comprises a rocker shaft, a roller rocker, a sliding seat rocker and a roller bearing, wherein one end of the roller rocker is fixedly connected with the rocker shaft, the other end of the roller rocker is fixedly connected with an inner ring of the roller bearing, one end of the sliding seat rocker is fixedly connected with the rocker shaft, the other end of the sliding seat rocker is connected with the sliding seat shaft, the roller rocker and the sliding column rocker are arranged at a certain included angle, an outer ring of the roller bearing is located on a motion track of a control cam of the cam mechanism, and the control cam is in contact with the outer ring of the roller bearing to drive the rocker mechanism to swing around the rocker shaft, so that the sliding seat is controlled to horizontally reciprocate.

5. A boxing device suitable for strawberry picking machines, as claimed in claim 4, wherein: the boxing controller comprises a base frame, wherein the base frame comprises a cam mounting seat, a rocker mounting seat and a guide mounting seat which are integrally arranged, the cam mounting seat and the guide mounting seat are respectively connected to two sides of the rocker mounting seat, and the rocker mounting seat is horizontally arranged and used for mounting a rocker mechanism; the cam mounting seat is vertically arranged on one side of the rocker mounting seat and is used for mounting the cam mechanism; the guide mounting seat; the adjusting device is used for installing the control sliding seat, a guide seat fixing plate is arranged on the opening side of the guide installation seat, a plurality of installation openings are formed in the guide seat fixing plate along the width direction of the conveying belt, a fixing arm is arranged on the outer side of the guide pipe, the fixing arm is installed in the installation openings through an adjusting bolt, and the relative position of the guide seat and the inclined plane stop block can be adjusted through the adjusting bolt.

6. A boxing device suitable for strawberry picking machines, in accordance with claim 5, wherein: the guide mounting seat is provided with a slide seat mounting plate for mounting a control slide seat, the slide seat mounting plate is vertically arranged and is positioned on the inner side of the guide pipe, a sliding hole is formed in the slide seat mounting plate, and the slide seat shaft penetrates through the sliding hole from one side of the slide seat mounting plate and is connected with a slide seat rocker on the other side.

7. A boxing device suitable for strawberry picking machines, in accordance with claim 6, wherein: the fixed deflector that is provided with in transport mechanism's both sides for can not take place skew when guaranteeing that the packing carton transports on the conveyer belt, the deflector is including fixed curb plate and direction curb plate, fixed curb plate level sets up, installs on the frame of conveyer belt both sides through the fastener, and the vertical upwards setting of direction curb plate is in the conveyer belt both sides, and the up end of fixed curb plate contacts with the bottom of packing carton under the push pedal promotes, realizes that the packing carton transports the direction to the conveyer belt to remove one by one on fixed curb plate.

8. A boxing device suitable for strawberry picking machines, in accordance with claim 6, wherein: elevating system includes bottom plate, location bandeau and posting, the posting is located the bottom plate directly over, and the framework of posting suits with the appearance of packing carton, and the posting is close to conveyer belt one side and is formed with the frame mouth that links up mutually with the conveyer belt, and the location bandeau is provided with many, and location bandeau both ends connect respectively posting and bottom plate to stationarity when being used for guaranteeing the packing carton and piling up.

9. A boxing device suitable for strawberry picking machines according to claim 8, wherein: elevating system still includes elevator motor, lift lead screw, direction optical axis and goes up and down to place the platform, elevator motor sets up the top at the lift lead screw, and lift lead screw and direction optical axis are located the both sides of the frame mouth department of location frame respectively, and both ends are connected through fixed connection board respectively about and, go up and down to place the platform and lie in between the flat area of location, the both sides that go up and down to place the platform are provided with respectively with lift lead screw complex lifting nut and with direction optical axis complex uide bushing, rotate through elevator motor drive lift lead screw to realize that the lift lead screw drives to go up and down to place the platform and carry out the lift adjustment.

10. A picking machine, characterized by: including a cartoning apparatus according to any one of claims 1 to 9, mounted on a chassis body of a picking machine.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121222073.7U CN214930928U (en) | 2021-06-02 | 2021-06-02 | Boxing device and picking machine suitable for strawberry picking machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202121222073.7U CN214930928U (en) | 2021-06-02 | 2021-06-02 | Boxing device and picking machine suitable for strawberry picking machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN214930928U true CN214930928U (en) | 2021-11-30 |

Family

ID=79053933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202121222073.7U Active CN214930928U (en) | 2021-06-02 | 2021-06-02 | Boxing device and picking machine suitable for strawberry picking machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN214930928U (en) |

-

2021

- 2021-06-02 CN CN202121222073.7U patent/CN214930928U/en active Active

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205602168U (en) | Automatic vanning assembly line | |

| CN202828974U (en) | Low-position in-out bottle unscrambler | |

| JPS61173722A (en) | Seedling growing facilities | |

| CN105000216A (en) | Automatic arranging and boxing machine for pipette heads | |

| CN102795482A (en) | Bottle stacking machine capable of feeding and discharging bottles from low position | |

| CN109937798B (en) | Spiral four-pack vertical automatic bagging machine | |

| CN109197060A (en) | Plug seedling Automatic Transplanter and method with the low damage quick seedling taking device of profiling | |

| CN105151398A (en) | Feeding machine for multiple medicine plates of bubble caps | |

| CN212937128U (en) | Full-automatic edible mushroom production line mushroom picking device | |

| CN214930928U (en) | Boxing device and picking machine suitable for strawberry picking machine | |

| CN113184258A (en) | Boxing device and picking machine suitable for strawberry picking machine | |

| CN114521389B (en) | Tomato harvesting vehicle and using method thereof | |

| CN215623050U (en) | Special-shaped cigarette stacking device | |

| US4392586A (en) | Apparatus for securing cartons on the top of articles carried in a case | |

| CN213044219U (en) | Vegetable harvester profiling header | |

| CN205060112U (en) | Automatic cartoning machine of arranging of rifle head | |

| CN211881434U (en) | Automatic grid frame machine and supporting device under edible mushroom package fungus stick | |

| CN209914631U (en) | Spiral four-bag vertical automatic bagging machine | |

| CN109051829B (en) | Stacking device | |

| CN111824754A (en) | Horizontal cigarette sorting machine | |

| CN217706451U (en) | A vanning device for apple cover net case packer | |

| CN214046926U (en) | Automatic mushroom picking equipment for hypsizygus marmoreus | |

| CN214139169U (en) | Automatic case packer of suit combination tableware plug-in mounting formula | |

| CN217074929U (en) | Apple picking work platform vanning system | |

| CN209956358U (en) | Biscuit count packaging system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |