CN1269632C - 可拉伸的复合片材和制造方法 - Google Patents

可拉伸的复合片材和制造方法 Download PDFInfo

- Publication number

- CN1269632C CN1269632C CNB028258436A CN02825843A CN1269632C CN 1269632 C CN1269632 C CN 1269632C CN B028258436 A CNB028258436 A CN B028258436A CN 02825843 A CN02825843 A CN 02825843A CN 1269632 C CN1269632 C CN 1269632C

- Authority

- CN

- China

- Prior art keywords

- layer

- composite sheet

- multicomponent

- helically

- polymer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/14—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyester as constituent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4391—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres

- D04H1/43912—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres fibres with noncircular cross-sections

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/04—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by a layer being specifically extensible by reason of its structure or arrangement, e.g. by reason of the chemical nature of the fibres or filaments

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4374—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece using different kinds of webs, e.g. by layering webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4391—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres

- D04H1/43918—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres nonlinear fibres, e.g. crimped or coiled fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/559—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving the fibres being within layered webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

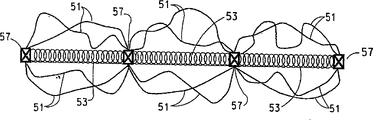

- D04H3/018—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the shape

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Nonwoven Fabrics (AREA)

- Multicomponent Fibers (AREA)

- Laminated Bodies (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US34327601P | 2001-12-21 | 2001-12-21 | |

| US60/343,276 | 2001-12-21 | ||

| US10/317,416 US7005395B2 (en) | 2002-12-12 | 2002-12-12 | Stretchable composite sheets and processes for making |

| US10/317,416 | 2002-12-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1608004A CN1608004A (zh) | 2005-04-20 |

| CN1269632C true CN1269632C (zh) | 2006-08-16 |

Family

ID=26980940

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB028258436A Expired - Fee Related CN1269632C (zh) | 2001-12-21 | 2002-12-13 | 可拉伸的复合片材和制造方法 |

Country Status (9)

| Country | Link |

|---|---|

| EP (1) | EP1456017B1 (enExample) |

| JP (2) | JP2005521566A (enExample) |

| KR (1) | KR100923610B1 (enExample) |

| CN (1) | CN1269632C (enExample) |

| AU (1) | AU2002361896A1 (enExample) |

| BR (1) | BR0215341B1 (enExample) |

| DE (1) | DE60218734T2 (enExample) |

| TW (1) | TWI302172B (enExample) |

| WO (1) | WO2003055674A1 (enExample) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7045211B2 (en) * | 2003-07-31 | 2006-05-16 | Kimberly-Clark Worldwide, Inc. | Crimped thermoplastic multicomponent fiber and fiber webs and method of making |

| WO2008041868A2 (en) | 2006-10-04 | 2008-04-10 | Formway Furniture Limited | A chair |

| JP5563459B2 (ja) * | 2007-09-07 | 2014-07-30 | インヴィスタ テクノロジーズ エスアエルエル | 可変伸長性多層不織布複合体 |

| USD600051S1 (en) | 2008-04-09 | 2009-09-15 | Formway Furniture Limited | Chair back |

| USD604535S1 (en) | 2008-04-09 | 2009-11-24 | Formway Furniture Limited | Chair |

| CA131020S (en) | 2008-12-12 | 2010-02-03 | Formway Furniture Ltd | Chair |

| USD601827S1 (en) | 2008-12-18 | 2009-10-13 | Formway Furniture Limited | Furniture base |

| KR102321603B1 (ko) * | 2016-05-18 | 2021-11-09 | 파이버텍스 퍼스널 케어 에이/에스 | 멜트블로운 및 스펀본드 층을 포함하는 부직 라미네이트 직물 |

| CZ307292B6 (cs) * | 2016-09-30 | 2018-05-16 | Pegas Nonwovens S.R.O. | Spunbondová netkaná textilie pro akvizičně distribuční vrstvu a absorpční výrobek |

| EP3939456B1 (en) * | 2017-03-17 | 2022-08-17 | Nike Innovate C.V. | Textiles and methods of making the same |

| CN108193382A (zh) * | 2017-12-07 | 2018-06-22 | 常州五荣化工有限公司 | 一种醋酸纤维过滤材料的制备方法 |

| CN108532050B (zh) * | 2018-04-20 | 2023-08-25 | 海宁昌顺化纤有限公司 | 一种dty加工用原丝架 |

| SE543168C2 (en) * | 2018-12-05 | 2020-10-20 | Stora Enso Oyj | A moldable fibrous sheet and a production method thereof |

| DE102019107771A1 (de) * | 2019-03-26 | 2020-10-01 | Reifenhäuser GmbH & Co. KG Maschinenfabrik | Verfahren zur Herstellung eines Vlieslaminates und Vlieslaminat |

| US20220235502A1 (en) * | 2019-05-10 | 2022-07-28 | Fare' S.P.A. | Process for the production of a multilayer fabric |

| TW202246610A (zh) * | 2021-02-17 | 2022-12-01 | 美商普利馬洛夫特公司 | 耐用的抗起球非織造絕緣材料 |

| CN113089187A (zh) * | 2021-02-21 | 2021-07-09 | 金大付 | 一种医疗长纤维无纺布面料制备装置及方法 |

| EP4373450A1 (en) * | 2021-11-10 | 2024-05-29 | Fibertex Personal Care A/S | Elastic nonwoven sheet |

| EP4279648A1 (en) * | 2022-05-17 | 2023-11-22 | Fare' S.p.A. a Socio Unico | Process and apparatus for producing a voluminous nonwoven fabric |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3671379A (en) * | 1971-03-09 | 1972-06-20 | Du Pont | Composite polyester textile fibers |

| US4720415A (en) * | 1985-07-30 | 1988-01-19 | Kimberly-Clark Corporation | Composite elastomeric material and process for making the same |

| JP2623330B2 (ja) * | 1987-06-10 | 1997-06-25 | 鐘紡株式会社 | 経緯伸縮性布帛及びその製造方法 |

| US5382400A (en) * | 1992-08-21 | 1995-01-17 | Kimberly-Clark Corporation | Nonwoven multicomponent polymeric fabric and method for making same |

| AU694214B2 (en) * | 1994-04-29 | 1998-07-16 | Kimberly-Clark Worldwide, Inc. | Slit elastic fibrous nonwoven laminates |

| US5540976A (en) * | 1995-01-11 | 1996-07-30 | Kimberly-Clark Corporation | Nonwoven laminate with cross directional stretch |

| JP2002543304A (ja) * | 1999-04-30 | 2002-12-17 | キンバリー クラーク ワールドワイド インコーポレイテッド | 伸縮性不織材料 |

| JP3609361B2 (ja) * | 2000-10-12 | 2005-01-12 | 花王株式会社 | 立体シート材料 |

-

2002

- 2002-12-13 BR BRPI0215341-6A patent/BR0215341B1/pt not_active IP Right Cessation

- 2002-12-13 CN CNB028258436A patent/CN1269632C/zh not_active Expired - Fee Related

- 2002-12-13 DE DE60218734T patent/DE60218734T2/de not_active Expired - Lifetime

- 2002-12-13 KR KR1020047009566A patent/KR100923610B1/ko not_active Expired - Fee Related

- 2002-12-13 WO PCT/US2002/041719 patent/WO2003055674A1/en not_active Ceased

- 2002-12-13 EP EP02797526A patent/EP1456017B1/en not_active Expired - Lifetime

- 2002-12-13 JP JP2003556233A patent/JP2005521566A/ja active Pending

- 2002-12-13 AU AU2002361896A patent/AU2002361896A1/en not_active Abandoned

- 2002-12-20 TW TW091136825A patent/TWI302172B/zh not_active IP Right Cessation

-

2009

- 2009-08-14 JP JP2009188059A patent/JP4912445B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN1608004A (zh) | 2005-04-20 |

| WO2003055674A1 (en) | 2003-07-10 |

| JP4912445B2 (ja) | 2012-04-11 |

| TWI302172B (en) | 2008-10-21 |

| EP1456017A1 (en) | 2004-09-15 |

| TW200302305A (en) | 2003-08-01 |

| DE60218734T2 (de) | 2007-11-15 |

| DE60218734D1 (de) | 2007-04-19 |

| HK1077257A1 (en) | 2006-02-10 |

| BR0215341A (pt) | 2004-11-16 |

| BR0215341B1 (pt) | 2012-06-26 |

| JP2005521566A (ja) | 2005-07-21 |

| AU2002361896A1 (en) | 2003-07-15 |

| KR20040068279A (ko) | 2004-07-30 |

| JP2010006070A (ja) | 2010-01-14 |

| KR100923610B1 (ko) | 2009-10-23 |

| EP1456017B1 (en) | 2007-03-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1269632C (zh) | 可拉伸的复合片材和制造方法 | |

| US7005395B2 (en) | Stretchable composite sheets and processes for making | |

| JP4381146B2 (ja) | 嵩高複合シートおよび製造方法 | |

| JP4456366B2 (ja) | 伸縮性の多成分不織布および製造方法 | |

| CN100347370C (zh) | 制备高膨松复合片材的方法 | |

| KR101079804B1 (ko) | 폴리에스터 장섬유 스펀본드 부직포 및 그의 제조방법 | |

| JP3562667B2 (ja) | 伸縮性長繊維不織布の製造方法 | |

| HK1077257B (en) | Stretchable composite sheets and processes for making | |

| HK1076846B (en) | Method for preparing high bulk composite sheets | |

| HK1076845B (en) | Stretchable multiple-component nonwoven fabrics and methods for preparing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1077257 Country of ref document: HK |

|

| ASS | Succession or assignment of patent right |

Owner name: INVISTA TECH SARL Free format text: FORMER OWNER: E. I. DU PONT DE NEMOURS AND CO. Effective date: 20060113 |

|

| C41 | Transfer of patent application or patent right or utility model | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20060113 Address after: Zurich Switzerland Applicant after: INVISTA TECHNOLOGIES S.A.R.L. Address before: Wilmington, Delaware, USA Applicant before: E. I. du Pont de Nemours and Co. |

|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20060816 Termination date: 20191213 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |