CN1269632C - 可拉伸的复合片材和制造方法 - Google Patents

可拉伸的复合片材和制造方法 Download PDFInfo

- Publication number

- CN1269632C CN1269632C CNB028258436A CN02825843A CN1269632C CN 1269632 C CN1269632 C CN 1269632C CN B028258436 A CNB028258436 A CN B028258436A CN 02825843 A CN02825843 A CN 02825843A CN 1269632 C CN1269632 C CN 1269632C

- Authority

- CN

- China

- Prior art keywords

- layer

- spirality crimping

- composite sheet

- bonding

- sheet material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 130

- 238000000034 method Methods 0.000 title claims abstract description 85

- 230000008569 process Effects 0.000 title claims description 24

- 239000000835 fiber Substances 0.000 claims abstract description 221

- 238000010438 heat treatment Methods 0.000 claims abstract description 52

- 239000000126 substance Substances 0.000 claims abstract description 31

- 239000004753 textile Substances 0.000 claims abstract description 7

- 239000010410 layer Substances 0.000 claims description 226

- 238000002788 crimping Methods 0.000 claims description 208

- 229920000642 polymer Polymers 0.000 claims description 111

- 239000000463 material Substances 0.000 claims description 94

- 239000000203 mixture Substances 0.000 claims description 71

- -1 tetramethylene glycol ester Chemical class 0.000 claims description 33

- 229920000728 polyester Polymers 0.000 claims description 32

- 239000013047 polymeric layer Substances 0.000 claims description 29

- KKEYFWRCBNTPAC-UHFFFAOYSA-N benzene-dicarboxylic acid Natural products OC(=O)C1=CC=C(C(O)=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-N 0.000 claims description 21

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 claims description 18

- 229920001577 copolymer Polymers 0.000 claims description 16

- 230000001070 adhesive effect Effects 0.000 claims description 15

- 239000000853 adhesive Substances 0.000 claims description 14

- WGCNASOHLSPBMP-UHFFFAOYSA-N hydroxyacetaldehyde Natural products OCC=O WGCNASOHLSPBMP-UHFFFAOYSA-N 0.000 claims description 13

- 239000013078 crystal Substances 0.000 claims description 12

- 238000009960 carding Methods 0.000 claims description 11

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 claims description 10

- 229920002215 polytrimethylene terephthalate Polymers 0.000 claims description 10

- 229920001223 polyethylene glycol Polymers 0.000 claims description 8

- 238000004043 dyeing Methods 0.000 claims description 7

- 150000002148 esters Chemical class 0.000 claims description 7

- 239000002759 woven fabric Substances 0.000 claims description 6

- WERYXYBDKMZEQL-UHFFFAOYSA-N 1,4-butanediol Substances OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 claims description 5

- FYIBGDKNYYMMAG-UHFFFAOYSA-N ethane-1,2-diol;terephthalic acid Chemical compound OCCO.OC(=O)C1=CC=C(C(O)=O)C=C1 FYIBGDKNYYMMAG-UHFFFAOYSA-N 0.000 claims description 5

- 159000000000 sodium salts Chemical class 0.000 claims description 5

- YZTJKOLMWJNVFH-UHFFFAOYSA-N 2-sulfobenzene-1,3-dicarboxylic acid Chemical compound OC(=O)C1=CC=CC(C(O)=O)=C1S(O)(=O)=O YZTJKOLMWJNVFH-UHFFFAOYSA-N 0.000 claims description 4

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 claims description 4

- 229910052708 sodium Inorganic materials 0.000 claims description 4

- 239000011734 sodium Substances 0.000 claims description 4

- 239000004745 nonwoven fabric Substances 0.000 abstract description 8

- 238000011084 recovery Methods 0.000 abstract description 2

- 239000004744 fabric Substances 0.000 description 54

- 230000008602 contraction Effects 0.000 description 20

- 239000000047 product Substances 0.000 description 20

- 150000001875 compounds Chemical class 0.000 description 13

- 238000010791 quenching Methods 0.000 description 11

- 230000004913 activation Effects 0.000 description 10

- 239000010408 film Substances 0.000 description 10

- 238000009987 spinning Methods 0.000 description 10

- 239000011230 binding agent Substances 0.000 description 9

- 238000010586 diagram Methods 0.000 description 9

- 238000002360 preparation method Methods 0.000 description 9

- 238000002156 mixing Methods 0.000 description 7

- 239000004743 Polypropylene Substances 0.000 description 6

- 238000002844 melting Methods 0.000 description 6

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 6

- 229920001155 polypropylene Polymers 0.000 description 6

- 238000012546 transfer Methods 0.000 description 6

- 230000007704 transition Effects 0.000 description 6

- 238000009940 knitting Methods 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 230000000171 quenching effect Effects 0.000 description 5

- 238000005303 weighing Methods 0.000 description 5

- 229910000831 Steel Inorganic materials 0.000 description 4

- 229920001903 high density polyethylene Polymers 0.000 description 4

- 239000004700 high-density polyethylene Substances 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 239000002245 particle Substances 0.000 description 4

- 229920005644 polyethylene terephthalate glycol copolymer Polymers 0.000 description 4

- 239000010959 steel Substances 0.000 description 4

- NFGXHKASABOEEW-UHFFFAOYSA-N 1-methylethyl 11-methoxy-3,7,11-trimethyl-2,4-dodecadienoate Chemical compound COC(C)(C)CCCC(C)CC=CC(C)=CC(=O)OC(C)C NFGXHKASABOEEW-UHFFFAOYSA-N 0.000 description 3

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- YMWUJEATGCHHMB-UHFFFAOYSA-N Dichloromethane Chemical compound ClCCl YMWUJEATGCHHMB-UHFFFAOYSA-N 0.000 description 3

- 239000004952 Polyamide Substances 0.000 description 3

- 238000009954 braiding Methods 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 239000007859 condensation product Substances 0.000 description 3

- 238000010276 construction Methods 0.000 description 3

- 238000002425 crystallisation Methods 0.000 description 3

- 230000008025 crystallization Effects 0.000 description 3

- 229910003460 diamond Inorganic materials 0.000 description 3

- 239000010432 diamond Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000007667 floating Methods 0.000 description 3

- 235000019253 formic acid Nutrition 0.000 description 3

- 239000002648 laminated material Substances 0.000 description 3

- 239000012528 membrane Substances 0.000 description 3

- 229920002647 polyamide Polymers 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 229920001169 thermoplastic Polymers 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- NMYFVWYGKGVPIW-UHFFFAOYSA-N 3,7-dioxabicyclo[7.2.2]trideca-1(11),9,12-triene-2,8-dione Chemical compound O=C1OCCCOC(=O)C2=CC=C1C=C2 NMYFVWYGKGVPIW-UHFFFAOYSA-N 0.000 description 2

- 241000723418 Carya Species 0.000 description 2

- 229920000742 Cotton Polymers 0.000 description 2

- 239000004698 Polyethylene Substances 0.000 description 2

- 241000656145 Thyrsites atun Species 0.000 description 2

- DTQVDTLACAAQTR-UHFFFAOYSA-N Trifluoroacetic acid Chemical compound OC(=O)C(F)(F)F DTQVDTLACAAQTR-UHFFFAOYSA-N 0.000 description 2

- 238000000137 annealing Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000003490 calendering Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 238000010924 continuous production Methods 0.000 description 2

- 238000005034 decoration Methods 0.000 description 2

- 238000009787 hand lay-up Methods 0.000 description 2

- 229920000573 polyethylene Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 229920000098 polyolefin Polymers 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- 125000000020 sulfo group Chemical group O=S(=O)([*])O[H] 0.000 description 2

- JTXMVXSTHSMVQF-UHFFFAOYSA-N 2-acetyloxyethyl acetate Chemical compound CC(=O)OCCOC(C)=O JTXMVXSTHSMVQF-UHFFFAOYSA-N 0.000 description 1

- BJVZSFDSSQFPMT-UHFFFAOYSA-N 3-(naphthalene-1-carbonyloxy)propyl naphthalene-1-carboxylate Chemical compound C1=CC=C2C(C(OCCCOC(=O)C=3C4=CC=CC=C4C=CC=3)=O)=CC=CC2=C1 BJVZSFDSSQFPMT-UHFFFAOYSA-N 0.000 description 1

- 229920002955 Art silk Polymers 0.000 description 1

- 239000005711 Benzoic acid Substances 0.000 description 1

- WPYMKLBDIGXBTP-UHFFFAOYSA-N Benzoic acid Natural products OC(=O)C1=CC=CC=C1 WPYMKLBDIGXBTP-UHFFFAOYSA-N 0.000 description 1

- 229920003043 Cellulose fiber Polymers 0.000 description 1

- 241000196324 Embryophyta Species 0.000 description 1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 229920001410 Microfiber Polymers 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 229920002292 Nylon 6 Polymers 0.000 description 1

- 229920002302 Nylon 6,6 Polymers 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 230000003213 activating effect Effects 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 238000004458 analytical method Methods 0.000 description 1

- 238000003556 assay Methods 0.000 description 1

- 235000010233 benzoic acid Nutrition 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000007334 copolymerization reaction Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 150000001991 dicarboxylic acids Chemical class 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 150000002085 enols Chemical class 0.000 description 1

- 230000005496 eutectics Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 238000007380 fibre production Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 229920000126 latex Polymers 0.000 description 1

- 238000011068 loading method Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000000289 melt material Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000003658 microfiber Substances 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920002239 polyacrylonitrile Polymers 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920006306 polyurethane fiber Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000003252 repetitive effect Effects 0.000 description 1

- 210000003660 reticulum Anatomy 0.000 description 1

- 229920006395 saturated elastomer Polymers 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 238000007493 shaping process Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 150000008054 sulfonate salts Chemical group 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- 229920005992 thermoplastic resin Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 125000003258 trimethylene group Chemical group [H]C([H])([*:2])C([H])([H])C([H])([H])[*:1] 0.000 description 1

- 229920001567 vinyl ester resin Polymers 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F8/00—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof

- D01F8/04—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers

- D01F8/14—Conjugated, i.e. bi- or multicomponent, artificial filaments or the like; Manufacture thereof from synthetic polymers with at least one polyester as constituent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4391—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres

- D04H1/43912—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres fibres with noncircular cross-sections

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/04—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by a layer being specifically extensible by reason of its structure or arrangement, e.g. by reason of the chemical nature of the fibres or filaments

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4374—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece using different kinds of webs, e.g. by layering webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4391—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres

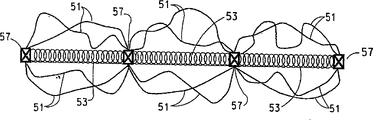

- D04H1/43918—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece characterised by the shape of the fibres nonlinear fibres, e.g. crimped or coiled fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/559—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving the fibres being within layered webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H3/00—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length

- D04H3/018—Non-woven fabrics formed wholly or mainly of yarns or like filamentary material of substantial length characterised by the shape

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Nonwoven Fabrics (AREA)

- Multicomponent Fibers (AREA)

- Laminated Bodies (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

Abstract

Description

Claims (36)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US34327601P | 2001-12-21 | 2001-12-21 | |

| US60/343,276 | 2001-12-21 | ||

| US10/317,416 US7005395B2 (en) | 2002-12-12 | 2002-12-12 | Stretchable composite sheets and processes for making |

| US10/317,416 | 2002-12-12 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1608004A CN1608004A (zh) | 2005-04-20 |

| CN1269632C true CN1269632C (zh) | 2006-08-16 |

Family

ID=26980940

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB028258436A Expired - Fee Related CN1269632C (zh) | 2001-12-21 | 2002-12-13 | 可拉伸的复合片材和制造方法 |

Country Status (10)

| Country | Link |

|---|---|

| EP (1) | EP1456017B1 (zh) |

| JP (2) | JP2005521566A (zh) |

| KR (1) | KR100923610B1 (zh) |

| CN (1) | CN1269632C (zh) |

| AU (1) | AU2002361896A1 (zh) |

| BR (1) | BR0215341B1 (zh) |

| DE (1) | DE60218734T2 (zh) |

| HK (1) | HK1077257A1 (zh) |

| TW (1) | TWI302172B (zh) |

| WO (1) | WO2003055674A1 (zh) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7045211B2 (en) * | 2003-07-31 | 2006-05-16 | Kimberly-Clark Worldwide, Inc. | Crimped thermoplastic multicomponent fiber and fiber webs and method of making |

| CA2665176C (en) | 2006-10-04 | 2016-01-19 | Formway Furniture Limited | A back portion for a chair with a moveable upper section |

| EP2190658B1 (en) * | 2007-09-07 | 2012-10-24 | Invista Technologies S.à.r.l. | Multilayer variable stretch nonwoven fabric composites |

| USD600051S1 (en) | 2008-04-09 | 2009-09-15 | Formway Furniture Limited | Chair back |

| USD604535S1 (en) | 2008-04-09 | 2009-11-24 | Formway Furniture Limited | Chair |

| CA131020S (en) | 2008-12-12 | 2010-02-03 | Formway Furniture Ltd | Chair |

| ES2835052T3 (es) * | 2016-05-18 | 2021-06-21 | Fibertex Personal Care As | Tejido de laminado no tejido que comprende capas de soplado en estado fundido y de unión por hilado |

| CZ307292B6 (cs) * | 2016-09-30 | 2018-05-16 | Pegas Nonwovens S.R.O. | Spunbondová netkaná textilie pro akvizičně distribuční vrstvu a absorpční výrobek |

| CN108193382A (zh) * | 2017-12-07 | 2018-06-22 | 常州五荣化工有限公司 | 一种醋酸纤维过滤材料的制备方法 |

| CN108532050B (zh) * | 2018-04-20 | 2023-08-25 | 海宁昌顺化纤有限公司 | 一种dty加工用原丝架 |

| SE543168C2 (en) * | 2018-12-05 | 2020-10-20 | Stora Enso Oyj | A moldable fibrous sheet and a production method thereof |

| DE102019107771A1 (de) * | 2019-03-26 | 2020-10-01 | Reifenhäuser GmbH & Co. KG Maschinenfabrik | Verfahren zur Herstellung eines Vlieslaminates und Vlieslaminat |

| US20220235502A1 (en) * | 2019-05-10 | 2022-07-28 | Fare' S.P.A. | Process for the production of a multilayer fabric |

| CN113089187A (zh) * | 2021-02-21 | 2021-07-09 | 金大付 | 一种医疗长纤维无纺布面料制备装置及方法 |

| EP4373450A1 (en) * | 2021-11-10 | 2024-05-29 | Fibertex Personal Care A/S | Elastic nonwoven sheet |

| EP4279648A1 (en) * | 2022-05-17 | 2023-11-22 | Fare' S.p.A. a Socio Unico | Process and apparatus for producing a voluminous nonwoven fabric |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3671379A (en) * | 1971-03-09 | 1972-06-20 | Du Pont | Composite polyester textile fibers |

| US4720415A (en) * | 1985-07-30 | 1988-01-19 | Kimberly-Clark Corporation | Composite elastomeric material and process for making the same |

| WO1988009838A1 (en) * | 1987-06-10 | 1988-12-15 | Kanebo, Ltd. | Lengthwise and crosswise stretchable cloth and process for its production |

| US5382400A (en) * | 1992-08-21 | 1995-01-17 | Kimberly-Clark Corporation | Nonwoven multicomponent polymeric fabric and method for making same |

| JPH09512504A (ja) * | 1994-04-29 | 1997-12-16 | キンバリー クラーク コーポレイション | スリット付き弾性繊維不織積層体 |

| US5540976A (en) * | 1995-01-11 | 1996-07-30 | Kimberly-Clark Corporation | Nonwoven laminate with cross directional stretch |

| BR0010131B1 (pt) * | 1999-04-30 | 2011-12-27 | material nço tranÇado estirÁvel e mÉtodo para produzir o mesmo. | |

| JP3609361B2 (ja) * | 2000-10-12 | 2005-01-12 | 花王株式会社 | 立体シート材料 |

-

2002

- 2002-12-13 KR KR1020047009566A patent/KR100923610B1/ko active IP Right Grant

- 2002-12-13 CN CNB028258436A patent/CN1269632C/zh not_active Expired - Fee Related

- 2002-12-13 WO PCT/US2002/041719 patent/WO2003055674A1/en active IP Right Grant

- 2002-12-13 EP EP02797526A patent/EP1456017B1/en not_active Expired - Lifetime

- 2002-12-13 BR BRPI0215341-6A patent/BR0215341B1/pt not_active IP Right Cessation

- 2002-12-13 JP JP2003556233A patent/JP2005521566A/ja active Pending

- 2002-12-13 DE DE60218734T patent/DE60218734T2/de not_active Expired - Lifetime

- 2002-12-13 AU AU2002361896A patent/AU2002361896A1/en not_active Abandoned

- 2002-12-20 TW TW091136825A patent/TWI302172B/zh not_active IP Right Cessation

-

2005

- 2005-10-17 HK HK05109140A patent/HK1077257A1/xx not_active IP Right Cessation

-

2009

- 2009-08-14 JP JP2009188059A patent/JP4912445B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| BR0215341A (pt) | 2004-11-16 |

| HK1077257A1 (en) | 2006-02-10 |

| KR20040068279A (ko) | 2004-07-30 |

| KR100923610B1 (ko) | 2009-10-23 |

| AU2002361896A1 (en) | 2003-07-15 |

| DE60218734T2 (de) | 2007-11-15 |

| EP1456017B1 (en) | 2007-03-07 |

| TW200302305A (en) | 2003-08-01 |

| BR0215341B1 (pt) | 2012-06-26 |

| JP2005521566A (ja) | 2005-07-21 |

| EP1456017A1 (en) | 2004-09-15 |

| JP2010006070A (ja) | 2010-01-14 |

| TWI302172B (en) | 2008-10-21 |

| JP4912445B2 (ja) | 2012-04-11 |

| CN1608004A (zh) | 2005-04-20 |

| WO2003055674A1 (en) | 2003-07-10 |

| DE60218734D1 (de) | 2007-04-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7005395B2 (en) | Stretchable composite sheets and processes for making | |

| CN1269632C (zh) | 可拉伸的复合片材和制造方法 | |

| JP4381146B2 (ja) | 嵩高複合シートおよび製造方法 | |

| US8252706B2 (en) | Stretchable multiple component nonwoven fabrics and methods for preparing | |

| US7588818B2 (en) | High bulk composite sheets | |

| CN100347370C (zh) | 制备高膨松复合片材的方法 | |

| WO2006041753A2 (en) | Hot melt adhesive lamination for forming a carpet backing and finished carpet | |

| CN1961108A (zh) | 制备弹性非织造纤网的方法 | |

| KR101079804B1 (ko) | 폴리에스터 장섬유 스펀본드 부직포 및 그의 제조방법 | |

| JP2004248864A (ja) | タフテッドカーペット一次基布 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: DE Ref document number: 1077257 Country of ref document: HK |

|

| ASS | Succession or assignment of patent right |

Owner name: INVISTA TECH SARL Free format text: FORMER OWNER: E. I. DU PONT DE NEMOURS AND CO. Effective date: 20060113 |

|

| C41 | Transfer of patent application or patent right or utility model | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20060113 Address after: Zurich Switzerland Applicant after: INVISTA TECHNOLOGIES S.A.R.L. Address before: Wilmington, Delaware, USA Applicant before: E. I. du Pont de Nemours and Co. |

|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20060816 Termination date: 20191213 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |