CN112716864B - Rose whitening and moisturizing mask - Google Patents

Rose whitening and moisturizing mask Download PDFInfo

- Publication number

- CN112716864B CN112716864B CN202110233798.4A CN202110233798A CN112716864B CN 112716864 B CN112716864 B CN 112716864B CN 202110233798 A CN202110233798 A CN 202110233798A CN 112716864 B CN112716864 B CN 112716864B

- Authority

- CN

- China

- Prior art keywords

- rose

- extract

- mixing

- mass ratio

- ethanol

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/96—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution

- A61K8/97—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution from algae, fungi, lichens or plants; from derivatives thereof

- A61K8/9783—Angiosperms [Magnoliophyta]

- A61K8/9789—Magnoliopsida [dicotyledons]

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/31—Hydrocarbons

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/33—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing oxygen

- A61K8/35—Ketones, e.g. benzophenone

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/33—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds containing oxygen

- A61K8/36—Carboxylic acids; Salts or anhydrides thereof

- A61K8/361—Carboxylic acids having more than seven carbon atoms in an unbroken chain; Salts or anhydrides thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/60—Sugars; Derivatives thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/64—Proteins; Peptides; Derivatives or degradation products thereof

- A61K8/645—Proteins of vegetable origin; Derivatives or degradation products thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/73—Polysaccharides

- A61K8/735—Mucopolysaccharides, e.g. hyaluronic acid; Derivatives thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/72—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds

- A61K8/84—Cosmetics or similar toiletry preparations characterised by the composition containing organic macromolecular compounds obtained by reactions otherwise than those involving only carbon-carbon unsaturated bonds

- A61K8/89—Polysiloxanes

- A61K8/891—Polysiloxanes saturated, e.g. dimethicone, phenyl trimethicone, C24-C28 methicone or stearyl dimethicone

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/92—Oils, fats or waxes; Derivatives thereof, e.g. hydrogenation products thereof

- A61K8/922—Oils, fats or waxes; Derivatives thereof, e.g. hydrogenation products thereof of vegetable origin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/96—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution

- A61K8/97—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution from algae, fungi, lichens or plants; from derivatives thereof

- A61K8/9783—Angiosperms [Magnoliophyta]

- A61K8/9794—Liliopsida [monocotyledons]

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

- A61Q19/02—Preparations for care of the skin for chemically bleaching or whitening the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

- A61Q19/08—Anti-ageing preparations

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/74—Biological properties of particular ingredients

- A61K2800/78—Enzyme modulators, e.g. Enzyme agonists

- A61K2800/782—Enzyme inhibitors; Enzyme antagonists

Abstract

The invention discloses a rose whitening and moisturizing mask and a preparation method thereof. The rose whitening and moisturizing mask is obtained by soaking a mask substrate in mask liquid; the mask liquid is prepared by uniformly mixing hyaluronic acid, peach gum extract, soybean polypeptide, astaxanthin, rose whitening essence and water. The rose whitening and moisturizing facial mask disclosed by the invention is added with plant natural rose extract, soybean polypeptide, hyaluronic acid, astaxanthin and peach gum extract, can effectively inhibit propionibacterium acnes and staphylococcus aureus, and has the effects of whitening and moisturizing as well as a good acne removing function.

Description

Technical Field

The invention relates to the technical field of masks, in particular to a rose whitening and moisturizing mask.

Background

Roses (Rose rugosa thumb.) are perennial evergreen or deciduous shrubs of the genus rosa of the family rosaceae and are widely grown worldwide. The roses have the functions of eating and health care, and are officially approved as new resource food by the state in 2010. Modern medicine shows that roses contain more than 300 chemical components, and the roses contain flavonoid compounds which have antioxidant activity and can reduce and eliminate free radicals. The plant flavonoid compound not only can eliminate free radicals in human bodies, but also can inhibit the generation of the free radicals, has the effects of preventing aging, cardiovascular diseases, cancers and the like, is an effective antioxidant, and is widely applied to the industries of foods, medical health products, cosmetics and the like. Text of materia medica (text of materia medica) Zhongdao: "Rose flower, clear but not turbid, and not fierce, liver softening and stomach awaking, qi-flowing and blood circulation promoting, and dredging and suffocating without the disadvantage of pungent, warm and hard dryness, among the qi-pushing-off and medicine-dividing, it is most quick and most tame, fragrant, so there is no way to match. The rose contains more than 300 chemical components, such as aromatic alcohol, aldehyde, fatty acid, phenol and oil and fat containing essence, and the rose product is usually eaten to soften liver and wake stomach, relax qi and activate blood, maintain beauty and keep young and refresh people. The flowers and roots of the rose can be used as medicine, has the functions of regulating qi, promoting blood circulation, astringing and the like, and is mainly used for treating irregular menstruation, traumatic injury, liver qi and stomach pain, breast swelling and pain and other symptoms. The rose pulp can be made into jam, has special flavor, contains abundant vitamin C and vitamin P, and can be used for preventing acute and chronic infectious diseases, coronary heart disease, liver disease, carcinogen generation and metastasis, etc. The rose essential oil (called rose dew) extracted from rose petal by distillation method can also improve skin texture, and promote blood circulation and metabolism. The current utilization of roses has the problems of low acquisition rate, insufficient activity maintenance of effective components and the like during filter pressing. Moreover, the prior art still has no acne-removing efficacy when the rose is applied to the mask.

Disclosure of Invention

Aiming at the defects in the prior art, the invention provides a rose whitening and moisturizing mask.

In order to solve the technical problems, the technical scheme adopted by the invention is as follows:

a rose whitening and moisturizing facial mask is prepared by soaking facial mask matrix in rose whitening essence. The mask liquid is prepared by uniformly mixing hyaluronic acid, peach gum extract, soybean polypeptide, astaxanthin, rose whitening essence and water.

Preferably, the mask liquid is prepared by uniformly mixing 1-10 parts by weight of hyaluronic acid, 5-15 parts by weight of peach gum extract, 1-10 parts by weight of soybean polypeptide, 1-10 parts by weight of astaxanthin, 30-60 parts by weight of rose whitening essence and 20-40 parts by weight of water.

Preferably, the preparation method of the peach gum extract comprises the following steps: adding 30-60 g of peach gum into 200-300 mL of water for soaking; stirring and extracting for 3-8 h at 60-90 ℃; cooling to room temperature, filtering, centrifuging, taking supernatant, and performing rotary evaporation and concentration to 30-50 mL; adding 200-300 mL of absolute ethyl alcohol, uniformly stirring, standing for 6-18 h, taking precipitate, washing, and drying in vacuum to obtain the peach gum extract.

Preferably, the rose whitening essence consists of water, a cosolvent, a thickening agent, a whitening agent, a softening agent, an emulsifier, a pH regulator and a preservative. Mixing water, cosolvent, whitening agent, emollient, emulsifier, pH regulator, and antiseptic, and homogenizing at 14000-16000rpm at 18-22 deg.C for 2-4min to obtain mixed solution; the concentrations of the cosolvent, the whitening agent, the emollient, the emulsifier, the pH regulator and the preservative are respectively (31.8-34.5) wt.%, (10.5-12.7) wt.%, (1.5-2.1) wt.%, (0.9-1.6) wt.%, (0.5-0.8) wt.%, (0.4-0.6) wt.% and the balance of water; and (3) mixing the mixed solution and the thickening agent according to the mass ratio of (96.6-97.0) to (3.0-3.4), and homogenizing at the temperature of 18-22 ℃ and at the rotating speed of 14000-16000rpm for 2-4min to obtain the rose whitening essence.

Preferably, the preparation method of the cosolvent comprises the following steps: mixing absolute ethyl alcohol, glycerol, propylene carbonate and 1, 3-butanediol according to the mass ratio of (26.3-28.9) to (10.5-14.6) to (6.3-8.2) to (4.9-6.2) at the temperature of 18-22 ℃, and homogenizing at the rotating speed of 14000-16000rpm for 1.5-3min to obtain the cosolvent.

Preferably, the preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol according to the mass ratio of (10.3-13.1) to (4.6-6.1) to (3.1-4.2) to (17.9-19.5) at 18-22 ℃, and stirring at the rotating speed of 1000-1500rpm for 12-17min to obtain the thickening agent.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris tonkinensis root extract, the sage herb extract, the Sudan cola seed extract and 1, 3-butanediol, and homogenizing to obtain the whitening agent. Further preferably, the preparation method of the whitening agent comprises the following steps: mixing flos Rosae Rugosae extract, iris pallida root extract, herba Salvia officinalis extract, sudan cola seed extract, and 1, 3-butanediol at 18-22 deg.C according to mass ratio of 65.6-70.2 (15.7-17.1) to 13.9-16.3 (5.2-8.3) to 198.1-219.3), and homogenizing at 14000-16000rpm for 1.5-3min to obtain the whitening agent.

Preferably, the preparation method of the softening agent comprises the following steps: mixing the cyclohexasiloxane, the polydimethylsiloxane, the squalane and the 1, 3-butanediol according to the mass ratio of (16.8-22.9) to (11.9-17.6) to (8.7-12.2) to (59.2-75.3) at the temperature of 18-22 ℃, and homogenizing at the rotating speed of 14000-16000rpm for 1.5-3min to obtain the softening agent.

Preferably, the preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyl tetradecyl polyether-20 and absolute ethyl alcohol are mixed according to the mass ratio of (11.9-19.7) to (2.3-7.1) to (41.2-53.7) at the temperature of 18-22 ℃, and the mixture is homogenized at the rotating speed of 14000-16000rpm for 1.5-3min to obtain the emulsifier.

Preferably, the preparation method of the pH regulator comprises the following steps: mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide and water according to the mass ratio of (7.8-12.6) to (3.1-5.2) to (1.8-4.5) to (28.8-40.3) at the temperature of 18-22 ℃, and stirring at the rotating speed of 1000-1500rpm for 8-12min to obtain the pH regulator.

Preferably, the preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium pyrosulfite and water according to the mass ratio of (1.6-4.6) to (0.1-1.7) to (8.2-20.3), and stirring at the rotating speed of 1000-1500rpm for 6-9min to obtain the preservative.

Most preferably, the preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, ethanol water solution and penetration enhancer, stirring, and performing ultrasonic treatment to obtain rose soaking material;

(2) carrying out filter pressing and centrifugation on the rose soaked substance obtained in the step (1), and collecting supernatant;

(3) concentrating the supernatant obtained in the step (2) to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol, stirring and carrying out ultrasonic treatment to obtain a concentrated solution-absolute ethyl alcohol mixture;

(5) regulating the pH of the concentrated solution-absolute ethyl alcohol mixture obtained in the step (4) by using malic acid, standing, centrifuging, taking precipitate, and drying to obtain a rose crude extract;

(6) soaking an adsorption resin in an ethanol aqueous solution, then washing the resin with the ethanol aqueous solution until an ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column;

(7) mixing the rose crude extract obtained in the step (5) with an ethanol water solution and stirring to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol water solution obtained in the step (7); then, washing with distilled water and ethanol water solution successively to remove impurities; collecting high-purity eluent;

(9) and (5) freeze-drying the high-purity eluent obtained in the step (8) until powdery solid is obtained, namely the rose extract.

Further preferably, the preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 72-76wt.% ethanol water solution and penetration enhancer according to the mass ratio of (4-6) to (0.8-1.3) at 22-26 ℃, stirring at the rotating speed of 240-360rpm for 18-22h, and simultaneously performing ultrasonic treatment with the power of 380-450w and the frequency of 36-45kHz to obtain rose soaking substances; the penetration enhancer is a mixture of litsea cubeba oil and lemongrass oil according to the mass ratio of (1-4) to (1-4);

(2) performing pressure filtration on the rose soaked substance obtained in the step (1) for 40-60min under the pressure of 0.9-1.2MPa to obtain a filtrate, centrifuging the filtrate at the rotating speed of 4800-5500rpm for 18-26min, and collecting a supernatant;

(3) concentrating the supernatant obtained in step (2) at (-55) - (-48) deg.C under 8-11kPa to (48-53)% of the original supernatant volume to obtain concentrated solution;

(4) mixing the concentrated solution obtained in step (3) with anhydrous ethanol at 22-26 deg.C, stirring at 240-360rpm for 30-50min, and treating with ultrasonic wave with power of 380-450w and frequency of 36-45kHz to obtain concentrated solution-anhydrous ethanol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture is 78-81wt.%;

(5) adjusting pH of the concentrated solution-anhydrous ethanol mixture obtained in step (4) to 2.8-3.2 with malic acid at 22-26 deg.C, standing at 2-5 deg.C for 28-34h, centrifuging at 2-5 deg.C at 4800-5500rpm for 20-27min, collecting precipitate, and oven drying at 5-7 deg.C to obtain crude extract of flos Rosae Rugosae;

(6) soaking FL-2 type macroporous adsorption resin in 12-18wt.% ethanol aqueous solution at 22-26 ℃ for 13-18h, then washing the resin with 12-18wt.% ethanol aqueous solution until the ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column according to the ratio of the diameter of the resin to the height of the column being 1 (8-10);

(7) mixing the rose crude extract obtained in the step (5) with an ethanol water solution with the concentration of 78-82wt.% according to the mass ratio (0.8-1.3) to (900-1100) at the temperature of 22-26 ℃, and stirring at the rotating speed of 240-360rpm for 18-22min to obtain the rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 22-26 ℃, wherein the loading amount is 12-16% of the weight of the resin, the loading flow rate is (0.8-0.95) mL/min, and the standing time is 22-28min; then, respectively washing with distilled water and 72-76wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is (4-6) to (0.8-1.3); the mass ratio of the 72-76wt.% ethanol aqueous solution to the resin is (4-6): 0.8-1.2); the washing flow rate is (28-32) mL/min, the elution flow rate is (36-40) mL/min, and high-purity eluent is collected;

(9) freeze-drying the high-purity eluent obtained in the step (8) at (-52) - (-48) DEG C under the air pressure of 9-11kPa until a powdery solid is obtained, namely the rose extract.

The rose extract contains a large amount of rose total flavonoids which are active ingredients with various beautifying effects of removing free radicals, resisting inflammation, resisting oxidation, removing yellow, brightening, resisting wrinkles, fading spots and the like, can improve the skin state after long-term use, and presents tender, white and bright water. The litsea cubeba oil and the lemongrass oil are rich in solvents with active chemical properties, such as alpha-lupinene, alpha-pinene and the like, and can effectively promote the total flavonoids of roses to seep out from cells of roses and improve the collection rate of the filtrate obtained by medium-pressure filtration of the rose soak solution; when the rose total flavonoids and the active ingredients are compounded for use, the rose total flavonoids can be promoted to exude, and the anti-oxidation protection effect is achieved, so that the rose extract with higher content of the rose total flavonoids and stronger activity of the active ingredients can be obtained. The active ingredients of the vetiver iris root extract, the salvia miltiorrhiza bunge extract, the sudan cola seed extract, squalane, trehalose, linoleic acid, polydimethylsiloxane and the like can improve the immunity of the skin and reduce the occurrence of inflammation and sensitivity phenomena, thereby reducing the content of red pigment and leading the whole appearance of the skin to be transparent, bright, white and shiny. The active antioxidant components such as total flavonoids in the rose extract prepared by the specific method can effectively remove free radicals, promote the metabolism of generated melanin, have strong inhibition effect on tyrosinase, simultaneously take effect at the two ends of the source and the route of the melanin, further reduce the content of the melanin in the skin and further improve the whiteness and the brightness of the skin.

The invention has the beneficial effects that:

the rose whitening and moisturizing mask disclosed by the invention is added with the plant natural rose extract, the soybean polypeptide, the hyaluronic acid, the astaxanthin and the peach gum extract, can effectively inhibit propionibacterium acnes and staphylococcus aureus, and has the effects of whitening and moisturizing and a good acne removing function.

Detailed Description

The above summary of the present invention is described in further detail below with reference to specific embodiments, but it should not be understood that the scope of the above subject matter of the present invention is limited to the following examples.

Introduction of some of the raw materials in this application:

absolute ethanol, CAS:64-17-5, available from Nanjing chemical reagents, inc., under the trade designation: c0692035010, specification: EP, molecular weight: 46.07. the function is as follows: a solvent. The content of the rose whitening essence is more than 14.61wt.%.

Glycerol, CAS:56-81-5, available from Nanjing Chemicals GmbH, under trade designation: c0690510224, specification: AR, molecular weight: 92.09. the function is as follows: solvent and humectant. The content of the rose whitening essence is 5.996-9.378wt.%.

Propylene carbonate, CAS:51260-39-0, available from sahn chemical technology (shanghai) ltd, under trade designation: a020006-100g, purity: 99.0%, molecular weight: 102.09. the function is as follows: solvent, viscosity control agent. The content of the rose whitening essence is 3.456-5.499wt.%.

1, 3-butanediol, CAS:107-88-0, available from western chemistry technologies (Shandong) Ltd, under trade designation: b15109-500g, specification: 99.0%, molecular weight: 90.12. the function is as follows: solvent and humectant, increase smoothness of product, and inhibit bacteria. The content of the rose whitening essence is more than 2.659wt.%.

Trehalose, CAS:99-20-7, available from western asia chemical technology (shandong) ltd, under trade designation: a14775-500g, specification: 99.0%, molecular weight: 342.30. the function is as follows: thickening agent, humectant and stabilizing agent. The content of the rose whitening essence is 0.7705-1.1509wt.%.

Betaine, CAS:107-43-7, available from western chemical technology, shandong, inc., under the trade designation: b11244-500g, specification: 99.0%, molecular weight: 117.15. the function is as follows: thickening agent and humectant. The content of the rose whitening essence is 0.3333-0.5545wt.%.

Linoleic acid, CAS:60-33-3, available from western chemistry technologies (Shandong) Ltd, under trade designation: a16095-500ml, specification: 95.0%, molecular weight: 280.46. the function is as follows: thickening agent, humectant, repairing skin injury, and keeping skin elasticity. The rose whitening essence comprises 0.2225-0.3859 wt%.

Iris pallida root extract, CAS:90045-89-9, purchased from Gansu Probiotics Biotech limited, purity: 98.0%, extract source: rhizoma Iridis Tectori (IRIS FLORENTINA). The function is as follows: enhancing metabolism of skin cells, resisting aging, relieving inflammation, and whitening skin. The content of the rose whitening essence is 0.4829-0.7024wt.%.

Sage extract, CAS:8022-56-8, available from Bailingwei science and technology, purity: 98.0%, extract source: salvia OFFICINALIS (Salvia OFFICINALIS). The function is as follows: tranquilizing, relieving, antiinflammatory, reducing oil secretion, and tightening skin. The rose whitening essence comprises 0.4288-0.6673wt.%.

Sudan cola nut seed extract, CAS:89997-82-0, available from Ningxia vanilla Biotechnology Ltd, purity: 98.0%, extract source: sudan COLA nut (COLA ACUMINATA). The function is as follows: improving skin cell activity, whitening skin, and inhibiting bacteria. The content of the rose whitening essence is 0.1608-0.3390wt.%.

Cyclohexasiloxane, CAS:540-97-6, available from carbofuran technologies ltd, under the trade designation: 9687.12-10MG, purity: 97.0%, molecular weight: 445. the function is as follows: smoothing agent, improving product ductility, improving skin feeling, and moistening agent. The content of the rose whitening essence is 0.2005-0.4542wt.%.

Polydimethylsiloxane, CAS:9006-65-9, available from chemical technology, west asia (Shandong), inc., under trade designation: a15581-100g, specification: and (5) AR. The function is as follows: promoting penetration and improving skin softness. The rose whitening essence comprises 0.1420-0.3505wt.%.

Squalane, CAS:111-01-3, available from west asia chemical technology (shandong) ltd, under the trade designation: b14680-500ml, specification: 98.0%, molecular weight: 422.81. the function is as follows: lubricant, improving skin softness, and promoting penetration. The content of the rose whitening essence is 0.1013-0.2483wt.%.

Isocetylpolyether-10, cas:69364-63-2, available from Nantong Chen Runji chemical Co., ltd, purity: 98.0 percent. The function is as follows: an emulsifier. The content of the rose whitening essence is 0.1423-0.4838wt.%.

PPG-6-decyltetradecanol polyether-20, CAS:72484-69-6, available from Nantong Chen Runji chemical Co., ltd, purity: 98.0 percent. The function is as follows: an emulsifier. The content of the rose whitening essence is 0.0264-0.1516wt.%.

Dipotassium phosphate, CAS:7758-11-4, available from chemical technology, west asia (shandong) ltd, under trade designation: b62544-500g, specification: GR, molecular weight: 174.18. the function is as follows: a buffering agent. The content of the rose whitening essence is 0.0652-0.2112wt.%.

Sodium bicarbonate, CAS:144-55-8, available from western chemical technology, santa, ltd, under the trade designation: c10227-500g, specification: AR, molecular weight: 84.01. the function is as follows: a buffer. The content of the rose whitening essence is 0.0398-0.0926wt.%.

Potassium hydroxide, CAS:1310-58-3, available from west asia chemical technology (shandong) ltd, under the trade designation: b10105-500g, specification: 95.0%, molecular weight: 56.11. the function is as follows: a buffer. The content of the rose whitening essence is 0.0145-0.0790wt.%.

Potassium sorbate, CAS:24634-61-5, available from western chemical technology, shandong, inc.: a12216-500g, specification: AR, molecular weight: 150.21. the function is as follows: and (4) a preservative. The content of the rose whitening essence is 0.0262-0.2075wt.%.

Sodium metabisulfite, CAS:7681-57-4 available from west asia chemical technology (Shandong) Ltd, under trade designation: b12071-500g, specification: AR, molecular weight: 190.11. the function is as follows: preservative and grease-resistant oxidant. The content of the rose whitening essence is 0.0023-0.0860wt.%.

Rose, variety: damascus rose purchased from Kunsheng flower nursery stock Limited of Qingzhou city.

Litsea cubeba oil, CAS:68855-99-2, available from Shanghai leaf Biotech Co., ltd, trade number: s25515-500ml. The function is as follows: and (5) promoting infiltration.

Lemon grass oil, CAS:8007-02-1, available from Hubei Nonakojic technologies, purity: 98.0 percent. The function is as follows: and (5) promoting infiltration.

Malic acid, CAS:97-67-6, available from western chemistry technologies (Shandong) Ltd, under trade designation: a11100-500g, purity: 99.0%, molecular weight: 134.09. the function is as follows: the pH is adjusted during the preparation of the rose extract.

FL-2 type macroporous adsorption resin, available from Tianjin Kaishi resin science and technology Limited. The function is as follows: adsorbing, washing and removing impurities.

The content of the rose extract prepared by the specific method in the rose whitening essence is 2.037-2.853wt.%.

Hyaluronic acid, CAS:9004-61-9 and has skin conditioning and moisturizing effects.

Peach gum, which is a gum substance secreted from the bark of Prunus persica (l.) or Prunus davidiana (carr.) Franch, etc., belonging to the rosaceous plants, origin: in Yunnan province.

The soybean polypeptide with the relative molecular mass of 300-1000 is purchased from Xian Puruis bioengineering GmbH.

Astaxanthin, chemical name 3,3' -dihydroxy-4, 4' -diketo- β, β ' -carotene, CAS No.: 472-61-7.

Example 1

A rose whitening essence comprises deionized water, cosolvent, thickening agent, whitening agent, softening agent, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotation speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris tonkinensis root extract, the sage extract, the sudan cola nut seed extract and 1, 3-butanediol according to a mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: the emollient is obtained by mixing cyclohexasiloxane, polydimethylsiloxane, squalane, 1, 3-butanediol at 20 ℃ in a mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol were mixed at a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is a mixture of litsea cubeba oil and lemongrass oil according to the mass ratio of 1;

(2) performing pressure filtration on the rose soaked substance obtained in the step (1) for 45min under the pressure of 1MPa to obtain a filtrate, centrifuging the filtrate at the rotating speed of 5000rpm for 25min, and collecting a supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant at-50 ℃ under the air pressure of 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture is 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethanol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, standing at 3 ℃ for 30h, centrifuging at 3 ℃ at 5000rpm for 25min, collecting precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 type macroporous adsorption resin in 15wt.% ethanol aqueous solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol aqueous solution until ethanol eluent is mixed with water without white turbidity, and then loading the washed resin into a column according to the ratio of the diameter of the resin to the height of the column being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% at the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain the rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15 percent of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, respectively washing with distilled water and 75wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol water solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) freeze-drying the high-purity eluent obtained in the step (8) at-50 ℃ and under the air pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Example 2

A rose whitening essence comprises deionized water, cosolvent, thickener, whitening agent, emollient, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotation speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the emollient, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, respectively, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris pallida extract, the sage extract, the sudan cola nut seed extract and the 1, 3-butanediol at the mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: the emollient is obtained by mixing cyclohexasiloxane, polydimethylsiloxane, squalane, 1, 3-butanediol at 20 ℃ in a mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol in a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is litsea cubeba oil;

(2) carrying out filter pressing on the rose soaked substance obtained in the step (1) for 45min by adopting the pressure of 1MPa to obtain filtrate, centrifuging the filtrate for 25min at the rotating speed of 5000rpm, and collecting supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant at-50 ℃ under the air pressure of 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture was 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethanol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, standing at 3 ℃ for 30h, centrifuging at 3 ℃ at 5000rpm for 25min, collecting precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 macroporous adsorbent resin in 15wt.% ethanol water solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol water solution until the ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column according to the ratio of the resin diameter to the column height being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% according to the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15% of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, washing with distilled water and 75wt.% ethanol water solution successively to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol water solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) freeze-drying the high-purity eluent obtained in the step (8) at-50 ℃ and under the air pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Example 3

A rose whitening essence comprises deionized water, cosolvent, thickening agent, whitening agent, softening agent, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotation speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris tonkinensis root extract, the sage extract, the sudan cola nut seed extract and 1, 3-butanediol according to a mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: mixing the cyclohexasiloxane, the polydimethylsiloxane, the squalane and the 1, 3-butanediol at the mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol in a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is lemongrass oil;

(2) performing pressure filtration on the rose soaked substance obtained in the step (1) for 45min under the pressure of 1MPa to obtain a filtrate, centrifuging the filtrate at the rotating speed of 5000rpm for 25min, and collecting a supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant under the conditions of-50 ℃ and 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture was 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethanol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, standing at 3 ℃ for 30h, centrifuging at 3 ℃ at 5000rpm for 25min, collecting precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 macroporous adsorbent resin in 15wt.% ethanol water solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol water solution until the ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column according to the ratio of the resin diameter to the column height being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% at the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain the rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15% of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, respectively washing with distilled water and 75wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol aqueous solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) and (5) freeze-drying the high-purity eluent obtained in the step (8) at the temperature of-50 ℃ under the pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Comparative example 1

A rose whitening essence comprises deionized water, cosolvent, thickener, whitening agent, emollient, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotation speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotating speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the emollient, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, respectively, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris tonkinensis root extract, the sage extract, the sudan cola nut seed extract and 1, 3-butanediol according to a mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: mixing the cyclohexasiloxane, the polydimethylsiloxane, the squalane and the 1, 3-butanediol at the mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol were mixed at a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is a mixture of peppermint oil according to a mass ratio of 1;

(2) carrying out filter pressing on the rose soaked substance obtained in the step (1) for 45min by adopting the pressure of 1MPa to obtain filtrate, centrifuging the filtrate for 25min at the rotating speed of 5000rpm, and collecting supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant under the conditions of-50 ℃ and 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture was 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethyl alcohol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, then standing for 30h at 3 ℃, subsequently centrifuging at 3 ℃ at 5000rpm for 25min, taking a precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 type macroporous adsorption resin in 15wt.% ethanol aqueous solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol aqueous solution until ethanol eluent is mixed with water without white turbidity, and then loading the washed resin into a column according to the ratio of the diameter of the resin to the height of the column being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% according to the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15% of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, respectively washing with distilled water and 75wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol water solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) freeze-drying the high-purity eluent obtained in the step (8) at-50 ℃ and under the air pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Comparative example 2

A rose whitening essence comprises deionized water, cosolvent, thickening agent, whitening agent, softening agent, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotation speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris pallida extract, the sage extract, the sudan cola nut seed extract and the 1, 3-butanediol at the mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: the emollient is obtained by mixing cyclohexasiloxane, polydimethylsiloxane, squalane, 1, 3-butanediol at 20 ℃ in a mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol in a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is a mixture of litsea cubeba oil and peppermint oil according to a mass ratio of 1;

(2) performing pressure filtration on the rose soaked substance obtained in the step (1) for 45min under the pressure of 1MPa to obtain a filtrate, centrifuging the filtrate at the rotating speed of 5000rpm for 25min, and collecting a supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant under the conditions of-50 ℃ and 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture is 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethyl alcohol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, then standing for 30h at 3 ℃, subsequently centrifuging at 3 ℃ at 5000rpm for 25min, taking a precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 macroporous adsorbent resin in 15wt.% ethanol water solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol water solution until the ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column according to the ratio of the resin diameter to the column height being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% according to the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15 percent of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, respectively washing with distilled water and 75wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol aqueous solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) and (5) freeze-drying the high-purity eluent obtained in the step (8) at the temperature of-50 ℃ under the pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Comparative example 3

A rose whitening essence comprises deionized water, cosolvent, thickener, whitening agent, emollient, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotating speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the emollient, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, respectively, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris tonkinensis root extract, the sage extract, the sudan cola nut seed extract and 1, 3-butanediol according to a mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: mixing the cyclohexasiloxane, the polydimethylsiloxane, the squalane and the 1, 3-butanediol at the mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol were mixed at a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals, 75wt.% ethanol water solution and a penetration enhancer according to a mass ratio of 5; the penetration enhancer is a mixture of peppermint oil and lemongrass oil according to a mass ratio of 1;

(2) carrying out filter pressing on the rose soaked substance obtained in the step (1) for 45min by adopting the pressure of 1MPa to obtain filtrate, centrifuging the filtrate for 25min at the rotating speed of 5000rpm, and collecting supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant under the conditions of-50 ℃ and 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture was 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethanol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, standing at 3 ℃ for 30h, centrifuging at 3 ℃ at 5000rpm for 25min, collecting precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 macroporous adsorbent resin in 15wt.% ethanol water solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol water solution until the ethanol eluent is mixed with water without white turbidity, and then packing the washed resin into a column according to the ratio of the resin diameter to the column height being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% according to the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15% of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, washing with distilled water and 75wt.% ethanol water solution successively to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol water solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) and (5) freeze-drying the high-purity eluent obtained in the step (8) at the temperature of-50 ℃ under the pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Comparative example 4

A rose whitening essence comprises deionized water, cosolvent, thickener, whitening agent, emollient, emulsifier, pH regulator, and antiseptic. The preparation method of the rose whitening essence comprises the following steps: mixing the deionized water, the cosolvent, the whitening agent, the softening agent, the emulsifier, the pH regulator and the preservative, and homogenizing at the rotating speed of 15000rpm at 20 ℃ for 3min to obtain a mixed solution; the concentrations of the cosolvent, the whitening agent, the emollient, the emulsifier, the pH regulator and the preservative are 33.2wt.%, 11.3wt.%, 1.7wt.%, 1.2wt.%, 0.7wt.% and 0.5wt.%, respectively, and the balance is deionized water; and mixing the mixed solution and the thickening agent according to a mass ratio of 96.8.

The preparation method of the cosolvent comprises the following steps: the cosolvent was obtained by mixing absolute ethanol, glycerin, propylene carbonate, and 1, 3-butanediol at a mass ratio of 27.2.

The preparation method of the thickening agent comprises the following steps: mixing trehalose, betaine, linoleic acid and absolute ethyl alcohol at a mass ratio of 11.7.

The preparation method of the whitening agent comprises the following steps: mixing the rose extract, the iris pallida extract, the sage extract, the sudan cola nut seed extract and the 1, 3-butanediol at the mass ratio of 67.3.

The preparation method of the softening agent comprises the following steps: mixing the cyclohexasiloxane, the polydimethylsiloxane, the squalane and the 1, 3-butanediol at the mass ratio of 19.1.

The preparation method of the emulsifier comprises the following steps: isocetyl polyether-10, PPG-6-decyltetradecyl polyether-20, anhydrous ethanol were mixed at a mass ratio of 13.8.

The preparation method of the pH regulator comprises the following steps: the pH adjuster was obtained by mixing dipotassium hydrogen phosphate, sodium bicarbonate, potassium hydroxide, and deionized water at 20 ℃ in a mass ratio of 9.1.

The preparation method of the preservative comprises the following steps: mixing potassium sorbate, sodium metabisulfite and deionized water according to a mass ratio of 1.7.

The preparation method of the rose extract comprises the following steps:

(1) mixing rose petals and 75wt.% ethanol water solution at a mass ratio of 1;

(2) performing pressure filtration on the rose soaked substance obtained in the step (1) for 45min under the pressure of 1MPa to obtain a filtrate, centrifuging the filtrate at the rotating speed of 5000rpm for 25min, and collecting a supernatant;

(3) concentrating the supernatant obtained in the step (2) to 50% of the volume of the original supernatant at-50 ℃ under the air pressure of 10kPa to obtain a concentrated solution;

(4) mixing the concentrated solution obtained in the step (3) with absolute ethyl alcohol at 25 ℃, stirring at the rotating speed of 300rpm for 40min, and simultaneously treating with ultrasonic waves with the power of 400w and the frequency of 42kHz to obtain a concentrated solution-absolute ethyl alcohol mixture; the concentration of absolute ethanol in the concentrate-absolute ethanol mixture was 80wt.%;

(5) adjusting the pH of the concentrated solution-absolute ethyl alcohol mixture obtained in the step (4) to 3 with malic acid at 25 ℃, then standing for 30h at 3 ℃, subsequently centrifuging at 3 ℃ at 5000rpm for 25min, taking a precipitate, and drying the precipitate at 65 ℃ to obtain a rose crude extract;

(6) soaking FL-2 type macroporous adsorption resin in 15wt.% ethanol aqueous solution at 25 ℃ for 15h, then washing the resin with 15wt.% ethanol aqueous solution until ethanol eluent is mixed with water without white turbidity, and then loading the washed resin into a column according to the ratio of the diameter of the resin to the height of the column being 1;

(7) mixing the rose crude extract obtained in the step (5) and an ethanol water solution with the concentration of 80wt.% according to the mass ratio of 1 to 1000, and stirring at the rotating speed of 300rpm for 20min to obtain a rose crude extract-ethanol water solution;

(8) loading the rose crude extract-ethanol aqueous solution obtained in the step (7) at 25 ℃, wherein the loading amount is 15% of the weight of the resin, the loading flow rate is 0.85mL/min, and the standing time is 25min; then, respectively washing with distilled water and 75wt.% ethanol water solution to remove impurities; the mass ratio of the distilled water to the resin is 5; the mass ratio of the ethanol aqueous solution with the concentration of 75wt.% to the resin is 5; the washing flow rate is 30mL/min, the elution flow rate is 38mL/min, and high-purity eluent is collected;

(9) and (5) freeze-drying the high-purity eluent obtained in the step (8) at the temperature of-50 ℃ under the pressure of 10kPa until a powdery solid is obtained, namely the rose extract.

Test example 1

And (3) testing the whitening effect: 112 subjects were selected, aged between 22 and 35 years, and all subjects were divided into 7 comparison groups, each consisting of half a total of 16 persons each. The rose whitening liquid prepared in examples 1 to 3 and comparative examples 1 to 4 was used by each comparative group for a total test period of 28 days, 3 times per day, and was applied to both cheeks uniformly after cleansing, in an amount of 1mL each time. No other whitening products were used during the test. The skin was tested for its haematochrome content and for its lightness (L-value) using a multi-probe skin tester (MPA 10, from CK company, germany) before (0 d), on day 14 (14 d) and on day 28 (28 d). The two indexes are the average value of the test results in each comparison group. The test results are shown in tables 1 and 2.

TABLE 1 Red pigment content of skin before and after use of the rose whitening liquid obtained by each example of the invention and comparative example

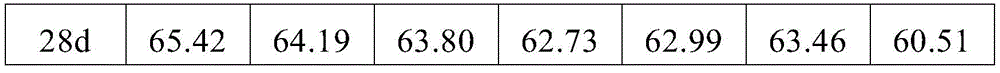

TABLE 2 skin Brightness before and after use of the rose whitening liquid obtained in each example of the present invention and comparative example

Test example 2

And (3) testing the flavone content: according to Al (NO) 3 ) 3 A color development method, which is to measure the absorbance value of the gradient concentration solution by using a rutin standard substance; the regression equation of the solution concentration (c) versus absorbance (A) curve is: c =10.24A +0.012 2 =0.9993. The rose extracts obtained in the embodiments and the comparative examples of the invention are diluted to proper concentrations, the flavone content in the rose extracts obtained in the embodiments is measured, the mass concentration of the diluted flavone extracting solution is obtained according to the regression equation, the mass concentration of the original rose extract is obtained according to the dilution times, and finally the mass concentration of the total flavone in the rose is calculated. The test results are shown in table 3.

TABLE 3 flavone content in rose extracts obtained from the examples of the present invention and the comparative examples

Test example 3

Free radical scavenging ability test: preparing a DPPH free radical standard solution: weighing 0.0256g of DPPH free radical reagent, and preparing a DPPH free radical standard solution with the mass concentration of 0.0256g/L by taking absolute ethyl alcohol as a solvent; respectively sucking 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0 and 10.0mL of the DPPH free radical standard solution in a test tube, wherein less than 10mL of the DPPH free radical standard solution is supplemented by absolute ethyl alcohol; thirdly, determining the absorbance of each solution at the wavelength of 517nm by taking absolute ethyl alcohol as a blank, and obtaining a regression equation of the relation curve of the absorbance and the mass concentration of the DPPH free radical solution: y =0.0259x +0.0018 (R2 = 0.9996), and the relation curve shows that the mass concentration and the absorbance of the DPPH free radical solution have a strong linear relation in the range of 2.56-25.60 mg/L, which indicates that the absorbance of the DPPH free radical solution in the range can be used as an index for measuring the mass concentration of DPPH free radical in the solution; fourth, absolute ethyl alcohol is used as a solvent, and rose extracts with mass concentrations of 0.004, 0.012, 0.016, 0.024, 0.050, 0.100, 0.150mg/mL and 0.300mg/mL obtained in each example of the invention and each comparative example are prepared as solutions to be tested; fifthly, absorbing 5mL of the solution to be detected, adding 5mL of the DPPH free radical standard solution, uniformly mixing, reacting for 30min, and measuring absorbance; sixthly, after the sample to be detected reacts with the DPPH free radical, the residual amount of the DPPH free radical can be obtained according to the following formula: residual DPPH radical/% = (DPPH radical t/DPPH radical 0) × l00, where: DPPH free radical 0 is the initial mass concentration of DPPH free radical; and (3) taking the DPPH free radical t as the mass concentration of DPPH free radicals in a system at the moment t, and subtracting the residual amount of the DPPH free radicals from 100% to obtain the DPPH free radical clearance rate of the rose extract obtained in each example. The test results are shown in table 4.

TABLE 4 DPPH radical scavenging ratio of rose extracts obtained from examples of the present invention and comparative examples

Haematochrome (14 d) =58.22e.u., haematochrome (28 d) =52.02e.u., (14 d) =59.73, L value (28 d) =65.42, flavone =728.6mg/g, DPPH free radical scavenging rate =96.8% which is significantly better than examples 2-3 (using litsea cubeba oil, one of lemongrass oil as the penetration enhancer), comparative examples 1-3 (using peppermint oil and/or litsea cubeba oil, one of lemongrass oil as the penetration enhancer), comparative example 4 (without the penetration enhancer) haematochrome (14 d) =59.89-68.11e.u., (28 d) =52.86-57.99e.u. =, L value (14 d) =53.40-57.62, L value (28 d) = 28.19.60 d) = 60.51.82, 0.95-60.51.82 g., 0-1.95.95 g, and DPPH/1-512.1.6 mg/g, since these are: the litsea cubeba oil and the lemongrass oil are rich in solvents with active chemical properties, such as alpha-lupinene, alpha-pinene and the like, can effectively promote the rose total flavonoids to seep out of cells of the rose, and improve the collection rate of the filtrate obtained by medium-pressure filtration of the rose soak solution; when the rose total flavonoids and the active ingredients are compounded for use, the rose total flavonoids can be promoted to exude, and simultaneously, the anti-oxidation protection effect is achieved, and a rose extract with higher content of the rose total flavonoids and stronger activity of the active ingredients can be obtained; the peppermint oil contains more menthol, menthyl acetate and other components, and the effect of improving the collection rate of the total rose flavone obtained from the rose soaked substance is not as good as that of litsea cubeba oil and lemongrass oil. The rose extract contains a large amount of rose total flavonoids which are active ingredients with various beauty treatment effects of free radical removal, anti-inflammation, antioxidation, yellow removal, brightening, wrinkle resistance, spot lightening and the like, and can improve the skin state and present tender, white and colorful water after long-term use. The active ingredients of the vetiver iris root extract, the salvia miltiorrhiza bunge extract, the sudan cola seed extract, the squalane, the trehalose, the linoleic acid, the polydimethylsiloxane and the like can effectively remove free radicals, improve the immunity of the skin, reduce inflammation and sensitivity, reduce the content of red pigment and enable the integral appearance of the skin to be transparent, bright, white and shiny. The active antioxidant components such as total flavonoids in the rose extract prepared by the specific method can promote the metabolism of the generated melanin, has stronger inhibition effect on tyrosinase, simultaneously acts at the source and the route of the melanin, further reduces the content of the melanin in the skin, and further improves the whiteness and the brightness of the skin.

Example 4

A rose whitening and moisturizing facial mask is obtained by soaking pure cotton facial mask paper in a facial mask solution, and the liquid carrying rate of the facial mask is controlled to be 900%.

The mask liquid is prepared by stirring and mixing 5 parts by weight of hyaluronic acid, 10 parts by weight of peach gum extract, 5 parts by weight of soybean polypeptide, 5 parts by weight of astaxanthin, 50 parts by weight of rose whitening essence prepared in example 1 and 25 parts by weight of deionized water at 200rpm for 30 min.

The preparation method of the peach gum extract comprises the following steps: soaking 50g of peach gum in 250ml of water for 24 hours; adding into a material mechanism, stirring at 10000rpm for 3min, and stirring at 80 deg.C and 100rpm for 6 hr; cooling to room temperature, and filtering with 100 mesh gauze; centrifuging the obtained filtrate for 15min at 8000rpm, taking supernatant, and concentrating to 50mL by rotary evaporation; adding 250mL of absolute ethyl alcohol, stirring uniformly, standing for 12h, taking the precipitate, washing with absolute ethyl alcohol, acetone and petroleum ether in sequence under the condition of reduced pressure suction filtration, and drying the obtained filter cake under vacuum at 50 ℃ for 24h to obtain the peach gum extract.

Example 5

A rose whitening and moisturizing facial mask is obtained by soaking pure cotton facial mask paper in facial mask liquid, and the liquid carrying rate of the facial mask is controlled to be 900%.

The mask liquid is prepared by stirring and mixing 5 parts by weight of hyaluronic acid, 10 parts by weight of peach gum extract, 5 parts by weight of soybean polypeptide, 5 parts by weight of astaxanthin, 50 parts by weight of rose whitening essence prepared in example 2 and 25 parts by weight of deionized water for 30min at 200 rpm.

The preparation method of the peach gum extract is the same as that of example 4, and is not repeated herein.

Example 6

A rose whitening and moisturizing facial mask is obtained by soaking pure cotton facial mask paper in a facial mask solution, and the liquid carrying rate of the facial mask is controlled to be 900%.

The mask liquid is prepared by stirring and mixing 5 parts by weight of hyaluronic acid, 10 parts by weight of peach gum extract, 5 parts by weight of soybean polypeptide, 5 parts by weight of astaxanthin, 50 parts by weight of rose whitening essence prepared in example 3 and 25 parts by weight of deionized water at 200rpm for 30 min.

The preparation method of the peach gum extract is the same as that of example 4, and is not repeated herein.

Test example 4

Acne (Acne), also known as Acne Juvenile, is a chronic inflammation of the hair follicles, sebaceous glands. It is usually applied to fatty areas of the skin, such as the forehead, the bridge of the nose, and the chest and back. Self-limiting, skin lesions with multiple forms, such as acne, papules, pustules, nodules, are often accompanied by seborrhea. Acne is a multifactorial dermatological disorder. It is mainly associated with increased sebum production, hyperkeratosis of the epithelium of the follicular orifice and proliferation of Propionibacterium acnes in the hair follicle.