CN101422213A - Frozen roasting method - Google Patents

Frozen roasting method Download PDFInfo

- Publication number

- CN101422213A CN101422213A CNA2008100971289A CN200810097128A CN101422213A CN 101422213 A CN101422213 A CN 101422213A CN A2008100971289 A CNA2008100971289 A CN A2008100971289A CN 200810097128 A CN200810097128 A CN 200810097128A CN 101422213 A CN101422213 A CN 101422213A

- Authority

- CN

- China

- Prior art keywords

- food materials

- aforementioned

- otch

- aforementioned food

- length

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Abstract

The present invention relates to a method for processing eel. The aim of the invention is to provide the eel processing method which can improve the barbecue. The eel processing method according to the invention comprises a step of roasting eel after a random food material selected from eel and conger eel is cut to open, and the method also comprises a groove cutting step. The opening cutting step comprises the following procedures before baking the food material: keeping the head of food material and eliminating the spinal column, and afterwards cutting a groove at interval in a direction which intersects the length direction of food material for about 2/3*L part in a direction from the part of food material except for the head to the tail part of the food material (L is the total length in length direction of food material which does not contain the head part of food material). A groove is not cut on the part of the residual food material for about 1/3*L length.

Description

Technical field

The present invention is a relevant frozen roasting method, particularly a kind of frozen roasting method that improves barbecue.

Background technology

Have the frozen roasting method that the food materials of the eel of bone, star eel etc. were cut and removed to a kind of barbecue open at present.(for example, with reference to Patent Document 1)

No. 3437131 communique of [Patent Document 1] patent (the 3rd figure)

But when utilizing aforesaid frozen roasting method to process the Pu burning in a large number, can roast uneven situation.This may be because when roasting under similarity condition, and " near head region " of eel, star eel etc. is more abundant than the meat of " near the tail position ", and the thickness of meat is difference and cause inhomogeneous to some extent.

If can control heating in response to the thickness of the meat of eel, star eel etc., no doubt good, but will be applied on mass-produced " frozen roasting method ", be inconvenient at present.

Therefore, if when be the benchmark barbecue with the thickness of meat abundant " near head region ", though " near head region " barbecue is good, " the close tail position " of the thinner thickness of meat then can present the state that burns that is dried to, and taste, sense of food are neither good.On the contrary, if when be the benchmark barbecue with " near the tail position " of the thinner thickness of meat, though " near the tail position " barbecue is good, the thickness of meat abundant " near head region " then has the not enough problem points generation of barbecue.

A method that addresses this problem a little is, for example, go up by " near the tail position " of " eel " that on production line, come in carrying and to cover cover and add heat with minimizing in manual mode, again, also can by hand operated will carry and " near the tail position " of " eel " that come move apart the heating position.

But because the method is former with hand operated on production line, not only efficient is not good, and because with the event of hand operated, " eel " goes up the meeting particle-bound bacteria, afterwards, even through barbecue, before still can remaining in, bacterium baked on the epidermis of " eel ", and also not satisfactory aspect administration of health.

Summary of the invention

The objective of the invention is is providing a kind of frozen roasting method that solves foregoing problems.

Frozen roasting method of the present invention is with eel, turnspit in addition more in addition again after arbitrary food materials in the star eel are cut open, wherein comprise the otch step, this otch step is before the aforementioned food materials of barbecue, aforementioned food materials are stayed head, remove spine, begin at position then from the aforementioned food materials except that head toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), cut out otch with the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch in the position of the aforementioned food materials of remaining about 1/3 * L length.

Again, 2 frozen roasting methods of being put down in writing of claim the are a kind of with eel, turnspit in addition again after arbitrary food materials in the star eel are cut open, it is characterized in that comprising the otch step, this otch step is before the aforementioned food materials of barbecue, aforementioned food materials are removed spine and head, then the leading section from the aforementioned food materials except that aforementioned head begin toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), cut out otch in the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch in the position of the aforementioned food materials of remaining about 1/3 * L length.

Again, 3 frozen roasting methods of being put down in writing of claim the are about aforementioned claim the 1 or 2 frozen roasting methods of being put down in writing, be between the barbecue step of otch step and barbecue food materials, in the length of aforementioned food materials to the length of cross-section aforementioned food materials to direction on cut off the cut-out step of aforementioned food materials; Perhaps, in aforementioned otch step and roast between the barbecue step of aforementioned food materials, in the length of cross-section aforementioned food materials to direction on cut off the cut-out step of aforementioned food materials, and after this cuts off step, with puncture string thorn step on bamboo let of the aforementioned food materials that cut off.

Again, 4 frozen roasting methods of being put down in writing of claim the are the frozen roasting methods about aforementioned claim the 1 or 2, are before the barbecue step of barbecue food materials, the flavoring juice smearing step of smearing flavoring juice on aforementioned food materials; Perhaps, before the barbecue step of barbecue food materials, the aforementioned food materials of boiling, the flavoring juice smearing step of on the aforementioned food materials of boiling, smearing flavoring juice then.

Again, 5 frozen roasting methods of being put down in writing of claim the are the frozen roasting methods about aforementioned claim the 1 or 2, and wherein the degree of depth of aforementioned otch is in the scope of the about 1/2 * T in the skin zone position~about 2/3 * T from the sliced meat top of the food materials that cut toward aforementioned food materials (T is meant from the sliced meat top of the aforementioned food materials that the cut aforementioned food materials thickness of the skin zone position of aforementioned food materials extremely).

Again, 6 frozen roasting methods of being put down in writing of claim the are the frozen roasting methods about aforementioned claim the 1 or 2, and wherein aforementioned interval is in the scope that is approximately the 7mm of 4mm~approximately.

Since begin from the position of the food materials except that head past aforementioned food materials the tail position the about 2/3 * L of direction part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), be that position fishbone than the aforementioned food materials of remaining about 1/3 * L length comes manyly, and the thickness of meat is also thicker, therefore from the position of the food materials except that head extremely the integral body at the tail position of aforementioned food materials all under similarity condition, for example, if beginning toward the part of the length of the about 2/3 * L of direction at the tail position of aforementioned food materials with the position from the food materials except that head is that benchmark is when roasting, although begin from the position of the food materials except that head toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length) barbecue is good, the position of aforementioned food materials that remains the length of about 1/3 * L toward the direction at tail position then can be roasted excessively; On the contrary, if the direction at tail position remained the position of aforementioned food materials of the length of about 1/3 * L when being the benchmark barbecue in the past, although this position barbecue is good, the part of the about 2/3 * L of direction that begins the tail position of past aforementioned food materials from the position of the food materials except that head is roasted incomplete undesirable state.

If by 1 frozen roasting method of being put down in writing of claim the, it is characterized in that comprising the otch step, this otch step is before the aforementioned food materials of barbecue, thickness thick " begin from the position of the aforementioned food materials except that head toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length) ", cut out otch in the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch on " positions of the aforementioned food materials of remaining about 1/3 * L length " of thin thickness, afterwards, roast aforementioned food materials, therefore can be by otch the passing through that on the thick position of thickness, cuts out in order to heat, so just, can eliminate the incomplete undesirable state of aforesaid barbecue, and, cut out otch by this and not only can cut off fishbone, more can roast the fishbone of cut-out, therefore can prevent that fishbone is stuck in the undesirable situation of throat.

From the leading section of the food materials except that head begin toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), be that fishbone than the position of the aforementioned food materials of remaining about 1/3 * L length comes manyly, and the thickness of meat is also thicker, therefore the integral body from the leading section of food materials to the tail position of aforementioned food materials is all under similarity condition, for example, if when beginning to be the benchmark barbecue toward the part of the length of the about 2/3 * L of direction at the tail position of aforementioned food materials with leading section from food materials, although from the leading section of food materials begin toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length) barbecue is good, the position of aforementioned food materials that remains the length of about 1/3 * L toward the direction at tail position then can form the state that burns that is dried to.On the contrary, if the direction at tail position remained the position of aforementioned food materials of the length of about 1/3 * L when being the benchmark barbecue in the past, although this position barbecue is good, begin to roast incomplete unfavorable state toward the part of the about 2/3 * L of direction at the tail position of aforementioned food materials from the leading section of food materials.

If by 2 frozen roasting methods of being put down in writing of claim the, it is characterized in that comprising the otch step, this otch step is before the aforementioned food materials of barbecue, thickness thick " from the leading section of the aforementioned food materials except that head begin toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length) ", cut out otch in the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch on " positions of the aforementioned food materials of remaining about 1/3 * L length " of thin thickness, afterwards, roast aforementioned food materials, therefore can be by otch the passing through that on the thick position of thickness, cuts out in order to heat, so just, can eliminate the incomplete undesirable state of aforesaid barbecue, and, cut out otch by this and not only can cut off fishbone, more can roast the fishbone of cut-out, therefore can prevent that fishbone is stuck in the undesirable situation of throat.

If the degree of depth of otch is less than about 1/2 * T, not only hot passing through is out of condition, and can produce the undesirable state that fishbone can't be cut off fully, again, if the degree of depth of otch is greater than about 2/3 * T, then after cutting out otch, even through barbecue, the part of incision, promptly otch can't wait by grease, the contraction of food materials itself and engage, and still leave otch, produce the not good undesirable situation of outward appearance.But if by 5 frozen roasting methods of being put down in writing of claim the, the degree of depth of otch is in the scope of the about 1/2 * T in the skin zone position~about 2/3 * T from the sliced meat top of the food materials that cut toward aforementioned food materials (T is meant from the sliced meat top of the aforementioned food materials that the cut aforementioned food materials thickness of the skin zone position of aforementioned food materials extremely), therefore except the effect of aforementioned claim the 1 or 2 inventions of being put down in writing, also the situation that aforementioned outward appearance is not good can be prevented, perfection can be more attained.

If the interval of otch, can produce the excessive situation of part barbecue of incision less than about 4mm, again, if the interval of otch is greater than about 7mm, not only can remaining fishbone in the meat, and can produce the not good situation of passing through of heat.

If by 6 frozen roasting methods of being put down in writing of claim the, at interval in the scope that is approximately 4mm~about 7mm, therefore add the effect of aforementioned claim the 1 or 2 inventions of being put down in writing, not only can prevent the situation that aforementioned outward appearance is not good, can more attain perfection.

Description of drawings

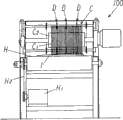

The 1st figure is one of the frozen roasting method of one of a present invention embodiment step, and " in the length of cross-section food materials to direction on the compartment of terrain cut out otch " the general view of notching device.

The 2nd figure is the outline elevation of the device of the 1st figure.

The 3rd figure is the summary sectional view of the 1st figure cathetus 3-3.

The 4th figure is the expansion summary part enlarged cross section figure partly that shows the 3rd figure.

The 5th figure is the summary sectional view of the device of the 3rd figure.

The 6th figure is the general view by the food materials of the notching device incision of the 1st figure.

The 7th figure is the summary part enlarged cross section figure of the food materials of the 6th figure.

The 8th figure is the general view of food materials different with the 7th figure.

The 9th figure is the summary part enlarged cross section figure of the food materials of the 8th figure.

[main element symbol description]

1 food materials H conveyer

The 1a head H

1Drive unit

1b gets rid of the position H of internal organ

2Transmission device

100 notching device K otch

C notch L does not contain the length of food materials of the head of food materials

To total length

C

0Drive unit T from the sliced meat top of the food materials that cut extremely

The food materials thickness of the skin zone position of food materials

C

1Otch member W distance

C

2Rotary body

D body stripping portion

D

0Conveyer belt

D

1Reverse member

D

2Reverse member

The specific embodiment

One of the graphic explanation of following reference frozen roasting method of the present invention embodiment (with reference to the 1st figure to the 7 figure).

Among the 1st figure 100 cuts out the notching device of otch K " otch step " on food materials 1.

Again, frozen roasting method of the present invention is the food materials 1 of eel, star eel etc. are cut open and to be removed spine, and on food materials 1, cut out otch K (with reference to the 7th figure) (otch step), afterwards, first turnspit in addition after the flavoring juice smearing step of smearing flavoring juice on the food materials 1, and first boiling food materials 1 are smeared behind the flavoring juice in addition turnspit from food materials 1 then.Wherein, except after the otch step, elder generation's boiling food materials 1, boiling is smeared flavoring juice later on food materials 1, roasted then outside " the barbecue step " of food materials 1, also include after cutting out otch K (with reference to the 7th figure) on the food materials 1, the what is called of " not smearing flavoring juice ground is roasted " " is done roasting ".Again, between from " otch step " to " barbecue step ", outside the food materials 1 of one tail longitudinal bodies are handled under the state of a whole tail, also include between the barbecue step of otch step and barbecue food materials 1, the length of food materials 1 to the length of cross-section food materials 1 to direction on cut off the cut-out step of the food materials 1 of a tail longitudinal bodies; Perhaps, the length of food materials 1 to the length of cross-section food materials 1 to direction on cut off the cut-out step of the food materials 1 of a tail longitudinal bodies, and after this cuts off step, with puncture string thorn step on bamboo let of the food materials 1 that cut off.

Conveyer (for example, conveyer belt) H sees through transmission device (for example, chain) H

2Automatic drive device (for example, motor) H in the future

1Driving transmit toward the direction of arrow of the 2nd figure, so that food materials 1 are transported to notch C.

Notch C (with reference to the 3rd figure to the 7 figure) is the otch member C with notch C

1(for example, cutting disc), shown in the 3rd figure and the 4th figure, approximately 4mm~approximately the mode of 7mm is installed on rotary body C at interval with each

2On, the distance that makes adjacent otch K is W (distance W is the distance shown in the 7th figure, and this distance is 4mm~about 7mm approximately).And shown in the 5th figure, otch member C

1(for example, cutting disc) rotation is the direction of rotation opposite with the carrying direction of food materials 1, and with the 5th figure, the carrying direction of food materials 1 is to be turned left by the right side, otch member C

1Direction of rotation be inverse clock rotation.

This otch member C

1Size be to be configured to begin on the direction at the tail position of food materials 1 at position from the food materials 1 except that aforementioned head 1a, till the part of about 2/3 * L, cut out otch K (with reference to the 7th figure) in the length of cross-section food materials 1 compartment of terrain that makes progress, and be not disposed at the position of the food materials 1 of remaining about 1/3 * L length, so that do not cut out otch (with reference to the 1st figure).Again, L be meant the head 1a that does not contain food materials 1 food materials 1 length to total length, and the 1b that is shown among the 1st figure and the 6th figure shows the position get rid of internal organ.

Again, otch member C

1Be by drive unit (for example, motor) C

0, and see through rotary body C

2And rotate.

Again, be shown in the body stripping portion D among the 2nd figure, when utilizing otch member C

1It is to be connected to above the food materials 1 during incision food materials 1, and will be attached to otch member C

1Food materials 1 from otch member C

1On peel off, and body stripping portion D is by the conveyer belt that is connected to food materials 1 (for example, the food of circular cross-section with circular band) D

0Constitute, and shown in the 3rd figure, body stripping portion D compartment of terrain is provided with most.

The conveyer belt D of this body stripping portion D

0, be to see through the reverse member D that reverses direction of rotation

1, D

2Transmission comes automatic drive device (for example, motor) H

1Driving, and be connected to conveyer belt D

0The top position of food materials 1, be that the carrying direction with food materials 1 is identical (direction of turning left by the right side of the 5th figure).

Therefore, by conveyer (for example, conveyer belt) H transportation flesh noodles up, epidermis food materials 1 down are during to notch C, utilize otch member C

1Begin the part of the about 2/3 * L of direction at sheet tail position at position from the food materials except that head 1a 1, cut out otch K in the length of cross-section food materials 1 compartment of terrain that makes progress, then do not cut out otch (with reference to the 6th figure) in the position of the food materials 1 of remaining about 1/3 * L length.

Again, the degree of depth of aforementioned otch K is shown in the 7th figure, from the sliced meat top of the food materials 1 that cut to the scope of the about 1/2 * T in skin zone position~about 2/3 * T of food materials 1.

At this, T is food materials 1 thickness (with reference to the 7th figure and the 9th figure) of sliced meat top to the skin zone position of food materials 1 of the food materials of cutting open 1 when cutting the belly (or back) of food materials 1.If the degree of depth of otch K is less than about 1/2 * T, then not only hot passing through is out of condition, and can produce the undesirable state that fishbone can't be cut off fully, again, if the degree of depth of otch K greater than about 2/3 * T, then after cutting out otch, even through barbecue, the part of incision can't refer to by food materials 1 oil own, contraction waits and engages, and still leaves otch K, produces the not good undesirable situation of outward appearance.

Again, on food materials 1, cut out otch K, then when notch C carries out, following butt conveyer (for example, the conveyer belt) H of food materials 1, the top then butt body stripping portion D of food materials 1, make food materials 1 be the state that is held, therefore, food materials 1 can not adhere to otch member C

1On, be involved in the notch C, can be taken out of notch C.

Afterwards, roast with the step of barbecue food materials 1.Though the barbecue step is not shown among the figure, in utilizing conveyer, for example conveyer belt carrying and the food materials 1 that come above or below, or in the top and below configuration burner roast well-known food materials.

Its result, because thickness thick " beginning the part of the about 2/3 * L of direction at the tail position of past food materials 1 from the position of the food materials except that head 1a 1 ", the compartment of terrain cuts out otch K, therefore identical with " positions of the food materials 1 of remaining about 1/3 * L length " of thin thickness, via passing through of heat, make " from removing head 1a " to the tail position, can bake fifty-fifty, can improve taste and sense of food simultaneously, even and not only the surface all can bake to the flesh noodles nexine.

And, can cut off fish-bone by otch K, add the fish-bone that can roast to cutting off, therefore can improve the undesirable situation that fishbone is stuck in throat.

Again, " barbecue " after otch K sees through can be joined together flesh noodles and flesh noodles each other, and not only identical with " former times know the otch that do not cut out roast ' Pu burning ' " in appearance, it is whole also can not feel aggrieved.

Again, otch K utilizes the hot gas that enters to bake from the center of flesh noodles by " barbecue " afterwards, therefore can moderately remove the grease of the food materials 1 of eel, star eel etc., more can alleviate the peculiar fishy smell of eel, star eel self.

Again, when smearing flavoring juice after the otch K, flavoring juice sees through otch K and soaks into food materials 1, by " the barbecue step " after " flavoring juice smearing step ", can obtain Pu fragrant and that sense of food is good and burn.

Again, in the previous embodiment, though be with the food materials 1 that cut eel, star eel etc. belly, remove spine to be the state of cutting open " fish piece " be example, but be not limited in this in the present invention, too applicable to for example, shown in the 8th figure and the 9th figure, " cut the food materials 1 of eel, star eel etc. the back, remove (the fish piece) that be the state of cutting open of spine and head ".Being shown in the 1b among the 8th figure, is the position of getting rid of internal organ, and otch K then is by otch member C

1The person of cutting out.

Claims (6)

1. frozen roasting method, be with eel, turnspit in addition again after arbitrary food materials in the star eel are cut open, it is characterized in that comprising the otch step, this otch step is before the aforementioned food materials of barbecue, aforementioned food materials are stayed head, remove spine, begin at position then from the aforementioned food materials except that aforementioned head toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), cut out otch in the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch in the position of the aforementioned food materials of remaining about 1/3 * L length.

2. frozen roasting method, be with eel, turnspit in addition again after arbitrary food materials in the star eel are cut open, it is characterized in that comprising the otch step, this otch step is before the aforementioned food materials of barbecue, aforementioned food materials are removed spine and head, then the leading section from the aforementioned food materials except that aforementioned head begin toward the about 2/3 * L of direction at the tail position of aforementioned food materials part (L be meant the head that does not contain aforementioned food materials aforementioned food materials length to total length), cut out otch in the length of the cross-section aforementioned food materials compartment of terrain that makes progress, then do not cut out otch in the position of the aforementioned food materials of remaining about 1/3 * L length.

3. as claim the 1 or 2 s' frozen roasting method, more be included between the barbecue step of otch step and barbecue food materials, in the length of aforementioned food materials to the length of cross-section aforementioned food materials to direction on cut off the cut-out step of aforementioned food materials; Perhaps, in aforementioned otch step and roast between the barbecue step of aforementioned food materials, in the length of cross-section aforementioned food materials to direction on cut off the cut-out step of aforementioned food materials, and after this cuts off step, with puncture string thorn step on bamboo let of the aforementioned food materials that cut off.

4. as claim the 1 or 2 s' frozen roasting method, more be included in before the barbecue step of barbecue food materials the flavoring juice smearing step of on aforementioned food materials, smearing flavoring juice; Perhaps, before the barbecue step of barbecue food materials, the aforementioned food materials of boiling, the flavoring juice smearing step of on the aforementioned food materials of boiling, smearing flavoring juice then.

5. as claim the 1 or 2 s' frozen roasting method, wherein the degree of depth of aforementioned otch is in the scope of the about 1/2 * T in the skin zone position~about 2/3 * T from the sliced meat top of the food materials that cut toward aforementioned food materials (T is meant from the sliced meat top of the aforementioned food materials that the cut aforementioned food materials thickness of the skin zone position of aforementioned food materials extremely).

6. as claim the 1 or 2 s' frozen roasting method, wherein aforementioned interval is in the scope that is approximately the 7mm of 4mm~approximately.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007284645A JP4750095B2 (en) | 2007-11-01 | 2007-11-01 | Processing method of Hagi Yaki |

| JP2007284645 | 2007-11-01 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101422213A true CN101422213A (en) | 2009-05-06 |

Family

ID=40613267

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA2008100971289A Pending CN101422213A (en) | 2007-11-01 | 2008-05-14 | Frozen roasting method |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP4750095B2 (en) |

| CN (1) | CN101422213A (en) |

| TW (1) | TW200920272A (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102150892A (en) * | 2011-01-28 | 2011-08-17 | 长乐聚泉食品有限公司 | Baked eel viscera and production process thereof |

| CN102488245A (en) * | 2011-12-30 | 2012-06-13 | 长乐太平洋食品有限公司 | Energy-saving eel roasting technology beneficial for improving product quality |

| CN107183578A (en) * | 2017-06-05 | 2017-09-22 | 舟山市齐晟水产有限公司 | A kind of Pu burns sliced eel preparation technology |

| CN107198148A (en) * | 2017-06-08 | 2017-09-26 | 舟山市齐晟水产有限公司 | A kind of Pu burns eel silk preparation technology |

| CN107373448A (en) * | 2017-06-05 | 2017-11-24 | 舟山市齐晟水产有限公司 | A kind of Pu burns eel silk preparation technology |

| CN110200054A (en) * | 2019-01-10 | 2019-09-06 | 邱全成 | The production method of disconnected thorn milkfish |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5303766B2 (en) * | 2011-09-27 | 2013-10-02 | 一彦 宇都宮 | Method for producing frozen grilled fish |

| JP5666736B1 (en) * | 2014-06-24 | 2015-02-12 | 日本水産株式会社 | Charcoal grilled meat manufacturing method. |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0395590A (en) * | 1989-09-08 | 1991-04-19 | Hitachi Ltd | Display pallet data setting circuit |

| JPH0733422Y2 (en) * | 1990-01-18 | 1995-07-31 | 和泉電気株式会社 | Assembly aid for device array |

| JP3437131B2 (en) * | 1999-11-12 | 2003-08-18 | 株式会社 竹田精工 | Kabayaki processing method |

| JP4771766B2 (en) * | 2005-07-27 | 2011-09-14 | 京丸うなぎ株式会社 | Process method and processing apparatus |

| JP4898417B2 (en) * | 2006-12-25 | 2012-03-14 | 株式会社 竹田精工 | Processing method of Hagi Yaki and White Yaki |

-

2007

- 2007-11-01 JP JP2007284645A patent/JP4750095B2/en active Active

- 2007-11-20 TW TW096143910A patent/TW200920272A/en unknown

-

2008

- 2008-05-14 CN CNA2008100971289A patent/CN101422213A/en active Pending

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102150892A (en) * | 2011-01-28 | 2011-08-17 | 长乐聚泉食品有限公司 | Baked eel viscera and production process thereof |

| CN102150892B (en) * | 2011-01-28 | 2012-09-05 | 长乐聚泉食品有限公司 | Baked eel viscera and production process thereof |

| CN102488245A (en) * | 2011-12-30 | 2012-06-13 | 长乐太平洋食品有限公司 | Energy-saving eel roasting technology beneficial for improving product quality |

| CN102488245B (en) * | 2011-12-30 | 2013-03-13 | 长乐太平洋食品有限公司 | Energy-saving eel roasting technology beneficial for improving product quality |

| CN107183578A (en) * | 2017-06-05 | 2017-09-22 | 舟山市齐晟水产有限公司 | A kind of Pu burns sliced eel preparation technology |

| CN107373448A (en) * | 2017-06-05 | 2017-11-24 | 舟山市齐晟水产有限公司 | A kind of Pu burns eel silk preparation technology |

| CN107198148A (en) * | 2017-06-08 | 2017-09-26 | 舟山市齐晟水产有限公司 | A kind of Pu burns eel silk preparation technology |

| CN110200054A (en) * | 2019-01-10 | 2019-09-06 | 邱全成 | The production method of disconnected thorn milkfish |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI354539B (en) | 2011-12-21 |

| JP4750095B2 (en) | 2011-08-17 |

| TW200920272A (en) | 2009-05-16 |

| JP2009106248A (en) | 2009-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101422213A (en) | Frozen roasting method | |

| TWI291856B (en) | Barbecue processing method and barbecue processing apparatus | |

| CN105077378B (en) | A kind of spiced tuna fillet processing technology | |

| CN101099574A (en) | Method for making sand meat and device for baking sand meat | |

| NL2015093B1 (en) | Food product and method for the manufacture and preparation thereof. | |

| JP4898417B2 (en) | Processing method of Hagi Yaki and White Yaki | |

| CN204410602U (en) | A kind of automatic barbecue oven of homogeneous heating | |

| US20040175469A1 (en) | Tortilla wrap food product and method for making same | |

| JP2011110061A (en) | Automatic fish broiler | |

| JP2009112210A (en) | Method for producing grilled oyster | |

| CN203483308U (en) | Automatic oven | |

| CN102987419B (en) | Preparation method for braised hu mutton with soy sauce | |

| JP7467573B2 (en) | How to cook chicken skin skewers | |

| CH696054A5 (en) | Fish kebab | |

| JP2006061132A5 (en) | ||

| CN104336622A (en) | Making method for special fried meat | |

| KR101567561B1 (en) | A Pizza Ingredient Manufacturing Unit Using Hwangtae and Manufacturing Method | |

| KR20100033051A (en) | Disposable grill | |

| KR101308289B1 (en) | Meat and fish, shellfish cooking method using bamboo barrel | |

| KR20180009986A (en) | Cooking method of pork belly | |

| JP2007174922A (en) | Method for producing pettitoes soup, and cooked pettitoes | |

| CN104207206A (en) | Making method of seafood in clay pot | |

| CN101091521A (en) | Method for preparing dish of crackling loins | |

| JPH0515415B2 (en) | ||

| KR200292906Y1 (en) | Yellow color clay roaster |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication |

Open date: 20090506 |