WO2021070747A1 - 耐炎性積層成形体 - Google Patents

耐炎性積層成形体 Download PDFInfo

- Publication number

- WO2021070747A1 WO2021070747A1 PCT/JP2020/037565 JP2020037565W WO2021070747A1 WO 2021070747 A1 WO2021070747 A1 WO 2021070747A1 JP 2020037565 W JP2020037565 W JP 2020037565W WO 2021070747 A1 WO2021070747 A1 WO 2021070747A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- flame

- fiber

- laminated molded

- thermoplastic

- molded product

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/281—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polyimides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/285—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polyethers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/286—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polysulphones; polysulfides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/28—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42

- B32B27/288—Layered products comprising a layer of synthetic resin comprising synthetic resins not wholly covered by any one of the sub-groups B32B27/30 - B32B27/42 comprising polyketones

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/302—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising aromatic vinyl (co)polymers, e.g. styrenic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/34—Layered products comprising a layer of synthetic resin comprising polyamides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/04—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the partial melting of at least one layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/08—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer the fibres or filaments of a layer being of different substances, e.g. conjugate fibres, mixture of different fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/02—Physical, chemical or physicochemical properties

- B32B7/027—Thermal properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/10—Interconnection of layers at least one layer having inter-reactive properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0223—Vinyl resin fibres

- B32B2262/023—Aromatic vinyl resin, e.g. styrenic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0246—Acrylic resin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0261—Polyamide fibres

- B32B2262/0269—Aromatic polyamide fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0276—Polyester fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0276—Polyester fibres

- B32B2262/0284—Polyethylene terephthalate [PET] or polybutylene terephthalate [PBT]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/101—Glass fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/106—Carbon fibres, e.g. graphite fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/14—Mixture of at least two fibres made of different materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2270/00—Resin or rubber layer containing a blend of at least two different polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/302—Conductive

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/30—Properties of the layers or laminate having particular thermal properties

- B32B2307/306—Resistant to heat

- B32B2307/3065—Flame resistant or retardant, fire resistant or retardant

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/732—Dimensional properties

- B32B2307/737—Dimensions, e.g. volume or area

- B32B2307/7375—Linear, e.g. length, distance or width

- B32B2307/7376—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/10—Batteries

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the present invention relates to a flame-resistant laminated molded product, and more particularly to a flame-resistant laminated molded product in which a specific fiber sheet material is provided on the outer surface portion of the resin molded product so that the surface of the molded product has high flame resistance.

- Resin molded products are used in various fields from the viewpoints of light weight and excellent moldability into a predetermined shape, but depending on the application, high flame retardancy, flame resistance, and flame insulation are required. There are times. In particular, high flame retardancy, flame resistance, and flame insulation may be required mainly on the surface and surface layer of the resin molded product.

- non-woven fabric or fibrous paper for example, a non-woven fabric composed of a composite of non-melted fibers (for example, flame-resistant yarn) and fibers made of polyphenylene sulfide as a polymer having high flame retardancy (for example, Patent Document 1). And paper (for example, Patent Document 2) are known.

- a non-woven fabric or paper itself can exhibit high flame resistance and flame-shielding property, but it is difficult to form a molded body having desired strength and rigidity with the non-woven fabric or paper itself, even if it is molded. Even if it can be made, it is likely to be extremely expensive because the non-woven fabric or paper needs to be made considerably thick. Moreover, it is difficult to ensure good moldability.

- the subject of the present invention is that, in view of the above-mentioned circumstances, it is possible to exhibit the high flame resistance and flame-shielding property required for the surface and surface layer portion of the resin molded product, and the molded product as a whole is required.

- An object of the present invention is to provide a flame-resistant laminated molded product capable of easily ensuring desired strength and rigidity, as well as good moldability into a desired shape.

- the present invention employs the following means. (1) Flame-resistant laminate in which at least one surface of the fiber sheet material containing the non-molten fiber A is exposed to the outside of the molded body and at least a part of the other surface side is bonded to the thermoplastic resin C constituting the molded body body. Molded body. (2) The flame-resistant laminated molded product according to (1), wherein the fiber sheet material contains the non-molten fiber A and the thermoplastic fiber B. (3) The flame-resistant laminated molded product according to (1) or (2), wherein the non-molten fiber A has a thermal conductivity of 0.060 W / m ⁇ K or less in accordance with ISO22007-3 (2008).

- thermoplastic fiber B has a LOI value of 25 or more according to JIS K 7201-2 (2007).

- the thermoplastic fiber B is an anisotropic molten polyester, a liquid crystal polyester, a flame-retardant poly (butylene terephthalate), a poly (acrylonitrile butadiene styrene), a flame-retardant polysulfone, a poly (ether-ether-ketone), or a poly.

- Fibers consisting of (ether-ketone-ketone), polyethersulfone, polyarylate, polyarylene sulfide, polyphenylsulfone, polyetherimide, polyamideimide and a resin selected from the group of mixtures thereof, (2) to The flame-resistant laminated molded body according to any one of (8).

- the thermoplastic resin C has a LOI value of 25 or more according to JIS K 7201-2 (2007).

- thermoplastic resin C is anisotropic molten polyester, liquid crystal polyester, flame-retardant polyamide 66, flame-retardant poly (butylene terephthalate), poly (acrylonitrile butadiene styrene), flame-retardant polysulfone, poly (ether-ether-. Consists of resins selected from the group of ether-ketone), poly (ether-ketone-ketone), polyethersulfone, polyarylate, polyallyrene sulfide, polyphenylsulfone, polyetherimide, polyamideimide and mixtures thereof, ( The flame-resistant laminated molded body according to any one of 1) to (11).

- thermoplastic fiber B and the thermoplastic resin C are made of the same resin, and the bonding strength between the fiber sheet material containing the non-molten fiber A and the thermoplastic fiber B and the thermoplastic resin C is 1.

- the fiber sheet material containing the non-molten fiber A and the thermoplastic fiber B can exhibit flame-shielding property by forming a film between the non-molten fiber A by melting the thermoplastic fiber B and carbonizing it under oxygen blocking.

- a fiber sheet material containing the non-molten fiber A and the thermoplastic fiber B is heat-sealed with the thermoplastic resin C, and a fused phase-bonded layer between the thermoplastic fiber B and the thermoplastic resin C.

- the fiber sheet material itself containing the non-molten fiber A can exhibit high flame resistance and flame-shielding property due to the presence of the non-molten fiber A. Since one surface of the fiber sheet material is bonded to the main body of the molded product made of thermoplastic resin C in a state of being exposed to the outside, the surface portion of the laminated molded product as a whole is efficiently and highly flame resistant. It becomes possible to develop flame-shielding properties. At the same time, since the molded body can be easily molded into a desired shape by substantially any molding method using the thermoplastic resin C, the desired strength and rigidity of the laminated molded body as a whole can be ensured depending on the molded body.

- thermoplastic resin C constituting the molded article body. It is characterized by being joined.

- the fiber sheet material containing at least the non-molten fiber A woven fabric, knitted fabric, felt, paper and the like can be used, and short fibers and long fibers processed by a known method can be used. Among them, non-woven fabric is preferable from the viewpoint of flame resistance.

- the thickness of the fiber sheet material is not particularly limited, but is preferably 0.05 to 10 mm from the viewpoint of reducing the weight, reducing the cost, and improving the performance of the laminated molded product.

- the non-molten fiber A in the present invention refers to a fiber that does not liquefy and retains its fiber shape when exposed to a flame, preferably one that does not liquefy and ignite at a temperature of 800 ° C., and liquefies and liquefies at a temperature of 1000 ° C. or higher. Those that do not ignite are more preferable.

- Examples of such non-molten fibers A include flame resistant fibers, metaaramid fibers, and glass fibers.

- the flame-resistant fiber is a fiber that has been subjected to a flame-resistant treatment using a fiber selected from acrylonitrile-based, pitch-based, cellulosic-based, and phenol-based fibers as a raw material.

- flame-resistant fibers having a low high-temperature shrinkage rate and the oxygen blocking effect of the film formed by the thermoplastic fiber B described later during flame contact promote carbonization and further improve the heat resistance at high temperatures are preferable.

- acrylonitrile-based flame-resistant fiber is more preferably used as a fiber having a small specific gravity, flexibility, and excellent flame retardancy, and the flame-resistant fiber uses acrylic fiber as a precursor in high-temperature air. Obtained by heating and oxidizing.

- Examples of commercially available products include the flame-resistant fiber PYRON (registered trademark) manufactured by Zoltek, which was used in Examples and Comparative Examples described later, and Pyromex (registered trademark) manufactured by Toho Tenax Co., Ltd.

- the high temperature shrinkage rate means that the fiber is left in a standard state (20 ° C., relative humidity 65%) for 12 hours, and then a tension of 0.1 cN / dtex is applied to measure the original length L0, and the fiber is measured. On the other hand, it was exposed to a dry heat atmosphere of 290 ° C.

- the non-molten fiber A in the present invention preferably has a thermal conductivity of 0.060 W / m ⁇ K or less as measured by a method conforming to ISO22007-3 (2008).

- Thermal conductivity is a numerical value of the ease of heat conduction, and low thermal conductivity means that when the material is heated from one side, the temperature of the unheated part rises. It means that it becomes smaller.

- Felt with a grain size of 200 g / m 2 and a thickness of 2 mm (density 100 kg / m 3 ) measured by a method conforming to JIS L1913 (2010) was used as a test piece, and measured by a method conforming to ISO22007-3 (2008).

- a material having a thermal conductivity of 0.060 W / m ⁇ K or less is difficult to transfer heat, and when it is made into a non-woven fabric and heated from one side, it is possible to suppress a temperature rise on the opposite side that is not heated. Even if a combustible material is placed on the opposite side, the possibility that the combustible material will ignite is reduced. It is preferable that the thermal conductivity is low, but the lower limit of the available fiber materials is about 0.020 W / m ⁇ K.

- non-molten fiber A preferably used in the present invention is preferably used by a method of combining the non-molten fiber alone or with a different material, and it is preferable to use the non-molten fiber A and the thermoplastic resin B in combination.

- the thermoplastic fiber B in the present invention preferably has a LOI value (Limiting Oxygen Index) of 25 or more according to JIS K7201-2 (2007).

- the LOI value is a volume percentage of the minimum amount of oxygen required to sustain the combustion of a substance in a mixed gas of nitrogen and oxygen, and it can be said that the higher the LOI value, the harder it is to burn. Therefore, thermoplastic fibers with a LOI value of 25 or more conforming to JIS K7201-2 (2007) are hard to burn, and even if they ignite, the fire is extinguished as soon as the fire source is released, and usually the part that has spread slightly A carbonized film is formed, and this carbonized portion can prevent the spread of fire.

- a high LOI value is preferable, but the upper limit of the LOI value of a substance actually available is about 65.

- thermoplastic fiber B in the present invention examples include anisotropic molten polyester, liquid crystal polyester, flame-retardant poly (butylene terephthalate), poly (acrylonitrile butadiene styrene), flame-retardant polysulfone, and poly (ether-ether-ketone). ), Poly (ether-ketone-ketone), polyethersulfone, polyallylate, polyarylene sulfide, polyphenylsulfone, polyetherimide, polyamideimide and a fiber composed of a thermoplastic resin selected from the group of mixtures thereof. Can be mentioned. These may be used alone or two or more kinds may be used at the same time.

- the LOI value is in the preferable range of the present invention, combustion in the air is suppressed and the thermoplastic resin is easily carbonized. Further, since the melting point is lower than the ignition temperature of the non-molten fiber A, the molten thermoplastic resin forms a film on the surface of the non-molten fiber A and between the fibers, and further carbonizes the film to block oxygen. The effect is enhanced, the oxidative deterioration of the non-molten fiber A can be suppressed, and the carbonized film exhibits excellent flame-shielding properties.

- the melting point of the thermoplastic fiber B is preferably 200 ° C. or higher, more preferably 300 ° C. or higher, lower than the ignition temperature of the non-molten fiber A.

- polyphenylene sulfide fiber (hereinafter, may be referred to as PPS fiber) is most preferable from the viewpoint of high LOI value, range of melting point and easy availability. Further, even a thermoplastic resin whose LOI value is not within the range specified by the present invention can be preferably used as long as the treated LOI value is within the range specified by the present invention by treating with a flame retardant. ..

- PPS fibers preferably used in the present invention - (C 6 H 4 -S ) - is a synthetic fiber made of a polymer containing as a main structural unit.

- Representative examples of PPS fibers containing the above structural units include polyphenylene sulfide (hereinafter, may be referred to as PPS), polyphenylene sulfide sulfone, polyphenylene sulfide ketone, random copolymers thereof, block copolymers, and theirs. Examples include mixtures.

- Particularly preferred PPS fibers as the main structural units of the polymer, - (C 6 H 4 -S ) - a represented by p- phenylene sulfide unit, preferably is preferable polyphenylene sulfide containing more than 90 mol%. PPS fibers made of polyphenylene sulfide containing 80% by weight, more 90% by weight or more of p-phenylene sulfide units are desirable.

- thermoplastic fiber B By containing a sulfur atom in the structure of the thermoplastic resin constituting the thermoplastic fiber B or in the flame retardant compounded as an additive in the thermoplastic resin, sulfuric acid is generated during the thermal decomposition of the polymer or the flame retardant, and the polymer is polymerized. It is possible to develop a mechanism for dehydrating and carbonizing the base material. From the viewpoint of containing sulfur atoms, PPS fiber is most preferable as the thermoplastic fiber B. When a flame retardant is used, a sulfur-based flame retardant is preferable. As the thermoplastic fiber B, it is preferable to use a fiber containing 15% by weight or more of a sulfur atom. Specific examples thereof include polyester to which PPS and a sulfur-based flame retardant are added.

- the upper limit of the ratio of sulfur atoms is preferably 50% by weight or less from the viewpoint of fiber strength.

- a thermogravimetric analyzer is used to raise the temperature of about 10 mg of a sample from room temperature to 800 ° C. at 10 ° C./min under air flow conditions to oxidatively decompose thermoplastic fibers. It is obtained by quantitatively analyzing the sulfur oxides in the decomposition gas by gas chromatography.

- the fiber sheet material in the present invention preferably contains non-molten fibers A and thermoplastic fibers B. If the mixing ratio of the thermoplastic fiber B in the fiber sheet material is too low, the thermoplastic fiber B does not spread sufficiently in a film shape between the non-molten fibers A of the aggregate, so that the mixing ratio of the thermoplastic fiber B in the fiber sheet material is high. It is preferably 20% by weight or more, and more preferably 30% by weight or more. If the mixing ratio of the thermoplastic fiber B is too high, the carbonized portion tends to become brittle at the time of flame contact and the flame shielding property is lowered. Therefore, the upper limit is preferably 85% by weight or less, and 75% by weight or less. More preferably.

- the fiber sheet material in the present invention may contain fibers D other than the non-molten fiber A and the thermoplastic fiber B in order to further add specific performance to the fiber sheet material.

- fibers D other than the non-molten fiber A and the thermoplastic fiber B in order to further add specific performance to the fiber sheet material.

- vinylon fiber, polyester fiber other than thermoplastic fiber B, nylon fiber and the like may be used.

- the mixing ratio of the fibers D is not particularly limited as long as the effects of the present invention are not impaired, but the mixing ratio of the fibers D other than the non-molten fibers A and the thermoplastic fibers B is preferably 20% by weight or less, preferably 15% by weight. It is more preferably less than or equal to%.

- the lower limit when the fiber D is used is not particularly limited as long as the desired performance is added, but it is usually preferably about 10% by weight.

- the thermoplastic resin C constituting the molded body of the flame-resistant laminated molded product of the present invention preferably has a LOI value of 25 or more in accordance with JIS K7201-2 (2007).

- the LOI value is a volume percentage of the minimum amount of oxygen required to sustain the combustion of a substance in a mixed gas of nitrogen and oxygen, and it can be said that the higher the LOI value, the harder it is to burn. Therefore, a thermoplastic resin having a LOI value of 25 or more conforming to JIS K7201-2 (2007) is hard to burn, and even if it ignites, the fire is extinguished as soon as the fire source is released, and usually it spreads slightly. A carbonized film is formed, and this carbonized portion can prevent the spread of fire.

- a high LOI value is preferable, but the upper limit of the LOI value of a substance actually available is about 65.

- thermoplastic resin C in the present invention examples include anisotropic fused polyester, liquid crystal polyester, flame-retardant polyamide 66, flame-retardant poly (butylene terephthalate), poly (acrylonitrile butadiene styrene), flame-retardant polysulfone, and poly.

- Thermoplastics selected from the group (ether-ether-ketone), poly (ether-ketone-ketone), polyethersulfone, polyallylate, polyarylene sulfide, polyphenylsulfone, polyetherimide, polyamideimide and mixtures thereof. It is preferably a resin. These may be used alone or in combination of two or more.

- Polyphenylene sulfide resin used preferably in the present invention (. Which hereinafter may be referred to as PPS resin) is, - (C 6 H 4 -S ) - which is a polymer whose main structural unit.

- PPS resins include polyphenylene sulfide, polyphenylene sulfide sulfone, polyphenylene sulfide ketone, random copolymers thereof, block copolymers and mixtures thereof.

- Particularly preferred PPS resin as the main structural units of the polymer, - (C 6 H 4 -S ) - a represented by p- phenylene sulfide unit, preferably is preferable polyphenylene sulfide resin containing 90 mol% or more.

- a polyphenylene sulfide resin containing 80% by weight, more 90% by weight or more of p-phenylene sulfide units is desirable.

- the thermoplastic resin C constituting the molded body of the flame-resistant laminated molded product of the present invention contains the above-mentioned sulfur-based flame retardant, reinforcing fibers such as carbon fiber and glass fiber, and sulfur as long as the object of the present invention is not impaired.

- Various additives other than flame retardants such as flame retardants, antioxidants, heat stabilizers, ultraviolet absorbers, lubricants, colorants or crystallization accelerators may be added.

- reinforcing fibers such as carbon fibers and glass fibers. These additives may be used alone or in combination.

- the flame-resistant laminated molded product of the present invention is characterized in that one surface of the fiber sheet material is exposed to the outside of the molded product, and at least a part of the other surface side is bonded to the thermoplastic resin C constituting the molded product body.

- a method for producing a laminated molded product by joining a fiber sheet material and a thermoplastic resin C include a method such as heat pressing, vibration welding, and laser welding, and a method by injection molding. Specifically, a method in which a fiber sheet material and a molded body containing a thermoplastic resin C are loaded into a heat press device and pressure is applied while applying heat to join them, and the fiber sheet material is placed on the thermoplastic resin molded body.

- Heater heat source high energy density heat source such as electron beam or laser beam, method of partial melt welding using heat source induced and heated by high frequency or electromagnetic wave, fiber sheet material is installed in advance in the mold, thermoplastic resin C Can be mentioned, for example, a method of filling a mold into a mold and injection molding. Of these, the injection molding method is preferable from the viewpoint of bonding strength and production cost.

- the fiber sheet material contains the thermoplastic fiber B

- a part of the thermoplastic resin B and a part of the thermoplastic resin C constituting the main body of the molded product are fused to each other. By fusing these, the bonding strength between the fiber sheet base material and the molded product can be improved.

- the thermoplastic fiber B and the thermoplastic resin C are the same resin.

- the compatibility between the thermoplastic fiber B and the thermoplastic resin C is increased when the thermoplastic resin C is melted, and the bonding strength between the fiber sheet material containing the thermoplastic resin B and the thermoplastic resin C is increased. ..

- the bonding strength is preferably 1.5 kg / cm 2 or more.

- the bonding strength is 1.5 kg / cm 2 or more, the fiber sheet material and the molded body are not separated even when the flame-resistant laminated molded body is exposed to flames, and the laminated molded body is not separated.

- the fiber sheet material and the thermoplastic resin C do not peel off due to the shrinkage difference between the fiber sheet material and the thermoplastic resin C due to a temperature change in the environment in which the body is used, and a sufficient flame resistance effect can be exhibited.

- the mechanism for exhibiting particularly excellent flame-shielding properties is as follows. is there.

- the thermoplastic fibers B are melted and formed into a film so as to fill the space between the non-molten fibers A.

- the film formation of the thermoplastic resin B blocks the contact between the non-molten fiber A and oxygen, and as a result, the non-molten fiber A is carbonized.

- the carbonized film thus completed exhibits flame-shielding properties.

- the fiber sheet material is a fiber sheet material containing non-molten fibers A and thermoplastic fibers B

- the fiber sheet material and the thermoplastic resin C are heat-sealed, resulting in heat fusion.

- the thickness of the fused phase-bonded layer of the formed thermoplastic fiber B and the thermoplastic resin C is preferably 10 ⁇ m or more.

- the thickness of the fused phase-bonded layer can be determined by the following method. After cutting the laminated molded product made of the fiber sheet material and the thermoplastic resin C to a predetermined size, the cross section is observed with a backscattered ray at a magnification of 200 times using a scanning electron microscope (manufactured by JEOL Ltd.). The observation width is about 600 ⁇ m, which is the same as the distance from the surface of the laminated molded body in which the fiber sheet material is partially present to the farthest non-molten fiber A at five cross-sectional positions at 100 ⁇ m equal intervals excluding both ends.

- the distance from the surface of the laminated molded body to the unfused interface between the thermoplastic fiber B and the thermoplastic resin C was measured, and the value obtained by subtracting the former distance from the latter distance was defined as the thickness of the fused phase-bonded layer. It was calculated by the average value of the cross-sectional positions of 5 places.

- the flame-resistant laminated molded product of the present invention is in a state in which the fiber sheet material is at least partially present on the surface of the thermoplastic resin C.

- the flame-shielding effect when a flame is applied to the fiber sheet material from the side where the fiber sheet material exists, the flame-shielding and flame-resistant effects are exhibited. That is, in the flame-resistant laminated molded body, the shape is such that the fiber sheet material exists in the portion where the flame comes into direct contact.

- the flame-shielding property in the present invention means that the flame is effectively blocked, and the flame-resistant property means that the flame is raised and combustion is not sustained even if the flame is ignited.

- the flame-resistant laminated molded product of the present invention can be applied to the fields of housing, aircraft, automobiles, etc. by taking advantage of its high flame-shielding property and flame resistance.

- it is useful for mounting on battery module loading packs, which are mounted on xEV automobiles (electric vehicles) and have flame resistance standards set by national regulations from the viewpoint of safety.

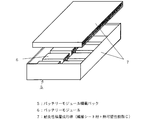

- FIG. 3 shows an example of a battery module loading pack as an embodiment of the flame-resistant laminated molded product according to the present invention.

- the battery module loading pack 5 in which the plurality of battery modules 6 are housed is composed of the flame-resistant laminated molded body 7 according to the present invention, which is made of the fiber sheet material and the thermoplastic resin C as described above.

- Non-molten fiber A ⁇ Flame resistant thread> A 7dtex flame-resistant fiber PYRON (registered trademark) manufactured by Zoltek was cut to 51 mm and used. When heated by a method conforming to JIS K7193 (2010), no ignition was observed even at 1000 ° C, and the ignition temperature was 1000 ° C or higher. The thermal conductivity was 0.042 W / m ⁇ K.

- Thermoplastic fiber B ⁇ Drawing yarn of PPS fiber>

- As the stretched PPS fiber a single fiber fineness of 2.2 dtex (diameter 14 ⁇ m), a cut length of 51 mm, “torque converter” manufactured by Toray Industries, Inc. (registered trademark), and product number S371 were used.

- the LOI value of this PPS fiber was 34.

- the ratio of sulfur atoms in the fiber was 26.2% by weight.

- the LOI value of this PPS resin was 47.

- a molded body was obtained using a glass fiber reinforced polyamide 6 resin (“Amilan” (registered trademark) product number CM1011G-30B2 manufactured by Toray Industries, Inc.).

- the LOI value of this polyamide resin was 24.

- a strip-shaped flat plate having a length of 80 mm, a width of 20 mm, and a thickness of 3 mm was also produced by cutting from the flat plate.

- the conditions of the simple tabletop hot presser are set to 320 ° C., which is also the injection molding temperature of PPS, and after pressurizing and preheating at a gauge pressure of 10 kN for 30 seconds, the pressurization of the simple tabletop hot presser is released, and then the glass fiber reinforced PPS resin.

- a square fiber sheet material having a length of 80 mm and a width of 80 mm is placed on a flat plate (a flat plate having a length of 80 mm, a width of 80 mm, and a thickness of 3 mm), and the pressure is applied again at a gauge pressure of 10 kN for 30 seconds to integrate them.

- a hot press joining method for evaluating flame resistance having a thickness of 3 mm, which is obtained by superimposing a fiber sheet material (1) having a length of 80 mm and a width of 80 mm and a thermoplastic resin C (2).

- a test piece of the flame-resistant laminated molded product of No. 1 was obtained. Under the same conditions, as shown in FIG.

- a glass fiber reinforced PPS resin flat plate (a strip-shaped flat plate having a length of 80 mm, a width of 20 mm, and a thickness of 3 mm) [thermoplastic resin C (4)] and a strip having a length of 80 mm and a width of 20 mm.

- thermoplastic resin C (4) thermoplastic resin C (4)

- a test piece for measuring the joint strength in a strip-shaped flame-resistant laminated molded body having a length of 150 mm and a width of 20 mm was obtained by overlapping each end of the fiber sheet material 3 having a shape by 10 mm and integrating them.

- Example 1 As the fiber sheet material, a non-woven fabric having a weight mixing ratio of 60:40 of the drawn yarn of PPS fiber and the flame-resistant yarn was obtained. The basis weight was 100 g / m 2 and the thickness was 1.21 mm.

- the obtained non-woven fabric and the glass fiber reinforced PPS resin were integrated by a hot press joining method to obtain a flame-resistant laminated molded product.

- the obtained flame-resistant laminated molded product has a fused phase-bonded layer thickness of 70 ⁇ m, a bonding strength of 4.3 kg / cm 2 in the tensile test, and a fracture form after the tensile test, which is good as the fracture of the base material of the non-woven fabric. It was a good result.

- Example 2 The weight mixing ratio of the drawn yarn of the PPS fiber of the non-woven fabric of Example 1 and the flame-resistant yarn was changed to 90:10 to obtain a non-woven fabric having a basis weight of 100 g / m 2 and a thickness of 1.53 mm.

- the obtained non-woven fabric and the glass fiber reinforced PPS resin were integrated by a hot press joining method in the same manner as in Example 1 to obtain a flame-resistant laminated molded product.

- the obtained flame-resistant laminated molded product had a fused phase-bonded layer thickness of 67 ⁇ m, a bonding strength of 3.9 kg / cm 2 in a tensile test, and a fracture form of fracture of the base material of the non-woven fabric, which were good results. It was.

- Example 3 The weight mixing ratio of the drawn yarn of the PPS fiber of the non-woven fabric of Example 1 and the flame-resistant yarn was changed to 10:90 to obtain a non-woven fabric having a basis weight of 100 g / m 2 and a thickness of 1.63 mm.

- the obtained non-woven fabric and the glass fiber reinforced PPS resin were integrated by a hot press joining method in the same manner as in Example 1 to obtain a flame-resistant laminated molded product.

- the thickness of the fused phase-bonded layer was 33 ⁇ m

- the bonding strength in the tensile test was 2.3 kg / cm 2

- the fracture form was the fracture of the base material of the non-woven fabric, which was a good result.

- Example 4 As the fiber sheet material of Example 1, carbon fiber (“Treca” (registered trademark) manufactured by Toray Industries, Inc. with a diameter of 30 microns) cut to 51 mm instead of flame-resistant yarn (thermal conductivity 8.4 W / m. Using K)), the ratio of the stretched PPS fibers to the carbon fibers was set to 60:40, and a non-woven fabric having a grain size of 100 g / m 2 and a thickness of 1.89 mm was obtained. The obtained non-woven fabric and the glass fiber reinforced PPS resin were integrated by a hot press joining method in the same manner as in Example 1 to obtain a laminated molded product.

- the thickness of the fused phase-bonded layer of the obtained laminated molded product was 26 ⁇ m, the bonding strength in the tensile test was 4.0 kg / cm 2 , and the fracture form was the fracture of the base material of the non-woven fabric, which were good results.

- the flame resistance test there was neither flame penetration nor ignition of the glass fiber reinforced PPS resin, but the maximum temperature at the center of the glass fiber reinforced PPS resin surface on the anti-flame side was 270 ° C. Significant carbonization and foaming were observed on the surface layer of the fiber sheet material on the flame contact side, the anti-flame side, and the bonding interface after the flame contact, and the deformation of the laminated molded product was 20 mm or more.

- Example 5 A flame-resistant laminated molded product was obtained by using a glass fiber-reinforced flame-retardant PBT resin (“Trecon” (registered trademark), product number 1184G-A30N, manufactured by Toray Industries, Inc.) instead of the glass fiber-reinforced PPS resin of Example 1.

- the LOI value of this PBT resin was 32.

- the injection molding temperature conditions at the time of manufacturing the laminated molded body were changed to a cylinder temperature of 260 ° C. and a mold temperature of 80 ° C.

- the temperature condition at the time of hot pressing was changed to 260 ° C., and the other conditions were the same as in Example 1.

- the thickness of the fused phase-bonded layer was 0 ⁇ m, and the non-woven fabric was only impregnated with the resin.

- the joint strength in the tensile test was 1.5 kg / cm 2 , and the fracture form was joint interface fracture.

- the flame did not penetrate in the flame resistance test, the flame ignited in the glass fiber reinforced flame-retardant PBT resin portion on the end face of the laminated molded body, but the fire was extinguished after the flame contact was completed.

- the maximum temperature at the center of the glass fiber reinforced flame-retardant PBT resin surface on the anti-flame side was 190 ° C.

- the surface layer of the fiber sheet material on the flame contact side after the flame contact was only carbonized, but a distortion deformation with a height of about 1 mm was observed on the anti-flame contact side.

- the fiber sheet material on the flame contact side after flame contact has only the surface layer carbonized, and there is no significant deformation or major change in appearance on the anti-flame side and the joint interface, and it has sufficient flame insulation and flame resistance. Was there.

- Example 6 As the fiber sheet material of Example 1, a non-woven fabric having a basis weight of 100 g / m 2 and a thickness of 2.02 mm was obtained using 100% flame-resistant yarn. The obtained non-woven fabric and the glass fiber reinforced PPS resin were integrated by a hot press joining method in the same manner as in Example 1 to obtain a laminated molded product. In the obtained flame-resistant laminated molded product, the thickness of the fused phase-bonded layer was 0 ⁇ m, and the non-woven fabric was only impregnated with the resin. The joint strength in the tensile test was 1.5 kg / cm 2 , and the fracture form was joint interface fracture.

- a laminated molded body was obtained by using a glass fiber reinforced polyamide 6 resin (“Amilan” (registered trademark) product number CM1011G-30B2 manufactured by Toray Industries, Inc.) instead of the glass fiber reinforced PPS resin of Example 1.

- the LOI value of this polyamide resin was 24.

- the injection molding temperature conditions at the time of manufacturing the laminated molded body were changed to a cylinder temperature of 260 ° C. and a mold temperature of 80 ° C.

- the temperature condition at the time of hot pressing was changed to 260 ° C., and the other conditions were the same as in Example 1.

- the thickness of the fused phase-bonded layer of the obtained laminated molded product was 0 ⁇ m, and the non-woven fabric was only impregnated with the resin.

- the joint strength in the tensile test was 1.3 kg / cm 2 , and the fracture form was joint interface fracture.

- the maximum temperature at the center of the glass fiber reinforced polyamide 6 resin surface on the anti-flame side was 198 ° C.

- the surface layer of the fiber sheet material on the flame contact side after the flame contact was only carbonized, but a distortion deformation with a height of about 1 mm was observed on the anti-flame contact side.

- the flame-resistant laminated molded product according to the present invention is excellent in its high flame-shielding property and flame resistance even when the fiber sheet material side comes into contact with a flame, so that its shape and characteristics can be maintained. It is applied to the fields of housing, aircraft, automobiles, etc. In particular, it can be suitably used for a battery module loading pack that is mounted on an xEV automobile and has a flame resistance standard set by national regulations from the viewpoint of safety.

Landscapes

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Laminated Bodies (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202080062690.7A CN114340888B (zh) | 2019-10-10 | 2020-10-02 | 耐燃性叠层成型体 |

| KR1020227001090A KR20220075303A (ko) | 2019-10-10 | 2020-10-02 | 내염성 적층 성형체 |

| EP20873817.9A EP4043211A4 (en) | 2019-10-10 | 2020-10-02 | Flame-resistant layered molded article |

| JP2020555075A JP7635551B2 (ja) | 2019-10-10 | 2020-10-02 | 耐炎性積層成形体 |

| US17/631,217 US12304183B2 (en) | 2019-10-10 | 2020-10-02 | Flame-resistant layered molded article |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019-186739 | 2019-10-10 | ||

| JP2019186739 | 2019-10-10 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021070747A1 true WO2021070747A1 (ja) | 2021-04-15 |

Family

ID=75438176

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/037565 Ceased WO2021070747A1 (ja) | 2019-10-10 | 2020-10-02 | 耐炎性積層成形体 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US12304183B2 (enExample) |

| EP (1) | EP4043211A4 (enExample) |

| JP (1) | JP7635551B2 (enExample) |

| KR (1) | KR20220075303A (enExample) |

| CN (1) | CN114340888B (enExample) |

| WO (1) | WO2021070747A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116512701A (zh) * | 2022-01-31 | 2023-08-01 | 揖斐电株式会社 | 防火构造体及其制造方法、以及电池模块 |

| WO2024142544A1 (ja) * | 2022-12-28 | 2024-07-04 | 積水化学工業株式会社 | 積層体 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115507960B (zh) * | 2022-10-21 | 2023-05-02 | 深圳职业技术学院 | 一种车库内电动汽车火灾测量装置 |

| EP4610043A1 (en) * | 2024-02-29 | 2025-09-03 | Mitsubishi Chemical Advanced Materials GmbH | Heat and fire shielding thermoplastic composite |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0396341A (ja) * | 1989-09-11 | 1991-04-22 | Toray Ind Inc | 積層体 |

| JP2000008260A (ja) * | 1998-06-16 | 2000-01-11 | Asahi Chem Ind Co Ltd | 吸音材 |

| JP2013169996A (ja) | 2012-02-22 | 2013-09-02 | Japan Vilene Co Ltd | 難燃性繊維シート |

| WO2017006807A1 (ja) | 2015-07-03 | 2017-01-12 | 東レ株式会社 | 遮炎性不織布 |

| JP2017114107A (ja) * | 2015-05-20 | 2017-06-29 | 王子ホールディングス株式会社 | 繊維強化プラスチック成形体及び繊維強化プラスチック成形体用基材 |

| WO2019188276A1 (ja) * | 2018-03-30 | 2019-10-03 | 東レ株式会社 | 不織布シート |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5024877A (en) * | 1989-04-14 | 1991-06-18 | The Dow Chemical Company | Fire resistant materials |

| EP1787807A4 (en) * | 2004-06-25 | 2010-07-07 | Kureha Corp | MULTILAYER SURFACE OF POLYGLYCOLIC ACID RESIN |

| JP2016190355A (ja) * | 2015-03-31 | 2016-11-10 | 三菱レイヨン株式会社 | 積層基材 |

| CN107735450B (zh) | 2015-07-06 | 2020-08-11 | 三菱瓦斯化学株式会社 | 树脂组合物、预浸料、树脂片、覆金属箔层叠板及印刷电路板 |

| WO2018043360A1 (ja) * | 2016-08-31 | 2018-03-08 | 帝人株式会社 | 積層体および繊維強化樹脂複合体の製造方法 |

| US11248319B2 (en) * | 2016-10-05 | 2022-02-15 | Toray Industries, Inc. | Flame-resistant woven fabric |

-

2020

- 2020-10-02 US US17/631,217 patent/US12304183B2/en active Active

- 2020-10-02 EP EP20873817.9A patent/EP4043211A4/en active Pending

- 2020-10-02 KR KR1020227001090A patent/KR20220075303A/ko active Pending

- 2020-10-02 WO PCT/JP2020/037565 patent/WO2021070747A1/ja not_active Ceased

- 2020-10-02 JP JP2020555075A patent/JP7635551B2/ja active Active

- 2020-10-02 CN CN202080062690.7A patent/CN114340888B/zh active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0396341A (ja) * | 1989-09-11 | 1991-04-22 | Toray Ind Inc | 積層体 |

| JP2000008260A (ja) * | 1998-06-16 | 2000-01-11 | Asahi Chem Ind Co Ltd | 吸音材 |

| JP2013169996A (ja) | 2012-02-22 | 2013-09-02 | Japan Vilene Co Ltd | 難燃性繊維シート |

| JP2017114107A (ja) * | 2015-05-20 | 2017-06-29 | 王子ホールディングス株式会社 | 繊維強化プラスチック成形体及び繊維強化プラスチック成形体用基材 |

| WO2017006807A1 (ja) | 2015-07-03 | 2017-01-12 | 東レ株式会社 | 遮炎性不織布 |

| WO2019188276A1 (ja) * | 2018-03-30 | 2019-10-03 | 東レ株式会社 | 不織布シート |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP4043211A4 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116512701A (zh) * | 2022-01-31 | 2023-08-01 | 揖斐电株式会社 | 防火构造体及其制造方法、以及电池模块 |

| WO2024142544A1 (ja) * | 2022-12-28 | 2024-07-04 | 積水化学工業株式会社 | 積層体 |

Also Published As

| Publication number | Publication date |

|---|---|

| US12304183B2 (en) | 2025-05-20 |

| CN114340888B (zh) | 2024-10-29 |

| KR20220075303A (ko) | 2022-06-08 |

| EP4043211A1 (en) | 2022-08-17 |

| JPWO2021070747A1 (enExample) | 2021-04-15 |

| US20220266578A1 (en) | 2022-08-25 |

| EP4043211A4 (en) | 2023-11-15 |

| CN114340888A (zh) | 2022-04-12 |

| JP7635551B2 (ja) | 2025-02-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2021070747A1 (ja) | 耐炎性積層成形体 | |

| TWI700186B (zh) | 擋火性不織布 | |

| EP3218119B1 (en) | Prepregs, cores and composite articles including expandable graphite materials | |

| EP0472388B1 (en) | Improved batting thermal insulation with fire resistant properties | |

| JP7036006B2 (ja) | 遮炎性織物 | |

| KR20100012674A (ko) | 방염성 원단 제조방법 및 이에 따른 방염성 원단 | |

| KR20200138186A (ko) | 부직포 시트 | |

| JP7172998B2 (ja) | 不織布 | |

| CN116615585A (zh) | 一种防火遮焰无纺布 | |

| US20200392657A1 (en) | Non woven fabric | |

| JP6439487B2 (ja) | 繊維強化プラスチック成形体用基材及び繊維強化プラスチック成形体 | |

| JP7740598B1 (ja) | シートおよびそれを用いた耐火材、二次電池 | |

| JP4827784B2 (ja) | 断熱材及びその製造方法 | |

| JP2007113158A (ja) | 耐熱性不織布 | |

| TW201500211A (zh) | 具防水、阻燃及高強度之瓦楞紙的製造方法 | |

| WO2025258497A1 (ja) | 遮炎断熱材 | |

| JPWO2019188277A1 (ja) | カーペット | |

| US20230122153A1 (en) | Fire retardant fiber preform and fire retardant vehicle component | |

| JP2019173225A (ja) | 不織布 | |

| KR20140002337A (ko) | 극저온에서 충격방지특성이 우수한 불연성 단열재 및 그 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2020555075 Country of ref document: JP Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20873817 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2020873817 Country of ref document: EP Effective date: 20220510 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 17631217 Country of ref document: US |