WO2021065599A1 - 吸収性物品 - Google Patents

吸収性物品 Download PDFInfo

- Publication number

- WO2021065599A1 WO2021065599A1 PCT/JP2020/035729 JP2020035729W WO2021065599A1 WO 2021065599 A1 WO2021065599 A1 WO 2021065599A1 JP 2020035729 W JP2020035729 W JP 2020035729W WO 2021065599 A1 WO2021065599 A1 WO 2021065599A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- seal

- seal portion

- absorbent article

- width direction

- exterior body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies

- A61F13/496—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape specially adapted to be worn around the waist, e.g. diapers, nappies in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

Definitions

- the present invention relates to a pants-type disposable diaper absorbent article.

- Absorbent items such as pants-type disposable diapers are intended to be worn by wearers who have difficulty in going to the toilet and excreting by themselves, for example.

- the absorbent article needs to make it easier for the caregiver to wear the absorbent article to the wearer at the time of wearing, and also to make it easier for the wearing wearer to move.

- this absorbent article has been designed so that the caregiver can easily make the wearer wear the absorbent article by providing an elastic member at the waist opening and the leg opening, and also has followability. It is designed to make it easier for the wearer to move.

- the caregiver will take off the absorbent article while the wearer is standing or lying down.

- the caregiver can easily remove the absorbent article from the wearer by tearing it up and down along the side seal portion of the absorbent article.

- the part to be torn is designed to be torn relatively easily (Patent Documents 1 to 3).

- Patent Document 1 describes the pants-type disposable diaper, which is located inside the side seal portion in the width direction, extends along the side seal portion, and has a breaking strength along the side seal portion of the exterior body.

- the invention discloses an invention including an easily broken portion that is reduced from the portion and is breakable along the side seal portion.

- this invention has the following problems. When the caregiver causes the wearer to wear the absorbent article or when the wearer performs daily movements, stress is likely to be applied to the vicinity of the side seal portion. In the case of an absorbent article having an easily broken portion in the side seal portion, this stress may cause the easily broken portion to break unexpectedly.

- Patent Document 3 discloses a pants-type disposable diaper having first to third seal patterns on the side seal portion.

- the first seal pattern is on the proximal end side with respect to the center in the width direction of the main body

- the second seal pattern is on the distal end side with respect to the center in the width direction of the main body

- the third seal pattern is with the first seal pattern.

- Each is located between the second seal patterns.

- the caregiver grasps the ventral and dorsal exteriors near the side seal with both hands and keeps both the ventral and dorsal exteriors away. By pulling in this way, the side seal portion is peeled off from the ventral exterior body and the dorsal exterior body and broken, and the main body is removed from the wearer.

- JP-A-2018-139718 Japanese Unexamined Patent Publication No. 2019-22602 Japanese Unexamined Patent Publication No. 2018-183486

- a main object of the present invention is to provide an absorbent article in which the seal pattern portion is difficult to tear when worn and easily torn along the inner end portion of the seal pattern when removed.

- the absorbent articles that have solved the above problems are as follows. ⁇ First aspect> It has an interior body, a ventral exterior body located at one end in the longitudinal direction of the interior body, and a dorsal exterior body located at the other end. It has a pair of side seal portions in which both side portions in the width direction of the ventral exterior body and both side portions in the width direction of the dorsal exterior body are superposed and welded. A leg opening formed by the ventral exterior body, the dorsal exterior body, and the interior body is provided at one end of the side seal portion in a direction orthogonal to the width direction.

- the side seal portions have a first seal pattern in which a plurality of horizontally long linear first seal portions are arranged at predetermined intervals in a direction orthogonal to the width direction, and a second seal portion at each of the predetermined intervals.

- the first seal portion and the second seal portion are separated from each other in a direction orthogonal to the width direction.

- Absorbent article characterized by that.

- the side seal portions arranged in the direction orthogonal to the width direction (vertical direction) of the absorbent article have a first seal pattern and a second seal pattern in which a plurality of horizontally elongated linear seal portions are arranged.

- the caregiver grasps each of the dorsal exterior body and the ventral exterior body near the side seal portion in the waist opening with the left and right hands, and the side seal portion is held on both sides in the width direction (that is, in the positive direction and the negative direction).

- the exterior body is torn inside the first seal pattern and the second seal pattern.

- the external force applied to the side seal part at this time is the external force applied when removing it.

- the side seals are not easily torn.

- the second seal pattern is located closer to the center than the inner end in the width direction in the first seal pattern and the first seal portion and the second seal portion are separated from each other, the inner end portion in the seal pattern is on the side. The seal portion is unintentionally made continuous and difficult to tear.

- ⁇ Second aspect> The ratio of the length of the predetermined interval between the first seal portions to the length of the second seal portion in the direction orthogonal to the width direction is 1.5: 1.0 to 3.0: 1.0. is there, The absorbent article of the first aspect.

- Each of the second seal portions has a vertically long linear shape.

- the welded second seal portion has a vertically long linear shape, the exterior body is guided to tear along the seal portion, so that when the absorbent article is to be torn, the side seal portion is torn in the vertical direction. It will be easier.

- Each of the second seal portions on the leg opening side of the second seal pattern is located at the center portion in the width direction of the first seal pattern.

- the shape of the side seal portion on the leg opening side changes according to the movement of the base of the wearer's leg. Due to this change, the opening side of the same leg receives an external force.

- the second seal portion on the leg opening side is located at the central portion in the first seal pattern, the longitudinal end edge of the second seal portion and the first seal pattern in the first seal pattern closest to the end edge thereof. The distance from the inner end of the seal portion is relatively long. Then, the external force from the same end edge to the same inner end becomes relatively difficult to be transmitted. Therefore, even if the wearer freely moves the base of the leg, the first and second seal portions on the leg opening side of the side seal portion are not easily torn when worn.

- the distance N1 between this one end and the inner end of the first seal pattern closest to the one end, and the other end and the other end are the closest.

- the length is different from the distance N2 from the inner end of the first seal pattern that is close to each other. If the distance N1 is longer than the distance N2, it becomes relatively difficult for the external force to be transmitted between the distances N1. Therefore, even if the wearer freely moves the base of the leg, the first and second seal portions on the leg opening side of the side seal portion are not easily torn.

- Each of the second seal portions on the leg opening side of the second seal pattern has a vertically long broken line shape.

- this second seal portion Since this second seal portion has a vertically long broken line shape, there is a gap between the solid lines adjacent to each other in the vertical direction. Breaking along this interval requires a stronger external force than breaking along the solid line.

- the length of the first seal portion in the longitudinal direction is 2.0 to 5.0 mm.

- the ratio of the longitudinal length of the first seal portion to the longitudinal length of the second seal portion is 1.0: 0.1 to 1.0: 0.5.

- the inner end portion of the seal pattern is less likely to tear when worn, and the absorbent article can be torn along the inner end portion when removed.

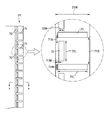

- FIG. 7 is a cross-sectional view taken along the line xx of FIG. It is sectional drawing of the pants type disposable diaper after tearing the side seal part.

- a pants-type disposable diaper as an example of an absorbent article will be described in detail with reference to the attached drawings.

- the dotted pattern portion in the figure indicates a joining means such as a hot melt adhesive.

- FIGS. 1 to 6 and 11 show pants-type disposable diapers.

- This pants-type disposable diaper (hereinafter, also simply referred to as a diaper) has an exterior body 20 extending from the front body F and the back body B, and an interior body fixed to the inner surface of the exterior body 20 so as to extend from the front body F to the back body B.

- the interior body 10 is formed by interposing an absorber 18 between the liquid-permeable top sheet 11 and the liquid-impermeable sheet 12.

- the back surface of the interior body 10 is joined to the inner surface (upper surface) of the exterior body 20 by a joining means such as hot melt adhesive (dot pattern portion in FIG. 2), and then the interior body 10 and the exterior body 20 are joined.

- a pants-type disposable diaper with a waist opening and a pair of left and right leg openings.

- the interior body 10 has a structure in which an absorber 18 is interposed between the top sheet 11 and the liquid-impermeable sheet 12, and the interior body 10 is transmitted through the top sheet 11.

- the excrement liquid is absorbed and held by the absorber 18.

- the planar shape of the interior body 10 is not particularly limited, but it is generally a substantially rectangular shape as shown in the illustrated form.

- a perforated or non-perforated non-woven fabric, a porous plastic sheet, or the like is preferably used as the top sheet 11 that covers the front side (skin contact surface side) of the absorber 18.

- the material fibers constituting the non-woven fabric can be olefin-based fibers such as polyethylene or polypropylene, synthetic fibers such as polyester-based and polyamide-based, recycled fibers such as rayon and cupra, and natural fibers such as cotton.

- a non-woven fabric obtained by an appropriate processing method such as a spun bond method, a thermal bond method, a melt blown method, or a needle punch method can be used.

- the spunlace method is excellent in that it is rich in flexibility and drapeability, and the thermal bond method is excellent in that it is bulky and soft.

- urine or the like is rapidly absorbed.

- the top sheet 11 extends to the back side of the absorber 18 by involving the side edge portion of the absorber 18.

- a liquid-impermeable plastic sheet such as polyethylene or polypropylene is used as the liquid-impermeable sheet 12 that covers the back side (non-skin contact surface side) of the absorber 18, but in recent years, it has moisture permeability from the viewpoint of preventing stuffiness. Those are preferably used.

- the water-impervious / moisture-permeable sheet can be obtained by melting and kneading inorganic fine particles such as calcium carbonate in an olefin resin such as polyethylene or polypropylene to form a sheet, and then stretching the sheet in the uniaxial or biaxial direction.

- a microporous sheet can be preferably used.

- the liquid-impermeable sheet 12 is folded back on both sides in the width direction of the absorber 18 together with the top sheet 11, but the structure is not limited to this, and other known structures may be adopted. Can be done.

- the three-dimensional gather BS has a fixed portion fixed to the side portion of the back surface of the interior body 10, and the side surface of the interior body from the fixed portion via the side of the interior body.

- the main body extending to the portion, the inverted portion formed by fixing the front and rear ends of the main body to the side portion of the surface of the interior body in the inverted state, and the portion of the inverted portion formed as non-fixed.

- the free portion is formed by a gather sheet 15 which is made into a double sheet by folding back, and an elongated gather elastic member 16 is arranged at the tip of the free portion or the like between the double sheets.

- the free portion protruding from the side edge portion of the absorber due to the contraction of the gather elastic member 16 rises in the product state as shown by the alternate long and short dash line in FIG.

- a non-woven fabric having water repellency is preferably used as the gather sheet 15.

- the gather elastic member 16 materials such as styrene rubber, olefin rubber, urethane rubber, ester rubber, polyurethane, polyethylene, polystyrene, styrene butadiene, silicone, and polyester, which are usually used, can be used. Further, in order to make it difficult to see from the outside, it is preferable to arrange the thickness at 925 dtex or less, the tension at 150 to 350%, and the interval at 7.0 mm or less. As the gather elastic member 16, a tape-shaped member having a certain width may be used in addition to the thread-shaped member as shown in the illustrated figure.

- the material fibers constituting the gather sheet 15 are synthetic fibers such as olefins such as polyethylene and polypropylene, polyesters and polyamides, recycled fibers such as rayon and cupra, and natural fibers such as cotton. It can be a fiber, and a non-woven fabric obtained by an appropriate processing method such as a spun bond method, a thermal bond method, a melt blown method, or a needle punch method can be used. It is better to use a non-woven fabric that suppresses and has excellent breathability.

- a silicone-based, paraffin metal-based, alkylchromic chloride-based water repellent etc. It is desirable to use a water-repellent treated non-woven fabric coated with.

- the exterior body 20 has a two-layer structure composed of a pressing sheet 20A made of a non-woven fabric or the like and a back sheet 20B, respectively, and is between the pressing sheet 20A and the back sheet 20B and the back.

- Elastic members 24 to 28 are arranged between the sheets of the folded portion 20C formed by folding the sheet 20B to the inner surface side at the edge of the waist opening, and the exterior body 20 contracts due to the contraction force of the elastic member in the natural length state. Elasticity is imparted to the exterior body 20.

- the planar shape is substantially an hourglass shape as a whole due to the concave leg circumference lines 29 formed to form leg openings on both sides of the middle.

- the waist elastic member 24 arranged in the vicinity of the waist opening 23, and the front body F and the back body B in the vertical direction. It has a plurality of lower waist elastic members 25 arranged along the width direction at intervals, and one side of each of the front body F and the rear body B, apart from the group of the lower waist elastic members 25. Crossing each other, curving and extending from the seal 21 to the crotch along one leg opening, across the crotch, and along the other leg opening to the other side seal 21. It includes a plurality of curved elastic members 26, 28 that are arranged at intervals without any problem.

- These elastic members 24 to 28 are fixed in a state of being extended at a predetermined extension rate along the extending direction thereof.

- the exterior body 20 is not provided with an elastic member that is continuous from the side seal portion of the front body F to the side seal portion of the rear body B along the leg circumference line 29.

- the waist elastic member 24 includes a plurality of thread rubbers and the like arranged at intervals in the vertical direction in the vicinity of the edge of the waist opening within the range of the side seal portion 21 in which the front body F and the back body B are joined. It is an elongated elastic member of the above, and is for attaching a diaper to the body by applying an elastic force so as to tighten the circumference of the body.

- thread rubber is used for the waist elastic member 24 in the illustrated example, for example, a tape-shaped elastic member may be used.

- the waist elastic member 24 of the illustrated form is sandwiched between the non-woven fabrics of the folded portion 20C of the back sheet 20B at the waist portion, it may be sandwiched between the pressing sheet 20A and the back sheet 20B.

- the waist lower elastic member 25 is an elongated elastic member such as a rubber thread arranged at intervals in the vertical direction in a range in the front-rear direction having a side seal portion 21, and is a waist of a front body F and a back body B.

- the purpose is to give elastic force in the width direction to the surrounding parts to bring the diaper into close contact with the body.

- the boundary between the waist elastic member 24 and the waist lower elastic member 25 does not necessarily have to be clear. For example, among the elastic members arranged in the width direction at intervals in the vertical direction on the front body F and the back body B, some of the elastic members on the upper side function as waist elastic members even if the number cannot be specified. It suffices that the remaining elastic member functions as the elastic member below the waist.

- the dorsal curved elastic member 26 arranged separately from the waist lower elastic member 25 is an elongated elastic member such as rubber thread, and is arranged along a predetermined curve.

- the dorsal curved elastic member 26 may be one, but is preferably a plurality, and in the illustrated example, it is an elongated elastic member such as four rubber threads, and these dorsal curved elastic members 26 are They are spaced apart from each other without intersecting each other.

- the dorsal curved elastic member 26 is not substantially arranged as a bundle with a few elastic members closely spaced, but is preferably 3 to 20 mm so as to form a predetermined expansion / contraction zone. 3 or more, preferably 4 or more, are arranged at intervals of about 6 to 16 mm.

- the ventral curved elastic member 28 arranged separately from the waist lower elastic member 25 is an elongated elastic member such as rubber thread, and is arranged along a predetermined curve. ..

- the ventral curved elastic member 28 may be one, but is preferably a plurality, and in the illustrated example, there are four filamentous elastic members, and these ventral curved elastic members 28 do not intersect with each other. , Are placed at intervals.

- the ventral curved elastic member 28 is not substantially arranged as a bundle with a few elastic members closely spaced, but is preferably 3 to 20 mm so as to form a predetermined expansion / contraction zone. 3 or more, preferably 4 or more, are arranged at intervals of about 6 to 16 mm.

- the waist lower elastic members 25 and the curved elastic members 26 and 28 arranged on the front body F and the rear body B are absorbed after being continuously fixed to the exterior body 20 at the time of manufacture.

- the middle part in the width direction (the part surrounded by the alternate long and short dash line in the figure) of the part overlapping the body 18 is finely cut with a predetermined cutting pattern to form a non-shrinkable part on which no contraction force acts, and the side of the non-shrinkable part.

- the portion extending in the direction can be a contraction portion on which a contraction force acts (that is, a portion in which the waist lower elastic member 25 and the curved elastic members 26 and 28 are continuously left). This makes it possible to prevent unnecessary shrinkage of the interior body (particularly the absorber 18) in the width direction.

- the waist lower elastic members 25 and the curved elastic members 26 and 28 can be continuously arranged across the interior body 10.

- the exterior body 20 described above can be manufactured by, for example, the techniques described in JP-A-4-28363 and JP-A-11-332913. Further, in order to cut the curved elastic members 26 and 28 on the interior body 10 to make them discontinuous, it is described in JP-A-2002-35029, JP-A-2002-178428 and JP-A-2002-273808. The cutting method is preferably adopted.

- the curved elastic members 26 and 28 may be provided only on either the front body F or the back body B.

- the curved elastic members 26 and 28 are provided on both the front body F and the rear body B, a part or all of the group of the curved elastic members 28 arranged on the front body F side and the rear body B side are arranged.

- a form (not shown) in which a part or all of the group of the curved elastic members 26 intersects with each other can be adopted, but as shown in the illustrated example, the group of the curved elastic members 28 arranged on the front body F side and the group of the curved elastic members 28 are used. It is preferable that the group of the curved elastic members 26 arranged on the back body B side is separated from each other in the vertical direction at a position slightly deviated to the front-rear intermediate portion, particularly the front body F, without intersecting with each other.

- the elongation rate of the elastic members 24 to 28 at the time of fixing can be appropriately determined, but in the case of a normal adult, the waist elastic member 24 is about 160 to 320%, the waist lower elastic member 25 is about 160 to 320%, and is curved.

- the elastic members 26 and 28 can be about 230 to 320%.

- the cover sheet 50 is used to cover the front and rear ends of the interior body 10 mounted on the inner surface of the exterior body 20 and to prevent leakage from the front and rear edges of the interior body 10. , 60 may be provided.

- the front cover sheet 50 extends over the entire width direction from the inner surface of the folded portion 20C of the waist side end portion of the inner surface of the front body F to the position where it overlaps with the front end portion of the interior body 10.

- the rear cover sheet 60 extends over the entire width direction from the inner surface of the folded portion 20C of the waist side end portion of the inner surface of the rear body B to the position where it overlaps with the rear end portion of the interior body 10. It is also possible to extend the folded portion 20C formed by folding the outer body 20 to the inner surface of the diaper to a portion overlapping the inner body 10 to form a portion equivalent to the cover sheets 50 and 60 of the illustrated example.

- the absorber 18 may have a single-layer structure or a multi-layer structure.

- the absorber 18 is a member containing the highly absorbent polymer particles, and is preferably a mixed aggregate of pulp fibers and the highly absorbent polymer particles.

- the absorber 18 may be wrapped with a liquid-permeable and liquid-retaining packaging sheet 14 such as crepe paper for shape, polymer retention, and the like.

- those used for this kind of absorbent article can be used as they are.

- they are sieved by sieving (shaking for 5 minutes) using a standard sieve (JIS Z8801-1: 2006) of 500 ⁇ m. It is desirable that the proportion of particles remaining on the sieve is 30% by weight or less, and the proportion of particles remaining on the sieve is determined by sieving (shaking for 5 minutes) using a standard sieve of 180 ⁇ m (JIS Z8801-1: 2006). 60% by weight or more is desirable.

- the highly absorbent polymer particles are not particularly limited, but those having a water absorption rate of 35 to 60 seconds and a water absorption amount of 50 to 70 g / g can be preferably used.

- Highly absorbent polymer particles include starch-based, cellulosic-based and synthetic polymer-based ones, which are starch-acrylic acid (salt) graft copolymers, saponified starch-acrylonitrile copolymers, and crosslinked sodium carboxymethyl cellulose.

- a product, an acrylic acid (salt) polymer, or the like can be preferably used.

- the basis weight of the highly absorbent polymer particles can be appropriately determined according to the amount of absorption required for the product. Therefore, although it cannot be said unconditionally, it can be set to 100 to 350 g / m 2 .

- the shape of the absorber 18 can be appropriately determined and may be rectangular, but it is preferable that the crotch portion has a constricted portion 13 narrower than both the front and rear sides thereof.

- the size of the constricted portion 13 can be appropriately determined, but the width 13w of the narrowest portion can be about 40 to 60% of the total width of the absorber 18.

- the ventral side of the exterior body 20 extending over the front body F and the rear view B is the ventral exterior body

- the dorsal side is the dorsal exterior body

- both sides in the width direction of the ventral exterior body and the width direction of the dorsal exterior body.

- a pair of side seal portions 21 are formed by overlapping and welding the both side portions of the above.

- a leg opening is formed by the ventral exterior body, the dorsal exterior body, and the interior body at one end in the direction orthogonal to the width direction (vertical direction) of the side seal portion 21, and the ventral exterior body and the back are formed at the other end.

- a waist opening is formed with the side exterior body.

- the side seal portion 21 has a first seal pattern in which a plurality of horizontally long linear first seal portions 71 are arranged at predetermined intervals in the vertical direction, and a second seal portion 72 is arranged at each of the predetermined intervals. It has a second seal pattern, which is made of. Since the ventral exterior body and the dorsal exterior body are welded to the first seal portion 71 and the second seal portion 72, the welded side seal portion 21 is combined with the side seal portion on the ventral exterior body side and the dorsal exterior. It cannot be peeled off from the side seal on the body side.

- the side seal portion of Patent Document 2 a plurality of seal portions are arranged at intervals in the vertical direction, but when the side seal portions are to be split in the vertical direction in this form, the exterior body is, for example, in the width direction at the same interval. It may tear outwards, making it difficult to continue tearing thereafter.

- the side seal portion 21 shown below, as shown in FIG. 11, the side seal portion 21 is continuously torn from the waist opening to the leg opening, and the absorbent article can be easily removed.

- a caregiver grasps the vicinity of the side seal portion in each of the ventral exterior body and the dorsal exterior body provided with the side seal portion 21 with the right hand and the left hand, and external force is applied to the side seal portion 21 in a direction in which the right hand and the left hand are kept away from each other.

- the case of adding for example, the inside of the absorbent article in the first seal portion 71 in the width direction, then the inside of the absorbent article in the second seal portion 72 in the width direction, and further, the inside of the absorbent article in the first seal portion 71 in the width direction.

- the inside of the absorbent article in the second seal portion 72 is sequentially torn in the width direction, that is, the first seal portion 71 and the second seal portion 72 are torn in the vertical direction inside the absorbent article in the width direction. ..

- the inventor has found that such tearing is due to the fact that the vicinity of the welded portion is easily torn and the portion other than the vicinity of the welded portion is not easily torn.

- the width 21W of the side seal portion is, for example, 2.0 to 7.0 mm, more preferably 4.0 to 5.0 mm. If it is shorter than 2.0 mm, it is difficult to weld the ventral exterior body and the dorsal exterior body, and if it is longer than 7.0 mm, the side seal portion becomes bulky.

- the seal portion 71 of the first seal pattern may have a horizontally long linear shape

- the horizontally long linear shape includes, for example, a horizontally long rectangular shape, a horizontally long rectangular shape with rounded corners, and a horizontally long elliptical shape.

- the horizontally long linear shape also includes a shape in which a horizontally long rectangular shape, a horizontally long rectangular shape with rounded corners, and a horizontally long elliptical shape are formed at a plurality of intervals in the horizontal direction. It is preferable that the length 71L of the seal portion 71 in the longitudinal direction is 2.0 to 5.0 mm, and the length 71W in the lateral direction is 0.2 to 1.0 mm.

- the seal portion 72 of the second seal pattern may have a circular shape, a vertically long linear shape, a vertically long rectangular shape, a vertically long rectangular shape with rounded corners, and a vertically long elliptical shape. Further, a vertically long rectangular shape, a vertically long rectangular shape with rounded corners, a vertically long elliptical shape having a plurality of intervals in the vertical direction, and a vertically long broken line shape may be used. Further, the seal portion 72 of the second seal pattern may have a length 72L in the longitudinal direction of 0.5 to 1.5 mm and a length 72W in the lateral direction of 0.2 to 1.0 mm.

- the distance 71S between the seal portions 71 of the first seal pattern is 1.5 to 4.0 mm. If it exceeds 4.0 mm, there are many portions where the ventral exterior body and the dorsal exterior body are not welded, and the strength of the side seal portion 21 becomes low. If it is less than 1.5 mm, there are many welded portions and the side seal portion 21 becomes hard, which may impair the flexibility of the absorbent article.

- the distance 71N between the seal portion 71 of the first seal pattern and the seal portion 72 of the second seal pattern is preferably at least 0.5 mm or more. If it is less than 0.5 mm, the interval portion may be torn unexpectedly.

- the second seal pattern is located closer to the center than the inner edge in the width direction of the first seal pattern.

- the distance 71M between the inner end of the seal portion 71 of the first seal pattern and the inner end of the seal portion 72 of the second seal pattern may be 0.2 to 2.5 mm.

- the center side can be, for example, up to the outer end in the width direction in the middle portion when the first seal pattern is divided into three equal parts in the longitudinal direction.

- the absorbent article It is not preferable to wear the side seal portion 21 because the side seal portion 21 is easily torn along the inner end in the width direction of each of the first seal pattern and the second seal pattern.

- the ratio of the length 71S of the predetermined interval between the first seal portions 71 to the length 72L of the second seal portion 72 in the direction orthogonal to the width direction is 1.5: 1.0 to 3.0:

- the form of 1.0 is preferable because the side seal portion 21 is not continuously torn when the caregiver grabs the exterior body and slides the absorbent article to the crotch portion to wear it. Specifically, even if the seal portions 72 arranged at the distance between the two seal portions 71, 71 are biased toward one of the seal portions 71, 71, they are separated from the other seal portion 71, for example. Therefore, even if one of the side seal portions 21 is torn, the tear does not continue.

- the length 71L of the first seal 71 in the longitudinal direction is longer than the length 72L of the second seal portion 72 in the longitudinal direction.

- the ratio of the length 71L in the longitudinal direction of the first seal 71 to the length 72L in the longitudinal direction of the second seal portion 72 may be appropriately adjusted, and is, for example, 1.0: 0.1 to 1.0. : 0.5, more preferably 1.0: 0.2 to 1.0: 0.3. Further, it may be 7.5: 1 to 2.5: 1.

- the first seal length 71L and the second seal length 72L are about the same, for example, if the first seal length 71L is relatively long, the second seal length 72L is also relatively long.

- the strength of the side seal portion 21 is weakened. Further, for example, if the first seal length 71L is relatively short, the second seal length 72L is also relatively short, and the total area of the seal portions is small, so that the strength of the side seal portion 21 is weak. Become.

- the second seal portion 72 is formed by a method of heat welding or ultrasonic welding.

- the second seal portion 72 may be formed to be thinner than the vicinity of the seal portion (FIG. 10 (a)) or may have a through hole formed (FIG. 10 (b)). ..

- the thickness D1 of the seal portions 71 and 72 is, for example, 0.30 times or less of the thickness D2 in the vicinity of the seal portion, welding is strengthened and the seal portions 71 and 72 have high strength, which is preferable. ..

- each of the second seal portions 72 on the leg opening side of the second seal pattern is located at the center portion in the width direction in the first seal pattern

- the side seal portion 21 provided with each of the second seal portions 72 is provided. It is desirable because it is hard to tear by the wearer's daily movements while wearing it. Further, when the side seal portion 21 is torn when removing the absorbent article, since the second seal portion 72 is located at the central portion, for example, the exterior body exceeds the second seal portion 72 and goes outward in the width direction. There is no tearing, and as a result, the tearing continues in the vertical direction.

- the side seal portion 21, specifically, the first seal pattern and the second seal pattern are provided at both ends in the width direction of the exterior body from the waist opening to the leg opening.

- the leg opening side of the second seal pattern is, for example, a second seal portion 72 located at the most leg opening of the second seal pattern to 20 to 25 pieces in the waist opening direction. It can be said that the seal portion 72 group. Further, assuming that the leg opening side of the second seal pattern has a total length of 21G in the vertical direction of the side seal portion 21, 0 of the same total length of 21G upward from the lower end (leg opening) of the side seal portion 21. It can also be said that the second seal portion 72 group is in the range of .15 to 0.30 times the length.

- the leg opening side of the second seal pattern is from the leg opening in the side seal portion 21 to the lower end edge of the cover sheet 50. (That is, the range in which the cover sheet 50 of the exterior body 20 is not arranged) and the range from the leg opening to the lower edge of the cover sheet 60 (that is, the cover sheet 60 of the exterior body 20). It can also be a range that is not arranged).

- the thickness of the lower part of the ventral exterior body or the dorsal exterior body in the vertical direction is relatively thin, the thickness of the side seal portion 21 is relative to that of the leg opening side of the second seal pattern. It can also be a thin part.

- the lower part of the ventral exterior body or the dorsal exterior body in the vertical direction can be, for example, a portion where the cover sheet is not arranged.

- the strength of the side seal portion 21 where the cover sheets 50 and 60 are not arranged and the portion where the thickness of the exterior body is relatively thin is relatively low. Therefore, in order to prevent tearing when the absorbent article is worn, the second seal arranged in these portions may be positioned at the center in the width direction in the first seal pattern or slanted as described later. It is advisable not to reduce the strength as much as possible. If the seal portions 71 and 72 are too close to each other or overlap each other, the strength of the seal portions 71 and 72 becomes low, and when the absorbent article is worn, the first seal pattern and the second seal pattern are used. There is a risk of tearing along.

- the central portion in the width direction in the first seal pattern can be, for example, the middle portion of the first seal pattern divided into three equal parts in the longitudinal direction, or the central portion in the longitudinal direction of the first seal pattern divided into four equal parts. It can also be said that it is the part excluding both ends of the.

- the longitudinal direction of each of the second seal portions 72 on the leg opening side of the second seal pattern is oblique with respect to the longitudinal direction of the first seal portion.

- the angle ⁇ formed by the longitudinal direction of the first seal portion and the longitudinal direction of the second seal portion is 30 ° to 90 °, preferably 30 ° to 60 °, and more preferably 40 ° to 50 °. It is good.

- the side seal portion 21 when the side seal portion 21 is torn, the direction of tearing is guided to the diagonally arranged seal portion 72, and the absorbent article is further torn outward in the width direction, resulting in tearing.

- the side seal portion 21 may be cut off at the diagonally arranged seal portion 72.

- FIG. 8 a form in which the first seal portion has a horizontal broken line shape (FIG. 8 (c)) and a form in which the second seal portion has a vertical broken line shape (FIG. 8 (b)) can be disclosed.

- the vertical direction is the direction (vertical direction) indicated by the symbol VE in FIG. 3 in a pants-type disposable diaper in which a waist opening and a pair of left and right leg openings are formed by forming a side seal portion, specifically. Means the linear direction connecting the center of the waist opening and the center of the interior.

- -"Unfolded state means a state in which the unfolded state is flat without shrinkage or slack.

- -"Elongation rate means a value when the natural length is 100%. For example, an elongation rate of 200% is synonymous with an elongation ratio of 2 times.

- ⁇ "Metsuke” is measured as follows.

- Pre-drying refers to making a sample or test piece constant in an environment at a temperature of 100 ° C. It is not necessary to pre-dry the fibers having an official moisture content of 0.0%.

- a sample having a size of 100 mm ⁇ 100 mm is cut out from the test piece in a constant weight state using a sampling template (100 mm ⁇ 100 mm). The weight of the sample is measured and multiplied by 100 to calculate the weight per square meter, which is used as the basis weight.

- -The "thickness” is automatically measured using an automatic thickness measuring device (KES-G5 handy compression tester) under the conditions of a load of 0.098 N / cm 2 and a pressurized area of 2 cm 2.

- -"Water absorption is measured by JIS K7223-1996 "Water absorption test method for highly water-absorbent resin”.

- -"Water absorption rate is the "time to the end point” when JIS K7224-1996 "Water absorption rate test method for superabsorbent polymer” was performed using 2 g of super absorbent polymer and 50 g of physiological saline. And.

- test or measurement shall be performed in a test room or equipment under standard conditions (test location: temperature 23 ⁇ 1 ° C, relative humidity 50 ⁇ 2%). To do. -Unless otherwise specified, the dimensions of each part mean the dimensions in the unfolded state, not in the natural length state.

- the present invention can be used for all absorbent articles of pants-type disposable diapers as in the above example.

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Epidemiology (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019-180454 | 2019-09-30 | ||

| JP2019180454A JP7387364B2 (ja) | 2019-09-30 | 2019-09-30 | 吸収性物品 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021065599A1 true WO2021065599A1 (ja) | 2021-04-08 |

Family

ID=75271736

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/035729 Ceased WO2021065599A1 (ja) | 2019-09-30 | 2020-09-23 | 吸収性物品 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP7387364B2 (enExample) |

| TW (1) | TWI824182B (enExample) |

| WO (1) | WO2021065599A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7538627B2 (ja) * | 2020-05-27 | 2024-08-22 | 日本製紙クレシア株式会社 | パンツ型吸収性物品 |

| JP7535023B2 (ja) | 2021-09-17 | 2024-08-15 | 大王製紙株式会社 | 使い捨て着用物品 |

| JP2024108055A (ja) * | 2023-01-30 | 2024-08-09 | 大王製紙株式会社 | パンツ型の吸収性物品 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3069887U (ja) * | 1999-12-22 | 2000-07-04 | トーヨー衛材株式会社 | 使い捨てパンツ |

| JP2010131193A (ja) * | 2008-12-04 | 2010-06-17 | Kao Corp | パンツ型着用物品 |

| JP2017148111A (ja) * | 2016-02-22 | 2017-08-31 | 花王株式会社 | パンツ型吸収性物品 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101558322B1 (ko) * | 2009-07-01 | 2015-10-19 | 가오 가부시키가이샤 | 팬츠형 흡수성 물품 및 그 제조방법 |

-

2019

- 2019-09-30 JP JP2019180454A patent/JP7387364B2/ja active Active

-

2020

- 2020-09-23 WO PCT/JP2020/035729 patent/WO2021065599A1/ja not_active Ceased

- 2020-09-30 TW TW109133995A patent/TWI824182B/zh active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3069887U (ja) * | 1999-12-22 | 2000-07-04 | トーヨー衛材株式会社 | 使い捨てパンツ |

| JP2010131193A (ja) * | 2008-12-04 | 2010-06-17 | Kao Corp | パンツ型着用物品 |

| JP2017148111A (ja) * | 2016-02-22 | 2017-08-31 | 花王株式会社 | パンツ型吸収性物品 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7387364B2 (ja) | 2023-11-28 |

| JP2021053231A (ja) | 2021-04-08 |

| TWI824182B (zh) | 2023-12-01 |

| TW202114610A (zh) | 2021-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107874918B (zh) | 一次性穿着物品及其制造方法 | |

| JP6826788B2 (ja) | 吸収性物品 | |

| JP6049228B1 (ja) | 吸収性物品 | |

| JP2017063923A5 (enExample) | ||

| WO2021065599A1 (ja) | 吸収性物品 | |

| JP5033750B2 (ja) | ウエストバンド及び吸収性物品 | |

| KR100266193B1 (ko) | 흡수제품에 사용하기 위한 예비접착된 섬유층을 갖는 탄성 망상 기재 | |

| JP6942590B2 (ja) | パンツタイプ使い捨て着用物品 | |

| JP2021049079A (ja) | 吸収性物品 | |

| JP2013135718A (ja) | 吸収性物品 | |

| CN110831557B (zh) | 一次性穿着物品 | |

| KR102519503B1 (ko) | 신축 부재 및 이 신축 부재를 갖는 일회용 착용 물품 | |

| JP5922365B2 (ja) | パンツ型吸収性物品 | |

| JP5999761B2 (ja) | パンツタイプ使い捨ておむつ | |

| KR100266542B1 (ko) | 라우드스피커 | |

| JP7421975B2 (ja) | 吸収性物品 | |

| JP2020092735A (ja) | 男性用パンツ型吸収性物品 | |

| JP2019150404A5 (enExample) | ||

| JP2019166217A (ja) | 使い捨て着用物品 | |

| KR102519500B1 (ko) | 신축 부재, 이 신축 부재를 갖는 일회용 착용 물품 및 신축 부재의 제조 방법 | |

| JP7129179B2 (ja) | 吸収性物品の伸縮構造 | |

| JP6829031B2 (ja) | パンツタイプ使い捨ておむつ | |

| WO2021065675A1 (ja) | パンツタイプ使い捨て着用物品 | |

| JP2023135824A (ja) | パンツタイプ使い捨て着用物品 | |

| WO2023042457A1 (ja) | 使い捨て着用物品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20872403 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20872403 Country of ref document: EP Kind code of ref document: A1 |