WO2019159887A1 - 垂直配向液晶硬化膜 - Google Patents

垂直配向液晶硬化膜 Download PDFInfo

- Publication number

- WO2019159887A1 WO2019159887A1 PCT/JP2019/004844 JP2019004844W WO2019159887A1 WO 2019159887 A1 WO2019159887 A1 WO 2019159887A1 JP 2019004844 W JP2019004844 W JP 2019004844W WO 2019159887 A1 WO2019159887 A1 WO 2019159887A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- liquid crystal

- film

- group

- cured film

- crystal cured

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- ORFAEUZTGBHBGO-XXUXADGJSA-N C=CC(OCCOC(CCC(OCCc(cc1)ccc1OC([C@H](CC1)CC[C@@H]1C(Oc(ccc(OC([C@H](CC1)CC[C@@H]1C(Oc1ccc(CCOC(CCC(OCCOC(C=C)=O)=O)=O)cc1)=O)=O)c1S2)c1SC2=C(C#N)C#N)=O)=O)=O)=O)=O Chemical compound C=CC(OCCOC(CCC(OCCc(cc1)ccc1OC([C@H](CC1)CC[C@@H]1C(Oc(ccc(OC([C@H](CC1)CC[C@@H]1C(Oc1ccc(CCOC(CCC(OCCOC(C=C)=O)=O)=O)cc1)=O)=O)c1S2)c1SC2=C(C#N)C#N)=O)=O)=O)=O)=O ORFAEUZTGBHBGO-XXUXADGJSA-N 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

- G02B5/3016—Polarising elements involving passive liquid crystal elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/02—Physical, chemical or physicochemical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/02—Physical, chemical or physicochemical properties

- B32B7/023—Optical properties

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/06—Non-steroidal liquid crystal compounds

- C09K19/34—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring

- C09K19/3402—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring having oxygen as hetero atom

- C09K19/3405—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring having oxygen as hetero atom the heterocyclic ring being a five-membered ring

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K19/00—Liquid crystal materials

- C09K19/04—Liquid crystal materials characterised by the chemical structure of the liquid crystal components, e.g. by a specific unit

- C09K19/06—Non-steroidal liquid crystal compounds

- C09K19/34—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring

- C09K19/3491—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring having sulfur as hetero atom

- C09K19/3497—Non-steroidal liquid crystal compounds containing at least one heterocyclic ring having sulfur as hetero atom the heterocyclic ring containing sulfur and nitrogen atoms

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/08—Optical elements characterised by the material of which they are made; Optical coatings for optical elements made of polarising materials

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

- G02B5/3025—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state

- G02B5/3033—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F9/00—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements

- G09F9/30—Indicating arrangements for variable information in which the information is built-up on a support by selection or combination of individual elements in which the desired character or characters are formed by combining individual elements

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/02—Details

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K59/00—Integrated devices, or assemblies of multiple devices, comprising at least one organic light-emitting element covered by group H10K50/00

- H10K59/50—OLEDs integrated with light modulating elements, e.g. with electrochromic elements, photochromic elements or liquid crystal elements

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2323/00—Functional layers of liquid crystal optical display excluding electroactive liquid crystal layer characterised by chemical composition

- C09K2323/02—Alignment layer characterised by chemical composition

- C09K2323/023—Organic silicon compound, e.g. organosilicon

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K59/00—Integrated devices, or assemblies of multiple devices, comprising at least one organic light-emitting element covered by group H10K50/00

- H10K59/80—Constructional details

- H10K59/8791—Arrangements for improving contrast, e.g. preventing reflection of ambient light

Definitions

- the present invention relates to a vertically aligned liquid crystal cured film, a laminate, an elliptically polarizing plate, and an organic EL display device.

- An elliptically polarizing plate is an optical member in which a polarizing plate and a retardation plate are laminated.

- a polarizing plate and a retardation plate are laminated.

- a so-called ⁇ / 4 plate is used as the retardation plate.

- the phase difference plate used for such an elliptically polarizing plate one showing reverse wavelength dispersion is suitable in that it exhibits the same phase difference performance in a wide wavelength range of visible light.

- a retardation plate As a retardation plate exhibiting reverse wavelength dispersion, a retardation plate comprising a horizontally aligned liquid crystal cured film obtained by polymerizing and curing a polymerizable liquid crystal compound exhibiting reverse wavelength dispersion in a horizontal direction is known. . There is also a need for a polarizing plate with an optical compensation function having a function of compensating for the same optical performance as seen from the front direction when viewed from an oblique direction.

- a polarizing plate with an optical compensation function a polarizing plate further comprising a vertically aligned liquid crystal cured film obtained by polymerizing and curing a polymerizable liquid crystal compound in a vertically aligned state together with a horizontally aligned liquid crystal cured film having reverse wavelength dispersion is known. It has been. Further, among these vertically aligned liquid crystal cured films, Patent Document 1 proposes a vertically aligned liquid crystal cured film using a polymerizable liquid crystal compound exhibiting reverse wavelength dispersion.

- a liquid crystal compound exhibiting reverse wavelength dispersion has an unstable molecular centroid, so that a large number of alignment defects are generated with the liquid crystal compound alone, and vertical alignment is difficult. Therefore, an alignment film for vertical alignment is required for the production of a vertically aligned liquid crystal cured film. However, in that case, a process of forming an alignment film for vertical alignment is required, which causes a problem that productivity is lowered.

- the present invention has been made in view of the above problems, and an object thereof is to provide a vertically aligned liquid crystal cured film in which the occurrence of alignment defects is suppressed without an alignment film.

- the present invention includes the following aspects.

- a vertically aligned liquid crystal cured film that is aligned in a direction perpendicular to the in-plane direction and includes at least one selected from the group consisting of a nonionic silane compound and an ionic compound.

- the nonionic silane compound is a silane coupling agent having an alkoxysilyl group and a polar group.

- RthC (550) represents the retardation value in the thickness direction of the vertically aligned liquid crystal cured film at a wavelength of 550 nm

- the vertically aligned liquid crystal cured film according to any one of [1] to [5], wherein [7]

- RthC (450) represents the retardation value in the thickness direction at a wavelength of 450 nm of the vertically aligned liquid crystal cured film

- RthC (550) represents the retardation in the thickness direction of the vertically aligned liquid crystal cured film at a wavelength of 550 nm.

- the phase difference value at a wavelength of 450 nm when rotated by 40 ° is shown]

- R0 (450) represents the in-plane retardation value of the laminate at a wavelength of 450 nm

- R0 (550) represents the in-plane retardation value of the laminate at a wavelength of 550 nm

- R40 ( 450) shows the retardation value at a wavelength of 450 nm when rotated by 40 ° around the fast axis direction of the film oriented in the horizontal direction of the laminate, and R40 (550) is oriented in the horizontal direction of the laminate.

- the polarizing film includes a horizontally aligned liquid crystal cured film B oriented in a horizontal direction with respect to the film plane of the polarizing film, and the horizontally aligned liquid crystal cured film B includes a dichroic dye.

- the elliptically polarizing plate according to any one of [17]. [19] The elliptically polarizing plate according to [18], wherein the dichroic dye has an azo group. [20]

- the horizontal alignment liquid crystal cured film B is a cured film obtained by curing the liquid crystal compound in a smectic phase in which the liquid crystal compound is aligned in the horizontal direction with respect to the in-plane direction of the film. Elliptical polarizing plate.

- An organic EL display device comprising the elliptically polarizing plate according to any one of [15] to [20].

- acryl and methacryl may be referred to as “(meth) acryl”.

- “system” is added after the compound name, and the compound and its derivatives may be collectively referred to.

- the name of a polymer is expressed by adding “system” after the compound name, the repeating unit of the polymer is derived from the compound or a derivative thereof, or the chemical modification after the polymerization to the repeating unit derived from the compound or the derivative thereof, etc. It means that the polymer is subjected to.

- the vertically aligned liquid crystal cured film of the present invention is aligned in a direction perpendicular to the in-plane direction and includes at least one selected from the group consisting of a nonionic silane compound and an ionic compound.

- the vertically aligned liquid crystal cured film is aligned in a direction perpendicular to the in-plane direction. That is, it includes a liquid crystal compound and / or a polymer of the liquid crystal compound that is aligned in a direction perpendicular to the in-plane direction of the vertically aligned liquid crystal cured film.

- the three-dimensional refractive index ellipsoid formed by the vertically aligned liquid crystal cured film may have biaxiality, but preferably has uniaxiality.

- the vertical alignment liquid crystal cured film of the present invention suppresses the occurrence of alignment defects even without the alignment film.

- the reason is presumed as follows.

- the vertically aligned liquid crystal cured film of the present invention includes at least one selected from the group consisting of a nonionic silane compound and an ionic compound.

- a composition for forming a vertically aligned liquid crystal cured film is applied to a substrate to form a coating film, the coating film is heated and dried to form a dry film.

- the ionic compound Due to the affinity between the functional silane compound and the liquid crystal compound and / or the affinity between the ionic compound and the liquid crystal compound, the ionic compound is present on the substrate surface side, and / or the surface side of the dry film (from the substrate surface)

- the distribution is such that a nonionic silane compound is present on the far side. Since such distribution increases the vertical alignment regulating force, the liquid crystal compound tends to be aligned in the direction perpendicular to the substrate surface in the dry film. For this reason, a cured film can be formed while maintaining a state in which the liquid crystal compound is vertically aligned. Therefore, the vertical alignment liquid crystal cured film of the present invention is considered to suppress the occurrence of alignment defects even without the alignment film.

- nonionic silane compound and an ionic compound As at least one selected from the group consisting of a nonionic silane compound and an ionic compound, three embodiments of a nonionic silane compound, an ionic compound, and a nonionic silane compound and an ionic compound can be mentioned. Only one of the nonionic silane compound and the ionic compound has the effect of increasing the vertical alignment regulating force, but from the viewpoint of further increasing the vertical alignment regulating force, both the nonionic silane compound and the ionic compound are included. Preferably it is.

- the vertically aligned liquid crystal cured film deteriorates the oblique reflection hue of the display including the elliptically polarizing plate including the vertically aligned liquid crystal cured film (for example, the problem that coloring such as red and blue is observed in the oblique hue of the display) )

- RthC (550) represents the retardation value in the thickness direction of the vertically aligned liquid crystal cured film at a wavelength of 550 nm] It is preferable to satisfy.

- the retardation value RthC (550) in the thickness direction of the vertically aligned liquid crystal cured film is more preferably from ⁇ 100 nm to ⁇ 40 nm, and more preferably from ⁇ 80 nm to from the viewpoint of further suppressing the deterioration of the oblique reflection hue of the display. More preferably, it is ⁇ 40 nm or less.

- the retardation value RthC (550) in the thickness direction of the vertically aligned liquid crystal cured film can be adjusted by the thickness dC of the vertically aligned liquid crystal cured film.

- NzC (550) indicates the refractive index at a wavelength of 550 nm in the thickness direction of the vertically aligned liquid crystal cured film, and dC indicates the film thickness of the vertically aligned liquid crystal cured film.] Therefore, in order to obtain a desired retardation value RthC (550) in the thickness direction, the three-dimensional refractive index and the film thickness dC may be adjusted.

- the vertically aligned liquid crystal cured film is used from the viewpoint of suppressing a decrease in ellipticity when viewed from the oblique side on the short wavelength side in the elliptically polarizing plate including the vertically aligned liquid crystal cured film.

- RthC (450) represents the retardation value in the thickness direction at a wavelength of 450 nm of the vertically aligned liquid crystal cured film

- RthC (550) represents the retardation in the thickness direction of the vertically aligned liquid crystal cured film at a wavelength of 550 nm. Show value] It is preferable to satisfy.

- RthC (450) / RthC (550) of the vertically aligned liquid crystal cured film is more preferably 0.95 or less, and further preferably 0.90 or less.

- the retardation value RthC (450) in the thickness direction of the vertically aligned liquid crystal cured film can be adjusted by the thickness dC of the vertically aligned liquid crystal cured film, similarly to RthC (550).

- the upper limit of the thickness of the vertically aligned liquid crystal cured film is preferably 3 ⁇ m or less, more preferably 2.5 ⁇ m or less, further preferably 2.0 ⁇ m or less, and particularly preferably 1.5 ⁇ m or less from the viewpoint of thinning.

- the lower limit of the thickness of the vertically aligned liquid crystal cured film is preferably 0.1 ⁇ m or more, more preferably 0.3 ⁇ m or more, and further preferably 0.4 ⁇ m or more.

- the thickness of the vertically aligned liquid crystal cured film can be measured using an ellipsometer or a contact-type film thickness meter.

- the nonionic silane compound is a compound that is nonionic and contains Si element.

- the nonionic silane compound sufficiently improves the vertical alignment of the liquid crystal compound (I) -1 in the production of a vertically aligned liquid crystal cured film, and further improves the vertical alignment of the liquid crystal compound in combination with the ionic compound. be able to.

- the nonionic silane compound can easily reduce the surface tension of the composition for forming a vertically aligned liquid crystal cured film, and can improve the wettability of the composition to the substrate.

- Nonionic silane compounds include, for example, silicon polymers such as polysilanes, silicone resins such as silicone oils and silicone resins, and organic inorganic silane compounds such as silicone oligomers, silses siloxanes, and alkoxy silanes (more specifically, Include silane coupling agents and the like.

- the nonionic silane compound may be a silicone monomer type or a silicone oligomer (polymer) type.

- Silicone oligomers are shown in the form of (monomer)-(monomer) copolymer: 3-mercaptopropyltrimethoxysilane-tetramethoxysilane copolymer, 3-mercaptopropyltrimethoxysilane-tetraethoxysilane copolymer, 3-mercapto Mercaptopropyl group-containing copolymers such as propyltriethoxysilane-tetramethoxysilane copolymer and 3-mercaptopropyltriethoxysilane-tetraethoxysilane copolymer; mercaptomethyltrimethoxysilane-tetramethoxysilane copolymer, mercaptomethyltrimethoxysilane- Tetraethoxysilane copolymer, mercaptomethyltriethoxys

- nonionic silane compounds may be used individually by 1 type, or may be used in combination of 2 or more type. Moreover, the silane containing compound illustrated to the term of a leveling agent can also be used. Of these nonionic silane compounds, a silane coupling agent is preferable from the viewpoint of further improving the adhesion.

- the silane coupling agent is selected from the group consisting of a vinyl group, an epoxy group, a styryl group, a methacryl group, an acrylic group, an amino group, an isocyanurate group, a ureido group, a mercapto group, an isocyanate group, a carboxy group, and a hydroxy group at the terminal. And a compound containing Si element having at least one functional group and at least one alkoxysilyl group or silanol group.

- the silane coupling agent is preferably a silane coupling agent having an alkoxysilyl group and another different reactive group (for example, the above functional group) from the viewpoint of further improving adhesion. Furthermore, the silane coupling agent is preferably a silane coupling agent having an alkoxysilyl group and a polar group. When the silane coupling agent has at least one alkoxysilyl group and at least one polar group in the molecule, the vertical alignment property of the liquid crystal compound is further improved, and the vertical alignment promoting effect is remarkably obtained.

- Examples of the polar group include an epoxy group, an amino group, an isocyanurate group, a mercapto group, a carboxy group, and a hydroxy group.

- the polar group may have a substituent or a protective group as appropriate in order to control the reactivity of the silane coupling agent.

- silane coupling agent examples include vinyltrimethoxysilane, vinyltriethoxysilane, vinyltris (2-methoxyethoxy) silane, N- (2-aminoethyl) -3-aminopropylmethyldimethoxysilane, N- (2- Aminoethyl) -3-aminopropyltrimethoxysilane, 3-aminopropyltriethoxysilane, 3-triethoxysilyl-N- (1,3-dimethyl-butylidene) propylamine, 3-glycidoxypropyltrimethoxysilane, 3-glycidoxypropylmethyldimethoxysilane, 2- (3,4-epoxycyclohexyl) ethyltrimethoxysilane, 3-chloropropylmethyldimethoxysilane, 3-chloropropyltrimethoxysilane, 3-methacryloyloxypropyltrimethoxysilane

- silane coupling agents examples include KP321, KP323, KP324, KP326, KP340, KP341, X22-161A, KF6001, KBM-1003, KBE-1003, KBM-303, KBM-402, KBM-403. , KBE-402, KBE-403, KBM-1403, KBM-502, KBM-503, KBE-502, KBE-503, KBM-5103, KBM-602, KBM-603, KBM-903, KBE-903, KBE Silane coupling agents manufactured by Shin-Etsu Chemical Co., Ltd. such as -9103, KBM-573, KBM-575, KBM-9659, KBE-585, KBM-802, KBM-803, KBE-846, and KBE-9007 Is mentioned.

- the content of the nonionic silane compound is preferably 0.01% by mass to 5% by mass, and preferably 0.05% by mass to 4% by mass with respect to the solid content of the composition for forming a vertically aligned liquid crystal cured film. %, More preferably 0.1% by mass to 3% by mass.

- the content of the nonionic silane compound is 0.01% by mass or more based on the solid content of the composition, the vertical alignment of the liquid crystal compound is further improved, and the content of the nonionic silane compound is If it is contained in an amount of 5% by mass or less based on the solid content, the applicability of the composition is hardly lowered.

- the ionic compound sufficiently improves the vertical alignment of the liquid crystal compound (I) -1 in the production of a vertically aligned liquid crystal cured film, and the vertical alignment of the liquid crystal compound (I) -1 by combination with a nonionic silane compound. The property can be further improved.

- the ionic compound examples include an onium salt (more specifically, a quaternary ammonium salt, a tertiary sulfonium salt in which a nitrogen atom has a positive charge, and a quaternary phosphonium in which a phosphorus atom has a positive charge. Salt).

- an onium salt more specifically, a quaternary ammonium salt, a tertiary sulfonium salt in which a nitrogen atom has a positive charge, and a quaternary phosphonium in which a phosphorus atom has a positive charge. Salt.

- an onium salt more specifically, a quaternary ammonium salt, a tertiary sulfonium salt in which a nitrogen atom has a positive charge, and a quaternary phosphonium in which a phosphorus atom has a positive charge. Salt.

- a quaternary onium salt is preferable from the viewpoint of further improving the vertical alignment

- the molecular weight of the ionic compound is preferably 100 or more from the viewpoint of further improving the vertical alignment of the liquid crystal compound (I) -1.

- the molecular weight of the ionic compound is preferably 10,000 or less, more preferably 5000 or less, and more preferably 3000 or less from the viewpoint of further improving the coating properties of the vertically aligned liquid crystal cured film forming composition. Is more preferable.

- the molecular weight of the ionic compound is more preferably 100 or more and 10,000 or less from the viewpoint of further improving the vertical alignment property of the liquid crystal compound (I) -1 and further improving the coating property of the composition.

- Examples of the cation component of the ionic compound include inorganic cations and organic cations. Of the cationic components of these ionic compounds, organic cations are preferred from the viewpoint of suppressing the occurrence of alignment defects in the liquid crystal compound. Examples of the organic cation include an imidazolium cation, a pyridinium cation, an ammonium cation, a sulfonium cation, and a phosphonium cation.

- ionic compounds generally have a counter anion.

- an anion component used as the counter ion of the said cation component an inorganic anion or an organic anion is mentioned, for example.

- an organic anion is preferable from the viewpoint of suppressing the occurrence of alignment defects in the liquid crystal compound.

- the cation and the anion do not necessarily have a one-to-one correspondence. Examples of the anion component include the following.

- ionic compound can be appropriately selected from the combination of the cation component and the anion component.

- Specific examples of the compound that is a combination of a cation component and an anion component include the following.

- (Imidazolium salt) 1-ethyl-3-methylimidazolium hexafluorophosphate, 1-ethyl-3-methylimidazolium bis (fluorosulfonyl) imide, 1-ethyl-3-methylimidazolium bis (trifluoromethanesulfonyl) imide, 1-ethyl-3-methylimidazolium p-toluenesulfonate, 1-butyl-3-methylimidazolium methanesulfonate, etc.

- the ionic compound may be used alone or in combination of two or more.

- the ionic compound preferably has a Si element and / or an F element in the molecular structure of the cation moiety. This is because if the ionic compound has Si element and / or F element in the molecular structure of the cation site, the ionic compound can be segregated on the surface of the vertically aligned liquid crystal cured film.

- ionic compounds whose constituent elements are all nonmetallic elements are preferred.

- a method for improving the vertical alignment property of the liquid crystal compound for example, there is a method of treating the surface of the substrate using a surfactant having an alkyl group having a long chain length to some extent.

- This method is described, for example, in “Liquid Crystal Handbook”, Chapter 2, Liquid Crystal Orientation and Physical Properties (issued by Maruzen Co., Ltd.).

- the method of improving the vertical alignment property of a liquid crystal compound with a surfactant can be applied to an ionic compound. That is, as a method for improving the vertical alignment property of the liquid crystal compound, for example, a method of treating the substrate surface with an ionic compound having an alkyl group having a long chain length to some extent can be mentioned.

- the ionic compound preferably satisfies the following formula (10) from the viewpoint of improving the vertical alignment of the liquid crystal compound. 5 ⁇ M ⁇ 16 (10)

- M is represented by the following formula (11).

- M (the number of covalent bonds from the positively charged atom to the end of the molecular chain of the substituent having the largest number of covalent bonds from the end of the molecular chain to the end of the molecular chain among the substituents directly bonded on the positively charged atom ) ⁇ (number of positively charged atoms) (11)

- the substituent having two or more positively charged atoms is counted from the positively charged atoms considered as the base point.

- the number of covalent bonds to the closest other positively charged atom is defined as “the number of covalent bonds from the positively charged atom to the end of the molecular chain” described in the definition of M above.

- the ionic compound is an oligomer or polymer having two or more repeating units, the structural unit is considered as one molecule, and the above M is calculated.

- the number of covalent bonds leading to the atom having the same positive charge via the ring structure, or the end of a substituent bonded to the ring structure Of the number of covalent bonds, the larger number of covalent bonds is defined as “the number of covalent bonds from the positively charged atom to the end of the molecular chain” described in the definition of M above.

- the content of the ionic compound is usually preferably 0.01 to 5% by mass, more preferably 0.05 to 4% by mass, based on the solid content of the composition for forming a vertically aligned liquid crystal cured film.

- the content is preferably 0.1 to 3% by mass.

- liquid crystal compound examples include the following formula (I) -1:

- Ar represents a divalent group having two or more ring structures, and one of the two or more ring structures is a 6-membered ring

- G 1 and G 2 each independently represent a divalent aromatic group or a divalent alicyclic hydrocarbon group, and are included in the divalent aromatic group and the divalent alicyclic hydrocarbon group.

- the carbon atoms contained in the divalent aromatic group and the divalent alicyclic hydrocarbon group may each independently be substituted with an oxygen atom, a sulfur atom, or a nitrogen atom, * Represents a bond]

- the liquid crystal compound (I) -1 represents a divalent group in which Ar in the formula (I) -1 has two or more ring structures, and one of the two or more ring structures is a 6-membered ring. There is a tendency to adopt a T-shaped structure because L 1 and L 2 are bonded to positions 1 and 4 of the 6-membered ring. A compound having such a structure generally tends to exhibit reverse wavelength dispersion. Therefore, the liquid crystal compound (I) -1 exhibits reverse wavelength dispersion. On the other hand, since the liquid crystal compound (I) -1 has a T-shaped structure, it is usually difficult to perform vertical alignment alone.

- the vertical alignment property of the liquid crystal compound (I) -1 is sufficiently improved by including a nonionic silane compound or an ionic compound in the composition for forming a vertically aligned liquid crystal cured film.

- a nonionic silane compound or an ionic compound in the composition for forming a vertically aligned liquid crystal cured film.

- the composition for forming a vertically aligned liquid crystal cured film preferably contains both a nonionic silane compound and an ionic compound.

- Ar represents a divalent group having two or more ring structures.

- the unit of the ring structure that Ar has is a single ring.

- Ar has four, two, and three ring structures, respectively.

- two or more monocycles may be condensed and adjacent to each other, two or more monocycles may be bonded to each other via a chemical bond, They may be adjacent to each other without condensing or via chemical bonds.

- the first aspect may be referred to as a condensed type

- the second aspect may be referred to as a bonded type

- the third aspect may be referred to as a spiro ring type.

- a single ring and a condensed ring (polycycle) in which a single ring is condensed may be bonded to each other via a chemical bond, and the polycycle and the polycycle may be bonded to each other via a chemical bond.

- a bond condensation type Liquid crystal compounds A, (A) -2, and (A) -3, which will be described later, are a bond condensation type, a condensation type, and a bond type, respectively.

- the chemical bond that connects two or more rings in the bond type and the bond condensation type includes, for example, a conjugated double bond (more specifically, —C ⁇ C— and —C ⁇ N— etc.) and a carbonyl group. May include a bond or group that expands the spatial extent of the conjugated system.

- Examples of the monocycle include monocyclic hydrocarbon rings (more specifically, cycloalkane rings and benzene rings) and monocyclic heterocycles.

- Examples of monocyclic heterocycles include 5-membered heterocycles (more specifically, pyrrole ring, furan ring, thiophene ring, oxazole ring, imidazole ring, pyrazole ring, thiazole ring, triazole).

- the polycycle is a structure having two or more ring structures, and the ring structure may be an aromatic ring or a hydrocarbon ring. Examples of the polycycle include those containing a condensed ring and a monocyclic heterocycle.

- the condensed ring is, for example, a ring obtained by condensing two or more of the same kind of monocycles, and a ring obtained by condensing two or more different kinds of single rings.

- the condensed ring include polycyclic hydrocarbon rings (more specifically, naphthalene ring, anthracene ring, and phenanthrene ring), and polycyclic heterocyclic rings (more specifically, quinoline ring, Quinoxaline ring, benzofuran ring, benzothiophene ring, fluorene ring, indole ring, carbazole ring, benzimidazole ring, benzothiazole ring, thienothiazole ring, benzoxazole ring, 1,3-benzodithiol ring, phenanthroline ring, etc.) Is mentioned.

- a polycyclic structure is preferable from the viewpoint of developing reverse wavelength dispersion characteristics, and a polycyclic heterocyclic

- the monocycle and polycycle may have a substituent.

- substituents that the monocyclic ring and polycyclic ring may have include a hydrogen atom, an alkyl group having 1 to 20 carbon atoms, and an alkoxy group having 1 to 20 carbon atoms.

- Group, imino group, alkapolyenyl group, cyano group, or amino group, and a carbon atom in the substituent may be further substituted with an oxygen atom, a nitrogen atom, or a sulfur atom ( In this case, the hydrogen atom bonded to the carbon atom may be increased or decreased in accordance with the valence of the atom to be substituted).

- the spatial spread of the conjugated system may be expanded like an imino group, alkapolyenyl group, cyano group, hydroxy group, and amino group. These substituents may be further substituted.

- Examples of the 6-membered ring possessed by Ar include a benzene ring and a cyclohexane ring.

- the 6-membered ring may contain a hetero atom as a ring member atom.

- Examples of condensed rings including 6-membered rings include quinoline ring, quinoxaline ring, benzofuran ring, benzothiophene ring, fluorene ring, indole ring, carbazole ring, benzimidazole ring, benzothiazole ring, thienothiazole ring, benzoxazole ring, Examples thereof include a 1,3-benzodithiol ring and a phenanthroline ring.

- Ar is preferably a divalent group containing a ring structure having one or more sulfur atoms as ring member atoms from the viewpoint of further improving the reverse wavelength dispersion of the polarizing plate.

- Ar preferably represents a divalent group represented by the following formula from the viewpoint of further improving the reverse wavelength dispersion. * Indicates a bond.

- X 1 , X 2 , and X 3 are each independently selected from CR 1X, R 2X , NR 3X , a sulfur atom, and an oxygen atom.

- R 1X , R 2X , and R 3X each independently represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms.

- U includes at least one ring structure, and examples of the ring structure include a structure including a monocyclic ring and / or a polycyclic ring described in paragraphs 0041 to 0043 above.

- Y may be an arbitrary substituent, but preferably contains at least one ring structure from the viewpoint of improving reverse wavelength dispersion, and the ring structure is described in the above paragraphs 0041 to 0043.

- L 10 is a divalent linking group, which is a single bond, —O—CO—O—, —N ⁇ N—, —C ⁇ C—, —CR a ⁇ CR b —, —CH ⁇ NN ⁇ CH— or —CR c ⁇ N—.

- R c to R g each independently represents a hydrogen atom or an alkyl group having 1 to 10 carbon atoms, and the carbon atom in the alkyl group may be substituted with a nitrogen atom, an oxygen atom, or a sulfur atom.

- Good in this case, the number of hydrogen atoms is appropriately increased or decreased according to the valence number).

- Z represents a hydrogen atom or a nonmetallic atom of Groups 14 to 16 to which a substituent may be bonded.

- Z is a structure that expands the spatial spread of the conjugated system (more specifically, a double bond site, a triple bond site, and an aromatic ring that satisfies the Hückel rule from the viewpoint of improving reverse wavelength dispersion.

- a heterocyclic ring and at least one selected from the group consisting of atoms selected from nitrogen atoms and sulfur atoms.

- Examples of the divalent linking group represented by L 1 and L 2 include an alkylene group having 1 to 4 carbon atoms, —O—, —S—, —R a1 OR a2 —, —R a3 COOR a4 —, —R a5 OCOR a6 —, R a7 OC ⁇ OOR a8 —, —N ⁇ N—, —CR c ⁇ CR d —, and —C ⁇ C—.

- R a1 to R a8 each independently represents a single bond or an alkylene group having 1 to 4 carbon atoms (more specifically, a methylene group, an ethylene group, a propylene group, a butylene group, or the like), and R c and R d each independently represents an alkyl group having 1 to 4 carbon atoms (more specifically, a methyl group, an ethyl group, a propyl group, a butyl group, or the like) or a hydrogen atom.

- L 1 and L 2 are each independently preferably a single bond, an alkylene group having 1 to 4 carbon atoms, —O—, —S—, —R a1 OR a2 —, —R a3 COOR a4 —, —R a5 OCOR a6 —, R a7 OC ⁇ OOR a8 —, —N ⁇ N—, —CR c ⁇ CR d —, or —C ⁇ C—.

- L 1 and L 2 are each independently more preferably a single bond, —OR a2-1 —, —CH 2 —, —CH 2 CH 2 —, —COOR a4-1 —, or OCOR a6-1 —. Represents.

- R a2-1 , R a4-1 , and R a6-1 each independently represents a single bond, —CH 2 —, or —CH 2 CH 2 —.

- L 1 and L 2 each independently represents a single bond, —O—, —CH 2 CH 2 —, —COO—, —COOCH 2 CH 2 —, or OCO—.

- Examples of the divalent aromatic group represented by G 1 and G 2 include a phenylenediyl group and a naphthylenediyl group.

- the divalent aromatic group may be substituted with a substituent such as a halogen atom (more specifically, a fluorine atom, a chlorine atom, a bromine atom, etc.) or an alkyl group having 1 to 4 carbon atoms.

- the divalent aromatic group may have a hetero atom (more specifically, an oxygen atom, a sulfur atom, a nitrogen atom, etc.) as a ring member atom.

- Examples of the divalent alicyclic hydrocarbon group represented by G 1 and G 2 include a cyclopentanediyl group, a cyclohexanediyl group, and a cycloheptanediyl group.

- the divalent alicyclic hydrocarbon group may be substituted with a substituent such as a halogen atom and an alkyl group having 1 to 4 carbon atoms.

- the aromatic group is a group having a planar structure having a planarity

- the number of ⁇ electrons of the cyclic structure is [4n + 2] according to the Hückel rule (n is a positive number of 1 or more). Indicates an integer).

- G 1 and G 2 are each independently preferably a 1,4-phenylenediyl group optionally substituted with at least one substituent selected from the group consisting of a halogen atom and an alkyl group having 1 to 4 carbon atoms.

- 1,4-cyclohexanediyl group optionally substituted with at least one substituent selected from the group consisting of a halogen atom and an alkyl group having 1 to 4 carbon atoms, more preferably 1 substituted with a methyl group , 4-phenylenediyl group, unsubstituted 1,4-phenylenediyl group, or unsubstituted 1,4-trans-cyclohexanediyl group, particularly preferably unsubstituted 1,4-phenylenediyl group or Substituted 1,4-trans-cyclohexanediyl group.

- At least one of a plurality of G 1 and G 2 is preferably a divalent alicyclic hydrocarbon group, and at least one of G 1 and G 2 bonded to L 1 or L 2. More preferably, it is a divalent alicyclic hydrocarbon group.

- the liquid crystal compound (I) -1 preferably has a maximum absorption in a wavelength range of 260 to 400 nm.

- the liquid crystal compound (I) -1 has an aromatic group having a hetero atom or a structure that expands the conjugated system, the absorption in the near ultraviolet region is shifted to the longer wavelength side than the benzene ring, so that the wavelength is 260 nm or more. In this way, it is preferable to have maximum absorption in the wavelength region of 260 nm or more from the viewpoint of improving reverse wavelength dispersion.

- the liquid crystal compound (I) -1 preferably has a maximum absorption in a region of a wavelength of 400 nm or less because coloring may occur when the absorption has a maximum in a wavelength region longer than the wavelength of 400 nm. Furthermore, from the viewpoint of further improving the wavelength dispersibility, it is more preferable to have a maximum absorption in a region of a wavelength of 280 nm to 400 nm, and it is more preferable to have a maximum absorption in a region of a wavelength of 300 nm to 400 nm.

- Liquid crystal compound (I) -1 is represented by the following formula (I) -2:

- liquid crystal compound (I) -2) A liquid crystal compound having a structure represented by the formula (hereinafter sometimes referred to as liquid crystal compound (I) -2) is preferred.

- Ar represents a divalent group having two or more ring structures, and one of the two or more ring structures is a 6-membered ring

- G 1 , G 2 , and G 3 each independently represent a divalent aromatic group or a divalent alicyclic hydrocarbon group, and the divalent aromatic group and the divalent alicyclic carbon group

- the hydrogen atom contained in the hydrogen group is independently a halogen atom, an alkyl group having 1 to 4 carbon atoms, a fluoroalkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, a cyano group, or a nitro group.

- the carbon atoms contained in the divalent aromatic group and the divalent alicyclic hydrocarbon group are each independently substituted with an oxygen atom, a sulfur atom, or a

- Formula (I) in -2 Ar, L 1, L 2 , G 1, and G 2 has the formula (I) in -1 Ar, L 1, L 2 , G 1, and G 2 and respectively synonymous is there.

- B 1 is preferably a single bond, an alkylene group having 1 to 4 carbon atoms, —O—, —S—, —R a1 OR a2 —, —R a3 COOR a4 —, —R a5 OCOR a6 —, R a7.

- L 1 and L 2 are each independently more preferably a single bond, —OR a2-1 —, —CH 2 —, —CH 2 CH 2 —, —COOR a4-1 —, or OCOR a6-1 —. Represents.

- R a2-1 , R a4-1 , and R a6-1 each independently represent a single bond, —CH 2 —, or —CH 2 CH 2 —.

- L 1 and L 2 each independently represents a single bond, —O—, —CH 2 CH 2 —, —COO—, —COOCH 2 CH 2 —, or OCO—.

- Examples of the divalent aromatic group represented by G 3 include a phenylenediyl group and a naphthylylenediyl group.

- the divalent aromatic group may be substituted with a substituent such as a halogen atom (more specifically, a fluorine atom, a chlorine atom, a bromine atom, etc.) or an alkyl group having 1 to 4 carbon atoms.

- Examples of the divalent alicyclic hydrocarbon group represented by G 3 include a cyclopentanediyl group, a cyclohexanediyl group, and a cycloheptanediyl group.

- the divalent alicyclic hydrocarbon group may be substituted with a substituent such as a halogen atom or an alkyl group having 1 to 4 carbon atoms.

- G 3 each independently preferably represents a 1,4-phenylenediyl group which may be substituted with at least one substituent selected from the group consisting of a halogen atom and an alkyl group having 1 to 4 carbon atoms, a halogen atom And a 1,4-cyclohexanediyl group optionally substituted with at least one substituent selected from the group consisting of alkyl groups having 1 to 4 carbon atoms, more preferably 1,4-cyclohexanediyl group substituted with a methyl group A phenylenediyl group, an unsubstituted 1,4-phenylenediyl group, or an unsubstituted 1,4-trans-cyclohexanediyl group, and particularly preferably an unsubstituted 1,4-phenylenediyl group or an unsubstituted 1 , 4-trans-cyclohexanediyl group.

- Liquid crystal compound (I) -1 is represented by the following formula (I) -3:

- liquid crystal compound (I) -3 It is more preferable that the liquid crystal compound has a structure represented by the formula (hereinafter sometimes referred to as “liquid crystal compound (I) -3”).

- Ar represents a divalent group having two or more ring structures, and one of the two or more ring structures is a 6-membered ring

- Binds L 1 and L 2 at the 4th and L 1 , L 2 , B 1 and B 2 each independently represent a single bond or a divalent linking group

- G 1 , G 2 , G 3 , and G 4 each independently represent a divalent aromatic group or a divalent alicyclic hydrocarbon group, and the divalent aromatic group or the divalent fat

- the hydrogen atom contained in the cyclic hydrocarbon group is a halogen atom, an alkyl group having 1 to 4 carbon atoms, a fluoroalkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, a cyano group, or a nitro group.

- the carbon atom contained in the divalent aromatic group or the divalent alicyclic hydrocarbon group may be substituted with an oxygen atom, a sulfur atom, or a

- Formula (I) in -3 Ar L 1, L 2 , G 1, and G 2 has the formula (I) in -1 Ar, L 1, L 2 , G 1, and G 2 and respectively synonymous is there.

- B 1 and G 3 in formula (I) -3 has the same meaning as B 1 and G 3, respectively formula (I) in -2.

- B 2 is preferably a single bond, an alkylene group having 1 to 4 carbon atoms, —O—, —S—, —R a1 OR a2 —, —R a3 COOR a4 —, —R a5 OCOR a6 —, R a7.

- L 1 and L 2 are each independently more preferably a single bond, —OR a2-1 —, —CH 2 —, —CH 2 CH 2 —, —COOR a4-1 —, or OCOR a6-1 —. Represents.

- R a2-1 , R a4-1 , and R a6-1 each independently represent a single bond, —CH 2 —, or —CH 2 CH 2 —.

- L 1 and L 2 each independently represents a single bond, —O—, —CH 2 CH 2 —, —COO—, —COOCH 2 CH 2 —, or OCO—.

- Examples of the divalent aromatic group represented by G 4 include a phenylenediyl group or a naphthylylenediyl group.

- the divalent aromatic group may be substituted with a substituent such as a halogen atom (more specifically, a fluorine atom, a chlorine atom, a bromine atom, etc.) or an alkyl group having 1 to 4 carbon atoms.

- Examples of the divalent alicyclic hydrocarbon group represented by G 3 include a cyclopentanediyl group, a cyclohexanediyl group, and a cycloheptanediyl group.

- the divalent alicyclic hydrocarbon group may be substituted with a substituent such as a halogen atom or an alkyl group having 1 to 4 carbon atoms.

- G 4 is preferably a 1,4-phenylenediyl group which may be substituted with at least one substituent selected from the group consisting of a halogen atom and an alkyl group having 1 to 4 carbon atoms, a halogen atom and 1 carbon atom.

- 1,4-cyclohexanediyl group optionally substituted with at least one substituent selected from the group consisting of ⁇ 4 alkyl groups, more preferably a 1,4-phenylenediyl group substituted with a methyl group, An unsubstituted 1,4-phenylenediyl group or an unsubstituted 1,4-trans-cyclohexanediyl group, particularly preferably an unsubstituted 1,4-phenylenediyl group or an unsubstituted 1,4-trans -A cyclohexanediyl group.

- the liquid crystal compound (I) -1 may have one or more polymerizable groups.

- a polymerizable group means a group that can participate in a polymerization reaction by an active species such as an active radical or an acid generated from a photopolymerization initiator.

- the polymerizable group include an epoxy group, vinyl group, vinyloxy group, 1-chlorovinyl group, isopropenyl group, 4-vinylphenyl group, acryloyloxy group, methacryloyloxy group, oxiranyl group, and oxetanyl group. .

- an acryloyloxy group and a methacryloyloxy group are preferable.

- the liquid crystal compound (I) -1 having a polymerizable group can form a polymer by a polymerization reaction.

- liquid crystal compound (I) -1 examples include liquid crystal compounds having structures represented by the formulas (A) -1 to (A) -5.

- the content of the liquid crystal compound (I) -1 (the total of the contents when a plurality of liquid crystal compounds are included) is 50 to 99 with respect to 100 parts by mass of the solid content of the vertically aligned liquid crystal cured film forming composition. 0.5 part by mass is preferable, 60 to 99 parts by mass is more preferable, and 70 to 99 parts by mass is still more preferable.

- the mass of the solid content of the composition means the total mass of the components excluding the solvent from the composition.

- the vertically aligned liquid crystal cured film is a cured product of the composition for forming a vertically aligned liquid crystal cured film.

- the method for producing a vertically aligned liquid crystal cured film includes a coating film forming step in which a composition for forming a vertically aligned liquid crystal cured film is applied to a substrate, a coating film is formed on the substrate, the coating film is dried, and a dry film is formed.

- the laminate produced by this production method is composed of a substrate and a vertically aligned liquid crystal cured film.

- the case where the liquid crystal compound has one or more polymerizable groups and the composition further contains a photopolymerization initiator will be described as an example.

- the composition is applied to a base material using a printing apparatus to form a coating film on the base material.

- the application method include printing methods such as a gravure coating method, a die coating method, and a flexo method.

- the coating film is dried using a heating device to form a dry film. After the coating film is heated and the solvent in the coating film is removed, the liquid crystal compound is vertically aligned and converted into a dry film.

- the heating temperature is preferably equal to or higher than the phase transition temperature of the liquid crystal compound so that the solvent can be removed.

- the dry film is irradiated with active energy rays (more specifically, ultraviolet rays or the like) to form a vertically aligned liquid crystal cured film.

- active energy rays more specifically, ultraviolet rays or the like

- the liquid crystal compound maintains a liquid crystal state that is aligned perpendicular to the substrate plane in the dry film.

- the liquid crystal compound is photopolymerized while maintaining a vertically aligned liquid crystal state. Thereby, a vertically aligned liquid crystal cured film can be directly formed on the substrate.

- the vertically aligned liquid crystal cured film can be directly formed on the substrate without forming the alignment film.

- the method for producing a vertically aligned liquid crystal cured film may further include a vertical alignment film forming step of forming a vertical alignment film for the purpose of further improving the orientation of the vertically aligned liquid crystal cured film.

- the vertically aligned liquid crystal cured film is indirectly formed on the substrate via the vertically aligned film.

- the vertical alignment film forming process is a process executed before the coating film forming process, and forms a vertical alignment film.

- the alignment film forming process includes a second coating film forming process, a second dry coating forming process, and an alignment film forming process.

- a vertical alignment film forming composition is applied onto the substrate using a printing apparatus to form the second coating film.

- the composition for forming a vertical alignment film includes, for example, an alignment polymer described later and the solvent described above.

- the second dry film forming step for example, the second coating film is heated using a heating device to dry the second coating film, thereby forming the second dry film.

- a vertical alignment film is formed by irradiating and curing the second dry film by using a UV irradiation apparatus.

- the manufacturing method of a vertical alignment liquid crystal cured film includes a vertical alignment film formation process, a vertical alignment liquid crystal cured film is formed on a vertical alignment film.

- composition for forming a vertically aligned liquid crystal cured film includes, for example, either a nonionic silane compound or an ionic compound, or both, and an additive added as necessary.

- the additive include a liquid crystal compound, a photopolymerization initiator, a leveling agent, a solvent, a polymerization inhibitor, and an adhesion improver.

- the liquid crystal compound include liquid crystal compound (I) -1. These additives may be used individually by 1 type, or may be used in combination of 2 or more type.

- a nonionic silane compound and an ionic compound and, if necessary, other components are agitated at a predetermined temperature to disperse these components substantially uniformly. Alternatively, it can be obtained by dissolving.

- the composition for forming a vertically aligned liquid crystal cured film is usually applied to a substrate or the like in a state dissolved in a solvent, it preferably contains a solvent.

- the solvent include water; methanol, ethanol, ethylene glycol, isopropyl alcohol, propylene glycol, ethylene glycol methyl ether, ethylene glycol butyl ether, 1-methoxy-2-propanol, 2-butoxyethanol, and propylene glycol monomethyl ether.

- Alcohol solvents such as ethyl acetate, butyl acetate, ethylene glycol methyl ether acetate, ⁇ -butyrolactone, propylene glycol methyl ether acetate and ethyl lactate; acetone, methyl ethyl ketone, cyclopentanone, cyclohexanone, 2-heptanone, and methyl Ketone solvents such as isobutyl ketone; aliphatic hydrocarbon solvents such as pentane, hexane, and heptane; Cycloaliphatic hydrocarbon solvents such as cyclohexane; aromatic hydrocarbon solvents such as toluene and xylene; nitrile solvents such as acetonitrile; ether solvents such as tetrahydrofuran and dimethoxyethane; chlorine-containing solvents such as chloroform and chlorobenzene Amide solvents such as dimethylacetamide, dimethyl

- solvent may be used individually by 1 type, or may be used in combination of 2 or more type.

- solvents alcohol solvents, ester solvents, ketone solvents, chlorine-containing solvents, amide solvents, and aromatic hydrocarbon solvents are preferable.

- solvent may be used individually by 1 type, or may be used in combination of 2 or more type.

- the content of the solvent is preferably 50 to 98 parts by mass, more preferably 70 to 95 parts by mass with respect to 100 parts by mass of the composition for forming a vertically aligned liquid crystal cured film. Therefore, the solid content in 100 parts by mass of the composition is preferably 2 to 50 parts by mass.

- the solid content of the composition is 50 parts by mass or less, since the viscosity of the composition is low, the thickness of the vertically aligned liquid crystal cured film becomes substantially uniform, and unevenness is hardly generated in the vertically aligned liquid crystal cured film. Tend.

- the solid content can be appropriately determined in consideration of the thickness of the vertically aligned liquid crystal cured film to be produced.

- the composition for forming a vertically aligned liquid crystal cured film may contain a photopolymerization initiator for the purpose of advancing the polymerization reaction.

- a photoinitiator provides an active species that absorbs active energy rays and initiates a polymerization reaction.

- the photopolymerization initiator can be used as a curable composition that cures by radical polymerization, such as (meth) acrylate or urethane (meth) acrylate, as a curable material.

- a photocationic polymerization initiator can be used.

- Examples of the photopolymerization initiator include a photoradical polymerization initiator and a photocationic polymerization initiator.

- Examples of the photo radical polymerization initiator include benzoin compounds, benzophenone compounds, benzyl ketal compounds, ⁇ -hydroxy ketone compounds, ⁇ -amino ketone compounds, triazine compounds, and the like.

- Examples of the cationic photopolymerization initiator include aromatic diazonium salts, onium salts such as aromatic iodonium salts and aromatic sulfonium salts, and iron-arene complexes.

- photopolymerization initiator examples include Irgacure (registered trademark) 907, Irgacure 184, Irgacure 651, Irgacure 819, Irgacure 250, Irgacure 369, Irgacure 379, Irgacure 127, Irgacure 2959, Irgacure 754, and Irgacure 379E.

- Photopolymerization initiators manufactured by BASF Japan, Inc . photopolymerization initiators manufactured by Seiko Chemical Co., Ltd., such as Sequol BZ, Sequol Z, and Sequol BEE, kayacure BP100 (manufactured by Nippon Kayaku Co., Ltd.), And Adeka optomer SP-152, Adeka optomer SP-170, Adeka optomer N-1717, Ade Photopolymerization initiators made by ADEKA Corporation, such as Optomer N-1919, Adeka Arcles NCI-831, Adeka Arcles NCI-930; Photopolymerization made by Nippon Siebel Hegner, such as TAZ-A and TAZ-PP Initiator; Photopolymerization initiator manufactured by Sanwa Chemical Co., such as TAZ-104; Photopolymerization initiator manufactured by Nippon Kayaku Co., Ltd., such as Kayrad (registered trademark) series; Dow Chemical Co., Ltd.

- Photoinitiators such as Cyracure UVI series Photopolymerization initiators manufactured by San-Apro Co., Ltd. such as CPI series; Photopolymerization initiators manufactured by Midori Chemical Co., Ltd. such as TAZ, BBI, and DTS; such as RHODORSIL (registered trademark) Examples include photopolymerization initiators manufactured by Rhodia Co., Ltd. These photoinitiators may be used individually by 1 type, or may be used in combination of 2 or more type. A photoinitiator can be suitably selected and used according to the material to be used.

- the maximum absorption wavelength of the photopolymerization initiator is preferably 300 nm to 400 nm, more preferably 300 nm to 380 nm.

- these photopolymerization initiators ⁇ -acetophenone polymerization initiators and oxime photopolymerization initiators are preferred.

- Examples of the ⁇ -acetophenone polymerization initiator include 2-methyl-2-morpholino-1- (4-methylsulfanylphenyl) propan-1-one, 2-dimethylamino-1- (4-morpholinophenyl) -2 -Benzylbutan-1-one (2-dimethylamino-2-benzyl-1- (4-morpholinophenyl) butan-1-one) and 2-dimethylamino-1- (4-morpholinophenyl) -2- ( 4-methylphenylmethyl) butan-1-one.

- ⁇ -acetophenone polymerization initiators include 2-methyl-2-morpholino-1- (4-methylsulfanylphenyl) propan-1-one and 2-dimethylamino-1- (4-morpholinophenyl) -2-benzyl Butan-1-one is preferred.

- Commercially available products of ⁇ -acetophenone compounds include ⁇ -acetophenone polymerization initiators manufactured by BASF Japan Ltd. such as Irgacure 369, 379EG, and 907, and ⁇ -acetophenone systems manufactured by Seiko Chemical Co., Ltd. such as Seikol BEE. A polymerization initiator etc. are mentioned.

- An oxime photopolymerization initiator generates radicals when irradiated with light. Polymerization of the composition for forming a vertically aligned liquid crystal cured film in the deep part of the coating film suitably proceeds by this radical. Moreover, it is preferable to use the oxime type photoinitiator which can utilize an ultraviolet-ray with a wavelength of 350 nm or more efficiently from a viewpoint of making a polymerization reaction in the deep part of a coating film progress more efficiently. Examples of the oxime photopolymerization initiator that can efficiently use ultraviolet rays having a wavelength of 350 nm or more include triazine compounds and oxime ester type carbazole compounds.

- Type carbazole compounds examples include 1,2-octanedione, 1- [4- (phenylthio) -2- (O-benzoyloxime)], and ethanone, 1- [9-ethyl-6- (2 -Methylbenzoyl) -9H-carbazol-3-yl] -1- (O-acetyloxime).

- oxime ester type carbazole compounds examples include, for example, oxime ester type carbazole compounds manufactured by BASF Japan, such as Irgacure OXE-01, Irgacure OXE-02, and Irgacure OXE-03, and Adekaoptomer N-1919, An oxime ester type carbazole compound manufactured by ADEKA Corporation, such as Adeka Arcles NCI-831, can be mentioned.

- the content of the photopolymerization initiator is usually 0 when the solid content (excluding the content of the solvent from the composition) contained in the vertically aligned liquid crystal cured film forming composition is 100 parts by mass.

- the amount is preferably 1 to 20 parts by mass, more preferably 0.5 to 10 parts by mass, and still more preferably 1 to 7 parts by mass.

- the photopolymerization initiator is 0.1 to 20 parts by mass with respect to 100 parts by mass of the composition, the polymerization reaction is likely to proceed sufficiently.

- the leveling agent is used for the purpose of adjusting the coating property of the composition for forming a vertically aligned liquid crystal cured film, i.e., adjusting the fluidity of the composition for coating, and further improving the surface of the layer obtained by coating the composition. You may add to this composition in order to make it flat.

- the leveling agent include a silicone leveling agent such as a silane coupling agent, a polyacrylate leveling agent, and a fluoroalkyl leveling agent. Of these leveling agents, silicone-based leveling agents and fluoroalkyl-based leveling agents are preferred from the viewpoint of further improving the vertical alignment of the liquid crystal compound.

- leveling agents examples include DC3PA, SH7PA, DC11PA, SH28PA, SH29PA, SH30PA, ST80PA, ST86PA, SH8400, SH8700, and FZ2123; leveling agents manufactured by Toray Dow Corning Corp .; , KP326, KP340, KP341, X22-161A, KF6001, KBM-1003, KBE-1003, KBM-303, KBM-402, KBM-403, KBE-402, KBE-403, KBM-1403, KBM-502, KBM -503, KBE-502, KBE-503, KBM-5103, KBM-602, KBM-603, KBM-903, KBE-903, KBE-9103, KBM-573, KBM Leveling agents manufactured by Shin-Etsu Chemical Co., Ltd.

- TSF400 TSF401, TSF410, TSF4300, TSF4440, TSF4445 Momentive Performance Materials Japan GK leveling agent such as TSF-4446, TSF4452, and TSF4460; Fluorinert (registered trademark) FC-72, FC-40, FC-43, and FC-3283 Leveling agents manufactured by Sumitomo 3M Co., Ltd .; Megafac® R-08, R-30, R-90, F-410, F-411, F-443, F- 445, F-470, F-4 7.

- Leveling agents manufactured by DIC Corporation such as F-479, F-482, F-482, and F-556; Ftop (trade name) EF301, EF303, EF351, and EF352 Leveling agent manufactured by Mitsubishi Materials Electronic Chemical Co., Ltd .; Surflon (registered trademark) S-381, S-382, S-383, S-393, SC-101, SC-105, KH-40 Leveling agents manufactured by AGC Seimi Chemical Co., Ltd., such as SA-100; Leveling agents manufactured by Daikin Fine Chemical Laboratory, Inc., such as trade names E1830 and E5844; BM-1000, BM-1100, BYK-352, Chemie leveling agents such as BYK-353 and BYK-361N (both trade names: BM). These leveling agents may be used individually by 1 type, or may be used in combination of 2 or more type.

- the leveling agent preferably has a content of 0.001 to 3% by mass, more preferably 0.01 to 3% by mass in the solid content of the composition for forming a vertically aligned liquid crystal cured film. ⁇ 3% by weight is more preferred.

- the content of the leveling agent in the solid content of the composition is 0.001 to 3% by mass, the coating property of the composition is further improved.

- the laminate includes the vertically aligned liquid crystal cured film.

- the laminate includes a base material, an alignment film for vertical alignment (hereinafter sometimes referred to as a vertical alignment film), an alignment film for horizontal alignment (hereinafter sometimes referred to as a horizontal alignment film), an adhesive layer, And / or a film oriented in the horizontal direction with respect to the in-plane direction of the vertical alignment liquid crystal cured film described later (hereinafter sometimes referred to as a horizontal alignment film).

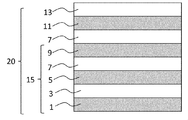

- a laminate comprising the vertical alignment liquid crystal cured film, a horizontal alignment film and a horizontal alignment film, a laminate comprising the vertical alignment liquid crystal cured film and a substrate, and the vertical alignment liquid crystal curing.

- a laminate including a film, a horizontal alignment film, a horizontal alignment film, and a substrate can be mentioned.

- the laminate since the vertically aligned liquid crystal cured film can be formed without an alignment film for vertical alignment, the laminate may not include the vertical alignment film.

- the vertically aligned liquid crystal cured film can be adjacent to the substrate.

- the vertical alignment liquid crystal cured film adjacent to the base material produced by the above-mentioned method can transfer only the vertical alignment liquid crystal cured film through the adhesive layer, and remove the base material to produce a laminate.

- Base material As a base material, a glass base material and a film base material are mentioned, for example, A film base material is preferable from a workability viewpoint, and a long roll-shaped film is more preferable at the point which can be manufactured continuously.

- the resin constituting the film substrate examples include polyolefins such as polyethylene, polypropylene, and norbornene-based polymers; cyclic olefin-based resins; polyvinyl alcohol; polyethylene terephthalate; polymethacrylic acid esters; And cellulose esters such as diacetyl cellulose and cellulose acetate propionate; polyethylene naphthalate; polycarbonate; polysulfone; polyethersulfone; polyetherketone; and plastics such as polyphenylene sulfide and polyphenylene oxide.

- the bonding surface of the base material with the adhesive layer may be subjected to a release treatment such as a silicone treatment.

- a commercially available cellulose ester base material for example, a cellulose ester base material manufactured by Fuji Photo Film Co., Ltd. such as Fujitac Film; manufactured by Konica Minolta Opto Co., Ltd.

- the cellulose ester base material of this is mentioned.

- Such a resin can be formed into a substrate by known methods such as a solvent casting method and a melt extrusion method.

- cyclic olefin resins examples include cyclic olefin resins manufactured by Ticona (Germany) such as “Topas (registered trademark); cyclic olefins manufactured by JSR Corporation such as“ Arton (registered trademark) ”. Type olefin resin; “ZEONOR (registered trademark)” and “ZEONEX (registered trademark)” cyclic olefin resin manufactured by Nippon Zeon Co., Ltd .; “Apel” (registered trademark) Mitsui Examples include cyclic olefin-based resins manufactured by Chemical Co., Ltd. Commercially available cyclic olefin resin base materials can also be used.

- cyclic olefin resin substrates examples include cyclic olefin resin substrates manufactured by Sekisui Chemical Co., Ltd., such as “ESCINA (registered trademark)” and “SCA40 (registered trademark)”; “ZEONOR FILM (registered trademark)”. And the cyclic olefin resin substrate made by JSR Corporation such as “Arton Film (registered trademark)”.

- the substrate has a thickness that facilitates laminating each layer and is easy to peel off.

- the thickness of such a substrate is usually 5 to 300 ⁇ m, preferably 10 to 150 ⁇ m.

- the alignment film is a film having an alignment regulating force that aligns the liquid crystal compound of the liquid crystal cured film in a predetermined direction.

- various alignments such as vertical alignment, horizontal alignment, hybrid alignment, and tilt alignment can be controlled depending on the type of alignment film material, rubbing conditions, and light irradiation conditions.

- Such processing for expressing the orientation regulating force is called orientation processing.

- the vertical alignment film is an alignment film having an alignment regulating force for aligning the liquid crystal compound in the vertical direction. For this reason, a vertical alignment liquid crystal film can be formed by using a vertical alignment film.

- the vertical alignment film preferably has a solvent resistance that does not dissolve when the composition for forming a vertical alignment liquid crystal cured film is applied, and has heat resistance in heat treatment for removing the solvent and aligning the liquid crystal compound.

- the vertical alignment film is preferably made of a material that lowers the surface tension of the surface of the substrate or the like.

- orientation polymers such as polyimide, polyamide, polyamic acid that is a hydrolyzate thereof, and fluoropolymers of perfluoroalkyl, silane compounds, and polysiloxane compounds obtained by a condensation reaction thereof.

- a composition containing such a material and a solvent for example, the solvent exemplified in the section of the vertical alignment liquid crystal cured film (hereinafter, also referred to as a composition for forming a vertical alignment film) is formed on a substrate or the like. After coating and removing the solvent, the coating film can be obtained by heating or the like.

- the vertical alignment film is composed of Si element and C element as constituent elements from the viewpoint of easily reducing the surface tension and improving the adhesion with the layer adjacent to the vertical alignment film.

- membrane containing the compound containing is preferable, and a silane compound can be used conveniently.

- the silane compound the nonionic silane compound described above or a silane-containing ionic compound exemplified in the section of the ionic compound can be used.

- the vertical alignment is regulated. You can increase your power.

- These silane compounds may be used individually by 1 type, may be used in combination of 2 or more type, and may be used in mixture with other materials.

- silane compound is a nonionic silane compound

- a silane compound having an alkyl group at the molecular terminal is preferable from the viewpoint of easily increasing the vertical alignment regulating force, and a silane compound having an alkyl group having 3 to 30 carbon atoms is more preferable.

- the thickness of the vertical alignment film is preferably 5 ⁇ m or less, more preferably 3 ⁇ m or less, still more preferably 2 ⁇ m or less, preferably 1 nm or more, more preferably 5 nm, from the viewpoint of expressing the alignment regulating force. Or more, more preferably 10 nm or more, and particularly preferably 30 nm or more.

- the film thickness of the vertical alignment film can be measured using an ellipsometer or a contact-type film thickness meter.

- the horizontal alignment film has an alignment regulating force that aligns the liquid crystal compound in the horizontal direction.

- the horizontal alignment film can form a horizontal alignment state of the horizontal alignment liquid crystal cured film when the horizontal alignment liquid crystal cured film forming composition is formed on the horizontal alignment film.

- the alignment regulating force can be arbitrarily adjusted depending on, for example, the type of the alignment film, the surface state, and the rubbing conditions. It is possible. Such processing for expressing the orientation regulating force is called orientation processing.

- the horizontal alignment film preferably has a solvent resistance that does not dissolve when the liquid crystal composition is applied or the like, and has heat resistance in heat treatment for removing the solvent or aligning the liquid crystal compound.

- the horizontal alignment film examples include a rubbing alignment film, a photo alignment film, and a groove alignment film having a concavo-convex pattern and a plurality of grooves on the surface.

- a photo-alignment film is preferable in that the alignment direction can be easily controlled.

- a rubbing alignment film is usually formed by applying a composition containing an orientation polymer and a solvent (hereinafter sometimes referred to as a rubbing alignment film forming composition) to a substrate and removing the solvent to form a coating film. Then, the alignment regulating force can be imparted by rubbing the coating film.

- a composition containing an orientation polymer and a solvent hereinafter sometimes referred to as a rubbing alignment film forming composition

- orientation polymer examples include polyamides and gelatins having amide bonds, polyimides having imide bonds, and polyamic acids, polyvinyl alcohols, alkyl-modified polyvinyl alcohols, polyacrylamides, polyoxazoles, polyethyleneimines, polystyrenes having imide bonds. , Polyvinyl pyrrolidone, polyacrylic acid, and polyacrylic acid esters. These orientation polymers may be used alone or in combination of two or more.

- the concentration of the alignment polymer in the composition for forming a rubbing alignment film may be in a range where the alignment polymer is completely dissolved in the solvent.

- the content of the alignment polymer is preferably 0.1 to 20 parts by mass, and more preferably 0.1 to 10 parts by mass with respect to 100 parts by mass of the rubbing alignment film forming composition.

- compositions for forming a rubbing alignment film include, for example, a composition for forming a rubbing alignment film manufactured by Nissan Chemical Industries, Ltd. such as Sanever (registered trademark), and a JSR (such as Optomer (registered trademark)).

- the composition for forming a rubbing alignment film manufactured by Co., Ltd. may be mentioned.

- Examples of the rubbing treatment include a method in which a rubbing cloth is wound and the coating film is brought into contact with a rotating rubbing roll. If masking is performed when the rubbing treatment is performed, a plurality of regions (patterns) having different orientation directions can be formed in the alignment film.

- a composition containing a polymer or monomer having a photoreactive group and a solvent (hereinafter sometimes referred to as a photo-alignment film-forming composition) is applied to a substrate, and the solvent is removed. It is obtained by irradiation with polarized light (preferably polarized UV) later.

- polarized light preferably polarized UV

- the photo-alignment film can arbitrarily control the direction of the alignment regulating force by selecting the polarization direction of the polarized light to be irradiated.

- the photoreactive group refers to a group that generates alignment ability when irradiated with light. Specific examples include groups that are involved in photoreactions that are the origin of alignment ability, such as alignment-induced reactions, isomerization reactions, photodimerization reactions, photocrosslinking reactions, or photodecomposition reactions of molecules generated by light irradiation.

- an unsaturated bond particularly a group having a double bond is preferable, and a carbon-carbon double bond (C ⁇ C bond), a carbon-nitrogen double bond (C ⁇ N bond), and nitrogen-nitrogen.

- a group having at least one double bond selected from the group consisting of a double bond (N ⁇ N bond) and a carbon-oxygen double bond (C ⁇ O bond) is particularly preferred.

- Examples of the photoreactive group having a C ⁇ C bond include a vinyl group, a polyene group, a stilbene group, a stilbazole group, a stilbazolium group, a chalcone group, and a cinnamoyl group.

- Examples of the photoreactive group having a C ⁇ N bond include groups having a structure such as an aromatic Schiff base and an aromatic hydrazone.

- Examples of the photoreactive group having a C ⁇ O bond include a benzophenone group, a coumarin group, an anthraquinone group, and a maleimide group. These groups may have a substituent such as an alkyl group, an alkoxy group, an aryl group, an allyloxy group, a cyano group, an alkoxycarbonyl group, a hydroxyl group, a sulfonic acid group, and a halogenated alkyl group.

- a group involved in the photodimerization reaction or the photocrosslinking reaction is preferable from the viewpoint of excellent orientation.