WO2019131111A1 - パンツ型吸収性物品 - Google Patents

パンツ型吸収性物品 Download PDFInfo

- Publication number

- WO2019131111A1 WO2019131111A1 PCT/JP2018/045482 JP2018045482W WO2019131111A1 WO 2019131111 A1 WO2019131111 A1 WO 2019131111A1 JP 2018045482 W JP2018045482 W JP 2018045482W WO 2019131111 A1 WO2019131111 A1 WO 2019131111A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- stretchable sheet

- absorbent article

- pants

- type absorbent

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/496—Absorbent articles specially adapted to be worn around the waist, e.g. diapers in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

Definitions

- the present invention relates to a pant-type absorbent article.

- a pant-type disposable diaper is known as a pant-type absorbent article.

- the absorbent main body is cross-linked between the front and back body exterior bodies, the widthwise side edges of the front and back body exterior bodies are joined to each other, and the waist opening is formed.

- An underpants-type disposable diaper is disclosed.

- an elastic material around the waist is fixed in an extended state between the inner sheet and the outer sheet (non-stretchable sheet).

- Patent Document 1 a string-like stretchable material is exemplified as a waist elastic material.

- a stretchable sheet instead, the front and rear body and the outer body (a waist portion) are worn by the wearer. It can be attached to Therefore, the trace of the stretchable material can be made difficult to remain.

- the stretch force is increased by the amount of the folded back stretchable sheet.

- the stretching force around the waist becomes larger than the designed force, making it difficult to widen the waist opening when worn.

- the present invention has been made in view of the above-described conventional problems, and its object is to reduce the unintended turning-off of the end portion of the stretchable sheet on the waist portion side of the stretchable sheet provided on the waist portion. It is providing a type

- a main invention for achieving the above object is a pants-type absorbent article having an absorbent core, a first waist part, and a second waist part, which has an up-down direction and a left-right direction.

- One waist portion has a stretchable sheet that can stretch in the left-right direction, a non-stretchable sheet laminated on the stretchable sheet, and a fixing part that fixes the stretchable sheet to the non-stretchable sheet

- the stretchable sheet has one end along the lateral direction and the other end, the one end of the stretchable sheet is positioned above the other end, and the fixing portion is the stretchable sheet

- the pants-type absorbent article is provided so as to straddle the one end in the vertical direction.

- the present invention it is possible to provide a pants-type absorbent article in which unintended turning of the end portion on the waist opening side of the stretchable sheet provided in the waist portion is suppressed.

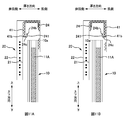

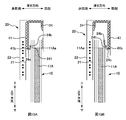

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

- FIG. 20 is a cross-sectional view of a modified example of the ventral-side waist portion 20.

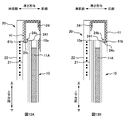

- FIG. 10 is an explanatory view of a crotch-side end of the stretchable sheet 24.

- FIG. 10 is an explanatory view of a crotch-side end of the stretchable sheet 24.

- FIG. 10 is an explanatory view of a crotch-side end of the stretchable sheet 24.

- FIG. 10 is an explanatory view of a crotch-side end of the stretchable sheet 24.

- FIG. 10 is an explanatory view of a crotch-side end of the stretchable sheet 24.

- the elastic sheet has one end along the other end, the one end of the stretchable sheet is positioned above the other end, and the fixing portion straddles the one end of the stretchable sheet in the vertical direction. It is a pants-type absorbent article characterized by being.

- the stretchable sheet is fixed to the non-stretchable sheet up to one end thereof by the fixing portion. Therefore, it is possible to suppress flipping of one end of the stretchable sheet due to the absence of the fixing portion, that is, to suppress unintentional flipping of the end of the stretchable sheet on the side of the waist opening. Further, the absence of the fixing portion prevents the end of the stretchable sheet from being curled up and folded back, and can prevent the stretchability of the end on the waist side opening of the stretchable sheet from increasing. Therefore, the ease of opening the waist opening can be maintained.

- the stretchable sheet is provided at an upper end portion of the first waist part.

- the non-stretch sheet has one end along the left-right direction and the other end, and the one end of the non-stretch sheet is positioned above the other end.

- the portion on the one end side of the non-stretchable sheet is folded downward, and in the vertical direction, the length from the upper end of the first waist part to the one end of the stretchable sheet is It is a pants-type absorbent article characterized by being shorter than the length from the upper end of the first waist part to the one end of the non-stretchable sheet.

- the stretchable sheet when the region on one end side of the stretchable sheet is not folded back, the stretchable sheet is not excessively positioned below. Therefore, the fit of the upper end portion of the ventral waistline portion can be maintained. Also, for example, when the portion on one end side of the stretchable sheet is folded back, the length of the folded back of the stretchable sheet is never too long. Therefore, the expansion-contraction force of the edge part by the side of the trunk periphery opening part of a 1st trunk periphery part can be restrained moderately.

- the fixing part is a first area for fixing one surface of the elastic sheet to the non-elastic sheet, and a second area other than the first area. And at least a part of the second region is not exposed.

- Such a pant-type absorbent article is a pant-type absorbent article characterized in that all of the second region is not exposed.

- the non-stretch sheet has one end along the left-right direction and the other end, and the one end of the non-stretch sheet is positioned above the other end.

- the portion on the one end side of the non-stretchable sheet is folded downward, and the second region of the fixing portion is covered by the portion of the non-stretchable sheet folded back.

- the second region of the fixing portion can be prevented from being exposed.

- the stretching force of the first waist part can be appropriately suppressed.

- the fixing portion has one end along the left-right direction and the other end, the one end of the fixing portion is positioned above the other end, and the fixing is performed.

- the part on the side of the one end of the part is a pant-type absorbent article characterized in that the part is not folded downward.

- the first waist part can be softened, and stimulation of the skin of the wearer can be suppressed.

- the one end of the stretchable sheet and the one end of the fixing portion are positioned lower than the upper end of the first waist portion. It is an absorbent article.

- the first waist part can be further softened, and stimulation of the skin of the wearer can be suppressed.

- the fixing portion has one end along the left-right direction and the other end, the one end of the fixing portion is positioned above the other end, and the fixing is performed.

- the part on the side of the one end of the part is a pants-type absorbent article characterized by being folded downward.

- the rigidity of the portion of the first waist part, in which the fixing part is folded downward, can be increased. Therefore, when pulling up the pants-type absorbent article, it becomes easy to grip the first waist part.

- the site at the one end of the stretchable sheet is folded downward, and the site at the one end of the stretchable sheet folded is folded back.

- the surface opposite to the portion of the elastic sheet is not a fixed type, is a pant-type absorbent article.

- the fixing portion is provided straddling in the vertical direction one end of the stretchable sheet folded back in the downward direction. Therefore, it is possible to suppress that the end of the stretchable sheet is unintentionally curled up with respect to the portion of the stretchable sheet folded back in the downward direction.

- a space is formed between the unfolded portion and the unfolded portion of the stretchable sheet. Therefore, the cushioning property of the first waist part can be enhanced, and the skin contact with the wearer can be improved.

- the pants-type absorbent article wherein the region on the other end side of the stretchable sheet is folded upward from the lower end of the fixing portion as a starting point. is there.

- the stretchable sheet is fixed to the non-stretchable sheet up to one end thereof by the fixing portion. Therefore, it is possible to suppress flipping of one end of the stretchable sheet due to the absence of the fixing portion, that is, to suppress unintentional flipping of the end of the stretchable sheet on the side of the waist opening.

- the other end side portion of the stretchable sheet is not fixed to the non-stretchable sheet by the fixing portion, and is folded upward starting from the lower end of the fixing portion, and the crotch-side end of the stretchable sheet

- the elasticity of the Therefore, positional displacement of the absorbent core can be suppressed. Therefore, the fit of the absorbent core to the wearer can be maintained even after excretion, and leakage of excrement can be reduced.

- the pants-type absorbent article according to the present invention an embodiment will be described by taking a disposable diaper for infants as an example.

- the pants-type absorbent article according to the present invention is not limited to disposable diapers for infants, and can also be used as disposable diapers for adults, menstrual shorts, and the like.

- FIG. 1 is a perspective view of a shorts-type disposable diaper 1 (hereinafter, "diaper").

- FIG. 2 is a plan view of the diaper 1 in the unfolded and stretched state.

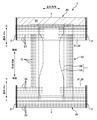

- FIG. 3 is a cross-sectional view taken along line II of FIG.

- the diaper 1 has a vertical direction and a horizontal direction in the pants-type state shown in FIG. 1, and the waist opening BH and the pair of leg openings LH are formed.

- the waist opening BH side is the upper side

- the crotch side is the lower side.

- the direction in which the materials constituting the diaper 1 are stacked is referred to as the thickness direction

- the side in contact with the wearer in the thickness direction is referred to as the skin side, and the side not in contact with the wearer. It is called the non-skin side.

- the diaper 1 has the absorptive main body 10, the ventral waistline part 20, and the back waistline part 30 which are three members of rectangular shape planar view.

- the ventral torso 20 is applied to the ventral side of the wearer and the dorsal torso 30 is applied to the dorsal side of the wearer.

- the ventral-side waist portion 20 and the back-side waist portion 30 are arranged such that their longitudinal direction is along the left-right direction of the diaper 1.

- the end of the absorbent main body 10 on one side in the longitudinal direction is disposed at the center of the ventral-side waist portion 20 in the left-right direction, and the length of the absorbent main body 10 is at the center of the back-side waist portion 30 in the left-right direction.

- the other end of the direction is disposed.

- the absorbent main body 10 is folded in half at the approximate center of the longitudinal direction so that the longitudinal direction of the absorbent main body 10 follows the vertical direction of the diaper 1.

- Both ends of the ventral waist portion 20 and both ends of the back waist portion 30 are joined by thermal welding, ultrasonic welding or the like to form a pair of joint regions 2 as shown in FIG. It becomes diaper 1 of a pants type state.

- the absorbent main body 10 is disposed on the non-skin side of the absorbent body 11, the liquid-permeable top sheet 12 disposed on the skin side of the absorbent body 11, and the absorbent body 11. It has a liquid-impermeable back sheet 13 and an exterior sheet 14 disposed on the non-skin side of the back sheet 13.

- Absorbent body 11 has absorptive core 11A which absorbs and holds waste fluid, such as urine, and liquid permeable core wrap sheet 11B which covers absorptive core 11A.

- the absorbent core 11A include those in which a liquid absorbent fiber such as pulp containing a high absorbent polymer (SAP) is molded into a predetermined shape.

- the leg elastic member 15 is provided in the both sides of the absorptive main body 10 in the left-right direction, and the diaper 1 fits around a leg of a wearer.

- the leg elastic members 15 are, for example, fixed in a stretched state in the longitudinal direction of the absorbent main body 10 between the exterior sheet 14 which is folded back inward in the left-right direction to form two layers.

- a thread-like elastic member or a stretchable sheet can be exemplified.

- the ventral-side waist portion 20 and the back-side waist portion 30 are, as shown in FIG. 3, respectively, inner layer sheets 21 and 31, outer layer sheets 22 and 32 laminated on the inner layer sheets 21 and 31, and a plurality of filamentous elastic members 23 and 33.

- the outer layer sheets 22 and 32 are arranged on the non-skin side of the inner layer sheets 21 and 31.

- the inner layer sheets 21 and 31 and the outer layer sheets 22 and 32 are disposed on the non-skin side of the absorbent main body 10.

- the upper ends 221 and 321 of the outer layer sheets 22 and 32 are folded downward to cover the longitudinal ends of the absorbent main body 10 from the skin side.

- the inner layer sheets 21 and 31 and the outer layer sheets 22 and 32 alone are non-stretchable sheets that do not substantially have stretchability in the left-right direction of the diaper 1.

- SMS non-woven fabric spun-bond / melt-blown / spun-bond non-woven fabric

- spun-bond non-woven fabric spun-bond non-woven fabric

- air-through non-woven fabric plastic sheet, apertured plastic sheet, and laminate sheets thereof as inner layer sheets 21 and 31 and outer layer sheets 22 and 32 Can.

- the plurality of thread-like elastic members 23 and 33 are arranged in the vertical direction between the inner layer sheets 21 and 31 and the outer layer sheets 22 and 32, and fixed in an extended state in the horizontal direction. Therefore, the ventral waist part 20 and the back waist part 30 expand and contract in the left-right direction, and fit around the wearer's waist.

- thread-like elastic members 23, 33 thread-like elastic members such as rubber and spandex can be exemplified.

- the thread-like elastic member 33 is disposed from the upper end to the lower end.

- the thread-like elastic member 23 is not disposed at the upper end portion of the ventral-side waist portion 20, and instead, the stretchable sheet 24 which is expanded and contracted in the left-right direction is disposed.

- the lower end portion of the stretchable sheet 24 and the thread-like elastic member 23 are arranged to overlap in the vertical direction, but they do not have to overlap.

- the stretchable sheet 24 without disposing the thread-like elastic member 23 at the upper end of the ventral waist portion 20 in this manner, the upper end portion of the ventral waist portion 20 is in close contact with the wearer by the surface. Therefore, local tightening can be suppressed, and traces of the expansion and contraction member can be made difficult to remain. In particular, since the abdomen of an infant is popping out, it is preferable to suppress the tightening of the ventral torso part 20.

- the stretchability of the upper end of the waist portion 20, 30 greatly influences the ease of opening the waist opening BH when the diaper 1 is worn.

- the stretchable sheet 24 has a property of being easily stretched from the natural state and difficult to shrink from the stretched state. Therefore, by arranging the stretchable sheet 24 at the upper end of the ventral waist portion 20, the waist opening BH can be easily spread when the diaper 1 is worn, and after the waist portions 20 and 30 are fitted to the wearer. It can prevent the tightening of the abdomen.

- the stretchable sheet 24 may be, for example, various types such as spunbonded non-woven fabric, air-through non-woven fabric, needle-punched non-woven fabric, etc. composed of elastic fibers having a mass of 10 to 40 g / m 2 , more preferably 15 to 30 g / m 2.

- a stretchable non-woven fabric produced by a known method can be used.

- the elastic fiber is made of a thermoplastic elastomer, rubber or the like as a raw material, and particularly when a thermoplastic elastomer is used as a raw material, melt spinning using an extruder is possible like an ordinary thermoplastic resin. Also, the fibers thus obtained are easily heat-sealed and are suitable as stretchable non-woven fibers.

- thermoplastic elastomer examples include styrene-based elastomers, olefin-based elastomers, polyester-based elastomers, and polyurethane-based elastomers. These can be used singly or in combination of two or more.

- the stretchable sheet may be any one that exhibits elasticity at least in the left-right direction, and may exhibit elasticity in two or more directions.

- the stretching ratio in the left-right direction of the stretchable sheet 24 is preferably about 1.2 to 3.0.

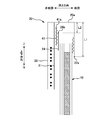

- FIG. 4 is a cross-sectional view of the ventral-side waist part 20 in the process of manufacturing.

- FIG. 5 is a cross-sectional view of the ventral torso part 20 in the product state.

- 6 is a plan view of the ventral torso part 20 shown in FIG. 4 and 5 are diagrams schematically showing the configuration of the ventral-side waist portion 20, and the thickness of the ventral-side waist portion 20 is drawn thick. The same applies to the sectional views described later.

- the thread-like elastic member 23 is omitted.

- the belly-side waist portion 20 includes the inner layer sheet 21, the outer layer sheet 22, and the stretchable sheet 24.

- the outer layer sheet 22, the inner layer sheet 21, and the elastic sheet 24 are laminated in order from the non-skin side in the thickness direction.

- Each of the inner layer sheet 21, the outer layer sheet 22, and the stretchable sheet 24 has one end 21a, 22a, 24a and the other end 21b, 22b, 24b extending along the left-right direction, as shown in FIG. In the product state (FIG. 5), one end 21a, 22a, 24a of each sheet is located above the other end 21b, 22b, 24b.

- the inner layer sheet 21 and the outer layer sheet 22 are joined by an adhesive (not shown) applied therebetween.

- the inner layer sheet 21 and the outer layer sheet 22 correspond to the non-stretchable sheet of the present invention.

- the inner layer sheet 21 and the outer layer sheet 22 are collectively referred to as a non-stretchable sheet.

- the position of one end 21a of the inner layer sheet 21 in the vertical direction is aligned with the position of one end 24a of the elastic sheet 24.

- the outer layer sheet 22 extends above the inner layer sheet 21 and the elastic sheet 24.

- the outer layer sheet 22 is folded downward with the positions of the inner layer sheet 21 and the ends 21 a and 24 a of the elastic sheet 24 as the folding position F.

- the portion 221 of the outer layer sheet 22 folded back covers the longitudinal end of the absorbent main body 10 from the skin side. Further, the portion 221 of the outer layer sheet 22 which has been folded back is fixed to the stretchable sheet 24 and the absorbent main body 10 by the adhesive 42.

- an adhesive 41 such as a hot melt adhesive is applied between the non-stretchable sheet (the inner layer sheet 21 and the outer layer sheet 22) and the stretchable sheet 24.

- the stretchable sheet 24 is fixed to the non-stretchable sheets 21 and 22 by the adhesive 41.

- the application region of the adhesive 41 is a rectangular region in plan view.

- the application area of the adhesive 41 corresponds to the fixing portion of the present invention.

- the application region of the adhesive 41 is also referred to as a fixing portion 41.

- the adhesive 41 may be partially applied to the application region of the adhesive 41, or the adhesive 41 may be applied to the entire region.

- Examples of the application pattern of the adhesive 41 may include known patterns such as a stripe pattern, a spiral pattern, and an ⁇ pattern.

- the planar shape of the application region of the adhesive 41 is not limited to the rectangular shape.

- the fixing portion is not limited to the adhesive 41, and may be a welding area in which the stretchable sheet 24 is fixed to the non-stretchable sheets 21 and 22 by heat welding, ultrasonic welding, or the like.

- the fixing portion 41 has one end 41a and the other end 41b extending in the left-right direction.

- one end 41a of the fixing portion 41 is located above the other end 41b.

- the fixing portion 41 is provided straddling one end 24 a of the stretchable sheet 24 in the vertical direction.

- the fixing portion 41 is provided between the stretchable sheet 24 and the inner layer sheet 21, and the skin of the outer layer sheet 22 beyond the one end 24a of the stretchable sheet 24 It is also provided on the side. Therefore, in the product state (FIG. 5), along with the folding of the outer layer sheet 22, a part of the fixing portion 41 is also folded downward, and the fixing portion 41 covers the one end 24a of the stretchable sheet 24 from above. There is. Therefore, the fixing portion 41 is provided straddling one end 24 a of the stretchable sheet 24 in the vertical direction in the product state (FIG. 5).

- the fixing portion 41 By providing the fixing portion 41 in this manner, the region on one end 24 a side of the stretchable sheet 24 is fixed to the non-stretchable sheets 21 and 22 up to the one end 24 a. Therefore, it is possible to prevent the site on the side of the one end 24a of the stretchable sheet 24 (that is, the end on the side of the waist opening BH) from being unintentionally curled up by the contraction force of the stretchable sheet 24 during manufacturing.

- That the stretchable sheet 24 is turned up means that the end of the stretchable sheet 24 rises in the thickness direction or the end of the stretchable sheet 24 is folded back in the vertical direction by the folding starting point extending in the left-right direction of the diaper 1 It is When the end portion of the stretchable sheet 24 is folded back and the stretchable sheet 24 is stacked, the stretching force in the left-right direction is increased by the amount of the folded back stretchable sheet 24.

- the stretchability of the upper end portion of the waist portion 20, 30 greatly influences the ease of opening the waist opening BH. Therefore, when the stretchable sheet 24 is provided at the upper end portion of the ventral-side waist portion 20 as in the diaper 1 of the present embodiment, the folding of the portion on the side of the one end 24a of the stretchable sheet 24 is particularly suppressed. Is effective. By doing so, it is possible to maintain the ease of opening the waistline opening BH.

- the stretchable sheet 24 When the stretchable sheet 24 is provided at the upper end portion of the ventral-side waist portion 20, at least a part of the stretchable sheet 24 is from the center CL (see FIG. 5) of the ventral-side waist portion 20 in the vertical direction. Is also located at the top. More preferably, all of the stretchable sheets 24 may be located above the center CL of the ventral waist portion 20.

- the portion on the side of the one end 22a of the outer layer sheet 22 is folded downward.

- the length in the vertical direction from the upper end 20a of the ventral-side waist portion 20 to one end (here, one end 22a of the outer layer sheet 22) of the non-stretchable sheet folded downward is a length L1.

- the length in the vertical direction from the upper end 20a of the ventral-side waist portion 20 to the one end 24a of the stretchable sheet 24 is zero.

- the length (zero) may be shorter than the length L1.

- one end 24 a of the stretchable sheet 24 may be positioned above the one end 22 a of the folded outer layer sheet 22. By doing so, the stretchable sheet 24 will not be positioned too low. Therefore, the fit of the upper end portion of the ventral-side waist portion 20 can be maintained.

- the fixing portion 41 is not limited to the first region 411 for fixing one surface 24A (non-skin side surface in FIG. 4) of both surfaces of the stretchable sheet 24 to the non-stretchable sheets 21 and 22, And the second area 412 of The second region 412 of the fixing portion 41 is continuous with the first region 411 and of the fixing portion 41 provided on the non-stretchable sheet (here, the outer layer sheet 22) beyond one end 24 a of the elastic sheet 24. It is an area.

- the 1st field 411 of fixed part 41 is located between elastic sheet 24 and inner layer sheet 21, and is not exposed.

- the second region 412 of the fixing portion 41 provided on the outer layer sheet 22 is exposed to the skin side. If the second region 412 of the fixing portion 41 is exposed to the skin side in the product state, the solidified adhesive 41 abuts on the wearer, and the wearing comfort of the ventral-side waist portion 20 is reduced. Moreover, although not illustrated, also when the 2nd field 412 of fixed part 41 is exposed to the non-skin side, touch feeling of belly side waist part 20 from the outside will fall.

- the second region 412 of the fixing portion 41 is not exposed. More preferably, all of the second region 412 of the fixing portion 41 may not be exposed. That is, it is good for the 2nd field 412 of fixed part 41 to be located between the materials which constitute diaper 1.

- the second region 412 of the fixing portion 41 is covered from the skin side with the portion 221 of the outer layer sheet 22 folded back downward.

- the second region 412 of the fixing portion 41 is located between the portion 221 of the outer layer sheet 22 which is folded back and the stretchable sheet 24 and is not exposed. Therefore, the fall of the wearing comfort of belly side waist part 20 and the fall of touch can be controlled.

- the configuration of the belly-side waist portion 20 is not limited to that shown in FIG.

- the inner layer sheet 21 folded downward, or another sheet other than the non-stretchable sheets 21 and 22 may be used.

- the portion on the side of the one end 24a of the stretchable sheet 24 is not folded downward. That is, the manufacturing method of the diaper 1 does not have the process of folding back the site

- the number of laminated stretchable sheets 24 is one. That is, the stretching force in the left-right direction at the upper end portion of the ventral-side waist portion 20 is appropriately suppressed. Therefore, when the diaper 1 is worn, the waist opening BH can be easily spread, and tightening of the wearer's abdomen can be prevented.

- the manufacturing method of the diaper 1 has the process of turning down the fixing

- the fixed portion 41 is stacked in the thickness direction at the upper end portion of the ventral-side waist portion 20. That is, the layer of the adhesive 41 becomes two layers, and the rigidity of the upper end portion of the ventral-side waist portion 20 is enhanced. Therefore, when the diaper 1 is worn, the upper end of the ventral waistline portion 20 can be easily grasped, and the diaper 1 can be easily pulled up. Moreover, it can suppress that the upper end part of belly side waist part 20 is turned up at the time of packing etc. and a fold is attached, and a fall of the appearance of diaper 1 can be prevented.

- FIG. 9A and 10A are views of the ventral torso part 20 in the process of being manufactured.

- the other figures are views of the ventral torso part 20 in the product state.

- part at the side of the one end 24a of the elastic sheet 24 is not folded downward similarly to FIG.

- one end 24 a of the stretchable sheet 24 is located below the upper end 20 a of the ventral-side waist portion 20. Then, the fixing portion 41 straddling the one end 24 a of the stretchable sheet 24 in the vertical direction suppresses the flipping of the part on the side of the one end 24 a of the stretchable sheet 24.

- the length L2 in the vertical direction from the upper end 20a of the ventral-side waist portion 20 to one end 24a of the elastic sheet 24 is the ventral-side waist portion

- the length L1 is shorter than the length L1 in the vertical direction from the upper end 20a of the sheet 20 to the end 22a of the outer layer sheet 22 (L2 ⁇ L1). That is, the stretchable sheet 24 is not positioned too low. Therefore, the fit of the upper end portion of the ventral-side waist portion 20 can be maintained.

- fixed part 41 is bend

- fixed part 41 is not return

- one end 24 a of the stretchable sheet 24 and one end 41 a of the fixing portion 41 are located below the upper end 20 a of the belly-side waist portion 20. Therefore, in the upper end portion of the ventral-side waist portion 20, there is a region where the stretchable sheet 24 and the fixing portion 41 are not located. Thus, the upper end of the ventral waistline portion 20 is softer.

- the upper end portion of the ventral-side waist portion 20 When the upper end portion of the ventral-side waist portion 20 is soft, it is possible to prevent the upper end (edge) 20 a of the ventral-side waist portion 20 from stimulating the skin of the wearer. Further, in the natural state of the diaper 1, the upper end portion of the ventral waistline portion 20 is likely to be frilled. Therefore, the user can have the impression that the diaper 1 is soft and comfortable to wear.

- the portion on the side of the one end 24a of the stretchable sheet 24 is folded downward. Therefore, in the state in the middle of production (FIG. 9A), the stretchable sheet 24 extends above the inner layer sheet 21 as the outer layer sheet 22 does. And the manufacturing method of the diapar 1 has the process of folding back the elastic sheet 24 with the outer-layer sheet 22 downward. Therefore, the number of laminated stretchable sheets 24 at the upper end portion of the ventral-side waist portion 20 is two. Therefore, in the belly-side waist portion 20 of FIG. 9B, the stretching force in the left-right direction is enhanced as compared with the belly-side waist portion 20 of FIG. 5 and the like.

- the fixing portion 41 straddling the end 24a of the stretchable sheet 24 suppresses the curling of the portion on the end 24a side of the stretchable sheet 24. Therefore, it is possible to prevent the number of laminated layers of the stretchable sheet 24 from being three or more and to make the stretchability of the belly-side waist portion 20 larger than the designed force.

- the adhesive for fixing the stretchable sheets 24 is not provided, and the portion on the side of the one end 24a of the folded-back stretchable sheet 24 and the stretchable unfolded The opposite surface to the portion of the sex sheet 24 is not fixed.

- a space 24B is formed between the folded back portion of the stretchable sheet 24 and the non-folded portion, and the cushioning property of the upper end portion of the ventral-side waist portion 20 is high. Therefore, the skin contact to the wearer can be improved.

- the surface of the portion provided with the stretchable sheet 24 is smoother than the portion provided with the thread-like elastic member 23, and the finger is less likely to be caught when the diaper 1 is pulled up.

- the stretchable sheet 24 has two layers, and the thickness of the upper end portion of the ventral-side waist portion 20 is increased by the space 24B formed therebetween. The thickened part becomes a handle and it is easy to pull up the diaper 1.

- the vertical length L2 from the upper end 20a of the ventral-side waist portion 20 to one end 24a of the stretchable sheet 24 is the outer layer sheet from the upper end 20a of the ventral-side waist portion 20. It is preferable that the length L1 to the end 22a of the end 22 be shorter than the length L1 (L2 ⁇ L1). By doing so, the length of the folded elastic sheet 24 does not become too long, and the area in which the elastic sheet 24 has two layers can be reduced. That is, the stretching force in the left-right direction of the ventral-side waist portion 20 can be appropriately suppressed.

- the stretchable sheet 24 may be fixed by the fixing portion 41 to the portion 221 of the outer layer sheet 22 which is folded downward.

- the folded elastic sheet 24 and the inner layer sheet 21 may be fixed by an adhesive 43.

- the lower end 24a of the stretchable sheet 24 becomes one end 24a of the stretchable sheet 24 and the fixing portion 41 extends downward beyond the lower end 24a of the stretchable sheet 24 in the process of manufacture (FIG. 10A). There is. By doing so, in the product state (FIG. 10B), it is possible to suppress the flipping of the portion on the side of one end 24a of the stretchable sheet 24 (that is, the end on the side of the waist opening BH).

- the fixing portion 41 for fixing the stretchable sheet 24 to the non-stretchable sheets 21 and 22 is provided across the other end 24b of the stretchable sheet 24 in the vertical direction. Good. In this case, it is possible to suppress the flipping of the portion on the side of the other end 24 b of the stretchable sheet 24 (that is, the end on the crotch side).

- the fixing portion 41 may not be provided straddling the other end 24 b of the stretchable sheet 24 in the vertical direction. That is, the fixing portion 41 may not be provided at a portion on the other end 24 b side of the stretchable sheet 24. In this case, as shown in FIGS. 11 to 15, the portion on the other end 24 b side of the stretchable sheet 24 is turned up by the contraction force of the stretchable sheet 24.

- a portion on the other end 24 b side of the stretchable sheet 24 overlaps with the absorbent main body 10 or is located in the vicinity of the absorbent main body 10. Therefore, the portion on the other end 24 b side of the stretchable sheet 24 is not only flipped up and rises in the thickness direction, but also tends to be folded upward starting from the lower end 41 b (other end) of the fixed portion 41.

- the stretchable sheet 24 may be folded back so as to form a broken line extending in the left-right direction, and as shown in FIG. 11A etc., the lower end of the stretchable sheet 24 is bent back. It may be curled. Moreover, in the figure before FIG. 9, in order to prevent the complexity of a figure, the site

- the stretching force in the left-right direction of the crotch-side end of the stretchable sheet 24 can be enhanced. That is, it is possible to enhance the stretchability of the portion overlapping with the absorbent main body 10 in the ventral waist portion 20 and the portion in the vicinity thereof. Therefore, position shift of absorptive main part 10 (absorbent core 11A) can be controlled. For example, it is possible to suppress drooping of the absorbent main body 10 that has absorbed the waste fluid. Therefore, the fit of the absorbent main body to the wearer can be maintained even after excretion, and leakage of excrement can be reduced. In addition, the wearer does not feel discomfort and it is easy to walk.

- the stretching force of the crotch-side end of the stretchable sheet 24 is less likely to affect the spreadability of the waist opening BH as compared with the stretching force of the end on the waist opening BH side. Therefore, even if the crotch-side end of the stretchable sheet 24 has two layers, the ease of opening the waistline opening BH can be maintained.

- the folding of the crotch-side end of the stretchable sheet 24 utilizes the contraction force of the stretchable sheet 24. That is, the manufacturing method of the diaper 1 does not have the process of folding back the site

- the underpants type diaper 1 has a pair of joining area

- the stretchable sheet 24 may be extended to the outside of the formation position of the bonding area 2 in the left-right direction.

- region 2 is formed in the state by which the site

- the folded back portion 241 is a portion from the portion 24 c of the stretchable sheet 24 in contact with the other end 41 b of the fixed portion 41 to the other end 24 b of the stretchable sheet 24.

- the folded portion 241 of the stretchable sheet 24 is positioned on the non-skin side of the absorbent main body 10.

- the folded-back part 241 of the stretchable sheet 24 is positioned closer to the skin than the absorbent main body 10.

- folding part 241 of elastic sheet 24 is located above upper end 10a of absorptive main part 10. As shown in FIG. That is, the folded-back portion 241 does not overlap with the absorbent main body 10 in the vertical direction.

- the folded back portion 241 can bring the portion of the belly-side waist portion 20 in the vicinity of the absorbent main body 10 into close contact with the wearer. Therefore, position shift of absorptive main part 10 (absorbent core 11A) can be controlled. In addition, the stretching force of the folded portion 241 is less likely to be inhibited by the highly rigid absorbent main body 10.

- the folded portion 241 of the stretchable sheet 24 is positioned below the upper end 10a of the absorbent main body 10 and positioned above the upper end 11Aa of the absorbent core 11A. doing. That is, in the vertical direction, the folded back portion 241 overlaps the upper end portion (top sheet 12, back sheet 13, exterior sheet 14, core wrap sheet 11B) of the absorbent main body 10, but overlaps with the absorbent core 11A. I did not.

- the folded portion 241 in FIG. 12A is located on the non-skin side of the absorbent main body 10.

- the folded back portion 241 can bring the upper end portion of the absorbent main body 10 into close contact with the wearer from the non-skin side, and can suppress positional deviation of the absorbent main body 10 (absorbent core 11A).

- the folded back portion 241 in FIG. 12B is located closer to the skin than the absorbent main body 10. Also in this case, the folded-back portion 241 can bring the portion of the belly-side waist portion 20 overlapping the upper end portion of the absorbent main body 10 into close contact with the wearer, and the positional deviation of the absorbent main body 10 (absorbent core 11A) Can be suppressed. Further, in FIG. 12B, the stretchable sheet 24 covers the upper end 10a of the absorbent main body 10 from the skin side together with the outer layer sheet 22. Therefore, the wearer hardly feels the contact of the upper end 10a (edge) of the absorbent main body 10, and it is difficult for the wearer to have a foreign body feeling.

- the rigidity is higher than in the region where the absorbent core 11A does not exist. Therefore, in the case of FIG. 12A and FIG. 12B, the stretching force of the folded portion 241 is less likely to be inhibited by the highly rigid absorbent core 11A.

- the folded-back part 241 of the stretchable sheet 24 is provided straddling the upper end 10 a of the absorbent main body 10 in the vertical direction.

- the number of materials can be gradually changed around the upper end 10 a of the absorbent main body 10.

- an area in which the stretchable sheet 24 is a single layer, an area in which the stretchable sheet 24 is a double layer (folded portion 241), and a stretchable sheet 24 in a double layer (folded portion) The area

- the folded back portion 241 of the stretchable sheet 24 covers the upper end 10a of the absorbent main body 10 from the skin side. Therefore, the wearer is less likely to feel the contact of the upper end 10a (edge) of the absorbent main body 10 than in the case of FIG. 12B, and the wearer is less likely to feel a foreign object.

- the folded portion 241 of the stretchable sheet 24 is located below the upper end 11Aa of the absorbent core 11A. That is, in the vertical direction, the folded back portion 241 overlaps the absorbent core 11A.

- the folded portion 241 in FIG. 14A is located on the non-skin side of the absorbent core 11A. Therefore, the folded back portion 241 can make the absorbent core 11A in close contact with the wearer from the non-skin side, and can suppress positional deviation of the absorbent main body 10 (absorbent core 11A).

- the absorbent core 11A absorbs waste fluid and becomes heavy, the portion of the absorbent main body 10 where the absorbent core 11A is present is most likely to be displaced. Therefore, in FIG. 14A, the site

- the folded back portion 241 in FIG. 14B is located closer to the skin than the absorbent core 11A. Also in this case, the folded-back portion 241 can bring the portion of the ventral-side waist portion 20 overlapping the portion of the absorbent main body 10 that is most likely to be dislocated, into close contact with the wearer. 11A) can be suppressed. Further, in FIG. 14B, the stretchable sheet 24 covers the absorbent main body 10 and the upper ends 10a and 11Aa of the absorbent core 11 from the skin side. Therefore, it becomes difficult for the wearer to feel the contact between the absorbent main body 10 and the upper ends (edges) 10a and 11Aa of the absorbent core 11, and it is difficult for the wearer to have a foreign body feeling.

- the folded-back part 241 of the stretchable sheet 24 is provided straddling the upper end 11Aa of the absorbent core 11A in the vertical direction.

- the number of materials can be gradually changed around the upper end 11Aa of the absorbent core 11A.

- an area where the upper end portion of the absorbent main body 10 and the elastic sheet 24 of one layer are laminated, the upper end portion of the absorbent main body 10 and the elastic sheet 24 of two layers folded

- the number of materials can be increased in order from the region where the portion 241 is stacked, the region where the absorbent core 11A is present in the absorbent main body 10, and the region where the two-layered stretchable sheet 24 is stacked. Therefore, the difference in level and rigidity between the area where the absorbent core 11A exists and the area where the absorbent core 11A does not exist is reduced, and it is difficult for the wearer to feel a foreign object.

- the folded back portion 241 of the stretchable sheet 24 covers the upper end 11Aa of the absorbent core 11 from the skin side. Therefore, the wearer is less likely to feel the contact of the upper end (edge) 11Aa of the absorbent core 11A than in the case of FIG. 14B, and the wearer is less likely to feel a foreign object.

- the ventral waist portion 20 has the stretchable sheet 24, the ventral waist portion 20 corresponds to the first waist portion of the present invention, and the back waist portion 20 is the second waist portion of the present invention. It corresponds to, but it is not limited to this.

- a mode in which the back waistline portion 20 has an elastic sheet 24, the back waistline portion 30 corresponds to a first waistline portion of the present invention, and the belly side waistline portion 20 corresponds to a second waistline portion of the present invention May be.

- the second waist portion of the present invention may have a stretchable sheet, and both the ventral waist portion 20 and the back waist portion 30 may have a stretch sheet.

- the fixing portion for fixing the stretchable sheet (the stretchable sheet of either the ventral waistline 20 or the back waistline 30) of the second waist portion to the non-stretch sheet is the stretchable sheet.

- One end may be straddled in the vertical direction, or may not be straddled.

- the stretchable sheet 24 is disposed at the upper end portion of the ventral-side waist portion 20.

- the stretchable sheet 24 may be located at any position of the ventral-side waist portion 20 in the vertical direction. May be arranged.

- ventral waistline portion 20 and the back waistline portion 30 are separated as the pants-type absorbent article, and the three members of the ventral waistline portion 20, the back waistline portion 30, and the absorbent main body 10

- the so-called 3 piece type diaper which it has is illustrated, it does not restrict to this.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| RU2020121411A RU2772176C2 (ru) | 2017-12-28 | 2018-12-11 | Впитывающее изделие в виде трусов |

| CN201880084016.1A CN111526845B (zh) | 2017-12-28 | 2018-12-11 | 短裤型吸收性物品 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-255005 | 2017-12-28 | ||

| JP2017255005A JP6703975B2 (ja) | 2017-12-28 | 2017-12-28 | パンツ型吸収性物品 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019131111A1 true WO2019131111A1 (ja) | 2019-07-04 |

Family

ID=67063521

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/045482 WO2019131111A1 (ja) | 2017-12-28 | 2018-12-11 | パンツ型吸収性物品 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6703975B2 (ru) |

| CN (1) | CN111526845B (ru) |

| WO (1) | WO2019131111A1 (ru) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3705097A4 (en) * | 2017-12-28 | 2020-12-09 | Unicharm Corporation | ABSORBENT ITEM |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7458781B2 (ja) * | 2019-12-26 | 2024-04-01 | ユニ・チャーム株式会社 | パンツ型使い捨ておむつ |

| JP7256775B2 (ja) | 2020-08-11 | 2023-04-12 | 大王製紙株式会社 | 使い捨て着用物品 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0484309U (ru) * | 1990-11-30 | 1992-07-22 | ||

| JP2008228835A (ja) * | 2007-03-16 | 2008-10-02 | Kao Corp | 使い捨ておむつ |

| JP2011136095A (ja) * | 2009-12-28 | 2011-07-14 | Unicharm Corp | 使い捨て着用物品 |

| WO2016159095A1 (ja) * | 2015-03-30 | 2016-10-06 | 大王製紙株式会社 | パンツタイプ使い捨ておむつ |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002119537A (ja) * | 2000-10-13 | 2002-04-23 | Uni Charm Corp | パンツ型の使い捨て着用物品 |

| SE0200473D0 (sv) * | 2002-02-19 | 2002-02-19 | Sca Hygiene Prod Ab | Elastisk absorberande byxa |

| KR20090084952A (ko) * | 2006-11-27 | 2009-08-05 | 유니 참 코포레이션 | 흡수성 물품 및 복합 시트 |

| JP5383122B2 (ja) * | 2008-09-01 | 2014-01-08 | ユニ・チャーム株式会社 | 使い捨ておむつ |

| JP6407693B2 (ja) * | 2014-12-15 | 2018-10-17 | 花王株式会社 | 使い捨て着用物品 |

-

2017

- 2017-12-28 JP JP2017255005A patent/JP6703975B2/ja active Active

-

2018

- 2018-12-11 CN CN201880084016.1A patent/CN111526845B/zh active Active

- 2018-12-11 WO PCT/JP2018/045482 patent/WO2019131111A1/ja active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0484309U (ru) * | 1990-11-30 | 1992-07-22 | ||

| JP2008228835A (ja) * | 2007-03-16 | 2008-10-02 | Kao Corp | 使い捨ておむつ |

| JP2011136095A (ja) * | 2009-12-28 | 2011-07-14 | Unicharm Corp | 使い捨て着用物品 |

| WO2016159095A1 (ja) * | 2015-03-30 | 2016-10-06 | 大王製紙株式会社 | パンツタイプ使い捨ておむつ |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3705097A4 (en) * | 2017-12-28 | 2020-12-09 | Unicharm Corporation | ABSORBENT ITEM |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2020121411A3 (ru) | 2022-01-28 |

| CN111526845A (zh) | 2020-08-11 |

| JP2019118581A (ja) | 2019-07-22 |

| RU2020121411A (ru) | 2022-01-28 |

| JP6703975B2 (ja) | 2020-06-03 |

| CN111526845B (zh) | 2022-06-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5000551B2 (ja) | 吸収性物品及び吸収性本体保持カバー | |

| JP6014448B2 (ja) | 吸収性物品 | |

| WO2019131111A1 (ja) | パンツ型吸収性物品 | |

| WO2016208255A1 (ja) | 吸収性物品 | |

| WO2019031124A1 (ja) | パンツ型吸収性物品 | |

| JP6220661B2 (ja) | パンツ型吸収性物品 | |

| WO2019131110A1 (ja) | 吸収性物品 | |

| WO2019131058A1 (ja) | パンツ型吸収性物品 | |

| WO2019131109A1 (ja) | パンツ型吸収性物品 | |

| JP2019205920A (ja) | パンツ型吸収性物品 | |

| JP2003038573A (ja) | パンツ型使い捨ておむつ | |

| JP6226910B2 (ja) | 吸収性物品 | |

| JP7271249B2 (ja) | パンツ型吸収性物品 | |

| WO2017002391A1 (ja) | 吸収性物品 | |

| CN111526844B (zh) | 吸收性物品的制造方法和吸收性物品的制造装置 | |

| JP4870825B2 (ja) | 紙おむつ | |

| JP2005211179A (ja) | パンツ型使い捨ておむつ | |

| RU2772176C2 (ru) | Впитывающее изделие в виде трусов | |

| KR102678055B1 (ko) | 흡수성 물품 | |

| TWI848079B (zh) | 吸收性物品 | |

| JP7179458B2 (ja) | 吸収性物品 | |

| JP6205230B2 (ja) | 使い捨ておむつ | |

| JP6427482B2 (ja) | 使い捨ておむつ | |

| JP4463322B2 (ja) | 紙おむつ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18897294 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18897294 Country of ref document: EP Kind code of ref document: A1 |