WO2018173633A1 - トルクリミッタ - Google Patents

トルクリミッタ Download PDFInfo

- Publication number

- WO2018173633A1 WO2018173633A1 PCT/JP2018/006833 JP2018006833W WO2018173633A1 WO 2018173633 A1 WO2018173633 A1 WO 2018173633A1 JP 2018006833 W JP2018006833 W JP 2018006833W WO 2018173633 A1 WO2018173633 A1 WO 2018173633A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- input

- output

- plate

- applied voltage

- torque

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D7/00—Slip couplings, e.g. slipping on overload, for absorbing shock

- F16D7/02—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J19/00—Accessories fitted to manipulators, e.g. for monitoring, for viewing; Safety devices combined with or specially adapted for use in connection with manipulators

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D27/00—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor

- F16D27/02—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with electromagnets incorporated in the clutch, i.e. with collecting rings

- F16D27/04—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with electromagnets incorporated in the clutch, i.e. with collecting rings with axially-movable friction surfaces

- F16D27/06—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with electromagnets incorporated in the clutch, i.e. with collecting rings with axially-movable friction surfaces with friction surfaces arranged within the flux

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D27/00—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor

- F16D27/12—Clutch systems with a plurality of electro-magnetically-actuated clutches

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D27/00—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor

- F16D27/14—Details

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D7/00—Slip couplings, e.g. slipping on overload, for absorbing shock

- F16D7/02—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type

- F16D7/024—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type with axially applied torque limiting friction surfaces

- F16D7/025—Slip couplings, e.g. slipping on overload, for absorbing shock of the friction type with axially applied torque limiting friction surfaces with flat clutching surfaces, e.g. discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W2710/00—Output or target parameters relating to a particular sub-units

- B60W2710/06—Combustion engines, Gas turbines

- B60W2710/0666—Engine torque

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60W—CONJOINT CONTROL OF VEHICLE SUB-UNITS OF DIFFERENT TYPE OR DIFFERENT FUNCTION; CONTROL SYSTEMS SPECIALLY ADAPTED FOR HYBRID VEHICLES; ROAD VEHICLE DRIVE CONTROL SYSTEMS FOR PURPOSES NOT RELATED TO THE CONTROL OF A PARTICULAR SUB-UNIT

- B60W30/00—Purposes of road vehicle drive control systems not related to the control of a particular sub-unit, e.g. of systems using conjoint control of vehicle sub-units

- B60W30/18—Propelling the vehicle

- B60W30/188—Controlling power parameters of the driveline, e.g. determining the required power

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D27/00—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor

- F16D27/10—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with an electromagnet not rotating with a clutching member, i.e. without collecting rings

- F16D27/108—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with an electromagnet not rotating with a clutching member, i.e. without collecting rings with axially movable clutching members

- F16D27/112—Magnetically- or electrically- actuated clutches; Control or electric circuits therefor with an electromagnet not rotating with a clutching member, i.e. without collecting rings with axially movable clutching members with flat friction surfaces, e.g. discs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D67/00—Combinations of couplings and brakes; Combinations of clutches and brakes

- F16D67/02—Clutch-brake combinations

- F16D67/06—Clutch-brake combinations electromagnetically actuated

Definitions

- the present invention relates to a torque limiter. More specifically, the present invention relates to a torque limit value, which is an upper limit value of torque transmitted from the input side to the output side. The present invention relates to a torque limiter that takes safety into account.

- a torque limiter that cuts off the transmission of torque when the torque transmitted from the input side to the output side is in an overload state exceeding a predetermined value.

- this torque limiter for example, as disclosed in Patent Document 1, there is one using an electromagnetic clutch that transmits torque from the input side to the output side using a magnetic force generated by energization.

- a torque limiter is disposed between the robot arm and the motor that operates the robot arm, and when an overload occurs between them, the transmission of torque between the motor and the robot arm is cut off. It is conceivable to provide it.

- the present invention has been devised by paying attention to such a problem.

- the purpose of the present invention is to make the torque limit value variable at the time of torque transmission from the input side to the output side. It is intended to provide a torque limiter that takes into account safety in case of power loss or emergency stop.

- the present invention is mainly configured so that the magnitude of the torque limit value that is the upper limit value of the torque transmitted from the input side member to the output side member can be electromagnetically adjusted.

- a torque limiter disposed between the input side member and the output side member, the input unit and the output unit by adjusting the magnetic force between them.

- the connecting structure has a connecting structure that can be switched between a connection state connected to each other and a non-connection state not connected to each other so as to be switched, and the connection structure includes an electromagnet that enables adjustment of the magnetic force by adjusting an applied voltage. And when the applied voltage is set to the connected state when the applied voltage is zero, and when the applied voltage is increased from the disconnected state, Bonding force of the input section and the output section is increased in a connected state, it adopts a configuration that is increased the torque limit value.

- the torque limit value can be changed by adjusting the applied voltage, and when used for various machine elements including a robot, various functions for transmission torque control, safety, direct teaching, etc. are provided. Can be realized.

- the applied voltage is zero, the connection state is secured between the input unit and the output unit, the input side of the power etc. is in a non-idling state, safety in case of unexpected power loss such as power failure or emergency stop Can be improved.

- the drive device when a drive device driven by a power source is arranged on the input side, the drive device is also stopped due to power loss or the like, but since the output side is connected to the drive device, The drive side can be used to brake the output side, and other configurations such as other emergency brakes are not required or simplified to ensure the surrounding safety in unexpected situations such as power loss. Can do.

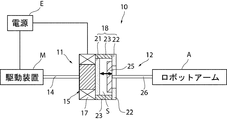

- FIG. 1 It is a conceptual diagram which shows the power transmission structure containing the torque limiter which concerns on 1st Embodiment.

- (A), (B) is a conceptual diagram explaining the action

- FIG. 1 is a conceptual diagram showing a power transmission configuration including a torque limiter according to the first embodiment.

- the torque limiter 10 is provided between a driving device M such as a motor serving as a power source and a robot arm A that is operated by the power from the driving device M. From the driving device M to the robot arm Torque is transmitted to A, and when torque exceeding a torque limit value that is the upper limit value of the torque is applied, the torque transmission is interrupted.

- the torque limiter 10 includes an input unit 11 connected to a driving device M serving as an input side member and an output unit 12 connected to a robot arm A serving as an output side member. It consists of an electromagnetic friction clutch that transmits and shuts off torque between the input unit 11 and the output unit 12 by being separated and approached by the action and performing frictional coupling and separation thereof.

- the input unit 11 includes an input shaft 14 that is rotated by power from the driving device M, and a main body 15 that is fixed to the distal end side of the input shaft 14 and serves as a joint portion with the output unit 12 side.

- the main body 15 can be joined to the output unit 12 by using contact friction between the electromagnet 17 that enables adjustment of the magnetic force generated by adjusting the applied voltage supplied from the power source E and the output unit 12. And a joining portion 18 to be provided.

- the joint 18 is a disc-shaped first input plate 21 located on the electromagnet 17 side, and a donut plate shape that is disposed closer to the output unit 12 than the first input plate 21 and has a hole formed in the center.

- a moving space S of the output unit 12 is formed between the connecting member 23 and the connecting member 23.

- the output unit 12 connects the output plate 25 and the robot arm A to a disk-shaped output plate 25 movably disposed in the moving space S between the first and second input plates 21 and 22. And an output shaft 26 to be fixed.

- the output plate 25 is formed of a material that can be attracted to the first input plate 21 side by the magnetic force of the electromagnet 17, and is disposed so as to face the first and second input plates 21 and 22, respectively.

- the input plates 21 and 22 are allowed to move away from each other.

- the output plate 25 is in a state shown in FIG. 1 when it is not energized from the power source E to the electromagnet 17, that is, in a non-contact state with the first input plate 21, while the second plate It arrange

- a pressing means including a biasing member including a spring is provided between the input portion 11 and the output portion 12, and the pressing means connects the output plate 25 to the second plate. A force in the direction of approaching the input plate 22 is applied to the output plate 25.

- the first and second input plates 21 and 22 can utilize the contact friction with the output plate 25 to transmit torque from the input unit 11 to the output unit 12 by mutual contact.

- at least the contact surface with the output plate 25 is formed by a friction material that generates the contact friction force that enables the torque transmission.

- a friction material here, the thing of the property which does not prevent the effect

- the torque limiter 10 having the above configuration allows the output plate 25 to be separated and approached from the first and second input plates 21 and 22 by the magnetic force of the electromagnet 17 generated when power is supplied from the power source E, and is applied to the electromagnet 17.

- By changing the voltage it is possible to switch between these connected states by friction welding between the input unit 11 and the output unit 12 and the disconnected state of the input unit 11 and the output unit 12.

- the connection state when a torque equal to or less than the joining force, which is a contact friction force at that time, acts between the input unit 11 and the output unit 12, the input unit 11 and the output unit 12 are connected so as not to be relatively rotatable.

- the connected state is established, and the driving force from the driving device M is transmitted to the robot arm A.

- the input unit 11 and the output unit 12 can be rotated relative to each other. 11 idles and the driving force from the driving device M is not transmitted to the robot arm A. Therefore, the torque corresponding to the joining force becomes the torque limit value that is the upper limit value of the torque transmitted from the input unit 11 to the output unit 12.

- the torque limiter 10 is provided so that the torque limit value can be varied by changing the voltage applied to the electromagnet 17.

- the output plate 25 is not in contact with the first input plate 21 as shown in FIG.

- the connection state is in contact with the two input plates 22, and the torque transmission between the input unit 11 and the output unit 12 is enabled by the friction welding at this time.

- the electromagnet 17 is energized from this state, the output plate 25 is attracted to the first input plate 21 side by magnetic force, so that the joining force that is the contact friction force with the second input plate 22 is obtained.

- the distance gradually decreases, and then moves away from the second input plate 22 and then moves in the moving space S toward the first input plate 21.

- the output plate 25 is brought into non-contact with the first and second input plates 21 and 22 through the non-connection state of FIG. ),

- the second input plate 22 is brought into contact with the first input plate 21 while being in non-contact with the second input plate 22.

- the suction force to the first input plate 21 is increased, and the bonding force with the first input plate 21 is increased.

- the second input plate 22 has substantially the same outer diameter as the first input plate 21, but contacts the output plate 25 rather than the first input plate 21 due to the presence of the central hole. The area is getting smaller.

- the maximum torque limit value when the second input plate 22 and the output plate 25 are joined is the maximum when the first input plate 21 and the output plate 25 are in contact with each other due to the shape and the magnitude of the magnetic force that can be generated. It is set smaller than the torque limit value.

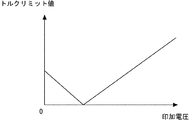

- the change characteristic of the torque limit value with respect to the applied voltage shown in FIG. 3 is obtained by the relative movement of the input unit 11 and the output unit 12 as described above.

- the output plate 25 comes into surface contact with the first input plate 21, and the input unit 11 and the output unit 12 are connected again.

- the suction force of the output plate 25 in the first input plate 21 is gradually increased to increase the joining force thereof, and the torque limit value is increased in proportion to the magnitude of the applied voltage. It will be.

- the magnetic force between them is adjusted with an applied voltage using an electromagnet or the like, and a connected state and a disconnected state that are not mutually connected

- the connected state is set when the applied voltage is zero, and the disconnected state is set at a predetermined value of the applied voltage, and the applied voltage is increased from the disconnected state.

- various structures and configurations can be adopted.

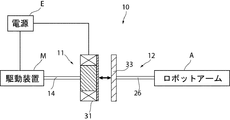

- the torque limiter 30 is characterized in that the input unit 11 and the output unit 12 are partially different from the torque limiter 10 of the first embodiment.

- the input unit 11 includes the input shaft 14 and an input plate 31 that is fixed to the distal end side of the input shaft 14 and serves as a joint portion with the output unit 12.

- the input plate 31 is composed of an electromagnet capable of changing the magnetic force generated according to the magnitude of the applied voltage from the power source E.

- the output unit 12 includes the output shaft 26 and a disk-shaped output plate 33 provided so as to be separated from and close to the input plate 31.

- the output plate 33 is made of a magnetic material such as a neodymium magnet.

- a pressing means for applying a pressing force in a direction in which the input plate 31 and the output plate 33 are brought into contact with each other is provided between the input unit 11 and the output unit 12.

- the pressing means as in the first embodiment, the input unit 11 and the output unit 12 are brought into the connected state with a certain fixed torque limit value even when no power is supplied.

- the pressing means is constituted by a biasing member including a spring that applies a force in a direction in which the output plate 33 is pressed against the input plate 31, and the input plate 31 and the output plate 33 using the pressing force at this time are configured. Enable to join by frictional force.

- the aforementioned friction material may be provided on at least one of the contact surfaces of the input plate 31 and the output plate 33. Further, without providing the friction material, or in combination with the friction material, when the input plate 31 and the output plate 33 are in contact with each other, an engagement member (not shown) that engages with each other so as to be relatively unrotatable is provided. Alternatively, a structure such as forming microscopic irregularities on the contact surfaces can be employed.

- the torque limiter 30 of the present embodiment operates as follows.

- the connection state is in contact with the input plate 31 and the output plate 33, and the input unit 11 and the output unit 12 are connected. Torque transmission between them.

- a positive voltage is applied to the input plate 31 from this state, the attractive force of the output plate 33 with respect to the input plate 31 increases due to the magnetic force, and the bonding force between the input plate 31 and the output plate 33 increases.

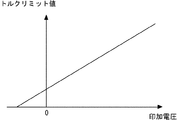

- the change characteristic of the torque limit value with respect to the applied voltage shown in FIG. 5 is obtained. That is, when the negative applied voltage to the input plate 31 is reduced from a predetermined negative applied voltage at which the input unit 11 and the output unit 12 are disconnected, the input unit 11 and the output unit are pressed by the pressing unit. As 12 becomes connected, the repulsive force of the output plate 33 with respect to the input plate 31 gradually decreases, and the torque limit value gradually increases. In addition, a certain torque limit value can be obtained even at the time of non-energization where the applied voltage becomes zero. When a positive voltage is applied to the input plate 31 from this non-energized state, the suction force of the output plate 33 to the input plate 31 gradually increases, and the torque limit value increases in proportion to the applied voltage. It will be.

- the action of the applied voltage “positive” or “negative” in the present embodiment is not limited, and the polarity may be reversed so that the same action and effect are generated.

- the attractive force can be generated with a negative applied voltage, while the repulsive force can be generated with a positive applied voltage.

- the torque limit value can be adjusted by adjusting the voltage applied to the input unit 11, but also the input unit so that a certain torque limit value can be obtained when de-energized. 11 and the output unit 12 can be secured. For this reason, the input unit 11 and the output unit 12 are not released from the connection state in the event of a power loss to the input unit 11 at the time of a power failure or an emergency stop, and the connection with a certain torque limit value is maintained. Will be. Therefore, at this time, the inertial movement of the robot arm A can be braked by using the stop of the driving device M due to power loss or the like, and unexpected collisions with people or objects around the robot arm A due to the inertial movement. Can be avoided and safety can be improved.

- connection structure by using an electromagnet or the like to adjust the magnetic force between them with the applied voltage, the connection state connected to each other and the non-connection state not connected to each other can be switched and separated and approached. Furthermore, when the applied voltage is zero, the connection state is established, the connection state is established with a predetermined applied voltage, and when the applied voltage is increased from the non-connection state, the connection state is established and the torque limit value is set. As long as it is a structure to raise, various things are employable.

- a power backup means that operates when the power supply E that supplies the applied voltage to the electromagnets 17 and 31 of the torque limiters 10 and 30 is cut off can be further provided.

- This power backup means is composed of a control circuit that is charged when the power source E is energized and that supplies the power to the electromagnets 17 and 31 in place of the power source E using the charged power when the power source E is shut off.

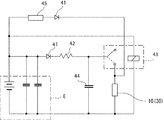

- the control circuit includes a diode 41, a resistor 42, a relay switch 43, a capacitor 44, a controller 45 that adjusts the voltage applied to the power source E, and the like.

- this control circuit power is supplied to the torque limiters 10 and 30 when energized, and a charging state using the capacitor 44 is established.

- the relay switch 43 is switched to the position indicated by the broken line in the figure, and power is supplied to the torque limiters 10 and 30 by using the charging of the capacitor 44.

- the input unit 11 and the output unit 12 are set to a higher torque limit value than when not energized.

- the robot arm A can be returned in a short time, and the robot arm A can continue to operate even if a power loss such as a power failure occurs.

- the torque limiter 10 according to the present invention is not limited to the application example in the above-described embodiment, but can be applied not only to robots having other configurations but also to general power transmission systems such as machines and devices.

- the components of the input unit 11 and the components of the output unit 12 in the aspect of each embodiment may be arranged in reverse between the input unit 11 and the output unit 12.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Robotics (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- One-Way And Automatic Clutches, And Combinations Of Different Clutches (AREA)

- Manipulator (AREA)

- Hydraulic Clutches, Magnetic Clutches, Fluid Clutches, And Fluid Joints (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/495,204 US11118634B2 (en) | 2017-03-19 | 2018-02-24 | Torque limiter |

| CN201880031588.3A CN110637170B (zh) | 2017-03-19 | 2018-02-24 | 扭矩限制器 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-053823 | 2017-03-19 | ||

| JP2017053823A JP6866981B2 (ja) | 2017-03-19 | 2017-03-19 | トルクリミッタ |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018173633A1 true WO2018173633A1 (ja) | 2018-09-27 |

Family

ID=63584523

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/006833 Ceased WO2018173633A1 (ja) | 2017-03-19 | 2018-02-24 | トルクリミッタ |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US11118634B2 (enExample) |

| JP (1) | JP6866981B2 (enExample) |

| CN (1) | CN110637170B (enExample) |

| WO (1) | WO2018173633A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3865725B1 (en) | 2020-02-17 | 2024-03-27 | Ratier-Figeac SAS | Torque limiter |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5419045A (en) * | 1977-07-13 | 1979-02-13 | Mitsubishi Electric Corp | Friction system coupling device |

| JPS645973Y2 (enExample) * | 1982-01-28 | 1989-02-15 | ||

| JPH01303326A (ja) * | 1988-05-31 | 1989-12-07 | Teijin Ltd | 巻取装置 |

| JPH0249852A (ja) * | 1988-08-11 | 1990-02-20 | Chieo Matsuura | 玄関上がり框下回転収納庫。 |

| JPH11247880A (ja) * | 1998-02-27 | 1999-09-14 | Canon Inc | トルクリミッタ及びシート給送装置及び画像処理装置 |

| JP2002086379A (ja) * | 2000-09-13 | 2002-03-26 | Toshiba Corp | ロボット、ロボットの制御方法およびロボットを動作するプログラムを記憶したコンピュータ読み取り可能な記憶媒体 |

| JP2007187283A (ja) * | 2006-01-16 | 2007-07-26 | Shinko Electric Co Ltd | 電磁クラッチ |

| JP2013076432A (ja) * | 2011-09-29 | 2013-04-25 | Nikon Corp | トルク制限機構、駆動装置及びロボット装置 |

| JP2015085390A (ja) * | 2013-10-28 | 2015-05-07 | 株式会社アイエイアイ | アクチュエータ装置 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2547137A (en) * | 1948-12-06 | 1951-04-03 | Bendix Aviat Corp | Electromagnet overload release clutch |

| US2966977A (en) * | 1957-10-17 | 1961-01-03 | Lear Inc | Overload limiting clutch |

| US3455421A (en) * | 1967-06-12 | 1969-07-15 | Bendix Corp | Stationary field clutch |

| US4397380A (en) * | 1981-09-08 | 1983-08-09 | Canadian Fram Limited | Fail safe electromagnetic clutch |

| JPH048834U (enExample) * | 1990-05-15 | 1992-01-27 | ||

| JP4138913B2 (ja) * | 1997-09-05 | 2008-08-27 | 勝行 戸津 | 電動回転工具およびねじ具の締付けトルク管理システム |

| JP2001003951A (ja) * | 1999-06-23 | 2001-01-09 | Kansai Tlo Kk | 力制限装置、トルクリミッタ、ロボットアーム、及びロボット |

| JP5550043B2 (ja) * | 2009-04-23 | 2014-07-16 | シンフォニアマイクロテック株式会社 | 電磁クラッチ |

| JP2013234699A (ja) * | 2012-05-08 | 2013-11-21 | Prospine:Kk | 磁気カップリング装置 |

| DE102014103837B4 (de) * | 2014-03-20 | 2015-12-17 | Kendrion (Villingen) Gmbh | Elektromagnetische Brems- oder Kupplungseinrichtung mit Dämpfungsmitteln zur verbesserten Geräuschreduzierung |

| JP6217499B2 (ja) | 2014-04-07 | 2017-10-25 | 株式会社デンソー | トルクリミッタ付き回転機器 |

| BR112016025520B1 (pt) * | 2014-04-30 | 2022-11-08 | Fpt Industrial S.P.A | Conjunto de bomba para recircular um fluido de arrefecimento de um motor térmico |

| FR3022526B1 (fr) * | 2014-06-20 | 2016-06-24 | Sagem Defense Securite | Actionneur electromecanique a limiteur de couple magnetique |

| JP6699843B2 (ja) * | 2015-07-04 | 2020-05-27 | 学校法人早稲田大学 | ロボットアームの制御システム |

-

2017

- 2017-03-19 JP JP2017053823A patent/JP6866981B2/ja active Active

-

2018

- 2018-02-24 WO PCT/JP2018/006833 patent/WO2018173633A1/ja not_active Ceased

- 2018-02-24 US US16/495,204 patent/US11118634B2/en active Active

- 2018-02-24 CN CN201880031588.3A patent/CN110637170B/zh active Active

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5419045A (en) * | 1977-07-13 | 1979-02-13 | Mitsubishi Electric Corp | Friction system coupling device |

| JPS645973Y2 (enExample) * | 1982-01-28 | 1989-02-15 | ||

| JPH01303326A (ja) * | 1988-05-31 | 1989-12-07 | Teijin Ltd | 巻取装置 |

| JPH0249852A (ja) * | 1988-08-11 | 1990-02-20 | Chieo Matsuura | 玄関上がり框下回転収納庫。 |

| JPH11247880A (ja) * | 1998-02-27 | 1999-09-14 | Canon Inc | トルクリミッタ及びシート給送装置及び画像処理装置 |

| JP2002086379A (ja) * | 2000-09-13 | 2002-03-26 | Toshiba Corp | ロボット、ロボットの制御方法およびロボットを動作するプログラムを記憶したコンピュータ読み取り可能な記憶媒体 |

| JP2007187283A (ja) * | 2006-01-16 | 2007-07-26 | Shinko Electric Co Ltd | 電磁クラッチ |

| JP2013076432A (ja) * | 2011-09-29 | 2013-04-25 | Nikon Corp | トルク制限機構、駆動装置及びロボット装置 |

| JP2015085390A (ja) * | 2013-10-28 | 2015-05-07 | 株式会社アイエイアイ | アクチュエータ装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20200025258A1 (en) | 2020-01-23 |

| CN110637170B (zh) | 2021-12-14 |

| CN110637170A (zh) | 2019-12-31 |

| JP2018155360A (ja) | 2018-10-04 |

| US11118634B2 (en) | 2021-09-14 |

| JP6866981B2 (ja) | 2021-04-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108603549B (zh) | 用于工业机器人的多盘式制动器和包括多盘式制动器的工业机器人 | |

| CN109328272B (zh) | 用于磁流变流体致动器单元的多模式控制系统 | |

| CN102852996B (zh) | 电磁接合装置 | |

| US10384535B2 (en) | Drive unit | |

| JP7033213B2 (ja) | 噛み合い電磁クラッチ | |

| US7726455B2 (en) | Electro-mechanical clutch | |

| JP5935906B2 (ja) | 断接機構 | |

| US20090294238A1 (en) | Electromechanical actuator for friction clutches | |

| JP2009041654A (ja) | ブレーキの制御装置 | |

| JP2021175917A (ja) | ロボットおよび他の用途のためのフェイルセーフブレーキ装置 | |

| WO2018173633A1 (ja) | トルクリミッタ | |

| EP2786054B1 (en) | Failsafe apparatus for use with linear actuators | |

| JP2021521019A (ja) | 駆動軸の制動装置 | |

| JPS63135621A (ja) | 平歯式電磁クラツチの制御方法 | |

| JP2018523799A (ja) | クラッチを作動させるためのシステム | |

| WO2025246148A1 (zh) | 一种自锁式联接器、差速器总成及差速器总成控制方法 | |

| KR101786219B1 (ko) | 더블 클러치조립체 및 그의 브레이크기구 | |

| JPS6248100B2 (enExample) | ||

| JPWO2022209678A5 (enExample) | ||

| JP2018096524A5 (enExample) | ||

| JP2006349109A (ja) | 回転伝達装置 | |

| JP2012122563A (ja) | 係合装置 | |

| JP2010014153A (ja) | 電磁連結装置 | |

| GB665602A (en) | Clutch device for transmitting rotary movement | |

| JP2008144948A (ja) | 回転伝達装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18770622 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18770622 Country of ref document: EP Kind code of ref document: A1 |