WO2017034016A1 - Article absorbant - Google Patents

Article absorbant Download PDFInfo

- Publication number

- WO2017034016A1 WO2017034016A1 PCT/JP2016/074928 JP2016074928W WO2017034016A1 WO 2017034016 A1 WO2017034016 A1 WO 2017034016A1 JP 2016074928 W JP2016074928 W JP 2016074928W WO 2017034016 A1 WO2017034016 A1 WO 2017034016A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- polymer

- absorber

- absorbent body

- superabsorbent polymer

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/535—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes

Definitions

- the present invention relates to absorbent articles such as sanitary napkins, panty liners, incontinence pads, and the like, and more particularly, to absorbent articles in which superabsorbent polymers are less likely to flow out by washing after use and are easy to wash.

- the absorber has an absorptive polymer, and the absorptive polymer is present in the lower layer portion on the non-skin contact surface side of the absorber in the thickness direction of the absorber, and in the lower layer portion.

- An absorptive article which is present in the center region in the width direction over the front and rear ends in the longitudinal direction of the absorbent body is disclosed.

- it has an absorber containing a water-absorbing polymer interposed between the top sheet and the back sheet, and is pressed together with the absorber from the top sheet side on both sides in the longitudinal direction of the absorbent article.

- an absorbent article in which a leak-proof groove is formed, the leak-proof groove has a bottom portion and a side wall portion, and a member under the bottom portion is joined to a back sheet.

- an absorbent article including an absorbent laminate formed by laminating an absorbent layer in which a superabsorbent polymer is disposed between nonwoven fabric sheets and a fiber assembly layer is disclosed. .

- a main problem of the present invention is to provide an absorbent article that does not easily cause the superabsorbent polymer to flow out by washing with water after use, facilitates washing with water, and does not reduce the absorption capacity.

- an absorbent article in which an absorber is interposed between a liquid-permeable top sheet and a back sheet,

- the absorbent body does not contain a superabsorbent polymer or has a basis weight of 30 g / m 2 or less, and a superabsorbent polymer is interposed between the upper layer sheet and the lower layer sheet adjacent to the non-skin side of the absorbent body.

- An absorbent article is provided in which the polymer sheet is disposed.

- the absorbent body since the absorbent body does not have a superabsorbent polymer or contains a low basis weight of 30 g / m 2 or less, the absorbent article may be manually squeezed or squeezed during washing.

- the superabsorbent polymer does not flow out from the absorber, or even if it flows out, it does not cause a significant hindrance to the cleaning operation. Therefore, washing with water becomes easy.

- the polymer sheet in which the superabsorbent polymer is interposed between the upper layer sheet and the lower layer sheet is disposed adjacent to the non-skin side of the absorber, the superabsorbent polymer is disposed on the upper layer sheet and the lower layer sheet.

- the absorption layer is comprised by the laminated body of the said absorber and polymer sheet, even if it makes the said absorber thin, an absorption capability comes to be able to be maintained with the said polymer sheet.

- seat along a longitudinal direction is respectively provided in the width direction both ends of the said polymer sheet, and it is width direction from the said right-and-left end junction part.

- the left and right end joints for joining the upper layer sheet and the lower layer sheet along the longitudinal direction are provided at both ends in the width direction of the polymer sheet, and the inner side in the width direction from the left and right end joints. Since the highly water-absorbing polymer is disposed, the highly water-absorbing polymer can be more reliably prevented from flowing out from the left and right ends of the polymer sheet.

- front and rear end joints for joining the upper layer sheet and the lower layer sheet along the width direction are respectively provided at both longitudinal ends of the polymer sheet, and the longitudinal direction from the front and rear end joints.

- the front and rear end joints for joining the upper layer sheet and the lower layer sheet along the longitudinal direction are provided at both longitudinal ends of the polymer sheet, and the longitudinally inner side from the front and rear end joints. Since the highly water-absorbing polymer is disposed, the outflow of the highly water-absorbing polymer from the front and rear ends of the polymer sheet can be more reliably prevented.

- the joints are provided along the periphery of the polymer sheet by the left and right end joints and the front and rear end joints, so that it is possible to more reliably prevent the superabsorbent polymer from flowing out. It becomes like this.

- the polymer sheet is partitioned into a plurality of polymer-encapsulated cells in which the superabsorbent polymer is encapsulated by a joining portion that joins the upper layer sheet and the lower layer sheet.

- An absorbent article according to any one of 1 to 3 is provided.

- the cell partition joint portion that joins the upper layer sheet and the lower layer sheet is partitioned into a plurality of polymer-encapsulated cells in which a highly water-absorbing polymer is sealed, the high-accuracy is more reliably increased. Outflow of the water-absorbing polymer can be prevented.

- an absorbent article according to any one of claims 1 to 4, wherein a second absorbent body is disposed adjacent to the non-skin side of the polymer sheet.

- the polymer sheet is provided between the absorber and the second absorber by disposing the second absorber adjacent to the non-skin side of the polymer sheet. Since an absorption layer having a three-layer structure is provided, it is possible to more reliably prevent the superabsorbent polymer from flowing out of the absorber.

- the polymer sheet is enclosed inside by providing an absorber joint portion that joins the absorber and the second absorber along the periphery of the absorber and the second absorber.

- An absorbent article according to claim 5 is provided.

- liquid-permeable surface sheet is composed mainly of relatively thick fibers, menstrual blood hardly remains on the liquid-permeable surface sheet, and the cleaning efficiency can be improved.

- the liquid-permeable surface may be broken in view of the fact that the liquid-permeable surface sheet may be broken if weak.

- the present invention it is possible to provide an absorbent article in which the superabsorbent polymer is less likely to flow out by washing with water after use, facilitating washing with water, and without reducing the absorption capacity.

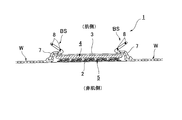

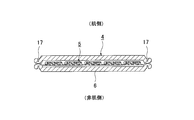

- FIG. 2 It is a partial fracture development view of sanitary napkin 1 concerning the present invention. It is the II-II arrow directional view of FIG. 2 is a partially broken plan view of a polymer sheet 5.

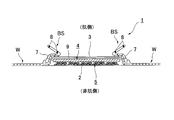

- FIG. FIG. 4 is a view taken along the line IV-IV in FIG. 3. It is a partially broken plan view of the polymer sheet 5 according to another embodiment. 3 is a cross-sectional view showing a laminated body of an absorbent body 4, a polymer sheet 5, and a second absorbent body 6.

- FIG. It is a top view which shows the laminated body of the absorber 4, the polymer sheet 5, and the 2nd absorber 6 which concerns on another form example.

- FIG. 8 is a view taken along line VIII-VIII in FIG. 7.

- FIG. (A) to (D) are cross-sectional views showing the procedure for producing the polymer sheet 5.

- the sanitary napkin 1 has a liquid-impervious back sheet 2 made of a polyethylene sheet, a polypropylene sheet, or the like, and a permeate that quickly permeates menstrual blood or a cage.

- a liquid surface sheet 3 an absorbent body 4 made of cotton-like pulp or synthetic pulp interposed between the two sheets 2 and 3, and side nonwoven fabrics 7 respectively disposed along the longitudinal direction on both sides of the surface. 7.

- the outer edge portions of the liquid-impervious back sheet 2 and liquid-permeable surface sheet 3 are adhesive such as hot melt, heat seal, etc.

- the liquid-impervious back sheet 2 and the side nonwoven fabric 7 which are joined by the adhering means and which extend laterally from the side edges of the absorbent body 4 at both side edges thereof are adhesives such as hot melt, Joined by an adhesive means such as heat sealing, an outer peripheral flap portion where the absorber 4 does not exist is formed on the outer periphery.

- the structure of the sanitary napkin 1 will be described in detail.

- a sheet material having at least water shielding properties such as an olefin resin sheet such as polyethylene or polypropylene is used.

- a laminated nonwoven fabric obtained by laminating a nonwoven fabric on a polyethylene sheet or the like, or A nonwoven fabric sheet (in this case, the waterproof film and the nonwoven fabric constitute a liquid-impervious back sheet) can be used after substantially impervious to liquid imperviousness by interposing a waterproof film.

- those having moisture permeability tend to be used from the viewpoint of preventing stuffiness.

- This water- and moisture-permeable sheet material is a microporous sheet obtained by forming a sheet by melting and kneading an inorganic filler in an olefin resin such as polyethylene or polypropylene, and then stretching in a uniaxial or biaxial direction. It is.

- the liquid-permeable surface sheet 3 is preferably a porous or non-porous nonwoven fabric or a porous plastic sheet.

- the material fibers constituting the nonwoven fabric include synthetic fibers such as polyethylene or polypropylene, synthetic fibers such as polyester and polyamide, recycled fibers such as rayon and cupra, and natural fibers such as cotton.

- a nonwoven fabric obtained by an appropriate processing method such as a lace method, a spun bond method, a thermal bond method, a melt blown method, or a needle punch method can be used.

- the spunlace method is excellent in terms of flexibility and the spunbond method is excellent in drapeability

- the thermal bond method and the air-through method are excellent in terms of being bulky and having high compression recovery properties.

- the non-woven fiber may be either a long fiber or a short fiber, but preferably a short fiber is used in order to give a towel texture.

- an olefin fiber such as polyethylene or polypropylene having a relatively low melting point.

- a composite fiber such as a core-sheath fiber, a side-by-side fiber, or a split fiber having a fiber having a high melting point as a core and a fiber having a low melting point as a sheath can be suitably used.

- the absorbent body 4 interposed between the liquid-impervious back sheet 2 and the liquid-permeable top sheet 3 is made of, for example, cotton-like pulp.

- the pulp include chemical fibers obtained from wood, cellulose fibers such as dissolved pulp, and artificial cellulose fibers such as rayon and acetate.

- Softwood pulp having a longer fiber length than hardwood pulp functions and It is preferably used in terms of price.

- the manufacturing method of the absorber 4 is preferably made of piled pulp so as to be rich in flexibility, it may be an airlaid absorber capable of reducing the bulk.

- the absorbent body 4 may be surrounded by an encapsulating sheet (not shown) made of crepe paper, non-woven fabric, or the like for shape retention and diffusibility improvement.

- the absorbent body 4 is composed only of the pulp and does not contain a superabsorbent polymer. Moreover, even when it has a highly water-absorbing polymer, it is preferable to contain with a low basis weight of 30 g / m 2 or less.

- the absorbent body 4 may be dispersed and mixed in the entire absorbent body 4, or may be disposed so as to be present more on the non-skin side (back side) of the absorbent body 4. . Since the absorbent body 4 does not have a highly water-absorbing polymer, the highly water-absorbing polymer does not flow out when the used sanitary napkin 1 is washed with water, and washing with water becomes easy.

- the highly water-absorbing polymer does not easily flow out during washing, and the water-absorbing polymer swollen by absorbing water during washing flows out.

- the amount is not so large as to greatly impair the cleaning operation.

- synthetic fibers may be mixed in the absorber 4.

- synthetic fiber for example, polyolefins such as polyethylene or polypropylene, polyesters such as polyethylene terephthalate and polybutylene terephthalate, polyamides such as nylon, and copolymers thereof can be used. It may be a mixture.

- a composite fiber such as a core-sheath fiber, a side-by-side fiber, or a split fiber having a fiber having a high melting point as a core and a fiber having a low melting point as a sheath can also be used.

- This synthetic fiber is desirably mixed with the absorbent body 4 in order to act as a binder when the absorbent body joint portion 17 described later is provided.

- side nonwoven fabrics 7 and 7 are provided on both side portions on the surface side of the sanitary napkin 1 along the longitudinal direction and over almost the entire length of the napkin 1, respectively.

- Wing-like flaps W and W are formed by a part of the liquid-impervious back sheet 2 that extends laterally and also laterally.

- a water-repellent treated nonwoven fabric or a hydrophilic treated nonwoven fabric can be used from the viewpoint of important functions. For example, if importance is placed on functions such as preventing permeation of menstrual blood or vaginal discharge, or enhancing the touch feeling, water repellent treatment coated with silicon, paraffin or alkylchromic chloride water repellent It is desirable to use a nonwoven fabric.

- a method of polymerizing a compound having a hydrophilic group for example, an oxidation product of polyethylene glycol, in the process of producing a synthetic fiber, ,

- a metal salt such as stannic chloride

- partially dissolving the surface to make it porous and depositing metal hydroxides to swell or make the synthetic fiber porous, applying capillary action to make it hydrophilic

- capillary action to make it hydrophilic It is desirable to use a hydrophilic treated non-woven fabric provided with.

- the inner side of the side nonwoven fabric 7 folds the side nonwoven fabric 7 almost double, and inside the double sheet, in the middle in the height direction, as appropriate at both ends or in the longitudinal direction.

- One or a plurality of, in the illustrated example, two thread-like elastic elastic members 8 and 8 are disposed, and the double sheet portion is erected on the skin side by the contraction force. Is formed.

- the superabsorbent polymer 12 is adjacent to the non-skin side of the absorbent body 4 between the upper layer sheet 10 disposed on the skin side and the lower layer sheet 11 disposed on the non-skin side.

- An intervening polymer sheet 5 is disposed.

- a porous or non-porous nonwoven fabric is used as the upper layer sheet 10 constituting the polymer sheet 5.

- the raw material fibers constituting the nonwoven fabric in the same manner as the liquid-permeable surface sheet 3, for example, synthetic fibers such as olefins such as polyethylene or polypropylene, polyesters, and polyamides, recycled fibers such as rayon and cupra, cotton Natural fibers such as

- the processing method of the said nonwoven fabric is not ask

- a nonwoven fabric processed by the air-through method is preferable because a bulky nonwoven fabric can be obtained, so that the superabsorbent polymer 12 can easily enter between the fibers, and the fixability of the superabsorbent polymer 12 is improved.

- a thermoplastic material when the upper layer sheet 10 is subjected to predetermined unevenness processing, it is preferable to include a thermoplastic material.

- the lower layer sheet 11 it is possible to use a sheet material having water shielding properties in addition to a perforated or non-porous nonwoven fabric.

- the processing method of the nonwoven fabric is not limited. However, in order to prevent the superabsorbent polymer 12 from falling off, the air-through method, the spunbond method, the melt blown method, the needle punch method, etc. are preferable. preferable.

- the water-impervious sheet material the same material as the liquid-impermeable back sheet 2 can be used. However, as will be described later, when the second absorbent body 6 is disposed adjacent to the non-skin side of the polymer sheet 5, it is preferable to use a water-permeable nonwoven fabric as the lower layer sheet 11.

- the superabsorbent polymer 12 examples include a cross-linked polyacrylate, a self-crosslinked polyacrylate, a saponified acrylate-vinyl acetate copolymer cross-linked product, and a cross-linked isobutylene / maleic anhydride copolymer. , A crosslinked polysulfonate, and a partially crosslinked water-swellable polymer such as polyethylene oxide and polyacrylamide. Among these, those based on acrylic acid or acrylate that are excellent in water absorption and water absorption speed are preferred. In the production process of the highly water-absorbing polymer having the water-absorbing performance, the water-absorbing force and the water-absorbing speed can be adjusted by adjusting the crosslinking density and the crosslinking density gradient. As the superabsorbent polymer 12, superabsorbent polymer granular powder (SAP) or superabsorbent polymer fiber (SAF) can be used.

- SAP superabsorbent polymer granular powder

- SAF superab

- the superabsorbent polymer 12 is interposed between the upper layer sheet 10 and the lower layer sheet 11. Therefore, even when the sanitary napkin 1 is manually squeezed or squeezed, the superabsorbent polymer 12 does not easily flow out to the outside, and the cleaning operation is facilitated. . Moreover, since the absorption layer is comprised by the laminated body of the absorber 4 and the polymer sheet 5, a liquid component is mainly absorbed and hold

- the absorber 4 layer it is possible to reduce the thickness of the absorber 4 layer. Therefore, the feeling of wearing improves and it becomes difficult to stuffy. Further, since the polymer sheet 5 is arranged on the non-skin side of the absorbent body 4, menstrual blood diffuses in the plane direction when passing through the absorbent body 4, and the diffused menstrual blood is dispersed by the polymer sheet 5. Thus, it is possible to absorb and hold, and the absorption capacity is improved.

- the polymer sheet 5 is preferably formed with a smaller plane size than the absorber 4 as shown in FIGS. That is, the edge of the absorbent body 4 extends outward from the edge of the polymer sheet 5, and the edge of the polymer sheet 5 is formed by the outer edge portion of the absorbent body 4 that extends outward from the polymer sheet 5. It is preferable to be covered. Thereby, even if the superabsorbent polymer 12 flows out from the edge of the polymer sheet 5, it is possible to prevent the absorbent body 4 from flowing out.

- the polymer sheet 5 has left and right end joint portions 13 that join the upper layer sheet 10 and the lower layer sheet 11 along the longitudinal direction at both ends in the width direction of the polymer sheet 5. It is preferable that the superabsorbent polymer 12 is disposed on the inner side in the width direction than the right and left end joints 13 and 13. By sealing both side edges of the polymer sheet 5 with the left and right end joints 13, it is possible to prevent the superabsorbent polymer 12 from flowing out from both side ends in the width direction when the used sanitary napkin 1 is washed. Become.

- the polymer sheet 5 has front and rear ends that join the upper layer sheet 10 and the lower layer sheet 11 along the width direction at both longitudinal ends of the polymer sheet 5, respectively. It is preferable to provide a joint 14 and dispose the superabsorbent polymer 12 on the inner side in the longitudinal direction from the front and rear joints 14 and 14. Providing the front and rear end joints 14 can prevent the superabsorbent polymer 12 from flowing out from both ends in the longitudinal direction. Further, by providing the front and rear end joint portions 14 and 14 in addition to the left and right end joint portions 13 and 13, the peripheral edge portion of the polymer sheet 5 is sealed by the joint portions 13 and 14 that are closed, and from the peripheral edge of the polymer sheet 5. This is preferable because the superabsorbent polymer 12 can be prevented from flowing out.

- the left and right end joints 13 and the front and rear end joints 14 are linear lines composed of continuous lines or intermittent lines provided slightly along the width direction both side edges or longitudinal direction both end edges of the upper layer sheet 10 and the lower layer sheet 11. It is a junction. Specifically, it is preferable to heat at the time of embossing to make an embossed heat fusion that joins the upper layer sheet 10 and the lower layer sheet 11, but adhesion by an adhesive such as hot melt or ultrasonic sealing It is good also as joining.

- the joint strength of the left and right end joints 13 and the front and rear end joints 14 is preferably 0.25 N or more, preferably about 1.0 to 3.0 N obtained by the following joint strength test.

- this bonding strength test the peripheral portions of the upper layer sheet 10 and the lower layer sheet 11 cut to a size of 60 mm long ⁇ 35 mm wide are bonded by the bonding portions 13, 14 and only a length of 15 mm from one end in the longitudinal direction. It peels, both ends of this peeled part are each clamped with a chuck

- the polymer sheet 5 includes a plurality of polymer-encapsulated cells 16, 16 in which a superabsorbent polymer 12 is encapsulated by a cell partition joint portion 15 that joins the upper layer sheet 10 and the lower layer sheet 11. You may divide into.... By partitioning into a plurality of polymer-encapsulated cells 16 in which the superabsorbent polymer 12 is encapsulated, the superabsorbent polymer 12 can be more reliably prevented from flowing out.

- the cell partition joint 15 is preferably embossed heat fusion that is heated and joined at the time of embossing pressurization, similar to the above-described left and right end joint 13 and front and rear end joint 14. Adhesion or ultrasonic sealing may be used.

- the left and right ends are arranged by the outer portion of the cell partition joint portion 15 located on the outer periphery of the polymer sheet 5 by arranging the square cell partition joint portions 15 in the front, rear, left and right in a regular lattice shape.

- a joint portion 13 and front and rear end joint portions 14 are respectively formed.

- the left and right end joints 13 and the front and rear end joints 14 may be provided separately from the cell partition joints 15 apart from each other.

- the planar shape of the cell partition junction 15 is formed in a square, but can be formed in an arbitrary planar shape such as a rectangle, a circle, an ellipse, a polygon, and a rhombus. .

- the polymer sheet 5 is not partitioned into a plurality of polymer-encapsulated cells, and the region surrounded by the left and right end joints 13 and 13 and the front and rear end joints 14 and 14 as shown in FIG.

- the polymer 12 may be encapsulated.

- the absorbent body 4 As shown in FIG. 6, by arranging the second absorbent body 6 adjacent to the non-skin side of the polymer sheet 5, the absorbent body 4, the polymer sheet 5, and the second absorbent body 6 form a three-layer structure. An absorption layer may be formed.

- the polymer sheet 5 is sandwiched between the absorber 4 and the second absorber 6, even if the superabsorbent polymer 12 falls off from the polymer sheet 5, the polymer sheet 5 flows out to the outside by the absorber 4 and the second absorber 6. Can be prevented.

- the polymer sheet 5 is formed with a smaller plane size than the absorbent body 4 and the second absorbent body 6, and outside the polymer sheet 5.

- the absorbent body 4 and the second absorbent body 6 it is preferable to form a laminated portion of the absorbent body 4 and the second absorbent body 6 where the polymer sheet 5 is not interposed on the outer periphery of the polymer sheet 5.

- the absorbent body 4 and the second absorbent body 4 provided along the peripheral edges of the absorbent body 4 and the second absorbent body 6 are used.

- the polymer sheet 5 may be enclosed inside by the absorber joint portion 17 that joins the absorber 6. That is, the polymer sheet 5 is formed with a smaller plane size than the absorbent body 4 and the second absorbent body 6, and the absorbent body 4 and the second absorbent body 6 are extended outside the polymer sheet 5, thereby the polymer sheet.

- a laminated portion of the absorbent body 4 and the second absorbent body 6 where the polymer sheet 5 is not interposed is formed on the outer periphery of the absorbent body 5, and the absorbent body 4 and the second absorbent body are formed by the absorbent body joint portion 17 in the laminated portion. 6 may be directly joined. Thereby, since the polymer sheet 5 is enclosed between the absorber 4 and the second absorber 6 by the absorber joint portion 17, the highly water-absorbing polymer 12 is more unlikely to flow out.

- the absorber joint portion 17 is an embossed heat-sealed or ultrasonic seal that heats and joins the absorbent body 4 and the second absorbent body 6 with heat-synthetic synthetic fibers and then presses them when embossing is applied. Alternatively, it may be bonded by a hot melt adhesive.

- the liquid-permeable surface sheet 3 is preferably composed mainly of relatively thick fibers having a fineness of 2.0 dtex or more, preferably 3.3 to 10 dtex.

- menstrual blood is less likely to be retained in the liquid-permeable surface sheet 3, and the discharged menstrual blood is easily transmitted to the absorber 4 side, and menstrual blood is less likely to remain in the liquid-permeable surface sheet 3 during cleaning.

- the cleaning effect can be improved.

- the concealment property of the menstrual blood absorbed by the lower absorber 4 becomes high, and menstrual blood becomes difficult to see from the surface.

- detergents are used to clean used sanitary napkins, but by using relatively thick fibers, there are more voids between the fibers, which improves foaming. The cleaning effect can be further improved.

- the fineness is a value measured according to JIS L1095.

- liquid-permeable surface sheet 3 it is preferable to use a non-woven fabric with a relatively high basis weight having a basis weight of 25 g / m 2 or more, preferably 40 to 150 g / m 2 .

- a non-woven fabric with a relatively high basis weight having a basis weight of 25 g / m 2 or more, preferably 40 to 150 g / m 2 .

- a large number of the liquid-permeable surface sheet 3 and the absorbent body 4 are disposed on the non-skin side of the liquid-permeable surface sheet 3.

- seat 9 which consists of a mesh sheet (porous resin film) which has an opening.

- this mesh sheet for example, an olefin-based thermoplastic resin film such as polyethylene or polypropylene is preferably used, but a polyamide-based resin such as polyester or nylon, EVA, or the like can also be used.

- the mesh sheet is provided with a large number of bodily fluid perforations for imparting bodily fluid permeability.

- the diameter of the bodily fluid permeation holes is 0.05 to 2.0 mm, preferably 0.1 to 1.0 mm, and the number of holes is preferably about 200 to 600 holes / cm 2 .

- the synthetic resin sheet is softened near the softening temperature and is positioned on the upper surface of the support having a large number of openings, and is sucked from below the support, There are a method of pressurizing air pressure from the upper surface and a method of stretching and opening the sheet material after impressing a large number of slits on the synthetic resin sheet material, but they can be formed by an appropriate method.

- the sanitary napkin 1 Since the sanitary napkin 1 is manually kneaded or squeezed at the time of washing after use, when the liquid-permeable surface sheet 3 is made of a nonwoven fabric, the fibers are unraveled and broken, and the superabsorbent polymer 12 comes out therefrom. Even if the liquid-permeable surface sheet 3 is torn, it is easy to arrange the second sheet 9 made of a mesh sheet that is not easily torn due to friction at the time of scouring, on the non-skin side of the liquid-permeable surface sheet 3. It can be set as the structure where the water absorbing polymer 12 does not flow out easily.

- the number of apertures in the second sheet 9 is preferably small from the viewpoint of preventing the superabsorbent polymer 12 from flowing out to the outside, and is preferably about 200 to 500 / cm 2 , more preferably about 200 to 300 / cm 2. It is good to do.

- the liquid-permeable surface sheet 3 is composed of a mesh sheet

- the liquid-permeable surface sheet 3 may be composed of a non-woven fabric, and a mesh sheet may be used as the second sheet 9 because the liquid-permeable surface sheet 3 may be attached to the skin and the wearing feeling may deteriorate. Is preferred.

- the weight of the superabsorbent polymer 12 disposed on the polymer sheet 5 is 20 to 300 g / m 2 , preferably 30 to 100 g / m 2 .

- the polymer sheet 5 on which the polymer-encapsulated cell 16 shown in FIG. 3 is formed will be described.

- the polymer-encapsulated cell 16 The first embossing roll 21 in which a large number of convex portions 21a, 21a... Corresponding to the first embossing roll 21 are arranged, and the second embossing roll 22 in which a large number of concave portions 22a, 22a.

- the polymer-encapsulated cell 16 is formed by meshing the convex portion 21a and the concave portion 22a, and by meshing the concave portion 21b and the convex portion 22b. It is preferable to use a manufacturing apparatus 20 that forms the polymer-free region 16.

- the superabsorbent polymer 12 is sprayed on the surface of the second embossing roll 22 on which the upper layer sheet 10 is disposed, and the superabsorbent polymer 12 is accommodated in the concave portion 22a corresponding to the polymer-encapsulated cell 16, and the first 2

- the lower layer sheet 11 conveyed from another path in a stacked state between the embossing roll 22 and the flat roll 23

- the upper layer sheet 10 and the upper layer sheet 10 are separated by the first bonding portion 13 and the second bonding portion 15.

- the lower sheet 11 is joined and integrated.

- joints are performed by applying a hot-melt adhesive or the like on the outer surface of the upper layer sheet 10 corresponding to the convex portion of the second embossing roll 22 and adhering to the lower layer sheet 11 or when meshing with the flat roll 23. This is performed by fusing the upper layer sheet 10 and the lower layer sheet 11 by heating or ultrasonic radiation of the convex portions of the second embossing roll 22.

- the upper layer sheet 10 is easily sucked and embossed at the time of embossing, and at the time of spraying the superabsorbent polymer 12, the polymer is prevented from falling. You may make it do. Further, after the superabsorbent polymer 12 is sprayed, the amount of the superabsorbent polymer 12 accommodated in the polymer-encapsulated cell 16 may be adjusted by leveling the surface with a scraper or the like.

- the polymer sheets 5, 5... Continuous in the longitudinal direction are cut at the joint between the upper layer sheet 10 and the lower layer sheet 11 where the polymer-encapsulated cells 16 are not provided.

- SYMBOLS 1 Sanitary napkin, 2 ... Liquid-impermeable back sheet, 3 ... Liquid-permeable surface sheet, 4 ... Absorber, 5 ... Polymer sheet, 6 ... 2nd absorber, 7 ... Side nonwoven fabric, 8 ... Thread-like elastic expansion and contraction Member: 9 ... Second sheet, 10 ... Upper layer sheet, 11 ... Lower layer sheet, 12 ... Super absorbent polymer, 13 ... Left and right end joint, 14 ... Front and rear end joint, 15 ... Cell partition joint, 16 ... Polymer encapsulated cell , 17 ... absorber joint

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Abstract

L'invention concerne un article absorbant qui est facilement rincé après utilisation, sans qu'un polymère superabsorbant s'écoule à l'extérieur, et ne perd pas de capacité d'absorption. Un corps absorbant (4) est interposé entre une feuille de surface perméable aux liquides (3) et une feuille arrière imperméable aux liquides (2) ; le corps absorbant (4) ne contient pas de polymère superabsorbant ou contient 30 g/m2 ou moins de ce dernier ; et une feuille polymère (5), ayant un polymère superabsorbant (12) interposé entre une feuille de couche supérieure (10) et une feuille de couche inférieure (11), est positionnée de manière adjacente au côté non-peau du corps absorbant (4). Des sections de liaison de bord gauche-droite (13, 13), qui relient la feuille de couche supérieure (10) et la feuille de couche inférieure (11), sont placées dans la direction de longueur au niveau des sections de bord dans la direction de largeur de la feuille polymère (5), et le polymère superabsorbant (12) est positionné sur le côté interne dans la direction de largeur de ces sections de liaison de bord gauche-droite (13).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015167398A JP6207557B2 (ja) | 2015-08-27 | 2015-08-27 | 吸収性物品 |

| JP2015-167398 | 2015-08-27 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017034016A1 true WO2017034016A1 (fr) | 2017-03-02 |

Family

ID=58100395

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/074928 WO2017034016A1 (fr) | 2015-08-27 | 2016-08-26 | Article absorbant |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6207557B2 (fr) |

| WO (1) | WO2017034016A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021131721A1 (fr) * | 2019-12-23 | 2021-07-01 | 花王株式会社 | Absorbeur et son procédé de production |

| RU2782001C1 (ru) * | 2019-12-23 | 2022-10-21 | Као Корпорейшн | Впитывающий элемент и способ его изготовления |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107693216A (zh) * | 2017-09-30 | 2018-02-16 | 安徽珂力智能电气有限公司 | 用于多种克重的棉芯成型装置和成型方法 |

| JP7436326B2 (ja) * | 2020-08-25 | 2024-02-21 | 花王株式会社 | 吸収性物品 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08299385A (ja) * | 1995-04-28 | 1996-11-19 | New Oji Paper Co Ltd | 吸収性シート材料 |

| JP2003505267A (ja) * | 1999-05-25 | 2003-02-12 | ビーケイアイ・ホールディング・コーポレーション | 端部シールが改善された多機能繊維物質 |

| WO2005120411A1 (fr) * | 2004-06-10 | 2005-12-22 | Daio Paper Corporation | Article d’absorption |

| JP2006167196A (ja) * | 2004-12-16 | 2006-06-29 | Hakujuji Co Ltd | 使い捨て吸収性物品 |

| JP2011255023A (ja) * | 2010-06-10 | 2011-12-22 | Kao Corp | 吸収性物品 |

| WO2012108331A1 (fr) * | 2011-02-10 | 2012-08-16 | 株式会社瑞光 | Procédé et appareil pour agencer un matériau granulaire |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2869537A1 (fr) * | 2004-05-03 | 2005-11-04 | Dgtec Soc Par Actions Simplifi | Compose pour produit cosmetique |

| JP5175147B2 (ja) * | 2008-08-29 | 2013-04-03 | 花王株式会社 | 吸収性物品 |

| JP5336138B2 (ja) * | 2008-09-26 | 2013-11-06 | 花王株式会社 | 吸収性物品 |

| JP6116942B2 (ja) * | 2013-03-01 | 2017-04-19 | カミ商事株式会社 | 吸収性物品 |

| JP6310718B2 (ja) * | 2014-02-12 | 2018-04-11 | 株式会社リブドゥコーポレーション | 吸収性物品 |

| JP6399306B2 (ja) * | 2015-02-02 | 2018-10-03 | 王子ホールディングス株式会社 | 吸収性物品 |

| JP6399304B2 (ja) * | 2015-01-13 | 2018-10-03 | 王子ホールディングス株式会社 | 吸収性物品 |

-

2015

- 2015-08-27 JP JP2015167398A patent/JP6207557B2/ja active Active

-

2016

- 2016-08-26 WO PCT/JP2016/074928 patent/WO2017034016A1/fr active Application Filing

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08299385A (ja) * | 1995-04-28 | 1996-11-19 | New Oji Paper Co Ltd | 吸収性シート材料 |

| JP2003505267A (ja) * | 1999-05-25 | 2003-02-12 | ビーケイアイ・ホールディング・コーポレーション | 端部シールが改善された多機能繊維物質 |

| WO2005120411A1 (fr) * | 2004-06-10 | 2005-12-22 | Daio Paper Corporation | Article d’absorption |

| JP2006167196A (ja) * | 2004-12-16 | 2006-06-29 | Hakujuji Co Ltd | 使い捨て吸収性物品 |

| JP2011255023A (ja) * | 2010-06-10 | 2011-12-22 | Kao Corp | 吸収性物品 |

| WO2012108331A1 (fr) * | 2011-02-10 | 2012-08-16 | 株式会社瑞光 | Procédé et appareil pour agencer un matériau granulaire |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2021131721A1 (fr) * | 2019-12-23 | 2021-07-01 | 花王株式会社 | Absorbeur et son procédé de production |

| CN114786639A (zh) * | 2019-12-23 | 2022-07-22 | 花王株式会社 | 吸收体及其制造方法 |

| RU2782001C1 (ru) * | 2019-12-23 | 2022-10-21 | Као Корпорейшн | Впитывающий элемент и способ его изготовления |

| CN114786639B (zh) * | 2019-12-23 | 2022-12-02 | 花王株式会社 | 吸收体及其制造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2017042379A (ja) | 2017-03-02 |

| JP6207557B2 (ja) | 2017-10-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6158992B2 (ja) | 吸収性物品 | |

| TWI722139B (zh) | 吸收性物品 | |

| JP6366565B2 (ja) | 吸収性物品 | |

| KR102648953B1 (ko) | 흡수성 물품 | |

| JP5318747B2 (ja) | 吸収性物品 | |

| JP6360540B2 (ja) | 吸収性物品 | |

| JP2017176315A5 (fr) | ||

| JP2017104263A5 (fr) | ||

| JP6479520B2 (ja) | 吸収性物品 | |

| WO2017030136A1 (fr) | Article absorbant | |

| WO2018180600A1 (fr) | Article absorbant | |

| JP2018086170A5 (fr) | ||

| JP7157532B2 (ja) | 吸収性物品 | |

| WO2017034016A1 (fr) | Article absorbant | |

| JP6441621B2 (ja) | 吸収性物品 | |

| WO2017033961A1 (fr) | Article absorbant | |

| JP6507282B1 (ja) | 吸収性物品の製造方法 | |

| JP2018015078A (ja) | 吸収性物品 | |

| JP6537658B1 (ja) | 吸収性物品 | |

| JP6169656B2 (ja) | 吸収性物品 | |

| JP4859508B2 (ja) | 吸収性物品 | |

| JP2015198798A (ja) | 吸収性物品 | |

| JP6396553B1 (ja) | 吸収性物品 | |

| JP2017029353A5 (fr) | ||

| JP7209565B2 (ja) | 吸収性物品及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16839363 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16839363 Country of ref document: EP Kind code of ref document: A1 |