WO2016132856A1 - コネクタ - Google Patents

コネクタ Download PDFInfo

- Publication number

- WO2016132856A1 WO2016132856A1 PCT/JP2016/052606 JP2016052606W WO2016132856A1 WO 2016132856 A1 WO2016132856 A1 WO 2016132856A1 JP 2016052606 W JP2016052606 W JP 2016052606W WO 2016132856 A1 WO2016132856 A1 WO 2016132856A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- press

- press contact

- wire

- twisted pair

- pair

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/24—Connections using contact members penetrating or cutting insulation or cable strands

- H01R4/2416—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type

- H01R4/242—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members being plates having a single slot

- H01R4/2425—Flat plates, e.g. multi-layered flat plates

- H01R4/2429—Flat plates, e.g. multi-layered flat plates mounted in an insulating base

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/24—Connections using contact members penetrating or cutting insulation or cable strands

- H01R4/2416—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type

- H01R4/2445—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members having additional means acting on the insulation or the wire, e.g. additional insulation penetrating means, strain relief means or wire cutting knives

- H01R4/245—Connections using contact members penetrating or cutting insulation or cable strands the contact members having insulation-cutting edges, e.g. of tuning fork type the contact members having additional means acting on the insulation or the wire, e.g. additional insulation penetrating means, strain relief means or wire cutting knives the additional means having two or more slotted flat portions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/70—Insulation of connections

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/646—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00 specially adapted for high-frequency, e.g. structures providing an impedance match or phase match

- H01R13/6461—Means for preventing cross-talk

- H01R13/6463—Means for preventing cross-talk using twisted pairs of wires

Definitions

- the present invention relates to a connector.

- Patent Document 1 discloses a connector in which two press contact terminals are provided side by side on a housing and two wires constituting a twisted pair wire are connected to separate press contact terminals. This connector is used as a joint connector for branching two twisted pair wires.

- the twisted pair wire is twisted in a spiral shape with two electric wires approaching each other. Therefore, when performing pressure contact with the two pressure contact terminals, in order to individually correspond the two wires to the two pressure contact terminals, the twisting of the two wires is performed in advance and the two wires are separated. Need to do.

- the present invention has been completed based on the above situation, and an object thereof is to reduce the number of work steps when the twisted pair wire is pressed.

- the connector of the present invention Two press-contact terminal fittings in which the electric wires constituting the twisted pair wires are individually pressed, A holder for holding the two press contact terminal fittings so that the press contact portion formed on the press contact terminal fitting is aligned in a direction intersecting with a wiring direction of the twisted pair wires; A distribution rib formed on the holder and separating the two electric wires so as to correspond to the two pressure contact portions in the process of approaching the twisted pair wire to the pressure contact position with the pressure contact portion. Has characteristics.

- the two wires are separated by the distribution rib so as to correspond to the pressure contact portion.

- the number of work steps can be reduced.

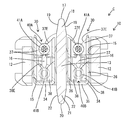

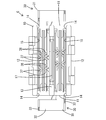

- Example 1 Plan view showing the state where the wires are distributed by the distribution ribs

- Side view showing the state in which the electric wires are distributed by the distribution ribs

- Enlarged cross-sectional view showing the state in which the electric wires are distributed by the distribution ribs

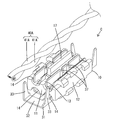

- Perspective view showing the state before distributing the wires

- a perspective view showing a state in which the electric wire is press-contacted to the press-contact portion.

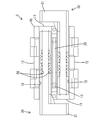

- Enlarged cross-sectional view showing the state where the wire is in pressure contact Top view of connector Bottom view of connector

- a guide portion having a wedge-shaped cross section that is narrower toward a distal end side in the protruding direction may be formed on the sorting rib. According to this configuration, the two electric wires can be reliably separated by interrupting the guide portion between the two electric wires.

- the press contact portion includes two pairs of press contact blades arranged at intervals in the wiring direction of the twisted pair wire, and the distribution rib in the wiring direction of the twisted pair wire.

- the forming region may be the same as or wider than the range including the two pairs of press contact blades. According to this structure, an electric wire can be reliably press-contacted with respect to two pairs of press-contacting blades.

- the connector according to the present invention includes a pair of support plate portions in which the press contact portions rise from both side edges of the substrate portion and are opposed to each other, and a press contact blade that protrudes from the opposing surfaces of the pair of support plate portions to form a pair.

- the distribution rib is configured to rise in substantially the same direction as the support plate portion, and in the rising direction of the support plate portion, the distribution rib is positioned higher than the rising edge of the support plate portion. You may stand up. According to this configuration, the two electric wires can be reliably separated before being inserted between the pair of support plate portions.

- the press contact portion includes a press contact blade that sandwiches the electric wire in a pair, and the press contact blade makes the pair by slidingly contacting the electric wire.

- a guide edge portion that is guided in between may be formed, and the sliding contact surface of the electric wire in the distribution rib and the guide edge portion may be arranged to form an obtuse angle. According to this configuration, the two electric wires separated by the distributing rib can smoothly enter between the press contact blades.

- the connector C uses the first twisted pair wire 40A (the twisted pair wire described in the claims) and the second twisted pair wire 40B (the twisted pair wire described in the claims) as the objects to be pressed.

- the first twisted pair wire 40A is obtained by twisting two first electric wires 41A (electric wires described in claims) close to each other while twisting them in a spiral shape.

- the second twisted pair wire 40B is also obtained by twisting the two second electric wires 41B (electric wires described in claims) while twisting them in a spiral shape.

- the connector C has a function as a pressure contact type joint connector C for connecting the first twisted pair wire 40A and the second twisted pair wire 40B, and realizes a reduction in work man-hours when the two twisted pair wires 40A, 40B are pressed. It is.

- the arrangement direction of the twisted pair wires 40A and 40B in the pressure contact area with the pressure contact terminal fitting 30 is defined as the front-rear direction.

- the first twisted pair wire 40A is attached and connected to the connector C from above, and the second twisted pair wire 40B is assembled and connected to the connector C from below.

- the connector C connects the first electric wire 41A constituting the first twisted pair wire 40A and the second electric wire 41B constituting the second twisted pair wire 40B so as to be conductive, and constitutes the first twisted pair wire 40A.

- the other first electric wire 41A and the other second electric wire 41B constituting the second twisted pair wire 40B are connected so as to be conductive.

- each of the electric wires 41 ⁇ / b> A and 41 ⁇ / b> B is a known one in which a conductor 42 is surrounded by an insulating coating 43.

- the connector C includes a holder 10 and a pair of press contact terminal fittings 30.

- the holder 10 is made of synthetic resin, and has a pair of end wall portions 11 that are opposed to each other with a space in the front-rear direction, and a pair of left and right side wall portions 12 that connect the left and right edges of the pair of end wall portions 11.

- a single component including a single partition wall 13 that connects the central portions of the pair of end wall portions 11 in the left-right direction.

- the side wall part 12 and the partition part 13 are extended long in the front-back direction. As shown in FIGS.

- a pair of left and right concave portions 14 each having a substantially semicircular shape are formed on the upper end edge and the lower end edge of the end wall portion 11.

- the concave portion 14 positions the electric wire in the left-right direction and regulates upward or downward displacement.

- the left and right two spaces surrounded by the wall portions 11, 12, and 13 in the holder 10 are a pair of left and right mounting spaces that are long in the front-rear direction and open on both the upper and lower sides. It is 15.

- Each attachment space 15 accommodates a pressure contact portion 34 to be described later.

- a beam portion 16 is disposed between the front and rear end wall portions 11. The beam portion 16 restricts the electric wire press-contacted to an upper press-contact blade 37 described later from being displaced downward, and restricts the electric wire press-contacted to the lower press-contact blade 38 from being displaced upward.

- the partition wall portion 13 is located between the two pressure contact portions 34 accommodated in the two mounting spaces 15.

- the partition wall 13 has an upper distribution rib 17 (upward distribution rib) configured to protrude upward from an upper end edge thereof and a lower distribution rib 20 (downward configuration) protruded downward from the lower end edge of the partition wall section 13.

- the upper distribution rib 17 and the lower distribution rib 20 are vertically symmetrical.

- the formation region of the upper and lower sorting ribs 17 and 20 in the front-rear direction includes a formation region of four pairs of press contact blades 37 and 38, which will be described later, and includes a region in front and rear of the four pairs of press contact blades 37 and 38. It is over.

- the upper distributing rib 17 has an upper guide portion 18 having a wedge-shaped cross section that narrows toward the upper side (the leading end side in the protruding direction of the upper distributing rib 17). Is formed.

- the upper guide portion 18 is formed over the entire region in the vertical direction (projection direction) of the upper distribution rib 17.

- the left and right outer surfaces of the upper guide portion 18 are upper slidable contact surfaces 19 (slidable contact surfaces described in claims).

- the lower distribution rib 20 is also formed with a lower guide portion 21 (a guide portion according to the claims) having a wedge-shaped cross section that narrows downward (toward the front end side in the protruding direction of the lower distribution rib 20).

- the lower guide portion 21 is also formed over the entire region in the vertical direction (protruding direction) of the lower sorting rib 20, similarly to the upper guide portion 18.

- the left and right outer surfaces of the lower guide portion 21 are lower sliding contact surfaces 22.

- the pair of press contact terminal fittings 30 have the same shape and dimensions, and are arranged so as to be point symmetric in plan view, as shown in FIGS.

- the press-contact terminal fitting 30 is a single part including an electric wire holding portion 31 and a press-contact portion 34 that is elongated from the electric wire holding portion 31 forward.

- the electric wire holding portion 31 includes a horizontal receiving plate portion 32 having a substantially square shape in plan view, and a pair of crimping pieces 33 rising from both left and right edges of the receiving plate portion 32.

- the press contact portion 34 is elongated vertically and horizontally from the right end portion of the front end edge of the receiving plate portion 32, and upwards at substantially right angles from the left and right side edges of the substrate portion 35.

- a pair of support plate portions 36 rising in a cantilever manner and four pairs of press contact blades 37 and 38 are provided.

- the pair of press contact blades 37, 38 have a shape that protrudes inward in a substantially V shape in plan view by bending a part of both the left and right support plate portions 36.

- the upper end edge of the upper press contact blade 37 is an upper guide edge portion 37E (guide edge portion described in claims) inclined with respect to the vertical direction (the press contact direction of the electric wire with respect to the upper press contact blade 37).

- the upper edge of the lower press contact blade 38 is a lower guide edge 38E inclined with respect to the vertical direction (the press contact direction of the electric wire with respect to the lower press contact blade 38).

- the four pairs of press contact blades 37 and 38 are arranged in two upper and lower stages.

- the two pairs of upper press contact blades 37 disposed on the upper side are disposed at a predetermined interval in the front and rear direction.

- Two pairs of lower press-contacting blades 38 arranged on the lower side are also arranged at a predetermined interval in the front-rear direction.

- the front upper press-contact blade 37 and the front lower press-contact blade 38 are arranged so as to be displaced in the front-rear direction.

- the rear upper press-contact blade 37 and the rear lower press-contact blade 38 are also displaced in the front-rear direction.

- the two press contact terminal fittings 30 are assembled to the holder 10 from below, and each press contact portion 34 is accommodated in the mounting space 15.

- the upper sorting rib 17 is positioned above the upper end edge of the support plate portion 36 and rises in the same direction as the rising direction of the support plate portion 36.

- the lower end portion of the upper sliding contact surface 19 is at the upper end portion of the upper guide edge portion 37E of the upper press contact blade 37 on the inner side (side closer to the partition wall portion 13 and the upper distribution rib 17) of the pair of upper press contact blades 37.

- they are positioned so that they form an obtuse angle and line up close to each other.

- the assembly of the holder 10 and the press contact terminal fitting 30 is performed in parallel with the press contact process of the press contact terminal fitting 30 and the electric wires 41A and 41B.

- the two second electric wires 41 ⁇ / b> B constituting the second twisted pair wire 40 ⁇ / b> B are distributed to the left and right by the lower distribution rib 20.

- the lower end edge of the lower sorting rib 20 is inserted into the gap between the two second electric wires 41B that are twisted together.

- the two second electric wires 41B are gradually slidably brought into mutual contact with the lower slidable contact surface 22 by the lower guide portion 21 of the lower guide portion 21 that becomes gradually wider. Increase the interval. Then, the two second electric wires 41 ⁇ / b> B that have passed through the lower distribution rib 20 are accommodated in the attachment space 15, respectively.

- the two pressure contact portions 34 are accommodated in the mounting space 15 from below the holder 10, respectively.

- the two second electric wires 41B are pushed upward by coming into contact with the upper guide edge 37E of the upper press contact blade 37, respectively.

- the second electric wire 41B is restricted from being displaced upward by coming into contact with the beam portion 16, the two pairs of upper press contact blades 37 pass through the second electric wire 41B.

- the two pairs of lower pressure contact blades 38 are pressed against the second electric wire 41B so as to be sandwiched from the left and right.

- the pair of lower press-contacting blades 38 are in contact with the conductor 42 so as to be sandwiched from both the left and right sides by cutting the insulating coating 43.

- the two second electric wires 41B constituting the second twisted pair wire 40B are separately pressed against the two press contact terminal fittings 30 and the two press contact terminal fittings 30 are assembled to the holder 10.

- the electric wire holding portion 31 is positioned so as to correspond to the end wall portion 11 outside the attachment space 15.

- the two first electric wires 41A constituting the first twisted pair wire 40A are pressed against the two press contact portions 34 while being distributed to the left and right.

- the upper end edge of the upper distribution rib 17 is inserted into the gap between the two first electric wires 41A.

- the two first electric wires 41A are moved upward by the upper guide portion 18 of the upper guide portion 18 that becomes gradually wider. Gradually increase the distance between each other while sliding.

- the two first electric wires 41 ⁇ / b> A that have passed through the upper distribution rib 17 are accommodated in the attachment space 15, respectively.

- the first electric wire 41 ⁇ / b> A moves from the lower end portion of the upper sliding contact surface 19 to the upper guide edge portion 37 ⁇ / b> E of the upper press contact blade 37.

- the upper slidable contact surface 19 and the upper guide edge 37E are arranged close to each other at an obtuse angle, the first electric wire 41A can be separated from the upper slidable contact surface 19 without being caught. Smooth transition to 37E.

- One first electric wire 41 ⁇ / b> A is in pressure contact with the press contact portion 34 of the one press contact terminal fitting 30, and the other first electric wire 41 ⁇ / b> A is press contacted with the press contact portion 34 of the other press contact terminal fitting 30.

- the first electric wire 41 ⁇ / b> A is pushed between the two pairs of upper and lower upper press contact blades 37.

- the pair of upper press contact blades 37 are in contact with the conductor 42 so as to be sandwiched from both the left and right sides by cutting the insulating coating 43.

- the two press contact portions 34 (pressure contact terminal fittings 30) and the two first electric wires 41A are individually connected so as to be conductive.

- one of the first electric wire 41A and the second twisted-pair wire 40B constituting the first twisted pair wire 40A are formed on one of the press-connecting terminal fittings 30 (the press-contacting portion 34).

- the second electric wire 41B is connected (joint) so as to be conductive.

- the other first electric wire 41A constituting the first twisted pair wire 40A and the other second electric wire 41B constituting the second twisted pair wire 40B can be electrically connected to the other press contact terminal fitting 30 (the press contact portion 34). Connected (joint).

- the four electric wires 41A and 41B are collectively held in each electric wire holding portion 31. That is, the four electric wires 41A and 41B (the first twisted pair wire 40A and the second twisted pair wire 40B) placed on the receiving plate portion 32 are surrounded by the two caulking pieces 33 that are paired on the left and right. As a result, the four electric wires 41 ⁇ / b> A and 41 ⁇ / b> B are held in pressure contact with the press contact portion 34, and the holder 10 and the two press contact terminal fittings 30 are fixed.

- the connector C of the present embodiment aims to reduce the work man-hours, and presses the two first electric wires 41A constituting the first twisted pair wire 40A individually and also constitutes the second twisted pair wire 40B.

- the holder 10 holding the two press contact terminal fittings 30 is arranged so that the press contact portions 34 formed on the press contact terminal fittings 30 are arranged in a direction intersecting with the wiring direction of the twisted pair wires 40A and 40B.

- the holder 10 has an upper distribution rib 17 that separates the two first electric wires 41 ⁇ / b> A so as to correspond to the two press contact portions 34 in the process of causing the first twisted pair wire 40 ⁇ / b> A to approach the press contact position with the press contact portion 34. It has. Therefore, when the first twisted pair wire 40 ⁇ / b> A is brought close to the press contact position with the press contact portion 34, the two first electric wires 41 ⁇ / b> A are separated so as to correspond to the press contact portion 34 by the upper distribution rib 17. As described above, according to the connector C of this embodiment, it is not necessary to separate the two first electric wires 41A in advance before the press-contacting process, so that the number of work steps can be reduced.

- the holder 10 is provided with lower distribution ribs 20 that separate the two second electric wires 41B so as to correspond to the two press contact portions 34 in the process of bringing the second twisted pair wire 40B closer to the press contact position with the press contact portion 34. I have. Therefore, when the second twisted pair wire 40 ⁇ / b> B is brought close to the press contact position with the press contact portion 34, the two second electric wires 41 ⁇ / b> B are separated by the lower distribution rib 20 so as to correspond to the press contact portion 34. As described above, according to the connector C of this embodiment, it is not necessary to separate the two second electric wires 41B in advance before the press-contacting process, so that the number of work steps can be reduced.

- the upper distribution rib 17 is formed with the upper guide portion 18 having a wedge-shaped cross section in which the width dimension in the arrangement direction of the pressure contact portions 34 is narrowed toward the tip (upper end), the two first electric wires 41A By interposing the upper guide portion 18 therebetween, the two first electric wires 41A can be reliably separated.

- the lower distribution rib 20 is also formed with the lower guide portion 21 having a wedge-shaped cross section in which the width dimension in the arrangement direction of the pressure contact portions 34 is narrowed toward the tip (lower end), and thus the two second electric wires 41B. By interposing the lower guide portion 21 between the two, the two second electric wires 41B can be reliably separated.

- the press contact portion 34 includes two pairs of upper press contact blades 37 arranged at intervals in the front-rear direction (wiring direction of the twisted pair wires 40A and 40B). And the formation area of the upper distribution rib 17 in the front-back direction extends over a wider range than the range including the two pairs of upper press contact blades 37.

- the two first electric wires 41 ⁇ / b> A when the two first electric wires 41 ⁇ / b> A are distributed to the left and right by the upper distributing rib 17, the two first electric wires 41 ⁇ / b> A cover a range including the formation region of the two pairs of upper press contact blades 37. Are separated. Therefore, following the step of distributing the first electric wire 41 ⁇ / b> A by the upper distributing rib 17, the first electric wire 41 ⁇ / b> A can be reliably pressed against the upper press contact blade 37.

- the press contact portion 34 includes a pair of support plate portions 36 that are arranged to face each other while rising from both side edges of the substrate portion 35, and upper press contact blades 37 that protrude from the opposing surfaces of the pair of support plate portions 36 to form a pair.

- the upper distribution rib 17 is configured to rise in substantially the same direction as the rising direction of the support plate portion 36. In the rising direction of the support plate part 36, the upper sorting rib 17 rises to a position higher than the rising edge of the support plate part 36. According to this configuration, the two first electric wires 41 ⁇ / b> A can be reliably separated before being inserted between the pair of support plate portions 36.

- the press contact portion 34 includes an upper press contact blade 37 that forms a pair and sandwiches the first electric wire 41A.

- the upper press contact blade 37 forms a pair by sliding the first electric wire 41A in sliding contact with the upper press contact blade 37.

- An upper guide edge portion 37E is formed to be guided therebetween.

- the upper sliding contact surface 19 with which the 1st electric wire 41A is slidably contacted in the upper distribution rib 17, and the upper guide edge 37E are arranged so that it may form in an obtuse angle. According to this configuration, the two first electric wires 41 ⁇ / b> A separated by the upper distribution rib 17 can smoothly enter between the upper press contact blades 37.

- the present invention is not limited to the embodiments described with reference to the above description and drawings.

- the following embodiments are also included in the technical scope of the present invention.

- the wedge-shaped cross-section guide portion is formed on the distribution rib in the above embodiment, the distribution rib may not have the wedge-shaped cross-section guide portion.

- the distribution area of the distribution ribs in the twisted pair wiring direction extends over a range wider than the range including the two pairs of upper press contact blades. The range may be the same as or narrower than the range including the upper press contact blade.

- the sliding contact surface of the upper distributing rib and the guide edge portion of the press contact blade are arranged so as to form an obtuse angle, but the sliding contact surface and the guide edge portion are arranged substantially at right angles. It may be arranged as follows.

- the sliding contact surface of the upper distributing rib and the guide edge of the press contact blade are arranged close to each other, but the sliding contact surface and the guide edge are arranged in a separated positional relationship. May be.

- two upper and lower distribution ribs are formed on one holder, but only one distribution rib or three or more distribution ribs may be formed on one holder.

- one press contact portion is formed on one press contact terminal fitting, but a plurality of press contact portions may be formed on one press contact terminal fixture.

- four pairs of press contact blades are formed on one press contact portion, but the number of press contact blades formed on one press contact portion may be three pairs or less, or five pairs or more.

- the press contact blades are formed at two different positions in the rising direction of the support plate portion, but the number of press contact blades arranged in the rising direction of the support plate portion may be three or more. The number of press contact blades arranged in the rising direction of the part may be only one.

- two press contact terminal fittings are attached to one holder, but the number of press contact terminal fittings attached to one holder may be one or three or more.

Landscapes

- Connections By Means Of Piercing Elements, Nuts, Or Screws (AREA)

- Multi-Conductor Connections (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Connector Housings Or Holding Contact Members (AREA)

- Connections Effected By Soldering, Adhesion, Or Permanent Deformation (AREA)

- Manufacturing Of Electrical Connectors (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE112016000800.7T DE112016000800T5 (de) | 2015-02-18 | 2016-01-29 | Verbinder |

| CN201680009314.5A CN107431284B (zh) | 2015-02-18 | 2016-01-29 | 连接器 |

| US15/548,182 US10084247B2 (en) | 2015-02-18 | 2016-01-29 | Connector |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-029439 | 2015-02-18 | ||

| JP2015029439A JP6358125B2 (ja) | 2015-02-18 | 2015-02-18 | コネクタ |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016132856A1 true WO2016132856A1 (ja) | 2016-08-25 |

Family

ID=56692121

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/052606 Ceased WO2016132856A1 (ja) | 2015-02-18 | 2016-01-29 | コネクタ |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10084247B2 (enExample) |

| JP (1) | JP6358125B2 (enExample) |

| CN (1) | CN107431284B (enExample) |

| DE (1) | DE112016000800T5 (enExample) |

| WO (1) | WO2016132856A1 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7044606B2 (ja) * | 2017-10-25 | 2022-03-30 | 矢崎総業株式会社 | 分岐コネクタ及び通信ネットワーク |

| DE102018218035B4 (de) | 2017-10-25 | 2024-05-23 | Yazaki Corporation | Verzweigungsverbinder und Kommunikationsnetzwerk |

| JP6993214B2 (ja) * | 2017-12-22 | 2022-01-13 | 京セラ株式会社 | コネクタ及び取付方法 |

| EP3595099B1 (de) * | 2018-07-13 | 2021-09-01 | Rosenberger Hochfrequenztechnik GmbH & Co. KG | Adernkreuzer |

| JP7629350B2 (ja) * | 2021-06-03 | 2025-02-13 | 矢崎総業株式会社 | 通信コネクタ |

| CN118198763B (zh) * | 2024-04-15 | 2024-11-22 | 惠阳晋煜工业有限公司 | 一种双线导线连接器 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001185249A (ja) * | 1999-12-22 | 2001-07-06 | Sumitomo Wiring Syst Ltd | 圧接コネクタ |

| JP2010003461A (ja) * | 2008-06-18 | 2010-01-07 | Furukawa Electric Co Ltd:The | 圧接ジョイントコネクタ |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4693537A (en) * | 1986-07-07 | 1987-09-15 | Adc Telecommunications, Inc. | Electrical connector |

| JPH08162183A (ja) * | 1994-12-07 | 1996-06-21 | Fujikura Ltd | コネクタ |

| US6050842A (en) * | 1996-09-27 | 2000-04-18 | The Whitaker Corporation | Electrical connector with paired terminals |

| US6045389A (en) * | 1998-06-30 | 2000-04-04 | The Whitaker Corporation | Contact and connector for terminating a pair of individually insulated wires |

| US6488525B2 (en) * | 2001-04-10 | 2002-12-03 | Avaya Technology Corp. | Wire lead guide for communication connectors |

| DE202005014718U1 (de) * | 2005-09-17 | 2007-02-01 | Weidmüller Interface GmbH & Co. KG | Anschluß-System zur Realisierung von Abzweigungen an durchgehenden Leitern |

| PT2044654E (pt) * | 2006-07-25 | 2010-03-03 | Adc Gmbh | Bloco de ligação |

| US9033725B2 (en) * | 2012-04-19 | 2015-05-19 | Panduit Corp. | GG45 plug with hinging load bar |

| EP2875554B1 (en) * | 2012-07-23 | 2022-02-09 | Molex, LLC | Electrical harness connector system with differential pair connection link |

-

2015

- 2015-02-18 JP JP2015029439A patent/JP6358125B2/ja not_active Expired - Fee Related

-

2016

- 2016-01-29 DE DE112016000800.7T patent/DE112016000800T5/de not_active Withdrawn

- 2016-01-29 WO PCT/JP2016/052606 patent/WO2016132856A1/ja not_active Ceased

- 2016-01-29 US US15/548,182 patent/US10084247B2/en not_active Expired - Fee Related

- 2016-01-29 CN CN201680009314.5A patent/CN107431284B/zh not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001185249A (ja) * | 1999-12-22 | 2001-07-06 | Sumitomo Wiring Syst Ltd | 圧接コネクタ |

| JP2010003461A (ja) * | 2008-06-18 | 2010-01-07 | Furukawa Electric Co Ltd:The | 圧接ジョイントコネクタ |

Also Published As

| Publication number | Publication date |

|---|---|

| US10084247B2 (en) | 2018-09-25 |

| CN107431284A (zh) | 2017-12-01 |

| US20180034168A1 (en) | 2018-02-01 |

| CN107431284B (zh) | 2019-12-31 |

| JP6358125B2 (ja) | 2018-07-18 |

| JP2016152147A (ja) | 2016-08-22 |

| DE112016000800T5 (de) | 2017-10-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6358125B2 (ja) | コネクタ | |

| JP5787864B2 (ja) | 分岐コネクタ | |

| JP5966041B1 (ja) | 分岐コネクタ | |

| JP2019145208A (ja) | 端子、及びコネクタ | |

| JP6939625B2 (ja) | 端子、及び端子付き電線 | |

| CN108075277A (zh) | 用于接触电导线的弹簧夹紧接触件、接线端子和用于制造弹簧夹紧接触件的方法 | |

| US10033116B2 (en) | Terminal, terminal-equipped electrical wire, and method for manufacturing terminal-equipped electrical wire | |

| JP6514142B2 (ja) | 分岐コネクタ | |

| US20210234286A1 (en) | Terminal | |

| JP6397864B2 (ja) | 分岐コネクタ | |

| JP6495216B2 (ja) | 分岐コネクタ | |

| WO2020196480A1 (ja) | ジョイントコネクタ | |

| US8900005B2 (en) | Insulation displacement terminal system with regulated wire compression | |

| KR101643218B1 (ko) | 커넥터용 터미널 및 이를 갖는 커넥터 | |

| CN107004965B (zh) | 用于刺穿电线的绝缘护套的电连接元件 | |

| KR20100083413A (ko) | 버스바조립체 | |

| JP2006505102A (ja) | 2つの導体を接続するためのプラグコネクタ | |

| WO2014068847A1 (ja) | 圧接コンタクト及びコネクタ | |

| CN204376028U (zh) | Idc连接器公头 | |

| JP3235510U (ja) | 突き刺し式電気コネクタ及び電気コネクタとケーブルとの接合用治具 | |

| CN215299539U (zh) | 易于组装弹片的端子台 | |

| JP6074684B2 (ja) | 圧接電気コネクタ | |

| JP2016134231A (ja) | 分岐コネクタ | |

| JP6401770B2 (ja) | 分岐コネクタ | |

| JP2015065027A (ja) | スプライス用部品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16752245 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15548182 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 112016000800 Country of ref document: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16752245 Country of ref document: EP Kind code of ref document: A1 |