WO2016121385A1 - 空調装置 - Google Patents

空調装置 Download PDFInfo

- Publication number

- WO2016121385A1 WO2016121385A1 PCT/JP2016/000395 JP2016000395W WO2016121385A1 WO 2016121385 A1 WO2016121385 A1 WO 2016121385A1 JP 2016000395 W JP2016000395 W JP 2016000395W WO 2016121385 A1 WO2016121385 A1 WO 2016121385A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- electric compressor

- refrigerant

- control

- temperature

- inverter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B31/00—Compressor arrangements

- F25B31/006—Cooling of compressor or motor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3205—Control means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H1/3204—Cooling devices using compression

- B60H1/3225—Cooling devices using compression characterised by safety arrangements, e.g. compressor anti-seizure means or by signalling devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/06—Cooling; Heating; Prevention of freezing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D25/00—Pumping installations or systems

- F04D25/02—Units comprising pumps and their driving means

- F04D25/06—Units comprising pumps and their driving means the pump being electrically driven

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D27/00—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids

- F04D27/004—Control, e.g. regulation, of pumps, pumping installations or pumping systems specially adapted for elastic fluids by varying driving speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B49/00—Arrangement or mounting of control or safety devices

- F25B49/005—Arrangement or mounting of control or safety devices of safety devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B49/00—Arrangement or mounting of control or safety devices

- F25B49/02—Arrangement or mounting of control or safety devices for compression type machines, plants or systems

- F25B49/022—Compressor control arrangements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B5/00—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity

- F25B5/04—Compression machines, plants or systems, with several evaporator circuits, e.g. for varying refrigerating capacity arranged in series

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B6/00—Compression machines, plants or systems, with several condenser circuits

- F25B6/04—Compression machines, plants or systems, with several condenser circuits arranged in series

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3236—Cooling devices information from a variable is obtained

- B60H2001/3255—Cooling devices information from a variable is obtained related to temperature

- B60H2001/3257—Cooling devices information from a variable is obtained related to temperature of the refrigerant at a compressing unit

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3269—Cooling devices output of a control signal

- B60H2001/327—Cooling devices output of a control signal related to a compressing unit

- B60H2001/3272—Cooling devices output of a control signal related to a compressing unit to control the revolving speed of a compressor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60H—ARRANGEMENTS OF HEATING, COOLING, VENTILATING OR OTHER AIR-TREATING DEVICES SPECIALLY ADAPTED FOR PASSENGER OR GOODS SPACES OF VEHICLES

- B60H1/00—Heating, cooling or ventilating [HVAC] devices

- B60H1/32—Cooling devices

- B60H2001/3286—Constructional features

- B60H2001/3292—Compressor drive is electric only

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/04—Refrigeration circuit bypassing means

- F25B2400/0409—Refrigeration circuit bypassing means for the evaporator

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2400/00—General features or devices for refrigeration machines, plants or systems, combined heating and refrigeration systems or heat-pump systems, i.e. not limited to a particular subgroup of F25B

- F25B2400/04—Refrigeration circuit bypassing means

- F25B2400/0411—Refrigeration circuit bypassing means for the expansion valve or capillary tube

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2500/00—Problems to be solved

- F25B2500/08—Exceeding a certain temperature value in a refrigeration component or cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/02—Compressor control

- F25B2600/021—Inverters therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2600/00—Control issues

- F25B2600/02—Compressor control

- F25B2600/025—Compressor control by controlling speed

- F25B2600/0253—Compressor control by controlling speed with variable speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21154—Temperatures of a compressor or the drive means therefor of an inverter

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2700/00—Sensing or detecting of parameters; Sensors therefor

- F25B2700/21—Temperatures

- F25B2700/2115—Temperatures of a compressor or the drive means therefor

- F25B2700/21156—Temperatures of a compressor or the drive means therefor of the motor

Definitions

- the present disclosure relates to an air conditioner including an electric compressor in which an inverter is integrated.

- Patent Document 1 proposes an air conditioner that measures the refrigerant temperature and prevents liquid compression and poor lubrication by limiting the upper limit rotation speed of the compressor when the refrigerant temperature is lower than a predetermined value. ing.

- the compressor operates by rotating an electric motor under the control of an inverter having electronic components such as power elements.

- the refrigerant sucked into the compressor may fall below the minimum operation guarantee temperature of the electronic component.

- the electronic component itself does not generate heat, but the refrigerant that has been circulated continues to flow into the compressor due to its inertia. As a result, the electronic component may be supercooled below the minimum guaranteed temperature and eventually damaged.

- the present disclosure provides an air conditioner that can prevent electronic components constituting an inverter from being destroyed by overcooling of an electric compressor integrated with the inverter in a low temperature environment. With the goal.

- the air conditioner of the present disclosure includes an electric compressor, a drive unit, a temperature detection unit, and a control unit.

- the electric compressor compresses the refrigerant sucked from the refrigerant suction port and discharges it from the refrigerant discharge port.

- the drive unit is integrated with the electric compressor so as to be cooled by the refrigerant sucked from the refrigerant suction port of the electric compressor, and operates the electric compressor according to the control signal.

- the temperature detection unit detects the temperature of the drive unit.

- the control unit outputs a control signal to the drive unit to control the drive unit.

- the control unit is configured to reduce the self-cooling amount of the electric compressor and the control to increase the self-heating amount of the driving unit. Either or both of these are performed on the drive unit.

- the drive unit since the amount of self-cooling of the electric compressor is reduced, the drive unit can be prevented from being cooled too much by the refrigerant. Moreover, since the self-heating amount of the drive unit increases, the temperature of the drive unit itself can be increased. For this reason, in a low temperature environment, it can avoid that the electronic component which comprises a drive part falls below minimum guarantee temperature by the supercooling of an electric compressor. Accordingly, it is possible to prevent the drive unit from being damaged.

- FIG. 1 is an overall configuration diagram of an air conditioner according to an embodiment. It is sectional drawing of the electric compressor with which the inverter was integrated. It is the flowchart which showed the control content of air-conditioner control ECU or an inverter. It is the flowchart which showed the content of 1st low temperature environment control. It is the flowchart which showed the content of 2nd low temperature environment control. It is the figure which showed the change of component temperature before and after stopping operation

- the air conditioner according to the present embodiment is mounted on a vehicle and controls air conditioning in the vehicle interior by a heat pump cycle.

- the heat pump cycle 200 heats or cools the air (blowing air) blown into the vehicle interior, which is the air-conditioning target space. Therefore, in this heat pump cycle 200, by switching the refrigerant flow path, heating operation (heating operation) in which the air that is the heat exchange target fluid is heated and the vehicle interior is heated as normal environment control, and the air is cooled and the vehicle is cooled. A cooling operation (cooling operation) for cooling the room can be performed.

- a normal chlorofluorocarbon refrigerant is adopted as the refrigerant, and a subcritical refrigeration cycle in which the high-pressure side refrigerant pressure does not exceed the critical pressure of the refrigerant is configured.

- This refrigerant is mixed with refrigerating machine oil for lubricating the electric compressor 210, and a part of the refrigerating machine oil circulates in the cycle together with the refrigerant.

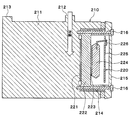

- the electric compressor 210 is disposed in the engine room, and inhales, compresses and discharges the refrigerant in the heat pump cycle 200. Specifically, as shown in FIG. 2, the electric compressor 210 has a configuration in which an inverter 220 is integrated with a housing 211.

- the housing 211 is a housing in which a refrigerant circulation space is formed, and has a refrigerant inlet 212 and a refrigerant outlet 213.

- the refrigerant sucked from the refrigerant suction port 212 flows through the refrigerant circulation space and is discharged from the refrigerant discharge port 213.

- the housing 211 houses an electric motor 210a and a compression mechanism 201b that compresses the refrigerant in the refrigerant circulation space.

- specific structures of the electric motor 210a and the compression mechanism 210b are omitted.

- the operation (rotation speed) of the electric motor 210a is controlled by driving the inverter 220 based on a control signal from an air conditioner control ECU 300 described later.

- air conditioner control ECU 300 is simply referred to as ECU 300.

- the electric motor 210a may employ either an AC motor or a DC motor.

- the compression mechanism 210b compresses the refrigerant and is driven by the electric motor 210a.

- a scroll type compression mechanism is employed as the compression mechanism 210b, but other mechanisms may be employed.

- the ECU 300 outputs a control signal for instructing the target rotational speed to the inverter 220, and the inverter 220 controls the rotational speed of the electric motor 210a, whereby the refrigerant discharge capacity of the compression mechanism 210b is adjusted. That is, when the rotation speed of the electric motor 210a is increased, the flow rate (flow velocity) of the refrigerant flowing through the refrigerant circulation space of the housing 211 increases. As a result, the refrigerant discharge capacity of the compression mechanism 210b increases. On the other hand, when the rotation speed of the electric motor 210a is reduced, the flow rate of the refrigerant flowing through the refrigerant circulation space of the housing 211 is reduced. As a result, the refrigerant discharge capacity of the compression mechanism 210b decreases.

- the inverter 220 is housed in a groove 214 provided on the refrigerant inlet side 212 of the refrigerant in the housing 211.

- the inverter 220 includes a heat sink 222, a power element 224, and a circuit board 225.

- the heat sink 222 is disposed in the groove 214 via the heat radiation grease 221.

- the power element 224 is disposed on the heat sink 222 via the heat dissipation grease 223.

- a power element 224 is mounted on the circuit board 225.

- the inverter 220 includes electronic components (not shown) such as a microcomputer. Inverter 220 drives power element 224 in accordance with a control signal input from ECU 300. By driving the power element 224, the electric motor 210a rotates.

- the heat sink 222 is pressed against the bottom of the groove 214 by the lid 215 and is fixed to the groove 214 by the screw 216. As a result, the inverter 220 is accommodated in the housing 211.

- the heat generated by the power element 224 is transmitted to the housing 211 via the heat radiation grease 223, the heat sink 222, and the heat radiation grease 221.

- the housing 211 sucks the refrigerant from the refrigerant suction port 212

- the heat of the power element 224 is absorbed by the refrigerant. That is, the inverter 220 is integrated with the electric compressor 210 so as to be cooled by the refrigerant sucked from the refrigerant suction port 212 of the electric compressor 210.

- a temperature detection element 226 for detecting the temperature of the inverter 220 is mounted on the circuit board 225 of the inverter 220.

- the temperature detection element 226 is, for example, a thermistor. Temperature detection element 226 outputs a temperature signal to ECU 300. Note that the temperature detection element 226 may not be mounted on the circuit board 225. That is, as long as the temperature of the inverter 220 can be detected, it may be disposed anywhere in the groove 214 of the housing 211.

- the indoor condenser 230 is disposed in the casing 241 of the indoor air conditioning unit 240 of the air conditioner 100, and heat exchanger for heating that exchanges heat between the high-temperature and high-pressure refrigerant flowing through the interior and the air after passing through the evaporator 250 described later. It is.

- the detailed configuration of the indoor air conditioning unit 240 will be described later.

- a heating expansion valve 260 is connected to the refrigerant outlet side of the indoor condenser 230 as a decompression section for heating operation that decompresses and expands the refrigerant flowing out of the indoor condenser 230 during the heating operation.

- the refrigerant inlet side of the outdoor condenser 270 is connected to the outlet side of the heating expansion valve 260.

- a bypass passage 261 is connected to the refrigerant outlet side of the indoor condenser 230 to guide the refrigerant flowing out of the indoor condenser 230 to the outdoor condenser 270 side by bypassing the heating expansion valve 260.

- a two-way valve 262 that opens and closes the bypass passage 261 is disposed in the bypass passage 261.

- the two-way valve 262 is an electromagnetic valve whose opening / closing operation is controlled by a control voltage output from the ECU 300, and is a refrigerant flow switching unit.

- the pressure loss that occurs when the refrigerant passes through the two-way valve 262 is extremely small with respect to the pressure loss that occurs when the refrigerant passes through the heating expansion valve 260. Therefore, the refrigerant flowing out of the indoor condenser 230 flows into the outdoor condenser 270 via the bypass passage 261 when the two-way valve 262 is open, and expands for heating when the two-way valve 262 is closed. It flows into the outdoor capacitor 270 through the valve 260. Thereby, the two-way valve 262 can switch the refrigerant flow path of the heat pump cycle 200.

- the outdoor condenser 270 exchanges heat between the low-pressure refrigerant circulating inside and the outside air blown from the outdoor fan 271.

- the outdoor condenser 270 is disposed in the engine room and functions as an evaporator that evaporates the low-pressure refrigerant and exerts an endothermic effect during the heating operation, and functions as a radiator that radiates heat from the high-pressure refrigerant during the cooling operation. It is an exchanger.

- the outdoor fan 271 is an electric blower in which the operating rate, that is, the rotation speed (the amount of air to be blown) is controlled by the control voltage output from the ECU 300.

- An electric three-way valve 280 is connected to the outlet side of the outdoor capacitor 270.

- the operation of the three-way valve 280 is controlled by a control voltage output from the ECU 300, and constitutes a refrigerant flow path switching unit in the same manner as the two-way valve 262 described above.

- the three-way valve 280 switches to a refrigerant flow path that connects an outlet side of the outdoor condenser 270 and an inlet side of an accumulator 290 described later during heating operation.

- the three-way valve 280 switches to a refrigerant flow path that connects the outlet side of the outdoor condenser 270 and the inlet side of the cooling expansion valve 281 during the cooling operation.

- the cooling expansion valve 281 is a decompression unit for cooling operation (for cooling operation) that decompresses and expands the refrigerant that flows out of the outdoor condenser 270 during the cooling operation, and the basic configuration thereof is the same as that of the heating expansion valve 260. .

- the refrigerant inlet side of the evaporator 250 is connected to the outlet side of the cooling expansion valve 281.

- the evaporator 250 is disposed in the casing 241 of the indoor air conditioning unit 240 on the upstream side of the air flow with respect to the indoor condenser 230, and performs heat exchange between the refrigerant circulating in the interior and the air to cool the air. It is a heat exchanger.

- the refrigerant outlet side of the evaporator 250 is connected to the inlet side of the accumulator 290.

- the refrigerant flow path from the three-way valve 280 through which the refrigerant during heating operation flows to the inlet side of the accumulator 290 constitutes a bypass passage 282 through which the refrigerant on the downstream side of the outdoor condenser 270 flows around the evaporator 250.

- the three-way valve 280 is a bypass passage switching unit that switches between a refrigerant circuit that guides the refrigerant downstream of the outdoor condenser 270 to the evaporator 250 side and a refrigerant circuit that guides the refrigerant downstream of the outdoor condenser 270 to the bypass passage 282 side. Is configured.

- the accumulator 290 is a gas-liquid separator for a low-pressure side refrigerant that separates the gas-liquid refrigerant flowing into the accumulator 290 and stores excess refrigerant in the cycle.

- the suction side of the electric compressor 210 is connected to the gas-phase refrigerant outlet of the accumulator 290. Therefore, the accumulator 290 suppresses the liquid refrigerant from being sucked into the electric compressor 210 and prevents liquid compression of the electric compressor 210.

- the indoor air conditioning unit 240 is disposed inside the instrument panel (instrument panel) at the foremost part of the vehicle interior, and houses the blower 242, the aforementioned indoor condenser 230, the evaporator 250, and the like in a casing 241 that forms the outer shell thereof. Is.

- the casing 241 forms an air passage for air to be blown into the passenger compartment, and is formed of a resin (for example, polypropylene) having a certain degree of elasticity and excellent strength.

- An inside / outside air switching device 243 that switches and introduces vehicle interior air (inside air) and outside air is disposed on the most upstream side of the air flow in the casing 241.

- the inside / outside air switching device 243 continuously adjusts the opening area of the inside air introduction port through which the inside air is introduced into the casing 241 and the outside air introduction port through which the outside air is introduced by the inside / outside air switching door, and the introduction ratio of the inside air to the outside air

- the inside / outside air switching device 243 is formed with an inside air introduction port for introducing inside air into the casing 241 and an outside air introduction port for introducing outside air. Furthermore, inside / outside air switching device 243 has an inside / outside air switching door that continuously adjusts the opening area of the inside air introduction port and the outside air introduction port to change the air volume ratio between the inside air volume and the outside air volume. Has been.

- the inside / outside air switching door is driven by an electric actuator (not shown) whose operation is controlled by a control signal output from the ECU 300.

- the suction port mode switched by the inside / outside air switching device 243 there is an inside air mode in which the inside air introduction port is fully opened and the outside air introduction port is fully closed to introduce the inside air into the casing 241.

- an outside air mode in which the inside air introduction port is fully closed and the outside air introduction port is fully opened to introduce outside air into the casing 241

- an inside and outside air mixing mode in which the inside air introduction port and the outside air introduction port are simultaneously opened.

- a blower 242 that blows air sucked through the inside / outside air switching device 243 toward the vehicle interior is disposed on the downstream side of the air flow of the inside / outside air switching device 243.

- the blower 242 is an electric blower that drives a centrifugal multiblade fan (sirocco fan) with a motor, and the number of rotations (the amount of blown air) is controlled by a control voltage output from the ECU 300.

- Evaporator 250 and indoor condenser 230 are arranged in this order with respect to the air flow on the air flow downstream side of blower 242.

- the evaporator 250 is arranged on the upstream side of the air flow with respect to the indoor condenser 230.

- the air mix door 244 that adjusts the air volume ratio that passes through the indoor condenser 230 in the air that has passed through the evaporator 250.

- a mixing space 245 for mixing the air heated by exchanging heat with the refrigerant in the indoor condenser 230 and the air not heated by bypassing the indoor condenser 230 is provided on the downstream side of the air flow of the indoor condenser 230. It has been.

- the most downstream part of the air flow of the casing 241 is provided with an opening hole for blowing the air merged in the mixing space 245 into the passenger compartment as a cooling target space as conditioned air. Therefore, the temperature of the air mixed in the mixing space 245 is adjusted by adjusting the ratio of the air volume that the air mix door 244 passes through the indoor condenser 230, and the temperature of the air blown out from the opening hole is adjusted. . That is, the air mix door 244 constitutes a temperature adjustment unit that adjusts the temperature of air (air conditioned air) blown into the vehicle interior.

- the air mix door 244 serves as a heat exchange amount adjustment unit that adjusts the heat exchange amount between the refrigerant discharged from the electric compressor 210 and the air blown into the vehicle interior in the indoor condenser 230 that constitutes the use side heat exchanger. Fulfills the function.

- the air mix door 244 is driven by a servo motor (not shown) whose operation is controlled by a control signal output from the ECU 300.

- the ECU 300 is an electronic control unit (ECU) including a known microcomputer including a CPU, a ROM, a RAM, and the like and a peripheral circuit thereof.

- ECU electronice control unit

- ECU 300 inputs sensor signals from a group of sensors for air conditioning control such as an inside air sensor, an outside air sensor, a solar radiation sensor, and a high pressure side pressure sensor (not shown). Further, the ECU 300 receives operation signals of various air conditioning operation switches from an operation panel (not shown) disposed near the instrument panel in the front part of the vehicle interior. ECU 300 performs various calculations and processes according to the air conditioning control program stored in the ROM. Thereby, ECU300 outputs a control signal to various air-conditioning control apparatuses, such as inverter 220 of electric compressor 210, two-way valve 262, outdoor fan 271, three-way valve 280, and air blower 242, and controls operation of each apparatus. .

- the above is the overall configuration of the air conditioner 100 according to the present embodiment.

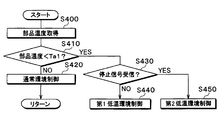

- the air conditioner 100 starts the processing shown in FIG. 3 when the user operates the operation panel in the passenger compartment.

- the contents shown in FIGS. 3 to 5 can be implemented in a microcomputer mounted on the inverter 220, the present embodiment will be described as the control of the ECU 300.

- the ECU 300 acquires the component temperature of the inverter 220 (S400). That is, ECU 300 receives a temperature signal from temperature detection element 226 mounted on inverter 220. Then, ECU 300 determines whether or not the component temperature of inverter 220 is lower than a predetermined first reference temperature Ta1 (S410).

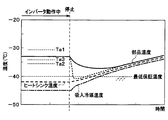

- the first reference temperature Ta1 is a temperature that may cause overcooling of the inverter when the component temperature of the inverter 220 is cooled to a level lower than the temperature. Accordingly, the first reference temperature Ta1 is set to a temperature higher than the minimum guaranteed temperature of each component constituting the inverter 220 (see FIG. 6 described later). Since the inverter 220 includes a plurality of electronic components such as the power element 224, the minimum guaranteed temperature of the inverter 220 is the highest minimum guaranteed temperature among the components.

- the ECU 300 When the component temperature of the inverter 220 is higher than the first reference temperature Ta1, the ECU 300 performs normal environmental control (S420). Specifically, first, ECU 300 calculates a target blowing temperature, which is a target temperature of air blown into the vehicle interior, based on the above-described sensor signals and operation signals of the operation panel. Then, ECU 300 performs feedback control for adjusting the rotational speed of electric compressor 210 and the like so that the target blowing temperature coincides with the actual blowing temperature that is the actual temperature in the passenger compartment.

- a target blowing temperature which is a target temperature of air blown into the vehicle interior

- the ECU 300 closes the two-way valve 262 and switches the three-way valve 280 to a refrigerant flow path that connects the outlet side of the outdoor capacitor 270 and the inlet side of the accumulator 290.

- the heat pump cycle 200 is switched to the refrigerant flow path through which the refrigerant flows, such as the electric compressor 210, the indoor condenser 230, the heating expansion valve 260, the outdoor condenser 270, the three-way valve 280, the accumulator 290, and the electric compressor 210. .

- the high-pressure refrigerant discharged from the electric compressor 210 flows into the indoor condenser 230.

- the refrigerant flowing into the indoor condenser 230 exchanges heat with the air blown from the blower 242 and passed through the evaporator 250 to dissipate heat. Thereby, air is heated.

- the ECU 300 opens the two-way valve 262 and switches the three-way valve 280 to a refrigerant flow path that connects the outlet side of the outdoor condenser 270 and the inlet side of the cooling expansion valve 281.

- the heat pump cycle 200 includes a refrigerant such as an electric compressor 210, an indoor condenser 230, a two-way valve 262, an outdoor condenser 270, a three-way valve 280, a cooling expansion valve 281, an evaporator 250, an accumulator 290, and an electric compressor 210. Is switched to the refrigerant flow path.

- the high-pressure refrigerant discharged from the electric compressor 210 flows into the indoor condenser 230 and exchanges heat with the air blown from the blower 242 and passed through the evaporator 250 to dissipate heat. .

- the high-pressure refrigerant that has flowed out of the indoor condenser 230 flows into the outdoor condenser 270 via the bypass passage 261 because the two-way valve 262 is open.

- the low-pressure refrigerant that has flowed into the outdoor condenser 270 further dissipates heat to the outside air blown by the outdoor fan 271.

- the three-way valve 280 switches to the refrigerant flow path that connects the outlet side of the outdoor condenser 270 and the inlet side of the cooling expansion valve 281.

- the refrigerant flowing out of the outdoor condenser 270 is decompressed and expanded by the cooling expansion valve 281.

- the refrigerant that has flowed out of the cooling expansion valve 281 flows into the evaporator 250 and absorbs heat from the air blown by the blower 242 and evaporates. Thereby, air is cooled.

- the ECU 300 acquires the component temperature of the inverter 220 again, and repeatedly executes the normal environment control described above if the component temperature is higher than the first reference temperature Ta1.

- the ECU 300 is one of control for reducing the self-cooling amount of the electric compressor 210 (second low-temperature environment control) and control for increasing the self-heat generation amount of the inverter 220 (first low-temperature environment control). One or both controls are performed on the inverter 220.

- control for reducing the self-cooling amount of the electric compressor 210 is control for reducing the ability to cool the inverter 220 by the refrigerant flowing into the electric compressor 210.

- control for increasing the self-heat generation amount of the inverter 220 is control for increasing the heat generation amount of the inverter 220 by increasing the electrical operation amount of the inverter 220.

- the ECU 300 determines whether or not a stop signal is received (S430).

- the stop signal is a signal indicating that the air conditioning control is stopped.

- the ECU 300 receives a stop signal from the operation panel, another ECU, or the like when the user operates the operation panel to stop the air conditioning in the vehicle interior or when the power supply of the vehicle is stopped.

- ECU300 performs 1st low temperature environment control, when the stop signal is not received (S440).

- the component temperature of the inverter 220 is lower than the first reference temperature Ta1

- the vehicle is placed in an environment where the outside air temperature is very low, and the user usually uses heating. Therefore, when the first low-temperature environment control is executed, it is assumed that the air conditioner 100 is performing a heating operation.

- the contents of the first low-temperature environment control will be described with reference to FIG.

- the ECU 300 determines whether or not the heating capacity of the electric compressor 210 can be limited (S441).

- the ECU 300 determines the determination based on, for example, the remaining battery capacity. When the remaining capacity of the battery is higher than a predetermined value, it is possible to limit the heating capacity. When the remaining capacity of the battery is lower than the predetermined value, it is difficult to limit the heating capacity. In addition, you may determine the restriction

- the ECU 300 controls the inverter 220 so that the rotation of the electric compressor 210 is decelerated (S442). That is, the rotational speed of the electric motor 210a of the electric compressor 210 is reduced. Thereby, since the flow volume of the refrigerant

- ECU 300 determines whether or not the efficiency of heat pump cycle 200 can be reduced (S443).

- the ECU 300 determines the determination based on, for example, the remaining battery capacity. When the remaining capacity of the battery is higher than a predetermined value, the efficiency of the heat pump cycle 200 can be reduced. When the remaining capacity of the battery is lower than the predetermined value, it is difficult to reduce the efficiency of the heat pump cycle 200. is there. In addition, you may determine the possibility of the efficiency fall of the heat pump cycle 200 using another criterion.

- the ECU 300 drives the inverter 220 so that the switching speed of the inverter 220 is increased (S444). That is, by increasing the switching frequency of the power element 224, the switching loss of the power element 224 increases, and the power element 224 generates heat. Thereby, since inverter 220 itself generates heat, the amount of self-heating of inverter 220 increases. Therefore, overcooling of the inverter 220 can be prevented.

- the ECU 300 returns to S400 shown in FIG. 3 and acquires the component temperature of the inverter 220 again.

- ECU 300 drives inverter 220 so that the switching speed of inverter 220 increases, so that the self-heat generation amount of inverter 220 is increased. To raise.

- ECU 300 determines that it is difficult to reduce the efficiency of heat pump cycle 200 after decelerating the rotation of electric compressor 210, ECU 300 ends the first low-temperature environment control and is shown in FIG. Return to S400.

- the second low temperature environment control is executed (S430, 450).

- the content of the second low-temperature environment control will be described with reference to FIG.

- the ECU 300 determines whether or not the rotation of the electric compressor 210 can be stopped at a reduced speed (S451). The ECU 300 determines the determination based on, for example, whether or not a special flag is set.

- the special flag refers to the electric motor 210a of the electric compressor 210, such as when a high voltage is used during traveling of the vehicle, when the power of the vehicle is turned off, when an abnormality occurs in the heat pump cycle 200, or the like. This flag stands when it is difficult to control the rotation.

- the special flag is not set, the rotation of the electric motor 210a of the electric compressor 210 can be stopped at a reduced speed, and when the special flag is set, the rotation of the electric compressor 210 is reduced at a reduced speed. It is difficult to stop.

- the ECU 300 controls the inverter 220 so that the rotation of the electric motor 210a of the electric compressor 210 is gently stopped (S452). That is, normally, when the electric compressor 210 is stopped, the electric motor 210a is suddenly stopped, but here, the electric motor 210a is stopped while being loosened so that the electric motor 210a does not stop suddenly.

- the refrigerant continues to flow into the electric compressor 210 due to the inertia of the refrigerant, but the refrigerant flows into the electric compressor 210 by gently stopping the electric compressor 210.

- the flow rate can be reduced. That is, the amount of self-cooling of the electric compressor 210 decreases. Therefore, overcooling of the inverter 220 can be prevented.

- the ECU 300 acquires the component temperature of the inverter 220 (S453), and determines whether or not the component temperature of the inverter 220 is lower than a predetermined second reference temperature Ta2 (S454).

- the second reference temperature Ta2 is a component temperature at which the inverter 220 will not be supercooled after the electric compressor 210 is stopped, and is set, for example, between a component temperature in a low temperature environment and a minimum guaranteed temperature (described later). (See FIG. 6).

- the ECU 300 ends the second low temperature environment control.

- the ECU 300 performs control to cause the power element 224 of the inverter 220 to generate heat (S455). That is, ECU 300 causes power element 224 to generate heat by operating power element 224 so that electric motor 210a of electric compressor 210 does not rotate. That is, the warm-up control of the power element 224 is performed. Thereby, the self-heating amount of the inverter 220 increases. Therefore, overcooling of the inverter 220 can be prevented.

- ECU 300 obtains the component temperature of inverter 220 (S456), and determines whether or not the component temperature of inverter 220 is lower than a predetermined third reference temperature Ta3 (S457).

- the third reference temperature Ta3 is a component temperature at which the inverter 220 is likely to be overcooled after the electric compressor 210 is stopped, and is set between, for example, the third reference temperature Ta3 and the minimum guaranteed temperature (described later). (See FIG. 6).

- the ECU 300 ends the second low temperature environment control.

- the ECU 300 performs control to cause the power element 224 of the inverter 220 to generate heat again.

- the ECU 300 normally stops the electric compressor 210 (S458). That is, the electric motor 210a is suddenly stopped. Thereafter, the ECU 300 controls the power element 224 to generate heat until the component temperature of the inverter 220 becomes higher than the third reference temperature Ta3 (S455, S456, S457).

- the component temperature does not fall below the minimum guaranteed temperature by the first low temperature environment control during the operation of the inverter 220 as shown in FIG.

- the inverter 220 is stopped by the stop signal, the self-cooling amount of the electric compressor 210 is decreased or the self-heat generation amount of the inverter 220 is increased by the second low temperature environment control. Therefore, the component temperature does not fall below the minimum guaranteed temperature after the inverter 220 is stopped.

- the refrigerant temperature sucked into the electric compressor 210 is the lowest.

- the heat sink 222 is cooled by the refrigerant and is lower than the minimum guaranteed temperature of the component temperature of the inverter 220.

- the suction refrigerant temperature and the temperature of the heat sink 222 become substantially the same as the component temperature when the inverter 220 is stopped.

- the ECU 300 increases the control for reducing the self-cooling amount of the electric compressor 210 and the self-heat generation amount of the inverter 220. Either or both of the controls are performed. As a result, the inverter 220 can be prevented from being overcooled by the refrigerant in a low temperature environment, and thus the inverter 220 can be prevented from being destroyed.

- the temperature detection element 226 of the present embodiment corresponds to the “temperature detection unit” of the present disclosure

- the ECU 300 corresponds to the “control unit” of the present disclosure

- an operation panel and other devices such as an ECU correspond to the “external device” of the present disclosure

- the first reference temperature Ta1 corresponds to the “reference temperature” of the present disclosure.

- the inverter 220 including the power element 224 and the circuit board 225 that are components for rotating the electric motor 210a of the electric compressor 210 in accordance with the control signal corresponds to the “drive unit” of the present disclosure.

- the configuration of the air conditioner 100 and the control content of the ECU 300 shown in each of the above embodiments are examples, and the present disclosure is not limited to the configuration described above, and other configurations that can realize the present disclosure can be employed.

- the control for decelerating the rotation of the electric motor 210a of the electric compressor 210 S442

- the control for increasing the switching speed of the inverter 220 S444

- the self-cooling amount of the electric compressor 210 can be reduced by the following control. For example, when operating in a one-stage heat pump cycle, there is a method of switching to a multistage compression cycle such as a gas injection cycle. Further, there is a method in which the refrigerant sucked into the electric compressor 210 is warmed by the outside air temperature by accelerating the rotation of the outdoor fan 271.

- the self-heat generation amount of the inverter 220 can be increased by the following control.

- two-phase modulation control is performed by the inverter 220

- the air conditioning control there is a method in which the refrigerant discharge pressure of the electric compressor 210 is increased by switching to the inside air circulation mode so that a high load state is obtained.

- the amount of refrigerant flowing into the electric compressor 210 is increased by increasing the rotational speed of the electric compressor 210, but the self-heat generation amount of the inverter 220 is further increased.

- a refrigerant shut-off valve is provided at the refrigerant inlet 212 of the electric compressor 210, and the refrigerant shut-off valve is closed when the electric compressor 210 is stopped, so that the refrigerant flows into the electric compressor 210. And the self-cooling amount of the electric compressor 210 can be reduced.

- the self-heating amount of the inverter 220 may be increased by energizing the electric motor 210a of the electric compressor 210 with an electrical angle at which the electric motor 210a does not rotate to generate heat in the power element 224 and the motor winding. it can.

- the ECU 300 performs the control combining the first low-temperature environment control and the second low-temperature environment control. However, only one of them may be performed.

- the ECU 300 performs the first low-temperature environment control and the second low-temperature environment control, and determines whether or not the execution is necessary.

- the first low-temperature environment control and the second low-temperature environment control may be performed and necessity determination may be performed by the microcomputer provided in the inverter 220 itself.

- the inverter 220 may be integrally provided with a control unit that performs the first low temperature environment control and the second low temperature environment control and determines whether or not to perform the first low temperature environment control.

- the air conditioner 100 is mounted on a vehicle, the air conditioner 100 is not limited to a vehicle.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Control Of Positive-Displacement Pumps (AREA)

- Compressor (AREA)

- Inverter Devices (AREA)

- Air-Conditioning For Vehicles (AREA)

- Air Conditioning Control Device (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201680007586.1A CN107208940B (zh) | 2015-01-30 | 2016-01-27 | 空调装置 |

| DE112016000555.5T DE112016000555B4 (de) | 2015-01-30 | 2016-01-27 | Klimatisierungsgerät |

| US15/543,287 US10465953B2 (en) | 2015-01-30 | 2016-01-27 | Air conditioning apparatus |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-016381 | 2015-01-30 | ||

| JP2015016381A JP6406039B2 (ja) | 2015-01-30 | 2015-01-30 | 空調装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016121385A1 true WO2016121385A1 (ja) | 2016-08-04 |

Family

ID=56543007

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/000395 Ceased WO2016121385A1 (ja) | 2015-01-30 | 2016-01-27 | 空調装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10465953B2 (cg-RX-API-DMAC7.html) |

| JP (1) | JP6406039B2 (cg-RX-API-DMAC7.html) |

| CN (1) | CN107208940B (cg-RX-API-DMAC7.html) |

| DE (1) | DE112016000555B4 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2016121385A1 (cg-RX-API-DMAC7.html) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105546754A (zh) * | 2016-01-04 | 2016-05-04 | 广东美的暖通设备有限公司 | 变频器的温度控制方法、装置及空调 |

| CN107367095A (zh) * | 2017-07-28 | 2017-11-21 | 广东美芝制冷设备有限公司 | 压缩机功率模块温度控制方法及控制系统 |

| CN116928106A (zh) * | 2023-09-15 | 2023-10-24 | 德耐尔能源装备有限公司 | 无油螺杆压缩机温度控制方法和系统 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6406039B2 (ja) * | 2015-01-30 | 2018-10-17 | 株式会社デンソー | 空調装置 |

| US10414241B2 (en) | 2016-06-30 | 2019-09-17 | Emerson Climate Technologies, Inc. | Systems and methods for capacity modulation through eutectic plates |

| US10569620B2 (en) | 2016-06-30 | 2020-02-25 | Emerson Climate Technologies, Inc. | Startup control systems and methods to reduce flooded startup conditions |

| US10974570B2 (en) * | 2018-04-19 | 2021-04-13 | Toyota Motor Engineering & Manufacturing North America, Inc. | Limit for compressor speed based on inverter temperature for air conditioner in vehicle |

| DE102018211413A1 (de) * | 2018-07-10 | 2020-01-16 | Brose Fahrzeugteile Gmbh & Co. Kommanditgesellschaft, Bamberg | Nebenaggregat |

| CN109026813B (zh) * | 2018-10-22 | 2024-05-17 | 中车洛阳机车有限公司 | 电力机车送风风机试验工装设备 |

| KR102186423B1 (ko) * | 2018-11-13 | 2020-12-03 | 엘지전자 주식회사 | 공기조화기 및 그의 동작 방법 |

| US11728757B2 (en) * | 2019-11-07 | 2023-08-15 | Carrier Corporation | System and method for controlling temperature inside electrical and electronics system |

| KR102230723B1 (ko) * | 2020-03-09 | 2021-03-22 | 주식회사 대우컴프레셔 | 밀폐형 압축기 및 이의 정지 제어 방법 |

| CN112248744A (zh) * | 2020-09-30 | 2021-01-22 | 广西玉柴机器股份有限公司 | 车辆空调的控制系统 |

| US11592225B2 (en) * | 2020-11-24 | 2023-02-28 | Lennox Industries Inc. | Method and system for the heat-pump control to reduce liquid refrigerant migration |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06159738A (ja) * | 1992-11-25 | 1994-06-07 | Daikin Ind Ltd | 空気調和機の発熱素子の冷却装置 |

| JPH07285323A (ja) * | 1994-04-19 | 1995-10-31 | Matsushita Electric Ind Co Ltd | 自動車用電動圧縮機の制御駆動装置 |

| JP2004212004A (ja) * | 2003-01-08 | 2004-07-29 | Toyota Industries Corp | モータ/コンプシステム、空調装置、及び空調装置におけるインバータの発熱抑制方法 |

| JP2004271167A (ja) * | 2003-02-19 | 2004-09-30 | Matsushita Electric Ind Co Ltd | 空気調和装置 |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6116278A (ja) * | 1984-07-03 | 1986-01-24 | Matsushita Electric Ind Co Ltd | 圧縮機の駆動装置 |

| JPS62680A (ja) * | 1985-06-26 | 1987-01-06 | Toshiba Corp | 冷凍サイクルの防振制御装置 |

| JPH0840053A (ja) | 1994-08-04 | 1996-02-13 | Matsushita Electric Ind Co Ltd | 電動圧縮機の保護方法及びそれを有する装置 |

| JP4155084B2 (ja) | 2002-06-12 | 2008-09-24 | 株式会社デンソー | 電動圧縮機 |

| JP2005291558A (ja) | 2004-03-31 | 2005-10-20 | Mitsubishi Heavy Ind Ltd | 空気調和装置 |

| JP4529540B2 (ja) | 2004-05-13 | 2010-08-25 | パナソニック株式会社 | 空気調和装置と圧縮機の予熱方法 |

| JP4975328B2 (ja) * | 2006-01-25 | 2012-07-11 | サンデン株式会社 | 電動圧縮機 |

| JP5011957B2 (ja) * | 2006-09-07 | 2012-08-29 | ダイキン工業株式会社 | 空気調和装置 |

| US20090092501A1 (en) * | 2007-10-08 | 2009-04-09 | Emerson Climate Technologies, Inc. | Compressor protection system and method |

| JP5315990B2 (ja) * | 2008-12-29 | 2013-10-16 | ダイキン工業株式会社 | 空気調和装置およびその制御方法 |

| JP5652240B2 (ja) * | 2011-02-18 | 2015-01-14 | 株式会社デンソー | 電動コンプレッサ |

| JP6141526B2 (ja) * | 2013-10-09 | 2017-06-07 | ジョンソン コントロールズ テクノロジー カンパニーJohnson Controls Technology Company | モータハウジング温度制御システム |

| DE102014211108A1 (de) * | 2014-06-11 | 2015-12-17 | BSH Hausgeräte GmbH | Kältegerät mit Heißgasabtauung und Abtauverfahren |

| JP5854109B2 (ja) | 2014-10-27 | 2016-02-09 | タイガー魔法瓶株式会社 | 炊飯器 |

| JP6406039B2 (ja) * | 2015-01-30 | 2018-10-17 | 株式会社デンソー | 空調装置 |

| WO2017177287A2 (en) * | 2016-04-12 | 2017-10-19 | Atlas Copco Airpower, Naamloze Vennootschap | Method for protecting an electric motor of a device with a motor driven consumer with a continuous capacity control system and choice of such a motor |

-

2015

- 2015-01-30 JP JP2015016381A patent/JP6406039B2/ja active Active

-

2016

- 2016-01-27 WO PCT/JP2016/000395 patent/WO2016121385A1/ja not_active Ceased

- 2016-01-27 DE DE112016000555.5T patent/DE112016000555B4/de not_active Expired - Fee Related

- 2016-01-27 CN CN201680007586.1A patent/CN107208940B/zh not_active Expired - Fee Related

- 2016-01-27 US US15/543,287 patent/US10465953B2/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06159738A (ja) * | 1992-11-25 | 1994-06-07 | Daikin Ind Ltd | 空気調和機の発熱素子の冷却装置 |

| JPH07285323A (ja) * | 1994-04-19 | 1995-10-31 | Matsushita Electric Ind Co Ltd | 自動車用電動圧縮機の制御駆動装置 |

| JP2004212004A (ja) * | 2003-01-08 | 2004-07-29 | Toyota Industries Corp | モータ/コンプシステム、空調装置、及び空調装置におけるインバータの発熱抑制方法 |

| JP2004271167A (ja) * | 2003-02-19 | 2004-09-30 | Matsushita Electric Ind Co Ltd | 空気調和装置 |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105546754A (zh) * | 2016-01-04 | 2016-05-04 | 广东美的暖通设备有限公司 | 变频器的温度控制方法、装置及空调 |

| CN105546754B (zh) * | 2016-01-04 | 2019-07-19 | 广东美的暖通设备有限公司 | 变频器的温度控制方法、装置及空调 |

| CN107367095A (zh) * | 2017-07-28 | 2017-11-21 | 广东美芝制冷设备有限公司 | 压缩机功率模块温度控制方法及控制系统 |

| CN107367095B (zh) * | 2017-07-28 | 2020-08-04 | 广东美芝制冷设备有限公司 | 压缩机功率模块温度控制方法及控制系统 |

| CN116928106A (zh) * | 2023-09-15 | 2023-10-24 | 德耐尔能源装备有限公司 | 无油螺杆压缩机温度控制方法和系统 |

| CN116928106B (zh) * | 2023-09-15 | 2023-12-12 | 德耐尔能源装备有限公司 | 无油螺杆压缩机温度控制方法和系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| US10465953B2 (en) | 2019-11-05 |

| DE112016000555B4 (de) | 2021-09-30 |

| JP2016142418A (ja) | 2016-08-08 |

| CN107208940A (zh) | 2017-09-26 |

| CN107208940B (zh) | 2019-12-03 |

| US20170370626A1 (en) | 2017-12-28 |

| JP6406039B2 (ja) | 2018-10-17 |

| DE112016000555T5 (de) | 2017-10-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6406039B2 (ja) | 空調装置 | |

| JP6278132B2 (ja) | ヒートポンプサイクル | |

| CN107848374B (zh) | 车辆用空调装置 | |

| CN112236322B (zh) | 空调装置 | |

| US11105536B2 (en) | Combined heat exchanger | |

| JP2011140291A (ja) | 車両用空調装置 | |

| JP2010266132A (ja) | インバータ冷却装置およびインバータ冷却方法ならびに冷凍機 | |

| JP2011208841A (ja) | ヒートポンプサイクル | |

| JP2009235982A (ja) | 車両用空調装置 | |

| JP6394505B2 (ja) | ヒートポンプサイクル | |

| JP2012042114A (ja) | 二段昇圧式冷凍サイクル | |

| WO2013145537A1 (ja) | 車両用の空調装置 | |

| JP2005241112A (ja) | 空調装置 | |

| JP6582800B2 (ja) | 熱交換システム | |

| CN111433538B (zh) | 制冷循环装置 | |

| JP6572695B2 (ja) | 統合弁 | |

| US12090814B2 (en) | Vehicle heat exchange system | |

| CN107076470B (zh) | 喷射器式制冷循环装置 | |

| JP6733625B2 (ja) | 冷凍サイクル装置 | |

| JP4957767B2 (ja) | 空調装置 | |

| JP2016008792A (ja) | ヒートポンプサイクル装置 | |

| JP2017053613A (ja) | 統合弁 | |

| JP7638924B2 (ja) | 空調装置 | |

| JP7651500B2 (ja) | 空調装置 | |

| JP7644043B2 (ja) | 空調装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16742989 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15543287 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 112016000555 Country of ref document: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16742989 Country of ref document: EP Kind code of ref document: A1 |