WO2012137833A1 - 木質合成建材の製造方法 - Google Patents

木質合成建材の製造方法 Download PDFInfo

- Publication number

- WO2012137833A1 WO2012137833A1 PCT/JP2012/059227 JP2012059227W WO2012137833A1 WO 2012137833 A1 WO2012137833 A1 WO 2012137833A1 JP 2012059227 W JP2012059227 W JP 2012059227W WO 2012137833 A1 WO2012137833 A1 WO 2012137833A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- raw material

- wood

- powder

- plywood

- synthetic resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/002—Manufacture of substantially flat articles, e.g. boards, from particles or fibres characterised by the type of binder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/02—Manufacture of substantially flat articles, e.g. boards, from particles or fibres from particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27N—MANUFACTURE BY DRY PROCESSES OF ARTICLES, WITH OR WITHOUT ORGANIC BINDING AGENTS, MADE FROM PARTICLES OR FIBRES CONSISTING OF WOOD OR OTHER LIGNOCELLULOSIC OR LIKE ORGANIC MATERIAL

- B27N3/00—Manufacture of substantially flat articles, e.g. boards, from particles or fibres

- B27N3/08—Moulding or pressing

- B27N3/28—Moulding or pressing characterised by using extrusion presses

Definitions

- the present invention relates to a method for producing a woody synthetic building material that is molded from a material.

- wood Conventionally, natural materials such as wood have been the mainstream as building materials, but recently, woody synthetic building materials for building formed by mixing wood powder and thermoplastic synthetic resin have become known. It has come to be used as exterior building materials and interior building materials. Such wood-based synthetic building materials are notable because they can effectively use waste materials (waste materials such as natural timber and synthetic building materials), as well as save petroleum resources as raw materials and reduce manufacturing costs. Collecting.

- the wood powder used contains an adhesive component, that is, if synthetic wood waste or plywood wood powder is used instead of natural wood wood powder, it will be dried against the raw material pellets. It is difficult to remove the adhesive component only by carrying out the process. For this reason, in the case of producing a wooden synthetic building material using synthetic building material waste and plywood wood powder, in order to suitably avoid the above-mentioned appearance, quality problems, or handling problems Decrease the mixing ratio of the wood flour (for example, 15% by weight or less of the synthetic resin raw material to be mixed) or leave the wood flour at a high temperature (for example, a temperature of 100 ° C. or more) for a sufficient time. It has been considered that it is effective to perform raw material blending and pelletization after preliminarily evaporating moisture and adhesive components in the wood flour by heating over time.

- the present invention has been made to solve the above-mentioned problems of the prior art, and can effectively use a waste material called plywood powder to save petroleum resources and keep raw material costs low.

- Another object of the present invention is to provide a method for producing a highly versatile woody synthetic building material, which can obtain a synthetic building material having a grain-like appearance similar to the texture of natural wood.

- the method for producing a woody synthetic building material according to the present invention comprises, as a main raw material, wood powder of a plywood produced by adding an adhesive to a wood fiber or a piece of wood, and applying pressure, and a thermoplastic synthetic resin.

- the material added with the auxiliary material is heated and melted at a temperature of 160 to 200 ° C., and then pelletized to form a raw material pellet.

- the raw material pellets are put into an extrusion molding machine or an injection molding machine and heated and melted at a temperature of 150 to 200 ° C.

- the residual moisture and adhesive components are used to express the wood grain flow pattern on the surface of the molded product.

- internal the original stream patterns in complex structure of the molded product is characterized by the formation of (raw material different aspects entangled randomly).

- thermoplastic synthetic resin 100 parts by weight of thermoplastic synthetic resin and 30 to 100 parts by weight of plywood powder are blended as main raw materials, and 5 to 10 parts by weight of filler and 2 to 3 parts by weight of pigment are added as auxiliary raw materials.

- thermoplastic synthetic resin it is preferable to blend, and as the thermoplastic synthetic resin, it is preferable to use polyvinyl chloride powder, polystyrene powder, polyethylene powder, or polypropylene powder.

- the method for producing a woody synthetic building material of the present invention it is possible not only to effectively use a waste material called wood powder of plywood, but also to obtain a synthetic building material exhibiting a grain-like appearance that approximates the texture of natural wood. Moreover, since the blending ratio of the synthetic resin raw material can be reduced, petroleum resources as the raw material for the synthetic resin can be saved, and the raw material cost can be kept low by using the waste material.

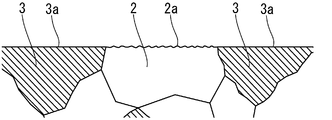

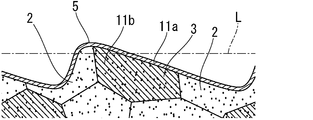

- FIG. 1 is a diagram schematically showing a part of a surface 4 and a cross section of a molded product manufactured by the method for manufacturing a wooden synthetic building material according to the present invention.

- FIG. 2 is a partially enlarged view of a cross section of the molded product shown in FIG.

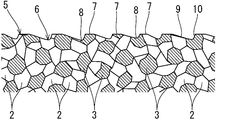

- FIG. 3 is a diagram showing another configuration example of a molded product manufactured by the method for manufacturing a wooden synthetic building material according to the present invention.

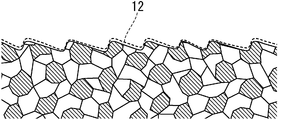

- FIG. 4 is a partially enlarged view showing an example of the shape of the surface of a molded product manufactured by the method for manufacturing a wooden synthetic building material according to the present invention.

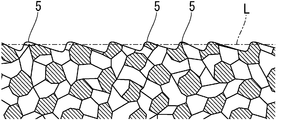

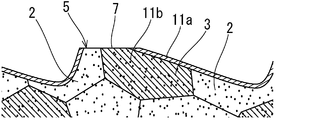

- FIG. 5 is an explanatory view of a method for producing the molded product shown in FIG. FIG.

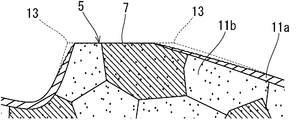

- FIG. 6 is an explanatory diagram of a method for manufacturing the molded product shown in FIG.

- FIG. 7 is an explanatory diagram of a method for manufacturing the molded product shown in FIG.

- FIG. 8 is an explanatory diagram of a method for producing the molded product shown in FIG.

- FIG. 9 is a view showing another configuration example of a molded product manufactured by the method for manufacturing a wooden synthetic building material according to the present invention.

- the method for producing a woody synthetic building material according to the present invention is basically to heat and melt a material obtained by adding an auxiliary material to a main material, pelletize it to produce a raw material pellet, and put this raw material pellet into an extruder. , Heating and melting and extruding from a mold to perform molding.

- thermoplastic synthetic resin polyvinyl chloride powder, polystyrene powder, polyethylene powder, polypropylene powder, acrylic resin, etc.

- plywood wood fiber or wood piece adhesive

- plywood produced by adding pressure for example, MDF (Medium Density Fiber board), HDF (High Density Fiber board), particle board, etc.) wood flour is used.

- the main raw material is blended with 30 to 100 parts by weight of plywood based on 100 parts by weight of the thermoplastic synthetic resin. Further, it is preferable to blend 5 to 10 parts by weight of filler and 2 to 3 parts by weight of pigment as auxiliary materials.

- Plywood wood powder which is the main raw material, contains moisture and adhesive components (phenol resin, urea resin, etc.).

- moisture and adhesive components phenol resin, urea resin, etc.

- raw material pellets under general temperature conditions When water is produced, moisture and adhesive components remain in the interior.

- extrusion molding is performed under general molding conditions using raw material pellets in which moisture and adhesive components remain, as described above, abnormal foaming, distortion of the molded product, surface roughness, variation in strength

- the raw material pellets are directly fed into an extrusion molding machine without actively removing the contained moisture and the contained adhesive component.

- the molding conditions heat and melting temperature, extrusion pressure, and residence time

- residual moisture and adhesive components Due to their changes

- the material before being extruded from the die (die) in the cylinder and the material in the cavity from the cylinder to the die

- the grain flow pattern can be displayed on the surface of the material, and a complex structure (a state in which different forms of raw materials are randomly entangled) can be formed inside the molded product.

- a synthetic building material having a grain-like appearance similar to the texture of natural wood can be obtained.

- the molding conditions are as follows. First, the heating and melting temperature of the raw material is set to 150 to 200 ° C. More specifically, among the cylinders of the extruder, the hopper side portion is 120 to 150 ° C., the middle portion is 140 to 190 ° C., the die side portion is 170 to 190 ° C., and the die is Is set to 160-200 ° C. Thus, the raw material in the extruder is adjusted so as to be heated and melted within the range of 150 to 200 ° C. The extrusion pressure of the raw material is in the range of 10 to 20 MPa. Also, the residence time of the raw material in the cylinder is 3 to 10 minutes on average.

- the raw material conveyed in the direction of the die in the cylinder becomes foamed inside and near the surface due to evaporation of residual moisture and residual adhesive components.

- the specific gravity of the raw material in the cylinder varies depending on the part. More specifically, the portion having a relatively large amount of residual moisture or adhesive component has a low specific gravity (if the thermoplastic synthetic resin used as the main raw material is PVC, 1.1 to 1.25, olefin 0.95 to 1.15 in the case of a system, and the specific gravity increases in a portion with a relatively small residual amount (1.25 to 1.4 for a PVC system, 1.15 to 1.25 for an olefin system). .

- the raw material in which a part with a small specific gravity and a part with a large specific gravity are mixed is conveyed in the direction of the die without controlling the flow rate (for example, without attaching a filter or mesh), and the specific gravity is made uniform.

- a portion 2 having a small specific gravity and a portion 3 having a large specific gravity are randomly entangled (thickness of each portion: 1 to About 5 mm) is formed.

- the part 2 having a small specific gravity has a relatively light color (a lot of foaming), whereas the part 3 having a high specific gravity has a relatively dark color (a little foaming), and the shade of the color tone is the surface of the molded product.

- a flow pattern is formed.

- the portion 2 having a small specific gravity has a rough surface because there are many foamed portions, A surface having a slight unevenness (uneven surface 2a) is formed.

- the portion 3 having a large specific gravity is not rough because the foamed portion is small, and a smooth surface (smooth surface 3a) like a mirror surface is formed along the finished surface of the die.

- the difference in texture between the uneven surface 2a and the smooth surface 3a and the difference in light reflection form a flow pattern on the surface of the molded product.

- the shade of color tone, the difference in texture, and the difference in the light reflection state occur, and by combining them, molding is performed.

- a flow pattern is formed on the surface of the object, and it is possible to manufacture a woody synthetic building material having a wood texture similar to the texture of natural wood.

- the following problems may occur when the molding conditions are out of the above-described proper range.

- the heating and melting temperature of the raw material is lower than 150 ° C.

- the adhesive component contained in the raw material pellet does not sufficiently decompose and foam, and if it is higher than 200 ° C., it is included in the raw material pellet.

- the decomposition of the wood flour that has started, and the performance cannot be maintained.

- the extrusion pressure of the raw material is less than 10 MPa, there is a problem that the raw material cannot be extruded from the die.

- the moisture and adhesive components remaining in the raw material pellets cause deterioration in the appearance and quality of the molded product.

- the molding conditions are appropriately set. By setting the range, the aspect in which they (water and volatile substances in the adhesive component) are separated from the raw material at the time of molding (the process from the cylinder to the die) is controlled. It is possible to obtain a wood-grained synthetic building material that approximates the texture of

- a raw material (a material obtained by adding an auxiliary raw material to a main raw material) is heated and melted under a temperature condition of 160 to 200 ° C., and then cooled and pelletized.

- thermoplastic synthetic resin When raw material pellets are produced under such temperature conditions, when 100 to 100 parts by weight of thermoplastic synthetic resin is blended with 30 to 100 parts by weight of plywood, about 0.3 to 0.9% by weight of water, As for volatile substances (toluene, xylene, etc.) contained in the adhesive component, a residual amount of about 0.5 to 1% by weight is obtained.

- the raw material pellets are put into an extrusion molding machine and the woody synthetic building material is manufactured by extrusion molding.

- the raw material pellets can be put into an injection molding machine and manufactured by injection molding.

- the die has a large number of ridges and dents formed on the surface, and after performing the grinding step described later, the ridges 5 and the dents as shown in FIG. 6, the top portion 7, the deepest portion 8, the gently inclined portion 9, and the steeply inclined portion 10 are formed, and the distance between the top portions 7 of the two adjacent protruding ridges 5, the width of the top portion 7 of the protruding ridge 5,

- FIG. 4 is a partially enlarged view showing an example of the shape of the surface of the molded product after molding.

- the broken line indicates the outline of the die 12.

- the shape of the surface of the cooled molding does not necessarily match the contour of the die 12 as a result of “sinks”.

- the tip portions of the ridges 5 are removed along a certain reference line L (see FIG. 5).

- the process to perform (the grinding process of the ridge tip part) is carried out.

- line 5 is carried out using grinding machines (or cutting devices), such as a sander, a grinder, an electric plane apparatus, or a wire brush roll, (reference line of FIG. 5). (A portion above L) is ground (or cut).

- a synthetic wood building material can be manufactured.

- a layer (inner layer 11b) in which the synthetic resin and the wood flour are evenly mixed is formed inside the molded product (portion other than the vicinity of the surface).

- the tip portion of the ridge 5 (the portion above the reference line L shown in FIG. 6) is cut and removed, the inner layer 11b is exposed at the top portion 7 of the ridge 5, as shown in FIG.

- the surface layer 11a remains in the other portions (the concave strip 6, the gently inclined portion 9, and the steeply inclined portion 10).

- the surface layer 11a has a high distribution density of synthetic resin as described above (a low distribution density of wood flour), a smooth surface is easily formed along the finished surface of the die compared to the inner layer 11b. Since the small portion 2 has many foamed portions, in the portion of the surface layer 11a where the portion 2 having a small specific gravity is exposed, the skin 2 is eventually roughened, and an uneven surface 2a (see FIG. 2) having slight unevenness is formed. It will be. In the portion where the portion 2 having a small specific gravity is exposed, the light reflectance is low. On the other hand, in the portion of the surface layer 11a where the portion 3 having a large specific gravity is exposed, the surface is not rough because there are few foamed portions, and a smooth surface 3a (see FIG. 2) is formed along the finished surface of the die, The light reflectivity increases.

- the concave strip 6 the gently inclined portion 9, and the steeply inclined portion 10 where the surface layer 11a remains, the portion where the portion 3 having a large specific gravity is exposed is glossy, and the appearance changes in color tone depending on the viewing angle. It becomes.

- the vicinity of the deepest portion 8 of the concave stripe 6 is configured as a concave curved surface, when the portion 3 having a large specific gravity is exposed in the vicinity, light from multiple directions is reflected and various color tones are reflected. It becomes.

- the inner layer 11b has a higher wood powder distribution density than the surface layer 11a, when the inner layer 11b is exposed outward, a large amount of wood powder mixed with the synthetic resin appears on the surface. It will be. And since the surface of these wood powders is not smooth, the reflectance of light is low. Therefore, the top part 7 of the ridge 5 where the inner layer 11b is exposed is a luster in which the color of wood powder and the color of synthetic resin are mixed. The color tone does not change so much even if the line-of-sight angle changes.

- the surface has a different color tone, that is, a glossy color tone that changes variously depending on the line of sight angle (concave strip 6, gently sloping portion 9 and steeply sloping portion 10), and a glossy mixture of wood flour color.

- the color tone (the top portion 7 of the ridge 5) appears in contrast, and the portion 2 with a low specific gravity is a relatively light color, whereas the portion 3 with a high specific gravity is a relatively dark color. Since a difference in texture and a difference in light reflection occur, the top 7 of the ridge 5 where the inner layer 11b is exposed also has the ridge 6 where the surface layer 11a remains, the gently inclined portion 9, and the steep Even in the inclined portion 10, a flow pattern is formed by the shade of the color tone, the difference in texture, and the difference in light reflection.

- the surface of the wood composite building material is a flat surface with a natural wood texture that exhibits a grain-like appearance that approximates the texture of natural wood due to uneven color tone, uneven light reflection,

- the natural wood board has a grain composed of a hard and dark colored part and a soft and pale colored part, so that the surface becomes smooth when sawing.

- irregularities are generated on the surface along the grain part (boundary part of the annual ring).

- the uneven shape on the surface is formed by thinning and denting the portion between the grain and the grain, and the point of the grain being relatively convex.

- the slope on one side of the ridges of the grain is a relatively gentle angle, the slope on the opposite side is often a steep angle. This tendency appears more markedly in the grain material than in the mesh material.

- a gentle inclined part 9 having a relatively gentle angle

- a steeply inclined part 10 having a tighter angle than those

- a two-type inclined part When arranged in combination one by one, it is possible to make a shape simulating the shape of the secular change that appears in the natural wood as described above. Therefore, it is possible to produce a woody synthetic building material having a texture closer to that of natural wood than a conventional woody synthetic building material.

- the distance between the tops 7 of the two adjacent ridges 5, the width of the top 7 of the ridges 5, the depth of the deepest part 8 of the ridges 6, the inclination angle of the gently inclined part 9, the steeply inclined part When the inclination angle of 10 and the curvature of the curved surface constituting the concave stripe 6 are not constant, a plurality of variations are set for each factor, and they are arranged irregularly, the surface is varied. Even if only one type of resin raw material (one type of material that is a mixture of thermoplastic synthetic resin, wood flour, and auxiliary materials) is used, A plane with a natural wood texture can be constructed.

- the top part 7 as shown in FIG. 7 by carrying out the grinding process of the ridge tip part, further using a grinding device having flexibility in the grinding part, such as a wire brush roll.

- a grinding device having flexibility in the grinding part, such as a wire brush roll.

- the step of grinding the shoulders 13 and 13 of the top 7 of the ridge 5 so as to be in the state shown in FIG. 8 grinding step of the ridge shoulder

- the surface layer 11a is cut to some extent.

- an appearance having intermediate characteristics between the surface layer 11a and the inner layer 11b is obtained.

- the layer appearing by scraping the shoulder portions 13 and 13 shown in FIG. 8 with a wire brush roll or the like has a wood powder distribution density lower than that of the inner layer 11b and higher than that of the surface side of the surface layer 11a.

- the degree of gloss is also intermediate between the surface side of the surface layer 11a and the inner layer 11b, and thus an appearance in which more various color tones are combined in a complex manner is exhibited, and the surface has a texture closer to that of natural wood.

- the provided plane can be configured.

- line shoulder part is not performed, but removal of the front-end

- the both shoulder portions 7a and 7a may be simultaneously cut in one step.

- the basic shape between the ridges 5 and the ridges 6 extending in the longitudinal direction on the surface is formed using a die that is formed as a curved surface instead of an inclined surface. It can also be done. In this case, a plurality of variations are set for the curvatures of the curved surfaces, and they are arranged irregularly. Further, the ridges 5 (all the ridges 5 formed on one surface are formed. It is preferable that 30% or more (more preferably 50% or more) of the left and right shapes are asymmetrical with respect to the center of the top portion 7.

- the distance between the tops 7 of the two adjacent ridges 5, the width of the top 7 of the ridges 5, the depth of the deepest part 8 of the recesses 6, etc. are not constant, and there are a plurality of factors for each factor.

- the surface will have an appearance that is a complex combination of various colors, and one kind of resin raw material (thermoplastic synthetic resin and wood flour) Even if only one kind of material mixed with the auxiliary material is used, a plane having a natural wood texture can be formed.

- the portion 2 having a small specific gravity and the portion 3 having a large specific gravity are clearly divided and schematically represented. It does not exist, and a stepwise change mode (gradation) is exhibited with respect to the difference in specific gravity value and color density.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Wood Science & Technology (AREA)

- Forests & Forestry (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Chemical And Physical Treatments For Wood And The Like (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/009,424 US9089990B2 (en) | 2011-04-05 | 2012-04-04 | Process for producing wooden synthetic construction material |

| CN201280016746.0A CN103459108B (zh) | 2011-04-05 | 2012-04-04 | 木质复合建材的制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-083481 | 2011-04-05 | ||

| JP2011083481A JP5432205B2 (ja) | 2011-04-05 | 2011-04-05 | 木質合成建材の製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012137833A1 true WO2012137833A1 (ja) | 2012-10-11 |

Family

ID=46969227

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/059227 Ceased WO2012137833A1 (ja) | 2011-04-05 | 2012-04-04 | 木質合成建材の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9089990B2 (cg-RX-API-DMAC7.html) |

| JP (1) | JP5432205B2 (cg-RX-API-DMAC7.html) |

| CN (1) | CN103459108B (cg-RX-API-DMAC7.html) |

| WO (1) | WO2012137833A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10521819B2 (en) * | 2012-08-09 | 2019-12-31 | American Express Travel Related Services Company, Inc. | Systems and methods for analytics in a cooperative data exchange |

| PL3189952T3 (pl) * | 2016-01-08 | 2019-03-29 | Omya International Ag | Powlekane in-line płyty na bazie drewna |

| EP3460349B1 (en) | 2017-09-21 | 2021-08-11 | Siemens Schweiz AG | Latent heat reduction |

| JP6719042B1 (ja) * | 2019-07-12 | 2020-07-08 | 株式会社手工仁久 | プラスチック廃棄物の粉砕方法、及び、プラスチック廃棄物を利用した合成樹脂成形品の製造方法 |

| JP7358311B2 (ja) * | 2020-08-24 | 2023-10-10 | ハンディテクノ株式会社 | 低蓄熱性木質合成建材 |

| PL444336A1 (pl) * | 2023-04-06 | 2024-10-07 | Uniwersytet Przyrodniczy W Poznaniu | Tworzywo poszyciowo – konstrukcyjne wytworzone z odpadów tartacznych i drewna średniowymiarowego |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0385797U (cg-RX-API-DMAC7.html) * | 1989-12-15 | 1991-08-29 | ||

| WO1994020280A1 (en) * | 1993-03-05 | 1994-09-15 | Misawa Homes Co., Ltd. | Method of manufacturing wood-like product and the product |

| JP2002225011A (ja) * | 2001-02-05 | 2002-08-14 | Taiyo Gosei Kk | 成形用木質系組成物及びその製造方法 |

| JP2006103014A (ja) * | 2004-10-01 | 2006-04-20 | Toppan Printing Co Ltd | 木質系化粧板 |

| JP2006150786A (ja) * | 2004-11-30 | 2006-06-15 | Toppan Printing Co Ltd | 木質樹脂成形体及びそれを用いた化粧材 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020106498A1 (en) * | 1992-08-31 | 2002-08-08 | Andersen Corporation | Advanced polymer wood composite |

| US5441801A (en) * | 1993-02-12 | 1995-08-15 | Andersen Corporation | Advanced polymer/wood composite pellet process |

| CN1103829A (zh) * | 1993-12-15 | 1995-06-21 | 行唐县新型装饰材料厂 | 塑木再生板材及其加工工艺 |

| CN1121940A (zh) * | 1994-10-26 | 1996-05-08 | 陈玉章 | 木质塑料 |

| JP3581180B2 (ja) * | 1994-12-14 | 2004-10-27 | アイン・エンジニアリング株式会社 | 補強樹脂合成板の押出成形方法及び装置 |

| JP3658714B2 (ja) | 1996-02-09 | 2005-06-08 | アイン興産株式会社 | 木質合成板の模様形成方法 |

| US5882564A (en) * | 1996-06-24 | 1999-03-16 | Andersen Corporation | Resin and wood fiber composite profile extrusion method |

| JPH10138212A (ja) | 1996-11-07 | 1998-05-26 | Shine Denshi Kk | 人造木材及び木目年輪模様入り製造方法 |

| GB9625068D0 (en) | 1996-12-02 | 1997-01-22 | Marlit Ltd | Method for production of lignocellulosic composite materials |

| US6280667B1 (en) * | 1999-04-19 | 2001-08-28 | Andersen Corporation | Process for making thermoplastic-biofiber composite materials and articles including a poly(vinylchloride) component |

| CN1101838C (zh) * | 1999-07-23 | 2003-02-19 | 四川大学 | 秸秆/塑料复合材料的生产方法 |

| JP3416111B2 (ja) | 2000-12-22 | 2003-06-16 | 日光化成株式会社 | 木目模様の塗装用木材・熱可塑性樹脂複合材 |

| JP2002331521A (ja) * | 2001-05-10 | 2002-11-19 | Tomoyuki Kasahara | 廃材を主材料とした異色・異硬度の積層板 |

| JP3860725B2 (ja) | 2001-06-25 | 2006-12-20 | ミサワホーム株式会社 | 床板材 |

| JP2003103603A (ja) * | 2001-09-28 | 2003-04-09 | Sumitomo Forestry Co Ltd | 成形木質材、住宅用造作材及びそれらの製造方法 |

| JP3085797U (ja) | 2001-11-02 | 2002-05-17 | ミサワホーム株式会社 | 木質様成形品 |

| JP3662242B2 (ja) * | 2003-01-29 | 2005-06-22 | ヤマハリビングテック株式会社 | ウッドプラスティックの製造方法 |

| JP4134050B2 (ja) | 2005-01-14 | 2008-08-13 | ハンディテクノ株式会社 | 木質合成板建材 |

| JP4303217B2 (ja) | 2005-05-02 | 2009-07-29 | ハンディテクノ株式会社 | 木質合成板建材の製造方法 |

-

2011

- 2011-04-05 JP JP2011083481A patent/JP5432205B2/ja active Active

-

2012

- 2012-04-04 WO PCT/JP2012/059227 patent/WO2012137833A1/ja not_active Ceased

- 2012-04-04 CN CN201280016746.0A patent/CN103459108B/zh not_active Expired - Fee Related

- 2012-04-04 US US14/009,424 patent/US9089990B2/en active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0385797U (cg-RX-API-DMAC7.html) * | 1989-12-15 | 1991-08-29 | ||

| WO1994020280A1 (en) * | 1993-03-05 | 1994-09-15 | Misawa Homes Co., Ltd. | Method of manufacturing wood-like product and the product |

| JP2002225011A (ja) * | 2001-02-05 | 2002-08-14 | Taiyo Gosei Kk | 成形用木質系組成物及びその製造方法 |

| JP2006103014A (ja) * | 2004-10-01 | 2006-04-20 | Toppan Printing Co Ltd | 木質系化粧板 |

| JP2006150786A (ja) * | 2004-11-30 | 2006-06-15 | Toppan Printing Co Ltd | 木質樹脂成形体及びそれを用いた化粧材 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103459108A (zh) | 2013-12-18 |

| JP2012218202A (ja) | 2012-11-12 |

| US20140027942A1 (en) | 2014-01-30 |

| US9089990B2 (en) | 2015-07-28 |

| JP5432205B2 (ja) | 2014-03-05 |

| CN103459108B (zh) | 2015-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5432205B2 (ja) | 木質合成建材の製造方法 | |

| US6890637B2 (en) | Composite materials, articles of manufacture produced therefrom, and methods for their manufacture | |

| US20220396090A1 (en) | Surface finish manufacturing system and process | |

| EP4048527A1 (en) | Surface finish manufacturing system and process | |

| US9694529B2 (en) | Extrusion die for synthetic wood, manufacturing apparatus and method using the same, and synthetic wood manufactured by the same | |

| US20130224437A1 (en) | Apparatus for manufacturing synthetic wood having stripes and the method thereof and the synthetic wood of the same | |

| KR20140032131A (ko) | 투명 표면층을 갖는 목재 플라스틱 복합재 | |

| EP1735131B1 (en) | Fibre polymer composite (fpc) material | |

| US9045369B2 (en) | Composite materials, articles of manufacture produced therefrom, and methods for their manufacture | |

| KR20120055800A (ko) | 미끄럼 저항성이 향상된 합성목재 제조장치 및 방법과 이로부터 제조된 합성목재 | |

| KR101004394B1 (ko) | 합성목재의 제조방법 | |

| KR101382541B1 (ko) | 합성목재 및 그 제조방법 | |

| KR20110065134A (ko) | 폴리프로필렌을 이용한 인조합성목재의 제조방법 | |

| KR101342251B1 (ko) | 나뭇결이 구현된 표면 강화 합성목재 제조장치 및 방법과 이로부터 제조된 합성목재 | |

| JP7358311B2 (ja) | 低蓄熱性木質合成建材 | |

| KR100912402B1 (ko) | 건축용 보드 | |

| RU2555019C1 (ru) | Дополнительная установка для вспомогательного экструдирования оконного профиля и установка для его изготовления, в которой она используется | |

| JP5524818B2 (ja) | 木質合成建材、及び、その製造方法 | |

| JP3574379B2 (ja) | 木質様製品の製造方法 | |

| JP2004167799A (ja) | 内部に空洞を有する木材・熱可塑性樹脂複合発泡成形品およびその製造方法 | |

| KR101338611B1 (ko) | 줄무늬 형상을 갖는 합성목재 제조장치 및 방법과 이로부터 제조된 합성목재 | |

| KR101219975B1 (ko) | 멀티 컬러 목무늬 패턴 압출 성형 방법 및 이를 이용하여 제조된 압출 성형품 | |

| JP2013212695A (ja) | 表面処理装置および表面処理方法 | |

| CN1129632A (zh) | 复合式板材、型材制造方法 | |

| JPH0952229A (ja) | 木質様製品の製造方法および木質様製品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12767763 Country of ref document: EP Kind code of ref document: A1 |

|

| DPE1 | Request for preliminary examination filed after expiration of 19th month from priority date (pct application filed from 20040101) | ||

| WWE | Wipo information: entry into national phase |

Ref document number: 14009424 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12767763 Country of ref document: EP Kind code of ref document: A1 |