WO2012020651A1 - Système de rétro-éclairage pour lettres boîtiers - Google Patents

Système de rétro-éclairage pour lettres boîtiers Download PDFInfo

- Publication number

- WO2012020651A1 WO2012020651A1 PCT/JP2011/067334 JP2011067334W WO2012020651A1 WO 2012020651 A1 WO2012020651 A1 WO 2012020651A1 JP 2011067334 W JP2011067334 W JP 2011067334W WO 2012020651 A1 WO2012020651 A1 WO 2012020651A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- led module

- bottom plate

- light

- led

- backlight

- Prior art date

Links

Images

Classifications

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F13/00—Illuminated signs; Luminous advertising

- G09F13/20—Illuminated signs; Luminous advertising with luminescent surfaces or parts

- G09F13/22—Illuminated signs; Luminous advertising with luminescent surfaces or parts electroluminescent

-

- G—PHYSICS

- G09—EDUCATION; CRYPTOGRAPHY; DISPLAY; ADVERTISING; SEALS

- G09F—DISPLAYING; ADVERTISING; SIGNS; LABELS OR NAME-PLATES; SEALS

- G09F13/00—Illuminated signs; Luminous advertising

- G09F13/04—Signs, boards or panels, illuminated from behind the insignia

- G09F13/14—Arrangements of reflectors therein

Definitions

- this channel character 1a has a mechanism in which the handwriting of the character is three-dimensionally engraved and the interior is illuminated to raise the handwriting with light (simply cut without illumination inside). Characters are also referred to as channel characters, but are outside the scope of the present invention).

- FIG. 2 is a sectional view showing the internal structure.

- a light source 2c is installed at the bottom of a groove (channel) composed of a side wall 2a and a bottom surface 2b, and a milky white light diffusion resin plate 2d (hereinafter referred to as a handwriting plate) cut out in the shape of a handwriting is illuminated from the inside of the channel.

- the handwriting is raised by the transmitted light.

- the present invention relates to a lighting system (backlight system) for the channel characters.

- a lighting system backlight system

- the application of the present invention will be described for “characters”, but the application of the present invention to “logo marks” other than “characters” or general “graphics” is not excluded.

- the channel character is generally formed by forming a channel surrounded by a bottom surface 2b and a side wall 2a as shown in FIG. 2 and placing a light source 2c (backlight) therein.

- a light source 2c backlight

- LED light sources with higher luminous efficiency, higher brightness, more colors, and smaller size have been adopted as light sources for such channel letters in comparison with conventional fluorescent lamps and neon tubes. It has become.

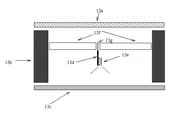

- FIG. 3 shows a conventional LED backlight for channel characters.

- Four or five LED lamps (3a) are grouped into a 4 to 5 cm square unit 3b and connected by flexible wiring 3c.

- the unitized backlight (hereinafter referred to as a unitized backlight) has a drawback that it cannot be applied to a finely shaped handwriting board (for example, Mincho Kanji) because the unit itself is large.

- the unitized backlight is manufactured by mounting a plurality of LED lamps etc. on the printed circuit board, but the wiring 3c between the units is a separate wiring process in order to ensure flexibility in arrangement. Need. For this reason, increasing the number of units directly leads to high manufacturing costs. For example, although it is possible to arrange each LED lamp as one unit and dispersively arrange on the bottom surface, in order to direct the optical axis of those LED lamps upward correctly, in any case, individual LEDs are placed on the base printed circuit board. In addition, it is necessary to mount the LED lamp, and the wiring cost for connecting these many LED lamps with electric wires having flexibility increases dramatically.

- the backlight system in order to ensure the uniformity of the brightness of the handwriting board, it is also an important role of the backlight system to diffuse the emitted light from the LED by some method.

- the simplest method for diffusing the emitted light is to ensure the distance between the backlight and the handwriting board. That is, in general, light from the light source diffuses radially, so that the light from the light source is diffused widely as the distance from the light source increases.

- the conventional unitized backlight cannot be expected to have a diffusion effect due to the dispersion of the light source, it is necessary to secure a large “diffusion space” by separating the light source away from the handwriting board.

- the distance between the handwriting board and the backlight needs to be at least twice the width of the handwriting board.

- the width is about 40 mm

- the channel thickness is about 80 mm.

- a liquid crystal display backlight technology using an LED as a backlight is well known as a conventional technology related to a reduction in the thickness of a display system with a backlight.

- Patent Document 1 a direct type (“Patent Document 1”), etc. are used in order to reduce the thickness while maintaining the surface luminance and achieve uniformity in luminance.

- an object of the present invention is to provide a backlight system that realizes dispersion of light sources and thinning of channel characters while ensuring freedom of arrangement of light sources. It aims to support fine characters and graphics, automate production, and improve efficiency.

- the disadvantages of the conventional unitized backlight are that the unit itself is large and that the distance between the light source and the handwriting board needs to be increased in order to ensure the uniformity of the brightness of the handwriting board.

- the side walls are usually made of metal such as, typically stainless steel.

- the bottom surface 4 a and the edge plate 4 b are first cut out according to the handwriting shape from the stainless steel thin plate, and a belt-like stainless steel side plate is welded along the two edges (4 c). This manual welding operation requires skill, and the more complicated the handwriting, the more difficult it becomes, which is the biggest factor in the cost of producing channel letters.

- the problem to be solved by the present invention is to develop a new backlight system, while maintaining the required brightness of the handwriting board and the uniformity of the brightness, Enables efficient production of channel characters with fine shapes such as logo marks, eliminates manual work such as welding, enables mechanization and efficiency of production, enables mass production, and can be easily produced by on-site work It is to do.

- the problem solving means provided by the present invention is that the backlight system has the following two functions.

- a function for efficiently realizing the dispersion while ensuring the degree of freedom of arrangement of the light source (B) A function for efficiently diffusing the emitted light from the light source.

- the function (A) is realized by developing a flexible LED module “Patent Document 2” as a light source.

- the LED lamp is provided with a side view type LED lamp 5b along the edge of the strip-shaped flexible substrate 5a, and the optical axis direction is kept constant while keeping the optical axis direction constant.

- the LED module used in the present invention may use LED lamps with different mounting angles (optical axis directions), or the flexible printed circuit board may not necessarily be a strip with parallel edges.

- a plurality of LED lamps are arranged on a flexible substrate, and are mounted so that the emitted light of each LED lamp is emitted to both surfaces of the flexible substrate, and each LED lamp is located on the same plane. It is based on an LED module that can be bent into a roll to form a display surface.

- the function (B) is realized based on the fact that the bottom plate of the channel character itself is used as a reflection plate and a diffusion plate for LED lamp radiation.

- the problem with the backlight system with such a structure is that the light source (or its supporting structure) itself blocks the reflected light, and the light source must be fixed with the optical axis facing the bottom plate while maintaining a certain distance from the bottom plate that is the reflector.

- these issues have also been solved by developing a backlight LED module with a new function. See Examples 3, 4, 5, 6). JP 2009-42260 A

- the uniformity of the surface brightness of the handwriting board can be secured even on the side wall having a low height (shallow depth), and the side wall height is greatly increased to about 10 mm. It becomes possible to decrease.

- it is most suitable for manufacturing a sidewall having such a height and is cut by a resin laser cutting machine or a router cutting machine widely used in the decoration / signboard industry for producing the channel letters without illumination. Processing methods are used.

- the combination of a new backlight system and a prevailing manufacturing method enables efficient production of fine and thin channel characters at low cost without compromising the brightness and uniformity of brightness of the handwriting board. It becomes.

- Example 1 is an example corresponding to the function (A) described in the problem solving means.

- the flexible LED module has a characteristic that each LED lamp 5b, which is the minimum unit as a light source, can be freely arranged along a curved line on a plane.

- the individual LED lamps, which are the minimum unit of the light source can be dispersed and provided with a function that can be arranged efficiently and freely.

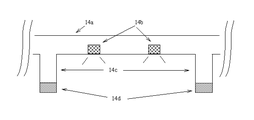

- an LED 6b is attached along one edge of the flexible printed circuit board 6a, and an embedded portion 6c having a constant width is provided along the opposite edge. Yes.

- the thickness of the flexible substrate is usually around 100 microns, and therefore the thickness of the embedded portion is also around 100 microns.

- a groove (fixed groove) 7c for embedding this embedded portion 7b is carved perpendicularly to the bottom plate surface on the bottom plate 7a of the channel character, so that the backlight LED module follows the shape of the fixed groove 7c. Fixed in a fixed shape.

- a conventional flexible LED module is also characterized by being fixed in a storage groove carved in a resin plate or the like ("Patent Document 2", FIG. 11 and the like).

- a groove having a width of at least several millimeters is required to accommodate the flexible LED module including the mounted component.

- the groove is fixed by simply embedding the embedded portion 6c, and therefore 100 microns. It can be fixed with a groove of about the width.

- the advantages born from this are as follows.

- (A) The leather beam diameter of a leather cutting machine is generally about 100 microns (adjustable), and a groove having a required width can be easily carved in one pass on a resin material or the like.

- the bottom plate itself is usually cut out according to the letter shape using a laser cutting machine. That is, it is efficient because grooving can be performed simultaneously with the bottom plate cutting.

- the advantages of the backlight LED module according to the present invention over the conventional unitized backlight are as follows.

- the light source can be dispersed in the minimum unit (each individual LED lamp), can handle high-definition channel characters, and can easily ensure the uniformity of the brightness of the handwriting board.

- Unitized backlight is fixed by manually bonding each unit to the bottom plate manually with double-sided tape, etc., but workability is poor, while the fixing groove of the backlight LED module is automatically processed It has good workability and can easily handle mass production.

- C Since the backlight LED module is basically a printed circuit board, production can be fully automated including mounting, and productivity is good.

- the embedded portion 6c of the backlight LED module does not necessarily have to be continuous, and may be provided with a cutout portion as necessary (see “Example 5”).

- the embedded portion of the backlight LED module is a continuous or intermittent strip-shaped section having a constant width, and two curves drawn by both edges of the section for the roll-shaped bending of the backlight LED module are LED lamps. It suffices to satisfy the constraint that it is parallel to the display surface formed by.

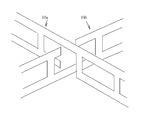

- “Embodiment 2” also relates to the efficiency of the distributed arrangement (A) of “Problem solving means” described above. That is, in principle, the channel character backlights are arranged substantially in the stroke order. In that case, for the characters (for example, “ten”) where the handwriting intersects, the two backlights are not cut off (the power line etc.), and the height of the display surface formed by both LED lamps is also aligned. If it can be handled by crossing, it is convenient to save the trouble of connecting the two backlights separately.

- Example 2 is obtained by adding the crossing function to a conventional flexible LED module. That is, as shown in FIG. 8, notches 8a and 8b are provided between the two LED lamps of the backlight LED module in the upward and downward directions. This is done by engaging the notches 8a and 8b.

- the cutout portions 8a and 8b may be manufactured by cutting out portions that do not affect the circuit manually with tools such as nippers when it is necessary to cross each other (see “Example 5”). It is also possible to prepare a module having only the upper notch and a module having only the lower notch in advance, and realize the intersection by combining them.

- “Diffusion by light scattering material” A method of diffusing light by passing a diffusing lens, resin material, etc. through a light diffusing medium. In the present invention (similar to conventional products) Adopts translucent milky white resin material and adopts this diffusion method. “Diffusion by diffusion space”... Diffusion by securing the “diffusion space”. “Diffusion due to reflection”: A diffusion method in which light is reflected on a material having light diffusivity other than a specular surface and the reflection direction varies.

- the light source 9b is positioned between the handwriting plate 9a and the bottom plate 9c with its optical axis directed toward the bottom plate 9c. It is installed and the handwriting board 9a is illuminated by the reflected light from the bottom board 9c.

- the substantial light source moves to the mirror image position 9d by the bottom plate 9c, which substantially increases the distance between the handwriting plate 9a and the light source, and a larger “diffusion space”.

- the diffusion effect can be enhanced.

- the “diffusion due to reflection” effect can be obtained at the same time. That is, with this structure, it is possible to compensate for the reduction in the light diffusion effect caused by setting the side wall height low.

- the bottom plate when used as a reflection plate, there is a drawback that the reflected light is blocked by the light source (or the support structure attached to the light source, wiring, etc.), and the shadow prevents the brightness of the handwriting plate from being made uniform.

- the optical axis of the unitized backlight described above is directed to the bottom plate and the diffused light is measured by the reflected light from the bottom plate, the shadow of the unit 3b or the wiring 3c falls on the handwriting plate, and it is possible to achieve uniform brightness Have difficulty.

- the flexible LED module is used as a light source in the backlight system using the bottom plate according to the present invention as a reflector.

- the flexible printed circuit board 5a constituting the flexible LED module is thin and can be formed narrow, and is always fixed in the same direction as the optical axis of the LED lamp 5b (in a direction not blocking the flow of light). . Therefore, the shielding of the reflected light from the bottom plate can be minimized.

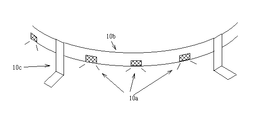

- the flexible LED module 10b can be bent into a roll shape and is “rigid” for bending with respect to an axis perpendicular to the directional axis where bending is possible, regardless of having flexibility, for example, as shown in FIG. Further, if the appropriate portion of the flexible LED module 10b is partially supported and fixed by the support column 10c so as to “float” from the bottom plate, the entire module 10b can be easily “floated” and fixed without dropping.

- Fig. 11 is a cross-sectional view of a channel character which is composed of a flexible LED module and uses a bottom plate as a reflector.

- a channel structure is formed by a handwriting plate 11a, a side plate 11b and a bottom plate 11c that also serves as a reflector, and the flexible LED is formed by a flexible substrate 11d and a side view type LED lamp 11e between the handwriting plate 11a and the bottom plate 11c.

- the module is installed with the optical axis facing the bottom plate 11c.

- the flexible LED module is supported and fixed at a certain distance between the handwriting plate 11a and the bottom plate 11c by the support structure shown in FIG. That is, the L-shaped support column 10c is installed in the middle of the LED lamp, the bottom surface thereof is bonded to the bottom plate 11c, and the upper end is bonded to the flexible substrate 11d of the flexible LED module.

- the flexible substrate 11d is rigid in the direction perpendicular to the direction in which it can be bent into a roll shape (up and down direction), the LED lamp does not hang down between the columns even if the column 10c is intermittent.

- the optical axis of 10e is fixed at a predetermined position so as to always face the direction of the bottom plate 11c and to ensure a certain distance from the bottom plate 11c.

- a mirror plate is used as the bottom plate.

- a reflection plate having a light reflection function and a light diffusion action is employed as the bottom plate 11c.

- Reflectors having a reflecting and diffusing effect are widely marketed as general resin materials such as white acrylic resin materials and translucent acrylic milk white resin materials. Moreover, you may use composite materials, such as sticking a diffusion sheet to a mirror surface board.

- the LED lamp 11e is installed at a certain distance from the bottom plate 11c, thereby producing an effect of widening the substantial distance between the light source and the handwriting board, and at the same time, the light emitted from the LED lamp 11e is on both sides of the flexible substrate 11d. Produces an effect that can be distributed to. That is, a “diffusion space” can be secured on both sides of the flexible substrate 11d, and the emitted light from the LED lamp is reflected and diffused by the bottom plate 11c on both sides of the flexible substrate 11d toward the handwriting plate 11a, so that the flexible substrate 11d is on the writing plate 11a. Creates an effect to prevent shadows from being cast on the screen. Further, in order to prevent light shielding and shadows by the support column 10c, the support column 10c is arranged between two adjacent LED lamps having the least influence.

- a distributed light source can be efficiently realized, and in addition to the “diffusion by light scattering material” effect by the handwriting board 11a, the diffusion effect by “diffusion space” and the “diffusion by reflection” effect are efficiently performed. Can be added automatically.

- the distance between the flexible substrate 11d and the handwriting plate 11a is about 3 to 4 mm, and the distance between the LED lamp 11e and the bottom plate 11c is about 3 to 4 mm. If the distance can be ensured, the uniformity of the brightness of the handwriting board 11a can be sufficiently ensured. In other words, a channel character having a side plate height of about 10 mm can be produced.

- a resin material having a thickness equal to the required height 12b of the side wall is vertically cut out by a cutting machine.

- the handwriting plate 11a and the bottom plate 11c are pasted to the side wall 12a having a thickness by using a double-sided adhesive tape or the like.

- flexible LED modules include ones whose emission color is fixed to a single color and ones capable of displaying full-color electric decoration images. It is possible to create channel letters that exist and change the color and pattern of the handwriting board.

- the present embodiment is a configuration example of a channel character that employs the backlight LED module with the embedded portion shown in the “embodiment 1” instead of the flexible LED module in the “embodiment 3”.

- a transparent resin plate 13f is installed between the handwriting plate 13a and the bottom plate 13c, and a fixing groove is cut in the transparent resin plate 13f.

- the backlight LED module 13d is inserted and fixed with the optical axis directed to the bottom plate 13c in a state of “floating” from the bottom plate in the fixing groove.

- Example 4 in order to “float” and fix the backlight LED module from the bottom plate, it was necessary to separately install a transparent plate.

- the present embodiment is an embodiment in which a fixing groove is cut in the bottom plate and the transparent resin plate can be omitted.

- the support 14c is added in advance to the flexible substrate 14a of the backlight LED module.

- the lower end 14d of the support column is an embedding part, and the flexible LED module is fixed to “float” from the bottom plate in a predetermined bent shape by being fitted into the groove of the bottom plate.

- the bottom plate also serves as a reflector, the wide groove affects the reflected light.

- the method of setting the embedded portion in advance requires a narrow groove for the fixed groove, and has little effect on the reflected light. Is also convenient.

- Each strut portion may be connected by a buried portion of the bottom plate, and wiring such as signal and power may be transferred to the buried portion and connected to the LED lamp via the strut portion.

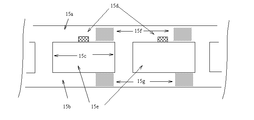

- FIG. 15 shows an example of a backlight LED module in which embedded portions are connected. That is, as shown in FIG. 15, this backlight LED module is composed of an upper belt 15a and a lower belt 15b, both of which are flexible belt-like printed circuit boards, and both are coupled by a column portion 15c. This is also a strip-shaped flexible printed circuit board (perforated).

- the structure and function of the upper band 15a are almost the same as those of the flexible LED module. Necessary signals and electric power flow along the band substrate, and an LED lamp 15d is attached to the lower part of the band substrate.

- the space surrounded by the upper band 15a, the lower band 15b, and the support column 15c located under the LED lamp spreads on both surfaces of the upper band 15a of the LED lamp 15d when the backlight LED module is erected vertically with respect to the bottom plate.

- a diffusion space is formed. That is, as in “Example 4”, the emitted light from the LED lamp is reflected and diffused in the direction of the handwriting board by the bottom plate on both sides of the upper band 15a.

- the lower band 15b is buried in the groove of the bottom plate in the same manner as the lower column 14d of FIG.

- all the signals and power flowing through the upper band 15a are also flowed to the lower band 15b, and these signals and power are connected to each other via the support column 15c. That is, necessary signals and electric power are passed through both the upper band 15a and the lower band 15b to constitute a double system.

- a double system is formed in the upper and lower belts, either one of them can be partly cut without hindering the lighting of the LED lamp 15d.

- the upper band severable part 15f and the lower band severable part 15g in FIG. 15 can be sliced without any problem in the lighting of the LED lamp 15d even if one of these parts is cut (within a range not separated into two). Shows the part.

- the upper band of one backlight LED module 16a is cut out, and the lower band of the other backlight LED module 16b is cut out, so that each electrical connection It is possible to cross three-dimensionally while maintaining

- Example 5 the upper band 15a is exposed to the reflected light.

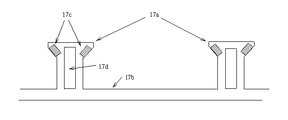

- the upper band 15a is substantially removed, and as shown in FIG. 17, the backlight LED module is formed only by the support 17a and the lower band 17b serving as the embedded portion. .

- Two LED lamps 17c are attached to each support column 17a at a fixed angle with respect to the bottom plate so that the reflected light can avoid the support column portion 17a and secure a larger diffusion space.

- a space 17d is provided in the column so that the angle of the radiation beam between these two LED lamps 17c attached to the same column 17a can flexibly follow the shape of the embedded portion (lower band 17b).

- Channel letter The structure of the conventional channel character is shown.

- a conventional backlight is shown. Shows the structure of channel letters by welding.

- a flexible LED module is shown.

- the back light LED module with an embedding part is shown.

- channel is shown.

- Fig. 2 shows a crossable backlight LED module.

- the cross section of the channel character which makes a baseplate a reflecting plate is shown.

- the structure of the channel character which uses the bottom plate by a flexible LED module as a reflecting plate is shown.

- the cross section of the channel character which uses the bottom plate by a flexible LED module as a reflecting plate is shown.

- the side wall cut out from the resin material is shown.

- the cross section of the channel character which makes the baseplate by the backlight LED module with an embedding part the reflector is shown.

- pillar is shown.

- the backlight LED module comprised from an upper band and a lower band is shown.

- the crossing method of the backlight LED module comprised from an upper zone and a lower zone is shown.

- pillar is shown.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Illuminated Signs And Luminous Advertising (AREA)

- Planar Illumination Modules (AREA)

Abstract

L'invention concerne les lettres boîtiers, qui sont formées en découpant un lettrage en bandes tridimensionnelles et qui paraissent flotter grâce à l'éclairage de plaques à lettres en résine diffusant la lumière au moyen de sources lumineuses incorporées. Afin d'éclairer uniformément les plaques à lettres par l'arrière, il est nécessaire de placer des sources lumineuses à une distance substantielle des plaques à lettres, aussi les parois latérales des lettres boîtiers sont-elles façonnées en soudant des plaques en acier inoxydable ou d'autres types de plaques métalliques, procédé à la fois onéreux et à forte intensité de main-d'œuvre. En outre, les sources lumineuses conventionnelles présentent les désavantages de ne pas se prêter à une répartition décentralisée, qui est cruciale pour éclairer uniformément les plaques à lettres, et de ne pas convenir aux lettres boîtiers présentant des formes complexes (par exemple des caractères kanji écrits dans une police Mincho). Pour y remédier, le présent système de rétro-éclairage permet une répartition décentralisée de sources lumineuses tout en offrant un haut degré de liberté quant à leur positionnement, et diffuse efficacement le rayonnement lumineux issu des sources lumineuses. Cela permet de façonner les parois latérales à partir de matériaux en résine découpés au laser, etc., de sorte que des lettres boîtiers complexes peuvent être façonnées à bas coût tout en assurant un éclairage uniforme des plaques à lettres.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010-179203 | 2010-08-10 | ||

| JP2010179203A JP5685790B2 (ja) | 2010-08-10 | 2010-08-10 | チャンネル文字用バックライトシステム |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012020651A1 true WO2012020651A1 (fr) | 2012-02-16 |

Family

ID=45567620

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/067334 WO2012020651A1 (fr) | 2010-08-10 | 2011-07-28 | Système de rétro-éclairage pour lettres boîtiers |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP5685790B2 (fr) |

| WO (1) | WO2012020651A1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6069726B2 (ja) * | 2012-09-11 | 2017-02-01 | 一成 小森 | 表示装置 |

| JP6030407B2 (ja) * | 2012-10-31 | 2016-11-24 | 株式会社イノアックコーポレーション | 発光装飾体 |

| JP6232340B2 (ja) * | 2014-05-09 | 2017-11-15 | 株式会社発研セイコー | 表示装置 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003075249A1 (fr) * | 2002-03-02 | 2003-09-12 | Noguchi Kogei Co., Ltd. | Dispositif d'affichage et source lumineuse dudit dispositif |

| JP2005222903A (ja) * | 2004-02-09 | 2005-08-18 | Rosso:Kk | 照明装置 |

| JP2006058828A (ja) * | 2004-08-20 | 2006-03-02 | Noguchi Kogei:Kk | 表示装置およびその光源 |

| JP2009175640A (ja) * | 2008-01-28 | 2009-08-06 | Panasonic Electric Works Co Ltd | 発光装置 |

| JP2009289724A (ja) * | 2008-05-28 | 2009-12-10 | Sigma Denki Kogyo Kk | 筒状電飾体の製造方法及び筒状電飾体の発光方向制御方法。 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004071342A (ja) * | 2002-08-06 | 2004-03-04 | Rosso:Kk | 照明装置 |

| JP2005208412A (ja) * | 2004-01-23 | 2005-08-04 | Denso:Kk | 発光表示装置 |

| JP3107982U (ja) * | 2004-09-29 | 2005-04-07 | 株式会社コート | 内照式標示装置 |

| KR100481682B1 (ko) * | 2004-10-13 | 2005-04-07 | 주식회사 엣세인 | 높이조절이 가능한 발광모듈 |

-

2010

- 2010-08-10 JP JP2010179203A patent/JP5685790B2/ja active Active

-

2011

- 2011-07-28 WO PCT/JP2011/067334 patent/WO2012020651A1/fr active Application Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003075249A1 (fr) * | 2002-03-02 | 2003-09-12 | Noguchi Kogei Co., Ltd. | Dispositif d'affichage et source lumineuse dudit dispositif |

| JP2005222903A (ja) * | 2004-02-09 | 2005-08-18 | Rosso:Kk | 照明装置 |

| JP2006058828A (ja) * | 2004-08-20 | 2006-03-02 | Noguchi Kogei:Kk | 表示装置およびその光源 |

| JP2009175640A (ja) * | 2008-01-28 | 2009-08-06 | Panasonic Electric Works Co Ltd | 発光装置 |

| JP2009289724A (ja) * | 2008-05-28 | 2009-12-10 | Sigma Denki Kogyo Kk | 筒状電飾体の製造方法及び筒状電飾体の発光方向制御方法。 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5685790B2 (ja) | 2015-03-18 |

| JP2012038635A (ja) | 2012-02-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100755010B1 (ko) | 조명장치 | |

| US20080285274A1 (en) | Panel light source for back-lit signs | |

| US20060221632A1 (en) | Signboard using LED light source | |

| JP2004206916A (ja) | 面状光源 | |

| CN110426894B (zh) | 一种异形结构的直下式背光模组 | |

| EP3339727A1 (fr) | Bande lumineuse pour étagère | |

| KR20090008749U (ko) | 보조표시를 위한 보조 led를 직하배치 한 측광형 led조명기구 | |

| JP5049945B2 (ja) | 看板、ディスプレイ、表示板、照明パネル等の大判背面照明装置 | |

| CN105556355A (zh) | 光漫射透镜以及包括光漫射透镜的发光装置 | |

| JP2009042360A (ja) | 照光表示装置 | |

| JP5685790B2 (ja) | チャンネル文字用バックライトシステム | |

| CN101430064A (zh) | Led背光源结构 | |

| CN204785863U (zh) | 高反射率的广告灯箱 | |

| JP2008256920A (ja) | 看板用照明切文字 | |

| KR101911467B1 (ko) | 라이팅 광고 패널 | |

| CN202221002U (zh) | 一种led发光板 | |

| WO2013015000A1 (fr) | Dispositif électroluminescent et dispositif d'affichage | |

| KR20070051079A (ko) | 스크래치보드 광고판 | |

| KR101229256B1 (ko) | 조명식 도로표시판 겸용 보조등 | |

| KR20020029057A (ko) | 발광다이오드를 이용한 광고판 | |

| JP2015011278A (ja) | 内照型掲示装置 | |

| KR102141402B1 (ko) | 아크릴 광고판 엘이디 조명장치 | |

| KR200374975Y1 (ko) | 라이트 패널 | |

| KR101195975B1 (ko) | 복수의 도광판 연결구조를 갖는 led 광고판 | |

| TWM279946U (en) | Sign using LED light |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11816317 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 11816317 Country of ref document: EP Kind code of ref document: A1 |