WO2011132349A1 - 電磁シールドを有する航空機のコックピット窓、航空機 - Google Patents

電磁シールドを有する航空機のコックピット窓、航空機 Download PDFInfo

- Publication number

- WO2011132349A1 WO2011132349A1 PCT/JP2011/000365 JP2011000365W WO2011132349A1 WO 2011132349 A1 WO2011132349 A1 WO 2011132349A1 JP 2011000365 W JP2011000365 W JP 2011000365W WO 2011132349 A1 WO2011132349 A1 WO 2011132349A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- window

- film

- retainer

- electromagnetic shield

- aircraft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C1/00—Fuselages; Constructional features common to fuselages, wings, stabilising surfaces or the like

- B64C1/14—Windows; Doors; Hatch covers or access panels; Surrounding frame structures; Canopies; Windscreens accessories therefor, e.g. pressure sensors, water deflectors, hinges, seals, handles, latches, windscreen wipers

- B64C1/1476—Canopies; Windscreens or similar transparent elements

- B64C1/1492—Structure and mounting of the transparent elements in the window or windscreen

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10009—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets

- B32B17/10036—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets comprising two outer glass sheets

- B32B17/10045—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the number, the constitution or treatment of glass sheets comprising two outer glass sheets with at least one intermediate layer consisting of a glass sheet

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10165—Functional features of the laminated safety glass or glazing

- B32B17/10174—Coatings of a metallic or dielectric material on a constituent layer of glass or polymer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/10165—Functional features of the laminated safety glass or glazing

- B32B17/10293—Edge features, e.g. inserts or holes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/10761—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer containing vinyl acetal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B17/00—Layered products essentially comprising sheet glass, or glass, slag, or like fibres

- B32B17/06—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material

- B32B17/10—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin

- B32B17/10005—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing

- B32B17/1055—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer

- B32B17/1077—Layered products essentially comprising sheet glass, or glass, slag, or like fibres comprising glass as the main or only constituent of a layer, next to another layer of a specific material of synthetic resin laminated safety glass or glazing characterized by the resin layer, i.e. interlayer containing polyurethane

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B64—AIRCRAFT; AVIATION; COSMONAUTICS

- B64C—AEROPLANES; HELICOPTERS

- B64C1/00—Fuselages; Constructional features common to fuselages, wings, stabilising surfaces or the like

- B64C1/14—Windows; Doors; Hatch covers or access panels; Surrounding frame structures; Canopies; Windscreens accessories therefor, e.g. pressure sensors, water deflectors, hinges, seals, handles, latches, windscreen wipers

- B64C1/1476—Canopies; Windscreens or similar transparent elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

Definitions

- the present invention relates to an aircraft cockpit window and an aircraft having an electromagnetic shield.

- Aircraft are radio-radio, television, radar, transmitters, and other sources of Electro-Magnetic Environment (HIRF).

- HIRF Electro-Magnetic Environment

- For Radiated Fields during cruise flight or takeoff and landing, there should be no malfunctions or untimely behavior (Up-Set), etc. so that it can fly safely. For this reason, the HIRF required by (14CFR) ⁇ 23.1308, 25.1317, 27.1317 and 29.1317, High-intensity Radiated Fields (HIRF) protection, which is the FAA (Federal Aviation Administration) Regulations Protective measures must be taken.

- FAA Federal Aviation Administration

- Electromagnetic noise (hereinafter simply referred to as electromagnetic noise) can adversely affect, for example, communication with a control tower and navigation communication and control for flying on a predetermined route. Therefore, as is well known, passengers are requested to refrain from using various electronic devices in the cabin.

- Aircraft fuselage is generally made of metal, so electromagnetic noise from the cabin (seat space) to the cockpit (flight deck) and electronics room (Avionics Bay) mainly passes through the cabin window and cockpit window. coming and going. Therefore, in order to prevent electromagnetic noise, which can be an obstacle, from entering the cockpit or electronic equipment room, ITO (Indium Tin Oxide) is installed in the cabin window made up of multiple acrylic window panels. In addition, a film made of gold, silver, or the like is sandwiched (see, for example, Patent Document 1).

- ITO Indium Tin Oxide

- a heater made of a film of ITO, gold, silver or the like is already sandwiched in order to prevent ice and fog. Therefore, it is also conceivable to use the film constituting the heater for preventing electromagnetic noise intrusion.

- a metal retainer mounting frame is integrally provided on the outer periphery of the window, and this mounting frame is fixed to a window frame made of a metal (conductive) material provided on the fuselage side with a fastener, so that the cockpit window Is attached to the aircraft.

- the heater film needs to be electrically insulated, if there is an electrical gap between the heater film and the fixed frame, electromagnetic noise enters the cockpit from this gap. Therefore, it is necessary to reliably perform the engagement between the film and the fixed frame in this portion, but since the technique described in Patent Document 1 targets the cabin window, no consideration has been given to that point.

- the cockpit window includes a main window on the front side and a side window located on the side of the main window.

- the film is provided mainly for anti-icing in the main window, and is provided for anti-fogging in the side window. Therefore, the resistance value required for the anti-fogging heater cannot obtain a sufficient electromagnetic shield attenuation effect because the heater film becomes thin.

- at least the outer layer is made of glass in order to wipe off raindrops etc. with a wiper, while the other layers are not limited to glass but are made of acrylic or the like. Sometimes it is done.

- the main window and the side window may have different uses for the film, the material of the window panel, the laminated structure, and the like, so that the connection between the film and the fixed frame has a dedicated structure as described above. This leads to an increase in cost.

- the outer periphery may be fastened with fasteners.

- a portion of the window panel outer periphery that is fastened with the fastener is made of a material that is more flexible than glass (for example, fiber Glass). Then, this portion is deformed by the fastening force of the fastener, and as a result, the film may be peeled off.

- the present invention has been made based on such a technical problem, and provides an aircraft cockpit window and an aircraft in which a film for preventing electromagnetic noise can be provided reliably, easily and at low cost. Objective.

- the aircraft cockpit window of the present invention is provided with a transparent window panel in which a plurality of sheets are laminated, an outer peripheral portion of the window panel, sandwiching the window panel, and an inner inner retainer and a conductive material.

- connection film is sandwiched between two window panels having one end opposed to each other and electrically connected to the electromagnetic shielding film, the other end is connected to the outer retainer outside the window panel, and the one end and the other end It is preferable to provide an intermediate portion between the outer peripheral portion of the window panel and the outer peripheral portion of the electromagnetic shield film and the outer retainer along the outer peripheral surface of the window panel. Thereby, intrusion of electromagnetic noise from between the outer peripheral portion of the electromagnetic shielding film and the outer retainer can be prevented.

- the electromagnetic shielding film may be provided on the inner peripheral side with respect to a portion fastened by the inner retainer and the outer retainer, and a connection film may be sandwiched between the portions.

- the fastening force by the inner retainer and the outer retainer can be prevented from acting on the electromagnetic shield film, and the electromagnetic shield film is peeled even when the outer peripheral portion of the window panel is made of a material more flexible than glass. Can be prevented.

- connection film and the electromagnetic shield film can be connected via a strip-shaped connection member made of a conductive material provided so as to surround the outer periphery of the electromagnetic shield film.

- a braided wire can be used as such a connection member.

- a heater layer for preventing ice or defogging can be provided between a plurality of window panels.

- the present invention may be an aircraft including a cockpit window having an electromagnetic shield as described above.

- the electromagnetic shielding film has a simple structure in which the outer peripheral portion of the electromagnetic shielding film provided between the two window panels facing each other and the outer retainer made of a conductive material are connected by the connection film. It is possible to electrically close the space between the membrane and the outer retainer, thereby preventing radio waves and electromagnetic noise from entering between the outer peripheral portion of the electromagnetic shield film and the outer retainer. Moreover, even when the portion fastened with the fastener on the outer periphery of the window panel is formed of a material that is more flexible than glass, the electromagnetic shielding film can be prevented from being peeled off by the fastening force of the fastener. In this way, an electromagnetic shielding film for preventing electromagnetic noise can be provided reliably, easily and at low cost. In addition, since it is sandwiched between window panels laminated with electromagnetic shielding films, scratches caused by dust, jumping stones, etc. and rubbing by wipers are not affected, so that maintenance during the maintenance of the airframe is unnecessary.

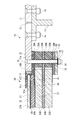

- FIG. 1 It is a figure which shows the cockpit part of the aircraft in this Embodiment. It is sectional drawing which shows the cross-section of a cockpit window, and the attachment structure to an airframe.

- A is an expanded sectional view of the connection part of an electromagnetic shielding film and a conductive film

- (b) is an expanded sectional view of the connection part of a conductive film and an outer retainer.

- FIG. 1 is a diagram for illustrating a configuration of cockpit window 20 of aircraft 10 in the present embodiment.

- the cockpit window (main window) 20 is provided in front of the cockpit of the aircraft 10.

- the cockpit window 20 is attached to an opening 12 formed in the outer skin 11 constituting the fuselage of the aircraft 10.

- the cockpit window 20 has a window portion 21 and an outer retainer 22 that surrounds the entire outer periphery of the window portion 21.

- the window section 21 is configured by laminating a plurality of window panels 23A to 23C in the present embodiment, in this embodiment.

- the cockpit window 20 as the main window of the window panels 23A to 23C, at least the surface window panel 23A facing the outside of the aircraft 10 is made of glass. Further, in the present embodiment, all of the window panels 23A to 23C are made of glass.

- Resin films 24A and 24B made of PVB (polyvinyl butyral) or the like are sandwiched between the window panels 23A and 23B and between the window panels 23B and 23C.

- a heater layer 25 made of a conductive material constituting a heater for preventing ice is formed between the window panel 23A and the resin film 24A.

- the heater layer 25 is formed from a thin film made of a conductive material such as ITO, gold, or silver.

- an intermediate layer 26 made of urethane resin or the like is provided between the heater layer 25 and the resin film 24A.

- the electromagnetic shielding film 27 is sandwiched between the resin film 24A and the window panel 23B.

- the electromagnetic shield film 27 is a thin film formed from a conductive material such as ITO, gold, or silver.

- Spacers 28A and 28B having the same thickness as the window panels 23B and 23C are provided on the outer peripheral portions of the window panels 23B and 23C so as to surround the entire periphery.

- the spacers 28A and 28B are connected to the window panels 23B and 23C by straps 29A and 29B provided on the front and back sides thereof.

- the spacers 28A and 28B and the straps 29A and 29B are made of, for example, fiberglass.

- the spacers 28 ⁇ / b> A and 28 ⁇ / b> B and the resin film 24 ⁇ / b> B project outward from the window panel 23 ⁇ / b> A, the resin film 24 ⁇ / b> A, the heater layer 25, and the electromagnetic shield film 27.

- a weather seal 31 made of a system material, resin or the like is provided.

- the weather seal 31 is provided so as to surround the entire outer periphery of the window portion 21.

- the weather seal 31 has a crank-like shape composed of a portion 31a along the spacer 28A and the window panel 23B, a portion 31b rising along the outer peripheral surface of the resin film 24A and the window panel 23A, and a portion 31c along the surface of the window panel 23A. It has a cross-sectional shape.

- the weather seal 31 includes a Z retainer (core material) 31Z having a crank-like cross-sectional shape.

- the Z retainer 31Z is made of a non-conductive material and can be made of, for example, fiberglass.

- the weather seal 31, the spacers 28A and 28B, and the resin film 24B are disposed on the inner side with the outer retainer 22 made of metal (conductive material) disposed on the outer side. It is sandwiched between the sealing material 30 and the inner retainer 32.

- the outer retainer 22, the weather seal 31, the spacer 28 ⁇ / b> A, the resin film 24 ⁇ / b> B, the spacer 28 ⁇ / b> B, the sealing material 30, and the inner retainer 32 are formed with through holes 33.

- a cylindrical sleeve 34 having a predetermined length is fitted into the inner peripheral surface of the through-hole 33 to regulate the interval between the outer retainer 22 and the inner retainer 32.

- a fastener (connecting member) 35 is inserted into the through-hole 33, and a washer 36 and a nut 37 are attached to the tip of the fastener 35 projecting from the inner retainer 32 to the inside of the machine, so that the outer retainer 22 and the inner retainer 32

- the weather seal 31, the window panels 23B and 23C, and the resin film 24B are fastened and fixed.

- the outer retainer 22 is fastened to a girder 13 constituting the body of the aircraft 10 by a fastener 14 such as a bolt or a rivet.

- the girder 13 is made of a metal which is a conductive material, and the outer skin 11 is fixed to one side thereof, and the outer retainer 22 is fixed to the other side via a sealing material.

- the electromagnetic shield film 27 is formed on the inner side (center side) of the window portion 21 than the portion fastened by the outer retainer 22 and the inner retainer 32. This is to prevent the electromagnetic shield film 27 from being peeled off by the fastening force of the outer retainer 22 and the inner retainer 32. This is because the fastening force by the outer retainer 22 and the inner retainer 32 does not directly act on the electromagnetic shield film 27 if the electromagnetic shield film 27 is provided inside the portion fastened by the outer retainer 22 and the inner retainer 32.

- a bus bar-like connection member 40 is provided on the outer peripheral edge of the electromagnetic shield film 27 so as to surround the entire circumference.

- the connecting member 40 is preferably a flat braided wire, but may be formed of another conductive material.

- the connecting member 40 is provided between the surface of the electromagnetic shield film 27 and the resin film 24A, and is electrically connected to the electromagnetic shield film 27 by soldering or the like.

- connection film 41 made of a material such as Ag, Al, Ni, or Cu surrounds the entire circumference of the electromagnetic shield film 27. Is provided. One end 41 a of the conductive film 41 is electrically connected to the connection member 40. Furthermore, the conductive film 41 is sandwiched between the surface of the window panel 23 ⁇ / b> B and the weather seal 31, and is led out so as to protrude from the window portion 21 to the outer peripheral side.

- the protruding portion (intermediate portion) 41b protruding from the window portion 21 to the outer peripheral side is bent toward the outer retainer 22 side (the body outer side), It is provided along the outer periphery of the weather seal 31.

- the projecting portion 41 b surrounds the entire circumference of the weather seal 31, and the tip portion 41 c is provided so that there is no gap in the outer retainer 22.

- another conductive film may be attached along the outer periphery of the weather seal after the conductive film is bent and cut.

- the protruding portion 41b is formed with a tab (other end) 41d protruding from a part of the circumferential direction.

- the tab 41d is bent along the back surface side of the outer retainer 22, and is electrically grounded to the outer retainer 22 by a fastener or the like.

- the grounding point is the minimum point, it may be the entire circumference (Peripheral) in order to improve the shielding performance.

- the electromagnetic shielding film 27 is provided on the window portion 21, and the conductive film 41 is provided between the electromagnetic shielding film 27 and the outer retainer 22 made of a conductive material.

- the conductive film 41 protrudes to the outer peripheral side of the window portion 21 and is provided along the outer peripheral portion of the weather seal 31 (window portion 21), and is electrically grounded to the outer retainer 22. This makes it possible to form a film made of a conductive material without any gap between the window portion 21 and the outer retainer 22 and the outer skin 11 of the airframe, thereby reliably preventing electromagnetic noise from entering the cockpit. can do.

- the conductive film 41 has flexibility, even when the fastening force of the outer retainer 22 and the inner retainer 32 is applied, it can be prevented from peeling or breaking.

- the conductive film 41 having flexibility as described above can be easily applied even when a portion protruding to the outer peripheral side of the window portion 21 is bent along the outer peripheral portion of the weather seal 31. In this way, an electromagnetic shielding film for preventing electromagnetic noise intrusion can be provided reliably, easily and at low cost.

- FIG. 4 is a diagram showing a configuration when the present invention is applied to the side window 50 of the cockpit.

- the heater layer 25 is provided between the window panel 23 ⁇ / b> C and the resin film 24 ⁇ / b> B, which is closer to the inside of the machine, in order to use the anti-fogging.

- the other configuration is the same as that of the cockpit window 20 shown in FIG.

- the conductive film 41 is provided in the same layer on the electromagnetic shield film 27 via the connection member 40, and the conductive film 41 is led out to the outer peripheral side of the weather seal 31 and is formed on the outer peripheral portion of the weather seal 31.

- the outer retainer 22 is electrically grounded.

- the configuration in which the electromagnetic shielding film for preventing electromagnetic noise intrusion can be shared by the cockpit window 20 and the side window 50. Thereby, an increase in production cost can be suppressed.

- the window panels 23B and 23C are made of glass, but it is also possible to make them made of acrylic resin.

- FIG. 5 is a diagram illustrating an example in which the window panels 23D and 23E are made of acrylic.

- the spacers 28A and 28B are not provided, and the through holes 33 can be formed in the window panels 23D and 23E as they are and fastened by the fasteners 35.

- the electromagnetic shielding film 27 is interposed between the window panels 23D and 23E, and the conductive film (connection film) 52 is connected to the outer peripheral portion thereof.

- the conductive film 52 is provided along the outer peripheral portion of the window portion 21, that is, the outer peripheral surface of the window panel 23D, and is electrically grounded (bonded) to the outer retainer 22 by tabs 52a provided at a plurality of locations in the circumferential direction.

- the number of layers of the window panel constituting the window portion 21, the laminated configuration, the material, and the like can be changed as appropriate.

- the layer on which the electromagnetic shielding film 27 is provided may be a layer other than the above. Also in that case, it is essential to close the space between the outer retainer 22 with the conductive films 41 and 52. In addition to this, as long as it does not depart from the gist of the present invention, the configuration described in the above embodiment can be selected or changed to another configuration as appropriate.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Aviation & Aerospace Engineering (AREA)

- Shielding Devices Or Components To Electric Or Magnetic Fields (AREA)

- Joining Of Glass To Other Materials (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP11771694.4A EP2562078B1 (en) | 2010-04-19 | 2011-01-24 | Aircraft cockpit window having electromagnetic shield, and aircraft |

| US13/496,105 US8714487B2 (en) | 2010-04-19 | 2011-01-24 | Cockpit window of aircraft having electromagnetic shield, and aircraft |

| BR112012005536-4A BR112012005536B1 (pt) | 2010-04-19 | 2011-01-24 | janela de cabina de pilotagem de uma aeronave tendo uma blindagem eletromagnética,e, aeronave |

| RU2012110055/11A RU2502632C2 (ru) | 2010-04-19 | 2011-01-24 | Остекление кабины экипажа летательного аппарата, снабженное электромагнитным экраном, и летательный аппарат |

| CN201180003845.0A CN102574572B (zh) | 2010-04-19 | 2011-01-24 | 具有电磁屏蔽的航空器的座舱窗、航空器 |

| CA2769734A CA2769734C (en) | 2010-04-19 | 2011-01-24 | Cockpit window of aircraft having electromagnetic shield, and aircraft |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2010-095810 | 2010-04-19 | ||

| JP2010095810A JP5492647B2 (ja) | 2010-04-19 | 2010-04-19 | 電磁シールドを有する航空機のコックピット窓、航空機 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011132349A1 true WO2011132349A1 (ja) | 2011-10-27 |

Family

ID=44833895

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/000365 Ceased WO2011132349A1 (ja) | 2010-04-19 | 2011-01-24 | 電磁シールドを有する航空機のコックピット窓、航空機 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8714487B2 (enExample) |

| EP (1) | EP2562078B1 (enExample) |

| JP (1) | JP5492647B2 (enExample) |

| CN (1) | CN102574572B (enExample) |

| BR (1) | BR112012005536B1 (enExample) |

| CA (1) | CA2769734C (enExample) |

| RU (1) | RU2502632C2 (enExample) |

| WO (1) | WO2011132349A1 (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013060136A (ja) * | 2011-09-14 | 2013-04-04 | Mitsubishi Aircraft Corp | 航空機の窓、開口部の閉塞体、ガスケットシール |

| WO2013105178A1 (ja) * | 2012-01-11 | 2013-07-18 | 三菱航空機株式会社 | 航空機の窓、航空機、航空機の窓の組立方法。 |

| WO2014059038A1 (en) * | 2012-10-10 | 2014-04-17 | The Boeing Company | Electromagnetic shielded aircraft passenger window |

| WO2014099068A1 (en) * | 2012-10-10 | 2014-06-26 | The Boeing Company | Infrared light enabled and electromagnetic shielding aircraft window |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9221533B1 (en) | 2011-10-24 | 2015-12-29 | The Boeing Company | Removable window system for space vehicles |

| CN102730989B (zh) * | 2012-07-03 | 2014-12-03 | 北京航空航天大学 | 一种有机电加温隐身夹层玻璃的制备方法 |

| JP6030494B2 (ja) * | 2013-04-19 | 2016-11-24 | 大成建設株式会社 | 電磁遮蔽窓用電磁遮蔽フィルム装着具、及びこれを用いた電磁遮蔽窓並びに電磁遮蔽窓の施工方法 |

| US9073620B2 (en) | 2013-06-07 | 2015-07-07 | Honda Patents & Technologies North America, Llc | Fastening device for window |

| ITPD20130318A1 (it) * | 2013-11-21 | 2015-05-22 | Isoclima Spa | Struttura di parabrezza, particolarmente per elicotteri |

| US9745046B2 (en) * | 2014-01-30 | 2017-08-29 | Ppg Industries Ohio, Inc. | Aircraft transparency with pressure seal and/or anti-static drain |

| JP2016132341A (ja) * | 2015-01-19 | 2016-07-25 | 三菱航空機株式会社 | 航空機および輸送機械 |

| JP2016132340A (ja) * | 2015-01-19 | 2016-07-25 | 三菱航空機株式会社 | 航空機および輸送機械 |

| JP2016141362A (ja) | 2015-02-05 | 2016-08-08 | 三菱航空機株式会社 | 航空機の風防 |

| JP6549855B2 (ja) | 2015-02-17 | 2019-07-24 | 三菱航空機株式会社 | 航空機の風防 |

| US10023289B2 (en) * | 2015-03-10 | 2018-07-17 | Bell Helicopter Textron Inc. | Variable-thickness windshield |

| KR101681558B1 (ko) * | 2015-11-09 | 2016-12-12 | 국방과학연구소 | 낙뢰전달기능의 레이돔 체결부재 및 이를 포함하는 레이돔 조립체 |

| US10293915B2 (en) * | 2016-12-13 | 2019-05-21 | The Boeing Company | Apparatuses and methods for aerodynamic window assemblies |

| FR3068857B1 (fr) * | 2017-07-06 | 2021-10-29 | Saint Gobain | Suppression du bruit de decharge electrostatique par conduction entre un element metallique en gradin et le presse glace |

| FR3068856B1 (fr) * | 2017-07-06 | 2021-10-29 | Saint Gobain | Suppression du bruit de decharge electrostatique par conduction entre un element metallique en gradin et le reseau electrique d'un vitrage |

| FR3068858B1 (fr) * | 2017-07-06 | 2021-04-02 | Saint Gobain | Suppression du bruit de decharge electrostatique par decharge precoce d'un element metallique en gradin |

| FR3089148B1 (fr) * | 2018-12-04 | 2020-12-11 | Saint Gobain | Vitrage feuillete a element en gradin peripherique en materiau polymere ayant une permeabilite a la vapeur d’eau maximale requise |

| CA3066586C (en) * | 2019-01-03 | 2022-12-06 | Bell Textron Inc. | Modular windshield |

| FR3096957B1 (fr) * | 2019-06-04 | 2023-06-09 | Airbus Operations Sas | Ensemble de pare-brise pour aéronef comprenant un encadrement périphérique entourant un ensemble de vitres séparées par des montants non structuraux à l’égard de l’encadrement périphérique |

| FR3111632B1 (fr) * | 2020-06-22 | 2023-01-20 | Saint Gobain | Vitrage monté sur une structure avec interposition d’un élément rigidifiant à surface d’appui localisée entre le vitrage et la structure |

| CN111891333B (zh) * | 2020-07-08 | 2024-04-09 | 中国航发北京航空材料研究院 | 一种承载型多功能电加温风挡 |

| FR3120849B1 (fr) * | 2021-03-16 | 2023-03-24 | Saint Gobain | Vitrage multiple à joint de montage incorporant un élément de renfort et d’étanchéité |

| FR3129624B1 (fr) * | 2021-11-29 | 2024-10-18 | Saint Gobain | Vitrage feuilleté à élément de blocage en gradin |

| FR3132502A1 (fr) * | 2022-02-10 | 2023-08-11 | Saint-Gobain Glass France | Ensemble vitré pour un aéronef, procédé de fabrication d’un tel ensemble vitré, et aéronef comprenant un tel ensemble vitré |

| CN116080887B (zh) * | 2022-12-14 | 2025-11-21 | 北京航玻新材料技术有限公司 | 一种电磁屏蔽观察窗及军用直升机 |

| USD1055833S1 (en) * | 2023-03-02 | 2024-12-31 | Textron Innovations Inc. | Cockpit window panel |

| FR3154700A1 (fr) * | 2023-10-27 | 2025-05-02 | Saint-Gobain Glass France | Vitrage aeronautique travaillant en membrane a performance structurale accrue et aeronef le comprenant |

| CN119460062B (zh) * | 2024-12-16 | 2025-11-04 | 中国航空工业集团公司西安飞机设计研究所 | 一种飞机座舱风挡玻璃结构 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000286591A (ja) * | 1999-03-30 | 2000-10-13 | Asahi Glass Co Ltd | 電磁遮蔽窓ガラス |

| JP2003523911A (ja) | 1999-04-28 | 2003-08-12 | サン−ゴバン グラス フランス | 電磁シールドを有する絶縁用多重ガラス、特に航空機の窓 |

| JP2008201206A (ja) * | 2007-02-19 | 2008-09-04 | Mitsubishi Heavy Ind Ltd | 航空機用窓材およびその製造方法 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1406441A (en) * | 1972-03-13 | 1975-09-17 | Triplex Safety Glass Co | Laminated transparent assemblies |

| US5139850A (en) * | 1987-02-03 | 1992-08-18 | Pilkington Plc | Electromagnetic shielding panel |

| GB8713437D0 (en) * | 1987-06-09 | 1987-07-15 | Pilkington Brothers Plc | Shielding panel |

| US4932608A (en) * | 1987-12-28 | 1990-06-12 | Ppg Industries, Inc. | Aircraft windshield design and method of use |

| US4933227A (en) * | 1988-12-30 | 1990-06-12 | Ppg Industries, Inc. | Aircraft windshield |

| GB8918859D0 (en) * | 1989-08-18 | 1989-09-27 | Pilkington Plc | Electromagnetic shielding panel |

| JPH1184041A (ja) * | 1997-09-12 | 1999-03-26 | Bridgestone Corp | 電磁波シールド性光透過窓材 |

| JPH1197878A (ja) * | 1997-09-19 | 1999-04-09 | Bridgestone Corp | 電磁波シールド性光透過窓材 |

| JP4201458B2 (ja) * | 2000-03-31 | 2008-12-24 | パナソニック株式会社 | 電磁波シールド方法及び電磁波シールド窓、並びに電磁波シールド窓を備えた電子回路基板加工機 |

| US6561460B2 (en) * | 2000-08-03 | 2003-05-13 | Ppg Industries Ohio, Inc. | Switchable electrochromic devices for use in aircraft transparency windows |

| US20040229607A1 (en) * | 2003-05-12 | 2004-11-18 | La Chapelle Michael De | Wireless communication inside shielded envelope |

| US7143979B2 (en) * | 2003-05-30 | 2006-12-05 | The Boeing Company | Vehicle windshield |

| US7913385B2 (en) * | 2005-12-02 | 2011-03-29 | The Boeing Company | Method of attenuating electromagnetic energy |

| RU80143U1 (ru) * | 2008-10-15 | 2009-01-27 | Мирослав Петров Маринов | Многослойное электрообогреваемое ветровое стекло |

-

2010

- 2010-04-19 JP JP2010095810A patent/JP5492647B2/ja active Active

-

2011

- 2011-01-24 CA CA2769734A patent/CA2769734C/en active Active

- 2011-01-24 BR BR112012005536-4A patent/BR112012005536B1/pt not_active IP Right Cessation

- 2011-01-24 US US13/496,105 patent/US8714487B2/en active Active

- 2011-01-24 CN CN201180003845.0A patent/CN102574572B/zh not_active Expired - Fee Related

- 2011-01-24 WO PCT/JP2011/000365 patent/WO2011132349A1/ja not_active Ceased

- 2011-01-24 EP EP11771694.4A patent/EP2562078B1/en active Active

- 2011-01-24 RU RU2012110055/11A patent/RU2502632C2/ru active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000286591A (ja) * | 1999-03-30 | 2000-10-13 | Asahi Glass Co Ltd | 電磁遮蔽窓ガラス |

| JP2003523911A (ja) | 1999-04-28 | 2003-08-12 | サン−ゴバン グラス フランス | 電磁シールドを有する絶縁用多重ガラス、特に航空機の窓 |

| JP2008201206A (ja) * | 2007-02-19 | 2008-09-04 | Mitsubishi Heavy Ind Ltd | 航空機用窓材およびその製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2562078A4 * |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013060136A (ja) * | 2011-09-14 | 2013-04-04 | Mitsubishi Aircraft Corp | 航空機の窓、開口部の閉塞体、ガスケットシール |

| WO2013105178A1 (ja) * | 2012-01-11 | 2013-07-18 | 三菱航空機株式会社 | 航空機の窓、航空機、航空機の窓の組立方法。 |

| US9598166B2 (en) | 2012-01-11 | 2017-03-21 | Mitsubishi Aircraft Corporation | Window of an aircraft with an electromagnetic shield |

| WO2014059038A1 (en) * | 2012-10-10 | 2014-04-17 | The Boeing Company | Electromagnetic shielded aircraft passenger window |

| WO2014099068A1 (en) * | 2012-10-10 | 2014-06-26 | The Boeing Company | Infrared light enabled and electromagnetic shielding aircraft window |

| US9085349B2 (en) | 2012-10-10 | 2015-07-21 | The Boeing Company | Infrared light enabled and electromagnetic shielding aircraft window |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2502632C2 (ru) | 2013-12-27 |

| US20130026296A1 (en) | 2013-01-31 |

| BR112012005536A2 (pt) | 2020-08-04 |

| EP2562078A4 (en) | 2014-09-24 |

| RU2012110055A (ru) | 2013-09-20 |

| CN102574572B (zh) | 2015-09-23 |

| EP2562078A1 (en) | 2013-02-27 |

| CA2769734A1 (en) | 2011-10-27 |

| CN102574572A (zh) | 2012-07-11 |

| JP2011225076A (ja) | 2011-11-10 |

| CA2769734C (en) | 2014-04-22 |

| BR112012005536B1 (pt) | 2021-01-19 |

| EP2562078B1 (en) | 2015-10-21 |

| US8714487B2 (en) | 2014-05-06 |

| JP5492647B2 (ja) | 2014-05-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5492647B2 (ja) | 電磁シールドを有する航空機のコックピット窓、航空機 | |

| JP5931447B2 (ja) | 航空機の窓、航空機、航空機の窓の組立方法。 | |

| EP2570342B1 (en) | Aircraft window | |

| JP6190216B2 (ja) | 航空機の窓、および開口部の閉塞部材 | |

| US20170167611A1 (en) | Gasket seal, door of aircraft, seal structure for opening portion of aircraft, and aircraft | |

| EP1944236B1 (en) | Light weight system for lightning protection of nonconductive aircraft panels | |

| US20100304069A1 (en) | Aircraft window member, method of manufacturing the same, and aircraft window assembly | |

| JP6301056B2 (ja) | 電子機器 | |

| US7642974B2 (en) | Window mounted antenna for a vehicle and a method for using the same | |

| ES2962641T3 (es) | Acristalamiento laminado que incorpora las antenas del sistema automático de ayuda al aterrizaje | |

| CN102099249A (zh) | 由雷暴对飞行器放电产生的雷电电流的引流系统 | |

| CN106797680A (zh) | 用于电磁屏蔽的加热玻璃面板 | |

| EP2906466B1 (en) | Infrared light enabled and electromagnetic shielding aircraft window | |

| CN212542670U (zh) | 一种共性雷达天线罩 | |

| BR112021023544B1 (pt) | Vidraça laminada que integra as antenas do sistema automático de auxílio à aterrissagem e aplicação da vidraça |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201180003845.0 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 11771694 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2769734 Country of ref document: CA |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2011771694 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13496105 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012110055 Country of ref document: RU |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112012005536 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 112012005536 Country of ref document: BR Kind code of ref document: A2 Effective date: 20120312 |