US1852056A - Hood latch - Google Patents

Hood latch Download PDFInfo

- Publication number

- US1852056A US1852056A US36193429A US1852056A US 1852056 A US1852056 A US 1852056A US 36193429 A US36193429 A US 36193429A US 1852056 A US1852056 A US 1852056A

- Authority

- US

- United States

- Prior art keywords

- hood

- rock shaft

- cam

- abutments

- cranks

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011435 rock Substances 0.000 description 69

- 230000000694 effects Effects 0.000 description 5

- 238000010411 cooking Methods 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B83/00—Vehicle locks specially adapted for particular types of wing or vehicle

- E05B83/16—Locks for luggage compartments, car boot lids or car bonnets

- E05B83/24—Locks for luggage compartments, car boot lids or car bonnets for car bonnets

- E05B83/247—Simultaneously actuated fasteners at separated positions

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S292/00—Closure fasteners

- Y10S292/14—Hood latches

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/1043—Swinging

- Y10T292/1044—Multiple head

- Y10T292/1045—Operating means

- Y10T292/1046—Cam

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T292/00—Closure fasteners

- Y10T292/08—Bolts

- Y10T292/1043—Swinging

- Y10T292/1075—Operating means

- Y10T292/1083—Rigid

- Y10T292/1085—Friction catch

Definitions

- Our invention relates to locking or latching means for closures and is herein shown as applied to an automobile hood.

- Onepurpose is the provision of simple and easily operated means for securing an automobile hood in closed position.

- Another object is the provision of means for drawing the hood downwardly and inwardly against its abutment on the frame of the automobile.

- Another object is the provision of means for permitting the actuation of a plurality of hood latching means by a single handle adapted both to latch and unlatch the hood and to raise and lower the hood.

- Other objects will appear from time to time in the course o" the specification and claims.

- Figure 2 is a section on the line 2-2 of Fi ure 1;

- igure 3 is a section on the line 3--3 of Figure 1;

- Figure 4 is a section on the line 1 -4 of Figure 1;

- Figure 5 is a side elevation showing the parts in different position

- Figure 6 is a vertical transverse section through a variant form

- Figure 7 is a side elevation of a variant form

- FIG 8 is a section on the line 8--8 of Figure 7 Like parts are indicated by like symbols throu hout the specification and drawings.

- A generally indicates the frame of the vehicle and A1 a hinged hood member.

- A2 indicates a hood abutment secured to the frame and adapted to limit the inward movement of the lower edge of the hood A1.

- rock shaft generally indicated as B, having the terminal offset portions or cranks B1 B1 adapted to engage locking abutments B2 B2 which may be mounted on the end abutments A5 or the hood.

- rllhe abutments are shown as having faces B3 inclined upwardly and inwardly from the hood.

- B10 indicatesa pro- 1929.

- the rock shaft may be mounted as in the bearings B5 secured to the hood.

- the rock shaft, between the bearings B5 is indicated as oiisetor deformed, as at B", the oii'set portion including what may be called a cam portion Bs which may be curved or angular as shown 1n Figure 2.

- C indicates the handle or control shaft with the exterior handle C1, the shaft passing through the hood.

- the cam member generally indicated as C2 which may have the hook or horn C8 adapted to cooperate with the portion B8 of the offset B".

- C2 At its inner end is mounted the cam member generally indicated as C2 which may have the hook or horn C8 adapted to cooperate with the portion B8 of the offset B".

- apron B9 which, when the device is in the locking position in which it is shown in Figure 1, overrides or overlies the o'set portion B7 of the rock shaft.

- It is provided with a side Hange B12v which engagesthe side Bs'of the offset portion, and limits further counter-clockwise movement, taking the parts in the position in which they are shown in Figure 1. This limit is preferably so arranged that at that position the handle C1 is horizontal, for convenience.

- D indicates an additional stop which may be mounted for example on the frame A, within the abutment A2 and which extends upwardly therefrom, as shown in Figure 8. It may have an outwardly curved or inclined portion D1.

- a stop or holding member Opposed to the member D, in the form of the device shown in Figures 7 and 8, is a stop or holding member generally indicated as D2, which may be formed integrally with or maybe secured to the cam. structure which may be identical with that above described.

- the parts are preferably so spaced that when the hood is lowered into the position in which it is shown in Figure 8, and the handle C1 is rotated to effect the locking action of the cranks B1 in relation to the abutments B2, the member D2 is at the same time moved into the position in which it is shown in Figures 7 and 8, whereby outward movement of the hood from the abutment is prevented.

- securing means are desirable which hold the hood firmly in position, which draw the lower edge of the hood downwardly, to hold it tight, and which also draw it inwardly or prevent it from outward movement.

- This handle member being preferably situated midway between the ends of the hood, not only serves to control the hood latching means, but also serves as a handle for lifting the hood when the latches are disengaged.

- latch abut-ments B2 mounted on the members A5, receive the cranks B1.

- latch abutments are mounted directly on the frame A.

- the crank ends of the rock shaft are given what in Figures 2 and 8 would be aclockwise rotation. They engage the inclined surfaces B3 or E1, the result being a camming effect,l

- the shaft being flexible, and being provided with relatively long lengths free from restricting bearings, a certain spring action or play is permitted which adds to the locking effect, and at the. same time compensates for irregularities and prevents undue strain on any part of the device.

- cam f or camming action we wish to cover any equivalent of the action obtained by the rotation o'r movement of the cam member in relation to the oEset portion B8 of the rock shaft.

- the result' is a'camming action, causing the rotation of the'shaft.

- a latching device for an lautomobile hood which includes a plurality of latch abutments within the hood, laterally inwardly spaced therefrom when the hood is in closed position, a rock shaft adapted to be supported upon the interior of said hood, said shaft having an intermediate offset portion, a cam member, adapted to engage said offset portion, rotatably mounted within and upon the hood, exterior means for rotating said cam member, and additional oHset portions on said shaft adapted to engage said latch abutments, and-.means for preventing movement of the cam in response to torsion of said shaft resultant from locking engagement of said odset portions with said abutments, including means carried by sa-idcam member and engageable with the rock shaft for releasably locking the parts in position when the offset portions of the shaft are in locking engagement with the latch abutments.

- a latching device for an automobile hood which includes a plurality of latch abutments within the hood, a rock shaft having an intermediate offset portion and additional voii'set portions aligned with and Aadapted to engage said abutments, a cam -rotatably mounted on the hood and adapted to engage the intermediate odset portion of the rock lshaft, and means for rotating it, and means, for holding said cam in its normal plane, during the latching engagement of the offset portions of the rock shaft with the latch abutments, comprising a flange adapted to engage and overlie said cam member.

- a latching device for an automobile hood which includes a plurality of latch abntments within the hood, a rock shaft having an. intermediate o'set portion and additional odsety portions aligned with and adapted to engage said abutments, a cam rotatably mounted on the hood and adapted to engage the intermediate' offset portion of the rock shaft, ⁇ and means for rotating it, and means for holding said cam in its normal plane, during the latching engagement of the oli'set portions of the rock shaft with the latch abutments, comprising a flange adapted to engage and overlie said cam' member, the cam member having a portion adapted, when the cam is in engagement with the flange, to'limit the rotation of the cam beyond a ⁇ predetermined point.

- a latching device for an automobile 4 hood which includes a pluralit7 of latch abutments within the hood, a roc shaft having an intermediate offset portion and additional oifset portions aligned with and adapted to engage said abutments, a cam rotatably mounted on'the hood and adapted to engage the intermediate offset portion of the rock shaft, and means for rotating it, and means for holding said cam in its normal plane,

- a latchingv device for an automobile hood wh? ch includes a plurality of lat-ch abutments positioned within the hood and laterally and inwardly spaced therefrom when vthe hood is in closed position, a rock shaft supported upon the interior of said hood, said shaft having an intermediate offset portion, and additional Aoffset portions adapted to engage the latch abutments, and means for rotating the rock shaft, including a cam member adapted to engage the intermediate offset portion of the rock shaft, an additional abutment, positioned within the hood, a locking member associated with the cam and adapted to engage said additional abutment when the offset portions of the rock shaft are in engagement with the first mentioned latch abutments to prevent cocking of the cam, and a second locking member associated with the cam member and engageable with the rock shaft to releasably lock the parts in position.

- a latching device for an automobile hood adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on thev inner face of the closure for rotation about a generally horizontal axis, cranks associated with sa1d rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in calnming relatonship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset port'on of said rock shaft, an additional cana member, adapted to engage said' odset por-4 bers to releasably lock the parts against movement in response to torsional stresses in the rock shaft.

- a ⁇ latching device for an automoblle hood adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with t-he opposed portions of the automobile, which includes a rock shaft mounted on the inner face of the closure for rotation about a generally horizontal axis, cranks associated with said rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks' being adapted, inresponse to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the oposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft, an additional cam member, adaptedrto engage said offset portion, rotatably mounted within and upon the hood, a rotatable support for said additional cam member and exterior means for rotating said additional cam member and support, and means for preventing cooking of

- a latching device for an automobile hood adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on the inner face of the closure for rotation about a generally horizontal axis, cranks associated with said rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft, ⁇ an additionall cam member, rotatably mounted within the hood, said additional cam member including separate cam portions spaced axially of the axis of rotation of said additional cam member and engaging opposite faces of said intermediate offset portion of the rock shaft to rock the same into locking and release positions, respectively, a rotatable

- a latching device for an automobile hood adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on the inner face of.

- cranks associated with Said rock shaft cranks associated with Said rock shaft, cam members positioned within said closure-for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portionsy of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft, an additional cam member, rotatably mounted within the hood, said additional cam member including separate cam portions operating in spaced planes substantially perpendicular to the axis of rotation of the additional .cam membervand engaging opposite faces of the intermediate offset portion of the rock shaft to move the same to locking and release positions, respectively a rotatable support for said additional cam member and exterior handle means for rotating said cam member and support, said additional cam member also including an arm lockingly engageable with the intermediate offset portion of the rock shaft when the latter is in locking position

- Alatching device for the hinged section ating offset lying at the termination of its of an automobile hood which includes a rock unlatching excursion, at a substantlal angle shaft mounted on the inner face of the hood, to the inner face of the hood.

- operating means engage'able with the actuating offset to rock the shaft to latching and release positions, l0 the latching offsets and the actuating offset of the' rock shaft lying in different radial planes, the plane of the latching offsets having a substantial angle of lead in the direction of release movement of the rock shaft with respect to the plane of the actuating oH- set whereby the latching offsets are moved into close proximity to the inner face of the hood to clear said latch abutments in release position of the rock shaft.

- A-latching device for'the hinged section of an automobile hood which includes a rock shaft mounted on the inner face of said section, latch abutments positioned Within the hood, the rock shaft being provided with plural axially offsets portions, rock shaft operating means carried by the hinged section of the hood, operative connections between said rock shaft operating means and one of said axially oset portions whereby 80 the shaft may be rocked from latching to release positions, the remaining axially offset portions of the rock shaft being cooperatively positioned with respect to the latch abutments to latchingly engage the same upon 86 predetermined movement of the rock shaft, said last mentioned offset portions of the rock shaft lying in a radial plane having a substantial angular lead in the direction of release movement of the rock shaft with respect to the radial plane of the first mentioned axial offset, whereby the last mentioned 0H- sets are moved closely adjacent to the inner face of the hinged hood section in release position of the rock shaft.

- a latching device for the hinged section of an automobile hood which includes a rock shaft mounted on the inner face of the hood, latch abutments ositioned within. the hood, the rock shaft eing provided with latching offsets engageable with the abutments, and with an actuating offset, operating means engageable with the actuating offset to rock the shaft to latching and release positions, the latching offsets and the actuating offset of the rock shaft lying in different radial planes, the plane of the latching offsets having a substantial angle of lead inone direction of release movement of the rock shaft with respect to the plane of the actuating offset, whereby, when the actuating offset is moved into unlatched position, the latching offsets are moved closely adjacent to and in substantial parallelism with the inner face of the hood, to clear said latch abutments in release position of the rock shaft, the actu- NORTON A. MEARS. DIBRELL P. HYN ES.

Landscapes

- Superstructure Of Vehicle (AREA)

Description

April 5, 1932.

HOOD LATCH Filed May 10 N. A. MEARS ET AL 1929 l 2 sheets-sheet 1 [n Wwffw' April 5, I N A, MEARS ET AL HOOD LATCH Filed May l0, 1929 2 Sheets-Sheet 2 [WWI Patented Apr. 5, 1932 UNITED STATES PATENT OFFICE NORTON A. MEARS AND DIBRELL'P. HYNES, OF CHICAGO, ILLINOIS, ASSIGNORS TO CHICAGO FORGING & MANUFACTURING CO., OF CHICAGO, ILLINOIS, A CORPORATION OF ILLINOIS HOOD LATCH Application iiled May 10,

Our invention relates to locking or latching means for closures and is herein shown as applied to an automobile hood. Onepurpose is the provision of simple and easily operated means for securing an automobile hood in closed position. Another object is the provision of means for drawing the hood downwardly and inwardly against its abutment on the frame of the automobile. Another object is the provision of means for permitting the actuation of a plurality of hood latching means by a single handle adapted both to latch and unlatch the hood and to raise and lower the hood. Other objects will appear from time to time in the course o" the specification and claims.

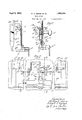

The invention is illustrated more or less diagramirnatitallyl in the accompanying drawings, wherein- Figure 1 is a side elevation;

Figure 2 is a section on the line 2-2 of Fi ure 1;

Figure 4 is a section on the line 1 -4 of Figure 1;

Figure 5 is a side elevation showing the parts in different position;

Figure 6 is a vertical transverse section through a variant form;

Figure 7 is a side elevation of a variant form;

Figure 8 is a section on the line 8--8 of Figure 7 Like parts are indicated by like symbols throu hout the specification and drawings.

Beigerring first to Figures 1 and 2 A generally indicates the frame of the vehicle and A1 a hinged hood member. A2 indicates a hood abutment secured to the frame and adapted to limit the inward movement of the lower edge of the hood A1.

Mounted within the hood is the rock shaft generally indicated as B, having the terminal offset portions or cranks B1 B1 adapted to engage locking abutments B2 B2 which may be mounted on the end abutments A5 or the hood. rllhe abutments are shown as having faces B3 inclined upwardly and inwardly from the hood. B10 indicatesa pro- 1929. Serial No. 361,934.

jection at the upper end of each such face. The rock shaft may be mounted as in the bearings B5 secured to the hood. As an example of one method of securing them we illustrate them as secured4 on the unitary base B6 which may be secured as a whole to the inner face of the hood. The rock shaft, between the bearings B5 is indicated as oiisetor deformed, as at B", the oii'set portion including what may be called a cam portion Bs which may be curved or angular as shown 1n Figure 2.

C indicates the handle or control shaft with the exterior handle C1, the shaft passing through the hood. At its inner end is mounted the cam member generally indicated as C2 which may have the hook or horn C8 adapted to cooperate with the portion B8 of the offset B". It is further provided with an apron B9 which, when the device is in the locking position in which it is shown in Figure 1, overrides or overlies the o'set portion B7 of the rock shaft. It is provided with a side Hange B12v which engagesthe side Bs'of the offset portion, and limits further counter-clockwise movement, taking the parts in the position in which they are shown in Figure 1. This limit is preferably so arranged that at that position the handle C1 is horizontal, for convenience. It will be understood that when the parts are in position as shown in Figure 1 the offsets or crank arms B1 are thrust into locking engagement with the inclined edges B8v of the abutments B2 and the result is the drawing downwardly or inwardly of the lower edges of the hood. B11 indicates a depression in the apron B, adapted to hold the parts locked when it engages the oii'set portion B".

Taking the parts in the position in which they are shown in Figure 1, when the cam is rotated clockwise, the horn C3 engages the offset B8 and exerts a camming action against its lower inclined portion and thus rotates the entire rock shaft in such fashion as' to withdraw the cranks B1 from the abutments B2. rllhe cam body and its apron are preferably so proportioned as to limit-the rotation of the handle to an arc of 18() degrees, in such fashion that the handle isin horizontal position when the cranks B1 have been removed eil) to inoperative position, and is therefore in the most convenient position for the manual lifting of the now released hood.

D indicates an additional stop which may be mounted for example on the frame A, within the abutment A2 and which extends upwardly therefrom, as shown in Figure 8. It may have an outwardly curved or inclined portion D1. Opposed to the member D, in the form of the device shown in Figures 7 and 8, is a stop or holding member generally indicated as D2, which may be formed integrally with or maybe secured to the cam. structure which may be identical with that above described.

The parts are preferably so spaced that when the hood is lowered into the position in which it is shown in Figure 8, and the handle C1 is rotated to effect the locking action of the cranks B1 in relation to the abutments B2, the member D2 is at the same time moved into the position in which it is shown in Figures 7 and 8, whereby outward movement of the hood from the abutment is prevented.

Referring to Figure 6 in the place of the abutments B2 mounted upon the members A5 wemay employ abutment means mounted on the frame A. The abutment member proper, E, with its upwardly and inwardly inclined edge E1 is mounted at the end of the horizontal arm E2 supported by a vertical arm E3 connected at its bottom by the horizontal member E? with the frame A. An advantage of this structure is that it may be positioned at any desired point between the edges of the hood.

It will be realized that Whereas we have described and shown a practical device, nevertheless many changes might be made in the size, shape, number and disposition of parts without departing from the spirit of oui` invention. We therefore wish our description and drawings to be taken as in a broad sense illustrative and diagrammatic rather than as limiting us to our specific showing.

The use and operation'of our invention are as follows:

In securing the hinged hood portions of automobiles and plates, securing means are desirable which hold the hood firmly in position, which draw the lower edge of the hood downwardly, to hold it tight, and which also draw it inwardly or prevent it from outward movement. We have provided means for effecting these results which are simple and eliicient and which respond to the movement of a single handle member. This handle member, being preferably situated midway between the ends of the hood, not only serves to control the hood latching means, but also serves as a handle for lifting the hood when the latches are disengaged. We preferably employ a handle o somewhat elongated form, to serve conveniently as a lifting as well as a turning means. We preferably so proportion the parts that the handle C1 is in generally horizontal position when the latch members B1 are disengaged. We find it-convenient to limit the rotation of the handle to an arc of 180 degrees, whereby the handle is also in horizontal position when the hood is latched.

In order to provide simple means for latching the hood in position we employ a rock shaft the ends of which may be bent or deformed to form crank arms or the equivalent of crank arms. In other words some part of the rock shaft, preferably the ends is so far offset from the center of rotation of the body of the rock shaft, that rotation of the rock shaft imparts such movement to the end or ends as will cooperate with a latch abutment to have the desired locking effect. v

Referring for example to Figure 1, latch abut-ments B2, mounted on the members A5, receive the cranks B1. In the form of Figure 6 latch abutments are mounted directly on the frame A. In either case in response to a locking rotation of the handle C1 the crank ends of the rock shaft are given what in Figures 2 and 8 would be aclockwise rotation. They engage the inclined surfaces B3 or E1, the result being a camming effect,l

whereby further rotation of the rock shaft tends to draw the lower edge of the hood both downwardly and inwardly. The shaft being flexible, and being provided with relatively long lengths free from restricting bearings, a certain spring action or play is permitted which adds to the locking effect, and at the. same time compensates for irregularities and prevents undue strain on any part of the device.

In some circumstances it may be desirable to employ additional means for limiting the outward movement of the lower edge of the hood. In such case we may provide the opposed members D and D2, as shown in` Figures 7 and 8, whereby, when the hood is in closed position and the handle C1 is rotated to move the cranks B1 into locking position, the member D2 is at the same time moved into locking position in relation to the abutment D. 1

In order to prevent cooking or tilting of the axis of the shaft C and handle C1 wex provide the llange B15, shown for exam le in Figures l, 2 and 5 which-is engaged y the upper edge port-ion'C1li ofthe cam structure, when the cam 4is in locking position. In Figures l and 5 we illustrate this flange B1Is as mounted on the unitary base B". It will be understood,however, that We do not wish to be specifically limited to this arrangement except so far as we limit ourselves to it in the language of the individual'claims. mounted on the base or not., the effect of the flange B1l5 is to maintain the axis of the con- IVhether abutments B2.

In. the description and claims herein it will be understood that in using' the term cam f or camming action we wish to cover any equivalent of the action obtained by the rotation o'r movement of the cam member in relation to the oEset portion B8 of the rock shaft. The result'is a'camming action, causing the rotation of the'shaft.

We claim:

1.- A latching device for an lautomobile hood which includes a plurality of latch abutments within the hood, laterally inwardly spaced therefrom when the hood is in closed position, a rock shaft adapted to be supported upon the interior of said hood, said shaft having an intermediate offset portion, a cam member, adapted to engage said offset portion, rotatably mounted within and upon the hood, exterior means for rotating said cam member, and additional oHset portions on said shaft adapted to engage said latch abutments, and-.means for preventing movement of the cam in response to torsion of said shaft resultant from locking engagement of said odset portions with said abutments, including means carried by sa-idcam member and engageable with the rock shaft for releasably locking the parts in position when the offset portions of the shaft are in locking engagement with the latch abutments.

2. A latching device for an automobile hood, which includes a plurality of latch abutments within the hood, a rock shaft having an intermediate offset portion and additional voii'set portions aligned with and Aadapted to engage said abutments, a cam -rotatably mounted on the hood and adapted to engage the intermediate odset portion of the rock lshaft, and means for rotating it, and means, for holding said cam in its normal plane, during the latching engagement of the offset portions of the rock shaft with the latch abutments, comprising a flange adapted to engage and overlie said cam member.

3. A latching device for an automobile hood, which includes a plurality of latch abntments within the hood, a rock shaft having an. intermediate o'set portion and additional odsety portions aligned with and adapted to engage said abutments, a cam rotatably mounted on the hood and adapted to engage the intermediate' offset portion of the rock shaft,`and means for rotating it, and means for holding said cam in its normal plane, during the latching engagement of the oli'set portions of the rock shaft with the latch abutments, comprising a flange adapted to engage and overlie said cam' member, the cam member having a portion adapted, when the cam is in engagement with the flange, to'limit the rotation of the cam beyond a` predetermined point.

4. A latching device for an automobile 4 hood, which includes a pluralit7 of latch abutments within the hood, a roc shaft having an intermediate offset portion and additional oifset portions aligned with and adapted to engage said abutments, a cam rotatably mounted on'the hood and adapted to engage the intermediate offset portion of the rock shaft, and means for rotating it, and means for holding said cam in its normal plane,

lduring the latching engagement of the oset portions of the rock shaft with the latch abutments, comprising a flange adapted to engage and overlie said cam member, the cam member having a portion adapted, when the cam is in engagement with the flange, to limit the rotation of the cam beyond a predetermined point, and means for limiting the arc of movement of the 'cam in the opposite direction of rotation.

5. A latchingv device for an automobile hood wh? ch includes a plurality of lat-ch abutments positioned within the hood and laterally and inwardly spaced therefrom when vthe hood is in closed position, a rock shaft supported upon the interior of said hood, said shaft having an intermediate offset portion, and additional Aoffset portions adapted to engage the latch abutments, and means for rotating the rock shaft, including a cam member adapted to engage the intermediate offset portion of the rock shaft, an additional abutment, positioned within the hood, a locking member associated with the cam and adapted to engage said additional abutment when the offset portions of the rock shaft are in engagement with the first mentioned latch abutments to prevent cocking of the cam, and a second locking member associated with the cam member and engageable with the rock shaft to releasably lock the parts in position.`

6. A latching device for an automobile hood, adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on thev inner face of the closure for rotation about a generally horizontal axis, cranks associated with sa1d rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in calnming relatonship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset port'on of said rock shaft, an additional cana member, adapted to engage said' odset por-4 bers to releasably lock the parts against movement in response to torsional stresses in the rock shaft. 7 A` latching device for an automoblle hood, adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with t-he opposed portions of the automobile, which includes a rock shaft mounted on the inner face of the closure for rotation about a generally horizontal axis, cranks associated with said rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks' being adapted, inresponse to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the oposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft, an additional cam member, adaptedrto engage said offset portion, rotatably mounted within and upon the hood, a rotatable support for said additional cam member and exterior means for rotating said additional cam member and support, and means for preventing cooking of said cam member and support in response to -torsion of said rock shaft resulting from locking engagement of the cranks and the first mentioned cam members,V including a keeperl element mounted on the hood and adapted to engage said additional cam, and means to limit the arc of rotation of said additional cam member in locking direction including a lug carried by the cam member and engageable with the intermediate offset formation of the rock shaft.

8. A latching device for an automobile hood, adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on the inner face of the closure for rotation about a generally horizontal axis, cranks associated with said rock shaft, cam members positioned within said closure for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portions of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft,`an additionall cam member, rotatably mounted within the hood, said additional cam member including separate cam portions spaced axially of the axis of rotation of said additional cam member and engaging opposite faces of said intermediate offset portion of the rock shaft to rock the same into locking and release positions, respectively, a rotatable support for said additional cam member land exterior handle means for rotating said additional cam member and support, said additional cam member including means engageable with another portion of said intermediate offset portion of the rock shaft to limit-the rotationy of said additional cam member in one direction.

9. A latching device for an automobile hood, adapted to draw the lower edge of a double hinged hood closure downwardly and inwardly into engagement with the opposed portions of the automobile, which includes a rock shaft mounted on the inner face of.

the closure for rotation about a generally horizontal axis, cranks associated with Said rock shaft, cam members positioned within said closure-for engagement with said cranks, said cranks being normally at all times in camming relationship with said cam members when the closure is locked, said cranks being adapted, in response to their engagement with the cam members, to draw the lower edge of the hood closure downwardly and inwardly against the opposed portionsy of the automobile, and means for rotating said cranks into camming locking engagement with the cam members, including an intermediate offset portion of said rock shaft, an additional cam member, rotatably mounted within the hood, said additional cam member including separate cam portions operating in spaced planes substantially perpendicular to the axis of rotation of the additional .cam membervand engaging opposite faces of the intermediate offset portion of the rock shaft to move the same to locking and release positions, respectively a rotatable support for said additional cam member and exterior handle means for rotating said cam member and support, said additional cam member also including an arm lockingly engageable with the intermediate offset portion of the rock shaft when the latter is in locking position to restrain the parts in the rock shaft.

10. Alatching device for the hinged section ating offset lying at the termination of its of an automobile hood which includes a rock unlatching excursion, at a substantlal angle shaft mounted on the inner face of the hood, to the inner face of the hood.

latch abutments ositioned within the hood,

Signed at Chica o, county of Cook and i 5 the rock shaft being provided with latching State of Illinois, this 7th day of May, 1929.

offsets engageable with the abutments, and

- with an actuating offset, operating means engage'able with the actuating offset to rock the shaft to latching and release positions, l0 the latching offsets and the actuating offset of the' rock shaft lying in different radial planes, the plane of the latching offsets having a substantial angle of lead in the direction of release movement of the rock shaft with respect to the plane of the actuating oH- set whereby the latching offsets are moved into close proximity to the inner face of the hood to clear said latch abutments in release position of the rock shaft.

1l. A-latching device for'the hinged section of an automobile hood which includes a rock shaft mounted on the inner face of said section, latch abutments positioned Within the hood, the rock shaft being provided with plural axially offsets portions, rock shaft operating means carried by the hinged section of the hood, operative connections between said rock shaft operating means and one of said axially oset portions whereby 80 the shaft may be rocked from latching to release positions, the remaining axially offset portions of the rock shaft being cooperatively positioned with respect to the latch abutments to latchingly engage the same upon 86 predetermined movement of the rock shaft, said last mentioned offset portions of the rock shaft lying in a radial plane having a substantial angular lead in the direction of release movement of the rock shaft with respect to the radial plane of the first mentioned axial offset, whereby the last mentioned 0H- sets are moved closely adjacent to the inner face of the hinged hood section in release position of the rock shaft.

12. A latching device for the hinged section of an automobile hood which includes a rock shaft mounted on the inner face of the hood, latch abutments ositioned within. the hood, the rock shaft eing provided with latching offsets engageable with the abutments, and with an actuating offset, operating means engageable with the actuating offset to rock the shaft to latching and release positions, the latching offsets and the actuating offset of the rock shaft lying in different radial planes, the plane of the latching offsets having a substantial angle of lead inone direction of release movement of the rock shaft with respect to the plane of the actuating offset, whereby, when the actuating offset is moved into unlatched position, the latching offsets are moved closely adjacent to and in substantial parallelism with the inner face of the hood, to clear said latch abutments in release position of the rock shaft, the actu- NORTON A. MEARS. DIBRELL P. HYN ES.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US36193429 US1852056A (en) | 1929-05-10 | 1929-05-10 | Hood latch |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US36193429 US1852056A (en) | 1929-05-10 | 1929-05-10 | Hood latch |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1852056A true US1852056A (en) | 1932-04-05 |

Family

ID=23423991

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US36193429 Expired - Lifetime US1852056A (en) | 1929-05-10 | 1929-05-10 | Hood latch |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1852056A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3572780A (en) * | 1968-07-16 | 1971-03-30 | Abbey Mfg Co Ltd | Locking device |

-

1929

- 1929-05-10 US US36193429 patent/US1852056A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3572780A (en) * | 1968-07-16 | 1971-03-30 | Abbey Mfg Co Ltd | Locking device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US1922062A (en) | Lock | |

| US1852056A (en) | Hood latch | |

| US2451537A (en) | Door fastener | |

| US1489965A (en) | Car-door lock | |

| US1908958A (en) | Automobile doorlock | |

| US1810760A (en) | Lock | |

| US1820238A (en) | Hood latch | |

| US1531090A (en) | Trunk lock | |

| US1510561A (en) | Lock | |

| US1622791A (en) | Door bolt | |

| US1831494A (en) | Hood latch | |

| US1502872A (en) | Sliding door and lock for washing-machine cylinders | |

| US1656275A (en) | Lock | |

| US1285827A (en) | Lock. | |

| US1400483A (en) | Lever-lock for end-gates | |

| US1536268A (en) | Trunk lock | |

| US1778687A (en) | Door-latching mechanism | |

| US2183672A (en) | Latch mechanism | |

| US2497982A (en) | Lock for doors and windows | |

| US1070865A (en) | Sliding-door fastener. | |

| US1477181A (en) | Lock | |

| US1623477A (en) | Closure | |

| US375528A (en) | Thomas beechee | |

| US1360474A (en) | End-gate-securing means | |

| US194205A (en) | Improvement in transom-openers |