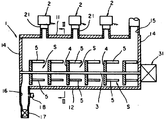

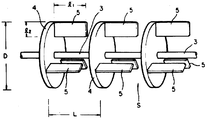

KR970010451B1 - 분립체의 건조·결정화 장치 - Google Patents

분립체의 건조·결정화 장치 Download PDFInfo

- Publication number

- KR970010451B1 KR970010451B1 KR1019890003980A KR890003980A KR970010451B1 KR 970010451 B1 KR970010451 B1 KR 970010451B1 KR 1019890003980 A KR1019890003980 A KR 1019890003980A KR 890003980 A KR890003980 A KR 890003980A KR 970010451 B1 KR970010451 B1 KR 970010451B1

- Authority

- KR

- South Korea

- Prior art keywords

- granules

- drying

- processing tank

- crystallizing

- isolation space

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B13/00—Conditioning or physical treatment of the material to be shaped

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B13/00—Conditioning or physical treatment of the material to be shaped

- B29B13/06—Conditioning or physical treatment of the material to be shaped by drying

- B29B13/065—Conditioning or physical treatment of the material to be shaped by drying of powder or pellets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B13/00—Conditioning or physical treatment of the material to be shaped

- B29B13/08—Conditioning or physical treatment of the material to be shaped by using wave energy or particle radiation

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B17/00—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement

- F26B17/18—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed by rotating helical blades or other rotary conveyors which may be heated moving materials in stationary chambers, e.g. troughs

- F26B17/20—Machines or apparatus for drying materials in loose, plastic, or fluidised form, e.g. granules, staple fibres, with progressive movement with movement performed by rotating helical blades or other rotary conveyors which may be heated moving materials in stationary chambers, e.g. troughs the axis of rotation being horizontal or slightly inclined

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F26—DRYING

- F26B—DRYING SOLID MATERIALS OR OBJECTS BY REMOVING LIQUID THEREFROM

- F26B3/00—Drying solid materials or objects by processes involving the application of heat

- F26B3/32—Drying solid materials or objects by processes involving the application of heat by development of heat within the materials or objects to be dried, e.g. by fermentation or other microbiological action

- F26B3/34—Drying solid materials or objects by processes involving the application of heat by development of heat within the materials or objects to be dried, e.g. by fermentation or other microbiological action by using electrical effects

- F26B3/343—Drying solid materials or objects by processes involving the application of heat by development of heat within the materials or objects to be dried, e.g. by fermentation or other microbiological action by using electrical effects in combination with convection

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Microbiology (AREA)

- Biotechnology (AREA)

- Biomedical Technology (AREA)

- Molecular Biology (AREA)

- Toxicology (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Drying Of Solid Materials (AREA)

- Polyesters Or Polycarbonates (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP88-134895 | 1988-05-31 | ||

| JP63-134895 | 1988-05-31 | ||

| JP63134895A JPH01301310A (ja) | 1988-05-31 | 1988-05-31 | 粉粒体の乾燥・結晶化装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR890017514A KR890017514A (ko) | 1989-12-16 |

| KR970010451B1 true KR970010451B1 (ko) | 1997-06-26 |

Family

ID=15139032

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1019890003980A Expired - Fee Related KR970010451B1 (ko) | 1988-05-31 | 1989-03-29 | 분립체의 건조·결정화 장치 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JPH01301310A (enExample) |

| KR (1) | KR970010451B1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100864527B1 (ko) * | 2007-06-08 | 2008-10-21 | 한국기계연구원 | 플라스틱 고효율 건조장치와 이를 이용한 건조방법 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2514231Y2 (ja) * | 1990-04-05 | 1996-10-16 | 株式会社松井製作所 | マイクロ波連続乾燥装置 |

| JP2015137144A (ja) * | 2014-01-20 | 2015-07-30 | 株式会社カワタ | 粉粒体供給装置 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5599573A (en) * | 1979-01-24 | 1980-07-29 | Hitachi Ltd | Microwave drier |

| JPS58117954A (ja) * | 1981-12-29 | 1983-07-13 | Nara Kikai Seisakusho:Kk | 粉粒体の熱交換装置 |

| JP2516466Y2 (ja) * | 1988-04-11 | 1996-11-06 | ホソカワミクロン株式会社 | スクリューフィーダ |

-

1988

- 1988-05-31 JP JP63134895A patent/JPH01301310A/ja active Granted

-

1989

- 1989-03-29 KR KR1019890003980A patent/KR970010451B1/ko not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100864527B1 (ko) * | 2007-06-08 | 2008-10-21 | 한국기계연구원 | 플라스틱 고효율 건조장치와 이를 이용한 건조방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR890017514A (ko) | 1989-12-16 |

| JPH01301310A (ja) | 1989-12-05 |

| JPH0440170B2 (enExample) | 1992-07-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4954681A (en) | Drying and crystallizing apparatus for granules, which employs a microwave device | |

| KR970010451B1 (ko) | 분립체의 건조·결정화 장치 | |

| RU2152571C1 (ru) | Сушилка для сыпучих материалов | |

| JP2004045013A (ja) | 乾燥装置 | |

| SU1768039A3 (ru) | Устройство дл сушки куриного помета | |

| JPH0615171B2 (ja) | プラスチツク粉粒体原料の乾燥装置 | |

| EP1703239B1 (en) | Apparatus for the fast and continuous dehumidification of loose materials, particularly pellets for a plastic moulding plant | |

| SU1250806A1 (ru) | Центробежна сушилка дл дисперсных материалов | |

| CN213687606U (zh) | 用于豆瓣翻晒的循环式干燥系统 | |

| JP2002250590A (ja) | 乾燥装置 | |

| JPH0417348B2 (enExample) | ||

| RU2050798C1 (ru) | Устройство для обжарки зерна и семян | |

| RU2847701C1 (ru) | Свч-установка для сушки сыпучих материалов | |

| CN118565164B (zh) | 籽瓜籽粒加工烘干装置 | |

| CN115435559B (zh) | 一种水平滚筒耦合微波的粮食干燥机 | |

| US3792536A (en) | Rotary dehydrator-granulator | |

| JP2939655B2 (ja) | 粉粒体加熱処理装置 | |

| SU892156A1 (ru) | Сушилка дл сыпучих материалов | |

| CA1234877A (en) | Apparatus for heating granular materials | |

| RU2226427C2 (ru) | Способ получения гранулированного комплексного удобрения и линия для его осуществления | |

| JP2514231Y2 (ja) | マイクロ波連続乾燥装置 | |

| JP2003202187A (ja) | 間接加熱型攪拌乾燥機 | |

| RU2181304C1 (ru) | Смеситель | |

| RU2752220C1 (ru) | Многосекционная установка для термообработки сыпучих материалов | |

| RU2149756C1 (ru) | Смеситель для сухих смесей |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

St.27 status event code: A-0-1-A10-A12-nap-PA0109 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| A201 | Request for examination | ||

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| G160 | Decision to publish patent application | ||

| PG1605 | Publication of application before grant of patent |

St.27 status event code: A-2-2-Q10-Q13-nap-PG1605 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U11-oth-PR1002 Fee payment year number: 1 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 7 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 8 |

|

| FPAY | Annual fee payment |

Payment date: 20050928 Year of fee payment: 9 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 9 |

|

| LAPS | Lapse due to unpaid annual fee | ||

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 20061014 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 20061014 |