KR20190132245A - 연마 헤드를 이용하여 연마 패드의 연마면을 검출하는 방법, 및 연마 장치 - Google Patents

연마 헤드를 이용하여 연마 패드의 연마면을 검출하는 방법, 및 연마 장치 Download PDFInfo

- Publication number

- KR20190132245A KR20190132245A KR1020190056958A KR20190056958A KR20190132245A KR 20190132245 A KR20190132245 A KR 20190132245A KR 1020190056958 A KR1020190056958 A KR 1020190056958A KR 20190056958 A KR20190056958 A KR 20190056958A KR 20190132245 A KR20190132245 A KR 20190132245A

- Authority

- KR

- South Korea

- Prior art keywords

- polishing

- head

- polishing head

- pad

- distortion sensor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000005498 polishing Methods 0.000 title claims abstract description 397

- 238000000034 method Methods 0.000 title claims abstract description 23

- 238000003825 pressing Methods 0.000 claims description 33

- 239000000758 substrate Substances 0.000 claims description 17

- 238000005452 bending Methods 0.000 claims description 10

- 238000003860 storage Methods 0.000 claims description 9

- 238000012545 processing Methods 0.000 claims description 7

- 230000008569 process Effects 0.000 claims description 3

- 235000012431 wafers Nutrition 0.000 description 53

- 239000007789 gas Substances 0.000 description 12

- 238000006073 displacement reaction Methods 0.000 description 11

- 239000007788 liquid Substances 0.000 description 10

- 230000006870 function Effects 0.000 description 9

- 239000012528 membrane Substances 0.000 description 9

- 239000012530 fluid Substances 0.000 description 8

- 230000007246 mechanism Effects 0.000 description 8

- 125000006850 spacer group Chemical group 0.000 description 6

- 238000006243 chemical reaction Methods 0.000 description 4

- 238000005096 rolling process Methods 0.000 description 4

- 239000002245 particle Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000004065 semiconductor Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 230000009471 action Effects 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000003750 conditioning effect Effects 0.000 description 1

- 229910003460 diamond Inorganic materials 0.000 description 1

- 239000010432 diamond Substances 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000012886 linear function Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000000611 regression analysis Methods 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

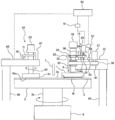

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/04—Lapping machines or devices; Accessories designed for working plane surfaces

- B24B37/07—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool

- B24B37/10—Lapping machines or devices; Accessories designed for working plane surfaces characterised by the movement of the work or lapping tool for single side lapping

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B49/00—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation

- B24B49/16—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation taking regard of the load

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/005—Control means for lapping machines or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

- B24B37/30—Work carriers for single side lapping of plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/34—Accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B49/00—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation

- B24B49/10—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation involving electrical means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B53/00—Devices or means for dressing or conditioning abrasive surfaces

- B24B53/017—Devices or means for dressing, cleaning or otherwise conditioning lapping tools

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B7/00—Measuring arrangements characterised by the use of electric or magnetic techniques

- G01B7/16—Measuring arrangements characterised by the use of electric or magnetic techniques for measuring the deformation in a solid, e.g. by resistance strain gauge

- G01B7/22—Measuring arrangements characterised by the use of electric or magnetic techniques for measuring the deformation in a solid, e.g. by resistance strain gauge using change in capacitance

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67092—Apparatus for mechanical treatment

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67242—Apparatus for monitoring, sorting or marking

- H01L21/67259—Position monitoring, e.g. misposition detection or presence detection

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L22/00—Testing or measuring during manufacture or treatment; Reliability measurements, i.e. testing of parts without further processing to modify the parts as such; Structural arrangements therefor

- H01L22/20—Sequence of activities consisting of a plurality of measurements, corrections, marking or sorting steps

- H01L22/26—Acting in response to an ongoing measurement without interruption of processing, e.g. endpoint detection, in-situ thickness measurement

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/32—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring the deformation in a solid

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018096000A JP2019198938A (ja) | 2018-05-18 | 2018-05-18 | 研磨ヘッドを用いて研磨パッドの研磨面を検出する方法、および研磨装置 |

| JPJP-P-2018-096000 | 2018-05-18 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20190132245A true KR20190132245A (ko) | 2019-11-27 |

Family

ID=68534563

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020190056958A Withdrawn KR20190132245A (ko) | 2018-05-18 | 2019-05-15 | 연마 헤드를 이용하여 연마 패드의 연마면을 검출하는 방법, 및 연마 장치 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20190351526A1 (enExample) |

| JP (1) | JP2019198938A (enExample) |

| KR (1) | KR20190132245A (enExample) |

| CN (1) | CN110497307A (enExample) |

| TW (1) | TW202003157A (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BR112021019580A2 (pt) | 2019-03-29 | 2021-12-14 | Saint Gobain Abrasifs Sa | Desempenho de soluções de retificação |

| CA3135979C (en) | 2019-04-03 | 2023-12-19 | Saint-Gobain Abrasives, Inc. | Abrasive article, abrasive system and method for using and forming same |

| CN111085931A (zh) * | 2019-12-31 | 2020-05-01 | 浙江芯晖装备技术有限公司 | 一种抛光头驱动装置及抛光设备 |

| EP3919192B1 (en) * | 2020-06-04 | 2023-11-29 | Sugino Machine Limited | Cleaning apparatus |

| KR102762332B1 (ko) * | 2020-09-02 | 2025-02-03 | 에스케이하이닉스 주식회사 | 기판의 평탄화 장치 및 방법 |

| JP7709281B2 (ja) | 2021-01-14 | 2025-07-16 | 株式会社荏原製作所 | 研磨装置、研磨方法、および基板の膜厚分布の可視化情報を出力する方法 |

| CN113458972A (zh) * | 2021-07-28 | 2021-10-01 | 北京烁科精微电子装备有限公司 | 一种抛光垫修整装置及抛光设备 |

| CN114633206A (zh) * | 2022-04-25 | 2022-06-17 | 北京烁科精微电子装备有限公司 | 一种修整装置及晶圆抛光系统 |

| CN114918832B (zh) * | 2022-05-20 | 2023-07-28 | 湖州师范学院 | 一种高精密的砂轮修整设备 |

| CN117718876B (zh) | 2024-02-07 | 2024-06-18 | 华海清科股份有限公司 | 用于化学机械抛光的监测方法和化学机械抛光设备 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014097553A (ja) | 2012-11-15 | 2014-05-29 | Ebara Corp | 基板保持装置および研磨装置 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2629746B1 (fr) * | 1988-04-06 | 1991-01-25 | Bertin & Cie | Procede et dispositif de polissage d'un composant optique |

| US20050197045A1 (en) * | 2003-11-24 | 2005-09-08 | Novak W. T. | Fine force control of actuators for chemical mechanical polishing apparatuses |

| US7172493B2 (en) * | 2003-11-24 | 2007-02-06 | Nikon Corporation | Fine force actuator assembly for chemical mechanical polishing apparatuses |

| US6855032B1 (en) * | 2003-11-24 | 2005-02-15 | Nikon Corporation | Fine force control of actuators for chemical mechanical polishing apparatuses |

| US7059939B2 (en) * | 2004-09-02 | 2006-06-13 | Taiwan Semiconductor Manufacturing Co., Ltd. | Polishing pad conditioner and monitoring method therefor |

| JP4597634B2 (ja) * | 2004-11-01 | 2010-12-15 | 株式会社荏原製作所 | トップリング、基板の研磨装置及び研磨方法 |

| EP2838110B1 (en) * | 2004-11-01 | 2016-04-27 | Ebara Corporation | Polishing apparatus |

| JP4817687B2 (ja) * | 2005-03-18 | 2011-11-16 | 株式会社荏原製作所 | 研磨装置 |

| CN2807472Y (zh) * | 2005-08-02 | 2006-08-16 | 童德黉 | 压力旋臂结构 |

| CN102101265B (zh) * | 2010-12-16 | 2012-05-16 | 浙江工业大学 | 一种检测抛光工件受力及定位抛光工具工作原点的夹具 |

| JP5454513B2 (ja) * | 2011-05-27 | 2014-03-26 | 信越半導体株式会社 | 研磨ヘッドの高さ方向の位置の調整方法及びワークの研磨方法 |

| JP2013111701A (ja) * | 2011-11-29 | 2013-06-10 | Hitachi Koki Co Ltd | 携帯用切断機 |

| JP6012104B2 (ja) * | 2012-12-18 | 2016-10-25 | 三菱日立パワーシステムズ株式会社 | バニシング装置及びそれを用いたバニシング方法 |

| JP6357260B2 (ja) * | 2016-09-30 | 2018-07-11 | 株式会社荏原製作所 | 研磨装置、及び研磨方法 |

-

2018

- 2018-05-18 JP JP2018096000A patent/JP2019198938A/ja active Pending

-

2019

- 2019-05-10 US US16/408,960 patent/US20190351526A1/en not_active Abandoned

- 2019-05-15 KR KR1020190056958A patent/KR20190132245A/ko not_active Withdrawn

- 2019-05-15 CN CN201910404342.2A patent/CN110497307A/zh active Pending

- 2019-05-15 TW TW108116736A patent/TW202003157A/zh unknown

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2014097553A (ja) | 2012-11-15 | 2014-05-29 | Ebara Corp | 基板保持装置および研磨装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| TW202003157A (zh) | 2020-01-16 |

| JP2019198938A (ja) | 2019-11-21 |

| CN110497307A (zh) | 2019-11-26 |

| US20190351526A1 (en) | 2019-11-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20190132245A (ko) | 연마 헤드를 이용하여 연마 패드의 연마면을 검출하는 방법, 및 연마 장치 | |

| JP6196858B2 (ja) | 研磨方法および研磨装置 | |

| US10987776B2 (en) | Calibration method and non-transitory computer-readable storage medium storing a program of calibration | |

| KR101512427B1 (ko) | 드레싱장치, 드레싱방법, 및 폴리싱장치 | |

| JP5161294B2 (ja) | 化学機械研磨装置および化学機械研磨方法 | |

| US11679472B2 (en) | Method for CMP pad conditioning | |

| TW411299B (en) | Wafer polishing apparatus and polishing quantity detection method | |

| TWI867252B (zh) | 用於拋光基板的表面的基板載體和拋光基板的方法 | |

| CN111230733A (zh) | 包括抛光垫监测方法的制造方法以及抛光设备 | |

| US20200368874A1 (en) | Polishing apparatus and polishing method | |

| JP7315332B2 (ja) | ダミーディスクおよびダミーディスクを用いた表面高さ測定方法 | |

| JP6961343B2 (ja) | 研磨装置 | |

| KR20240021142A (ko) | 워크피스의 연마 레이트의 응답성 프로파일을 작성하는방법, 연마 방법 및 프로그램이 저장된 컴퓨터 판독 가능한 기록 매체 | |

| JP7689937B2 (ja) | 研磨パッド寿命推定方法および研磨装置 | |

| TWI901892B (zh) | 工件研磨率之響應性形貌圖的製作方法、研磨方法、及儲存有程式之電腦可讀取記憶媒體 | |

| US20240198480A1 (en) | Method of creating responsive profile of polishing rate of workpiece, polishing method, and polishing apparatus | |

| JP2005081461A (ja) | ウェハ等の研磨方法およびその装置 | |

| JP2020192634A (ja) | 研磨ヘッドの高さを調整する方法および研磨方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20190515 |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20211222 Comment text: Request for Examination of Application Patent event code: PA02011R01I Patent event date: 20190515 Comment text: Patent Application |

|

| PC1202 | Submission of document of withdrawal before decision of registration |

Comment text: [Withdrawal of Procedure relating to Patent, etc.] Withdrawal (Abandonment) Patent event code: PC12021R01D Patent event date: 20220214 |

|

| WITB | Written withdrawal of application |