KR20180098652A - 축조 재료 용기 - Google Patents

축조 재료 용기 Download PDFInfo

- Publication number

- KR20180098652A KR20180098652A KR1020187021902A KR20187021902A KR20180098652A KR 20180098652 A KR20180098652 A KR 20180098652A KR 1020187021902 A KR1020187021902 A KR 1020187021902A KR 20187021902 A KR20187021902 A KR 20187021902A KR 20180098652 A KR20180098652 A KR 20180098652A

- Authority

- KR

- South Korea

- Prior art keywords

- reservoir

- container

- containers

- build

- construction materials

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/30—Auxiliary operations or equipment

- B29C64/307—Handling of material to be used in additive manufacturing

- B29C64/321—Feeding

- B29C64/329—Feeding using hoppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/20—Apparatus for additive manufacturing; Details thereof or accessories therefor

- B29C64/255—Enclosures for the building material, e.g. powder containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/14—Treatment of metallic powder

- B22F1/145—Chemical treatment, e.g. passivation or decarburisation

- B22F1/147—Making a dispersion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F12/00—Apparatus or devices specially adapted for additive manufacturing; Auxiliary means for additive manufacturing; Combinations of additive manufacturing apparatus or devices with other processing apparatus or devices

- B22F12/50—Means for feeding of material, e.g. heads

- B22F12/52—Hoppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/004—Filling molds with powder

-

- B22F3/1055—

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/20—Apparatus for additive manufacturing; Details thereof or accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y40/00—Auxiliary operations or equipment, e.g. for material handling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y99/00—Subject matter not provided for in other groups of this subclass

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03B—MANUFACTURE, SHAPING, OR SUPPLEMENTARY PROCESSES

- C03B19/00—Other methods of shaping glass

- C03B19/01—Other methods of shaping glass by progressive fusion or sintering of powdered glass onto a shaping substrate, i.e. accretion, e.g. plasma oxidation deposition

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/10—Metallic powder containing lubricating or binding agents; Metallic powder containing organic material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/10—Metallic powder containing lubricating or binding agents; Metallic powder containing organic material

- B22F1/107—Metallic powder containing lubricating or binding agents; Metallic powder containing organic material containing organic material comprising solvents, e.g. for slip casting

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/10—Formation of a green body

- B22F10/14—Formation of a green body by jetting of binder onto a bed of metal powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/20—Direct sintering or melting

- B22F10/28—Powder bed fusion, e.g. selective laser melting [SLM] or electron beam melting [EBM]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F12/00—Apparatus or devices specially adapted for additive manufacturing; Auxiliary means for additive manufacturing; Combinations of additive manufacturing apparatus or devices with other processing apparatus or devices

- B22F12/50—Means for feeding of material, e.g. heads

- B22F12/55—Two or more means for feeding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F12/00—Apparatus or devices specially adapted for additive manufacturing; Auxiliary means for additive manufacturing; Combinations of additive manufacturing apparatus or devices with other processing apparatus or devices

- B22F12/70—Gas flow means

-

- B22F2003/1056—

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Dispersion Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Plasma & Fusion (AREA)

- Organic Chemistry (AREA)

Abstract

Description

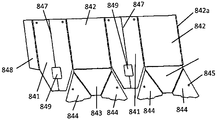

도 2는 축조 재료 외부 구조체의 일례의 개략도,

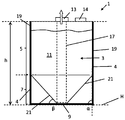

도 3a는 축조 재료 용기의 일례의 개략적인 측면도,

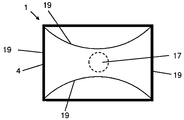

도 3b는 도 3a의 예시적인 축조 재료 용기의 개략적인 평면도,

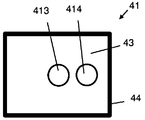

도 4a는 축조 재료 용기의 다른 예를 통한 개략적인 단면도,

도 4b는 도 4a의 에시적인 축조 재료 용기의 개략적인 평면도,

도 4c는 도 4a의 예시적인 축조 재료 용기의 개략적인 측면도,

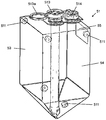

도 5는 축조 재료 용기의 다른 예의 사시도,

도 7a는 축조 재료 용기의 다른 예의 개략적인 측면도,

도 7b는 도 7a의 예시적인 축조 재료 용기의 개략적인 평면도,

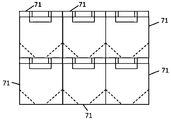

도 7a는 상대적으로 편평한 구성의 예시적인 축조 재료 용기의 세트의 개략적인 측면도,

도 7b는 사용시 구성의 도 7a의 예시적인 축조 재료 용기의 세트의 개략적인 측면도,

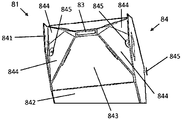

도 8a는 상대적으로 편평한 구성의 다른 예시적인 축조 재료 용기의 사시도,

도 8b는 사용시 구성의 도 7a의 예시적인 축조 재료 용기의 부분 사시도,

도 8c는 예시적인 보강 구조체를 형성하도록 예시적인 피스의 재료의 사시도,

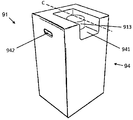

도 9는 다른 예시적인 축조 재료 용기의 사시도,

도 10a는 다른 예시적인 축조 재료 용기의 사시도,

도 10b는 도 9a의 예시적인 축조 재료 용기의 사시도,

도 11은 다른 예시적인 축조 재료 용기의 사시도,

도 12는 예시적인 3D 프린팅 시스템과 함께 사용하는 예시적인 축조 재료 용기의 개략도,

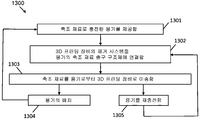

도 13은 용기로부터 3D 프린팅 시스템으로 축조 재료를 제공하기 위한 예시적인 방법의 흐름도,

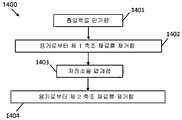

도 14는 용기로부터 축조 재료를 제거하기 위한 예시적인 방법의 흐름도.

Claims (16)

- 3D 프린팅 축조 재료 용기에 있어서,

축조 재료를 보유하는 저장소와,

적어도 하나의 선택된 위치에서 상기 저장소에 부착된 보강 구조체를 포함하고,

상기 저장소 및 보강 구조체는 상대적으로 편평한 구성에서 상기 저장소가 축조 재료로 충전가능한 사용시 구성으로의 상기 용기의 재구성을 허용하는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 사용시 구성의 용기에 의해 차지된 용적은 상기 상대적으로 편평한 구성의 용기에 의해 차지된 용적보다 적어도 80% 초과인

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 저장소는 상대적으로 가요성이고, 상기 보강 구조체는 상대적으로 강성인

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 보강 구조체는 단일 피스의 재료를 포함하는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 용기가 사용시 구성으로 있을 때, 상기 저장소는, 적어도 충전되고 압괴되지 않은 상태에 있을 때, 비-수렴 상부 섹션 및 수렴 하부 섹션을 포함하는

3D 프린팅 축조 재료 용기. - 제 4 항에 있어서,

상기 적어도 하나의 선택된 위치는 상기 상부 섹션에 구성되는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 용기가 사용시 구성으로 있고, 의도된 사용시 배향으로 있을 때, 상기 보강 구조체는 비-수렴 상부 섹션 및 수렴 하부 섹션을 포함하는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 보강 구조체는 상기 용기가 사용시 구성으로 있을 때 상기 저장소의 적어도 하나의 부분의 압괴에 저항하도록 구성되는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

축조 재료가 상기 저장소를 빠져나가게 하는 축조 재료 출구 구조체를 더 포함하는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

가스가 상기 저장소로 들어가게 하는 가스 입구 구조체를 더 포함하는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 보강 구조체는 절첩가능한

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 보강 구조체는 상기 용기가 사용시 구성으로 있을 때 입방형 구조체의 대향하는 측벽을 형성하는 한 쌍의 섹션을 포함하고, 상기 한 쌍의 섹션의 각 섹션은 상기 용기가 편평한 구성으로 있을 때 절첩되는

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 용기를 사용시 구성으로 유지하는 지지 구조체를 더 포함하고, 상기 지지 구조체는, 상기 용기가 편평한 구성으로 있을 때에는 상기 보강 구조체 및 상기 저장소로부터 공간적으로 분리가능하고, 상기 용기가 사용시 구성으로 있을 때에는 상기 보강 구조체에 연결되는

3D 프린팅 축조 재료 용기. - 제 13 항에 있어서,

상기 지지 구조체는 절첩가능한

3D 프린팅 축조 재료 용기. - 제 1 항에 있어서,

상기 저장소는 플라스틱 재료로 형성되고, 상기 보강 구조체는 판지로 형성되는

3D 프린팅 축조 재료 용기. - 3D 프린팅 축조 재료 용기에 있어서,

축조 재료를 수용 및 유지하기 위한 상대적으로 가요성 재료로 형성된 내부 부분과,

상기 내부 부분 주위에 배치되고 상기 내부 부분에 연결되는 상대적으로 강성 재료로 형성된 외부 부분을 포함하고,

상기 용기는 상기 용기의 최소 외부 치수가 상대적으로 작은 값을 갖는 제 1 구성과, 상기 용기의 최소 외부 치수가 상대적으로 큰 값을 갖는 제 2 구성 사이에서 재구성가능한

3D 프린팅 축조 재료 용기.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2016/060795 WO2017194151A1 (en) | 2016-05-12 | 2016-05-12 | Build material containers |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020207030492A Division KR102229766B1 (ko) | 2016-05-12 | 2016-05-12 | 축조 재료 용기 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180098652A true KR20180098652A (ko) | 2018-09-04 |

Family

ID=55969156

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187021902A Ceased KR20180098652A (ko) | 2016-05-12 | 2016-05-12 | 축조 재료 용기 |

| KR1020207030492A Active KR102229766B1 (ko) | 2016-05-12 | 2016-05-12 | 축조 재료 용기 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020207030492A Active KR102229766B1 (ko) | 2016-05-12 | 2016-05-12 | 축조 재료 용기 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US11254051B2 (ko) |

| EP (1) | EP3271158B1 (ko) |

| JP (1) | JP6868631B2 (ko) |

| KR (2) | KR20180098652A (ko) |

| CN (1) | CN108602257B (ko) |

| BR (1) | BR112018014972B1 (ko) |

| WO (1) | WO2017194151A1 (ko) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180098652A (ko) * | 2016-05-12 | 2018-09-04 | 휴렛-팩커드 디벨롭먼트 컴퍼니, 엘.피. | 축조 재료 용기 |

| WO2022148547A1 (en) | 2021-01-11 | 2022-07-14 | Readily3D Sa | System and method for a sterile, precise and fast handling of resin containers in volumetric printers |

Family Cites Families (77)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1623107A (en) * | 1926-09-18 | 1927-04-05 | Albert M Goodykoontz | Gasoline receptacle |

| US1891839A (en) * | 1928-11-29 | 1932-12-20 | Robinson E S & A Ltd | Cardboard or like box and carton |

| US2177918A (en) * | 1935-08-19 | 1939-10-31 | Owens Illinois Glass Co | Container for packaging pourable materials |

| US2171717A (en) * | 1935-10-08 | 1939-09-05 | Owens Illinois Glass Co | Collapsible container |

| US2345646A (en) * | 1940-07-13 | 1944-04-04 | Marshall I Williamson | Box, carton, or similar device |

| US2618409A (en) * | 1949-09-07 | 1952-11-18 | Eisenberger Sidney | Liquid container comprising a flexible envelope |

| US2894666A (en) * | 1956-03-05 | 1959-07-14 | Jr Claude N Campbell | Bulk dispensing container |

| US3061165A (en) * | 1960-09-01 | 1962-10-30 | Racine Ind Plant Inc | Lined container package |

| US3132789A (en) * | 1961-10-25 | 1964-05-12 | Gerald V Forrest | Packaging containers |

| US3171571A (en) * | 1963-03-08 | 1965-03-02 | Bastian Blessing Co | Beverage dispenser |

| SE212884C1 (ko) | 1963-10-24 | 1967-05-16 | ||

| US3339721A (en) * | 1966-02-08 | 1967-09-05 | Milprint Inc | Bag carrier |

| US4121389A (en) | 1977-02-02 | 1978-10-24 | Waldemar Ptaszek | Portable, collapsible storage bins |

| US4197962A (en) * | 1977-06-24 | 1980-04-15 | Lever Brothers Company | Packaging container |

| US4120420A (en) * | 1978-02-16 | 1978-10-17 | The Procter & Gamble Company | Lined parallelepipedal package for dispensing flowable materials |

| FI60844C (fi) * | 1980-07-11 | 1982-04-13 | Unicont Ky | Palettbehaollare foer engaongsbruk |

| AU597472B2 (en) * | 1986-08-30 | 1990-05-31 | Lb Europe Limited | Device facilitating filling and unfolding of bag within outer casing |

| GB2228725A (en) | 1989-03-03 | 1990-09-05 | Unilever Plc | Bag-in-box containers |

| BE1004754A6 (fr) | 1991-04-29 | 1993-01-26 | Dow Corning Sa | Grand recipient pour vrac, empilable, reutilisable, a parois rabattables. |

| DE4115126C1 (en) | 1991-05-08 | 1992-06-11 | Gerd 5620 Velbert De Kueppersbusch | Packing container for loose goods - has rigid plastics outer box containing flexible inner bag attached to hard flat lid |

| US5480057A (en) | 1991-06-27 | 1996-01-02 | Entapack Pty. Ltd | Bulk container having flexible inner container and rigid outer container |

| JP3288141B2 (ja) * | 1993-06-25 | 2002-06-04 | 大日本印刷株式会社 | バッグインカートン |

| JP3285682B2 (ja) * | 1992-10-28 | 2002-05-27 | 大日本印刷株式会社 | バッグインカートン |

| US5402915A (en) * | 1993-11-30 | 1995-04-04 | Kaneka Texas Corporation | Bottom draining bin-type, bulk fluid container with insert |

| USD378660S (en) * | 1995-01-30 | 1997-04-01 | Tohoku Ricoh Co., Ltd. | Container for liquid ink for a printing machine |

| JPH09202357A (ja) * | 1996-01-23 | 1997-08-05 | Fujimori Kogyo Kk | バックインボックス |

| US6467652B2 (en) * | 1998-01-28 | 2002-10-22 | A. R. Arena Products, Inc. | Discharge of pumpable material from shipper bags |

| FR2779055B1 (fr) | 1998-05-28 | 2001-05-04 | Oreal | Composition de teinture directe pour fibres keratiniques avec un colorant direct cationique et un polyol et/ou un ether de polyol |

| JP2000194182A (ja) * | 1998-10-19 | 2000-07-14 | Ricoh Co Ltd | トナー収納容器および該トナー収納容器を用いる画像形成装置 |

| CN1222839C (zh) * | 2000-01-07 | 2005-10-12 | 株式会社理光 | 粉体收纳容器,粉体排出装置及图像形成装置 |

| JP4157681B2 (ja) * | 2000-02-14 | 2008-10-01 | 株式会社リコー | トナー収納容器 |

| US6591077B2 (en) * | 2000-05-08 | 2003-07-08 | Ricoh Company, Ltd. | Image forming apparatus and toner container therefor |

| JP4194254B2 (ja) * | 2000-06-22 | 2008-12-10 | 株式会社リコー | トナー収納容器および画像形成装置 |

| TWI282310B (en) * | 2002-06-28 | 2007-06-11 | Oce Tech Bv | Ink tank |

| JP4220798B2 (ja) * | 2002-09-20 | 2009-02-04 | 株式会社リコー | 粉体収納容器 |

| US6808092B2 (en) * | 2003-01-06 | 2004-10-26 | Weyerhaeuser Company | Hopper box |

| GB0314815D0 (en) * | 2003-06-25 | 2003-07-30 | Stephenson John | Bag in box |

| JP4532894B2 (ja) * | 2003-12-18 | 2010-08-25 | 株式会社リコー | 梱包箱 |

| USD519833S1 (en) * | 2004-05-11 | 2006-05-02 | Ricoh Company, Ltd. | Package for a toner cartridge |

| WO2006051284A2 (en) * | 2004-11-09 | 2006-05-18 | John Stephenson | Bag cartridge with anti-torque collar |

| JP4584701B2 (ja) * | 2004-12-22 | 2010-11-24 | 株式会社リコー | 画像形成用粉体を内包する易変形性容器用容器収納箱 |

| US7552838B2 (en) * | 2005-02-01 | 2009-06-30 | Menasha Corporation | Cartridge and method for filling a bulk container with a flowable substance |

| US7296599B2 (en) | 2005-03-31 | 2007-11-20 | 3D Systems, Inc. | Pneumatic powder transport system |

| US20070026102A1 (en) * | 2005-07-28 | 2007-02-01 | Devos John A | Systems and methods of solid freeform fabrication with improved powder supply bins |

| CN101495294B (zh) * | 2006-05-26 | 2013-03-13 | 3D系统公司 | 用于处理三维打印机中材料的装置和方法 |

| JP2010516585A (ja) * | 2007-01-30 | 2010-05-20 | アドバンスド テクノロジー マテリアルズ,インコーポレイテッド | ライナベース加圧式配給システムにおけるライナの閉塞遮断の防止 |

| US9016555B2 (en) | 2007-04-03 | 2015-04-28 | Cdf Corporation | Flexible liner and bag-in-box container systems |

| US7954670B2 (en) * | 2007-06-07 | 2011-06-07 | Plastic Systems, Inc. | Container evacuation system |

| EP2103548B1 (en) * | 2008-03-22 | 2014-10-01 | Pall Corporation | System comprising a tote and a flexible container |

| US8474655B2 (en) * | 2008-05-12 | 2013-07-02 | Hewlett-Packard Development Company, L.P. | Bag-in-box container including a pre-positioned, secured dispensing spout |

| NZ592229A (en) * | 2008-10-23 | 2013-08-30 | Dow Agrosciences Llc | Foldable container for holding a pourable product |

| CA2790821C (en) * | 2010-02-26 | 2019-05-07 | Monsanto Technology Llc | Container assemblies for storing, shipping, and/or dispensing fluids, and related methods |

| CA3010089A1 (en) * | 2010-02-26 | 2011-09-01 | Dow Agrosciences Llc | Container |

| DE102010011208A1 (de) * | 2010-03-09 | 2011-09-15 | Vita Pak Ug | Verpackungssystem |

| ES2639815T3 (es) * | 2011-11-28 | 2017-10-30 | Nanomakers | Procedimiento de utilización de un contenedor |

| MY175154A (en) * | 2012-04-27 | 2020-06-11 | Dialog Construction Sdn Bhd | Bulk storage container and bulk material handling assembly therewith |

| GB201209226D0 (en) * | 2012-05-25 | 2012-07-04 | Miriad Cs Ltd | Container, container blank and filling apparatus |

| US20140008361A1 (en) * | 2012-07-05 | 2014-01-09 | Don Nguyen | Collapsible hopper with cable engagement |

| US9850046B2 (en) * | 2013-11-06 | 2017-12-26 | The Procter & Gamble Company | Flexible containers with vent systems |

| US10000009B2 (en) | 2014-02-05 | 2018-06-19 | Nathan Christopher Maier | Sterile environment for additive manufacturing |

| US10059486B2 (en) * | 2014-03-26 | 2018-08-28 | Van M. Kassouni | Shipping container and insert |

| TWI510279B (zh) * | 2014-04-22 | 2015-12-01 | 研能科技股份有限公司 | 粉末回收系統 |

| AR105259A1 (es) * | 2015-07-10 | 2017-09-20 | Int Paper Co | Un sistema para la distribución completa de materiales fluibles desde un recipiente de embarque para materiales a granel |

| WO2017194108A1 (en) * | 2016-05-12 | 2017-11-16 | Hewlett-Packard Development Company, L.P., | Additive manufacturing material management station |

| WO2017194145A1 (en) * | 2016-05-12 | 2017-11-16 | Hewlett-Packard Development Company, L.P. | Build material container |

| EP3386722B1 (en) * | 2016-05-12 | 2022-01-26 | Hewlett-Packard Development Company, L.P. | Outlet structure |

| CN109153180A (zh) * | 2016-05-12 | 2019-01-04 | 惠普发展公司,有限责任合伙企业 | 3d打印系统中的后处理 |

| US20190134908A1 (en) * | 2016-05-12 | 2019-05-09 | Hewlett-Packard Development Company, L.P. | Waste routing of non-fused build material |

| WO2017194139A1 (en) * | 2016-05-12 | 2017-11-16 | Hewlett-Packard Development Company, L.P. | Build material container |

| CN108698260B (zh) * | 2016-05-12 | 2021-02-12 | 惠普发展公司,有限责任合伙企业 | 构建材料容器 |

| KR20180098652A (ko) * | 2016-05-12 | 2018-09-04 | 휴렛-팩커드 디벨롭먼트 컴퍼니, 엘.피. | 축조 재료 용기 |

| US10669071B2 (en) * | 2016-06-28 | 2020-06-02 | Delavan Inc | Powder container systems for additive manufacturing |

| JP6798012B2 (ja) * | 2016-10-27 | 2020-12-09 | ヒューレット−パッカード デベロップメント カンパニー エル.ピー.Hewlett‐Packard Development Company, L.P. | 構築材料容器用の入口 |

| WO2018181551A1 (ja) * | 2017-03-30 | 2018-10-04 | 日本製紙株式会社 | 詰め替え用液状内容物収容用紙製内容器 |

| EP3434446B1 (en) * | 2017-07-28 | 2021-12-29 | Hewlett-Packard Development Company, L.P. | Build material container |

| US11111066B2 (en) * | 2017-10-20 | 2021-09-07 | Yushin Co., Ltd. | Composite pack for filling liquid material |

| US20200017269A1 (en) * | 2018-07-11 | 2020-01-16 | Printpack Illinois, Inc. | Flexible Reinforcement for Flexible Container |

-

2016

- 2016-05-12 KR KR1020187021902A patent/KR20180098652A/ko not_active Ceased

- 2016-05-12 JP JP2018539909A patent/JP6868631B2/ja active Active

- 2016-05-12 EP EP16722664.6A patent/EP3271158B1/en active Active

- 2016-05-12 CN CN201680080315.9A patent/CN108602257B/zh active Active

- 2016-05-12 KR KR1020207030492A patent/KR102229766B1/ko active Active

- 2016-05-12 BR BR112018014972-1A patent/BR112018014972B1/pt active IP Right Grant

- 2016-05-12 US US16/068,881 patent/US11254051B2/en active Active

- 2016-05-12 WO PCT/EP2016/060795 patent/WO2017194151A1/en not_active Ceased

Also Published As

| Publication number | Publication date |

|---|---|

| BR112018014972A2 (pt) | 2018-12-11 |

| CN108602257A (zh) | 2018-09-28 |

| US20190054693A1 (en) | 2019-02-21 |

| EP3271158B1 (en) | 2019-12-04 |

| KR20200123493A (ko) | 2020-10-29 |

| JP6868631B2 (ja) | 2021-05-12 |

| WO2017194151A1 (en) | 2017-11-16 |

| EP3271158A1 (en) | 2018-01-24 |

| US11254051B2 (en) | 2022-02-22 |

| JP2019510653A (ja) | 2019-04-18 |

| CN108602257B (zh) | 2021-06-29 |

| BR112018014972B1 (pt) | 2022-02-01 |

| KR102229766B1 (ko) | 2021-03-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20180099817A (ko) | 축조 재료 용기 | |

| US11007716B2 (en) | Build material container | |

| US10850447B2 (en) | Build material container | |

| US11787114B2 (en) | Gas inlet structure for a build material reservoir | |

| CN108602258B (zh) | 构建材料容器 | |

| US11325306B2 (en) | Build material container | |

| US20190061252A1 (en) | Build material containers | |

| KR20180098652A (ko) | 축조 재료 용기 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

Patent event date: 20180727 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20191224 Patent event code: PE09021S01D |

|

| AMND | Amendment | ||

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20200626 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20191224 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |

|

| X091 | Application refused [patent] | ||

| AMND | Amendment | ||

| PX0901 | Re-examination |

Patent event code: PX09011S01I Patent event date: 20200626 Comment text: Decision to Refuse Application Patent event code: PX09012R01I Patent event date: 20200221 Comment text: Amendment to Specification, etc. |

|

| PX0601 | Decision of rejection after re-examination |

Comment text: Decision to Refuse Application Patent event code: PX06014S01D Patent event date: 20200922 Comment text: Amendment to Specification, etc. Patent event code: PX06012R01I Patent event date: 20200827 Comment text: Decision to Refuse Application Patent event code: PX06011S01I Patent event date: 20200626 Comment text: Amendment to Specification, etc. Patent event code: PX06012R01I Patent event date: 20200221 Comment text: Notification of reason for refusal Patent event code: PX06013S01I Patent event date: 20191224 |

|

| X601 | Decision of rejection after re-examination | ||

| A107 | Divisional application of patent | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20201022 |