KR20180098615A - 듀플렉스 스테인레스 강 튜브를 제조하는 방법 - Google Patents

듀플렉스 스테인레스 강 튜브를 제조하는 방법 Download PDFInfo

- Publication number

- KR20180098615A KR20180098615A KR1020187021492A KR20187021492A KR20180098615A KR 20180098615 A KR20180098615 A KR 20180098615A KR 1020187021492 A KR1020187021492 A KR 1020187021492A KR 20187021492 A KR20187021492 A KR 20187021492A KR 20180098615 A KR20180098615 A KR 20180098615A

- Authority

- KR

- South Korea

- Prior art keywords

- tube

- cold rolling

- duplex stainless

- stainless steel

- cold

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B23/00—Tube-rolling not restricted to methods provided for in only one of groups B21B17/00, B21B19/00, B21B21/00, e.g. combined processes planetary tube rolling, auxiliary arrangements, e.g. lubricating, special tube blanks, continuous casting combined with tube rolling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B3/00—Rolling materials of special alloys so far as the composition of the alloy requires or permits special rolling methods or sequences ; Rolling of aluminium, copper, zinc or other non-ferrous metals

- B21B3/02—Rolling special iron alloys, e.g. stainless steel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/02—Making uncoated products

- B21C23/04—Making uncoated products by direct extrusion

- B21C23/08—Making wire, rods or tubes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C23/00—Extruding metal; Impact extrusion

- B21C23/02—Making uncoated products

- B21C23/04—Making uncoated products by direct extrusion

- B21C23/08—Making wire, rods or tubes

- B21C23/085—Making tubes

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/02—Hardening articles or materials formed by forging or rolling, with no further heating beyond that required for the formation

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/004—Heat treatment of ferrous alloys containing Cr and Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/005—Heat treatment of ferrous alloys containing Mn

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/008—Heat treatment of ferrous alloys containing Si

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

- C21D8/105—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies of ferrous alloys

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

- C21D9/085—Cooling or quenching

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C1/00—Making non-ferrous alloys

- C22C1/02—Making non-ferrous alloys by melting

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/001—Ferrous alloys, e.g. steel alloys containing N

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/58—Ferrous alloys, e.g. steel alloys containing chromium with nickel with more than 1.5% by weight of manganese

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B2261/00—Product parameters

- B21B2261/02—Transverse dimensions

- B21B2261/08—Diameter

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B2261/00—Product parameters

- B21B2261/02—Transverse dimensions

- B21B2261/10—Cross-sectional area

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/001—Austenite

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/005—Ferrite

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Heat Treatment Of Steel (AREA)

Abstract

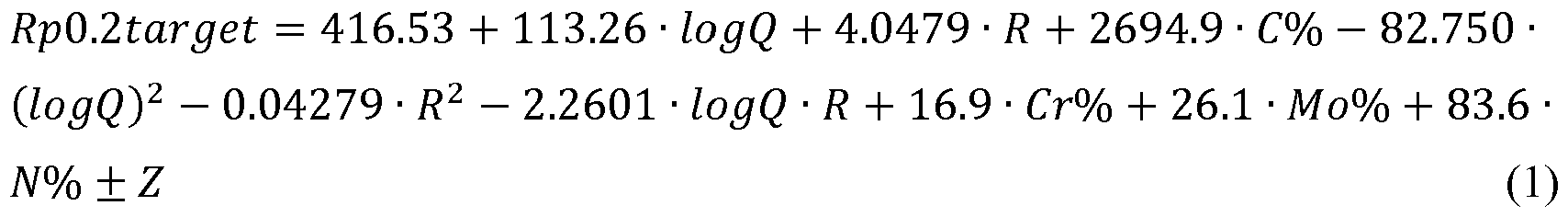

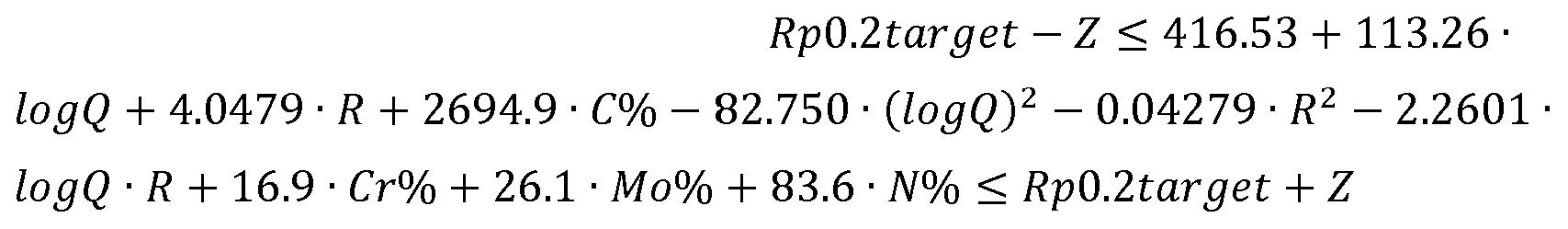

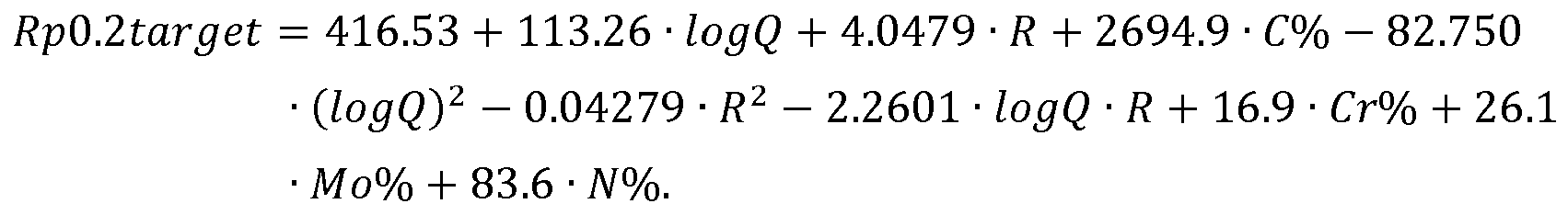

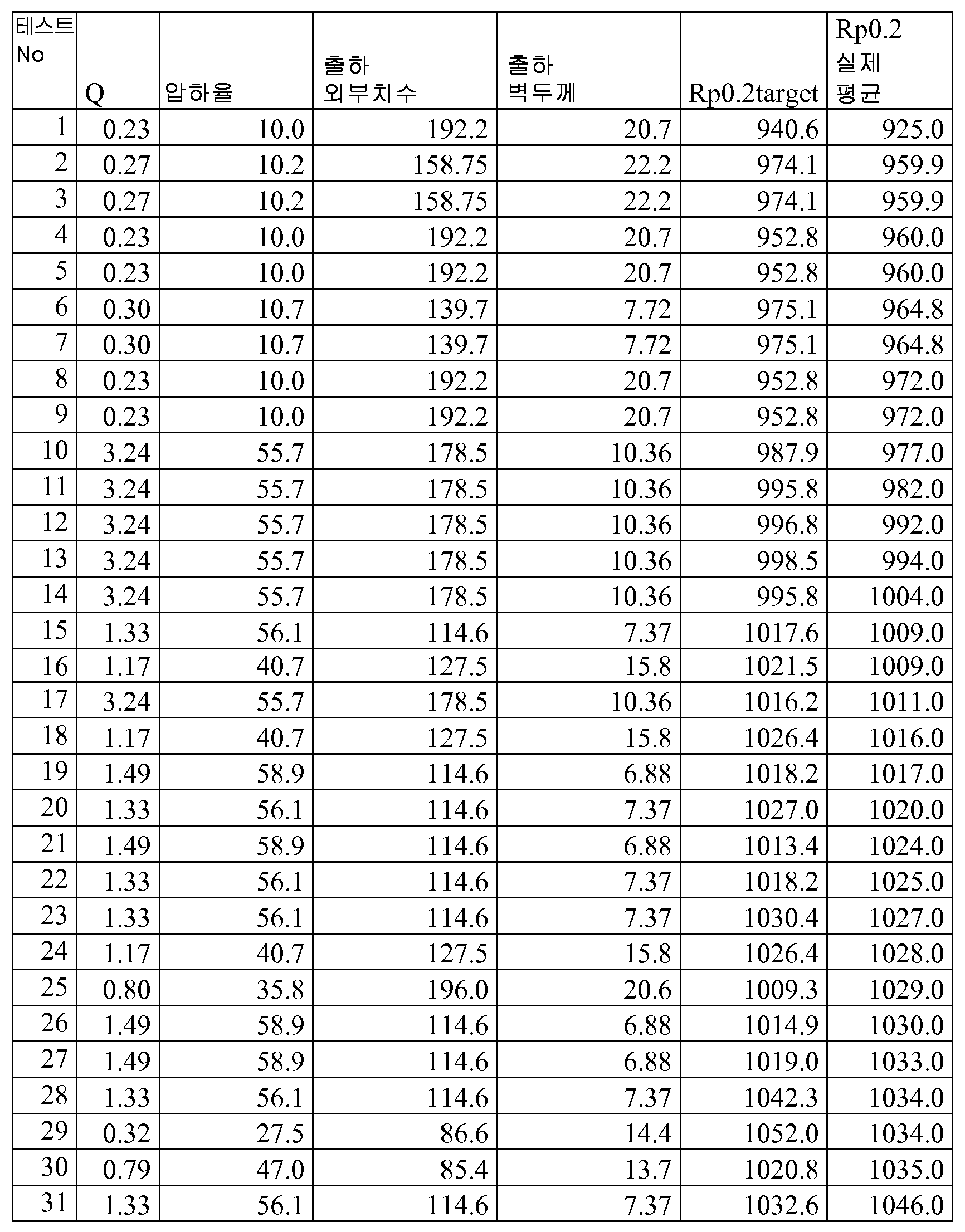

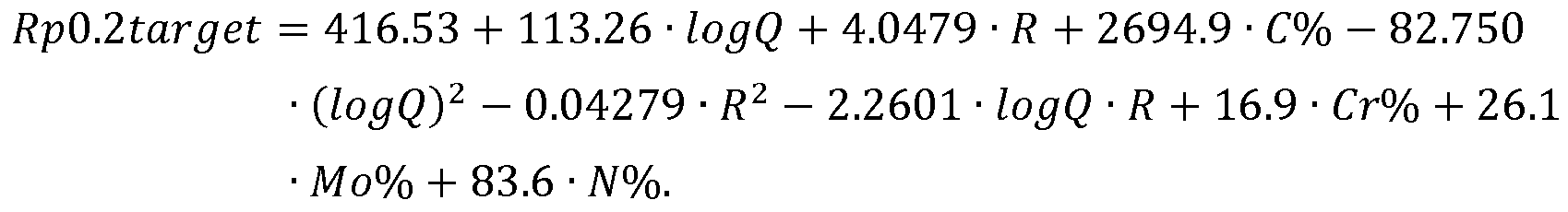

상기 냉간 압연하는 단계 동안, R 및 Q 는 다음의 식을 만족하도록 설정되고:

여기서, - Rp0.2target 은 타겟팅된 항복 강도이고 800-1100 MPa 이고, - Q = (W0 - W1)x(OD0-W0)/W0((OD0-W0)-(OD1-W1)) (2)

- 여기서, W1 은 냉간 압연 전에 튜브 벽 두께이고, W0 는 냉간 압연 후에 튜브 벽 두께이고, OD1 는 냉간 압연 전에 튜브의 외부 치수이고, OD0 는 냉간 압연 후에 튜브의 외부 치수이고, - R 은 냉간 압하율이고 다음과 같이 규정되고,

여기서 A1 는 냉간 압연 전에 튜브 단면적이고 A0 는 냉간 압연 후에 튜브 단면적이고, - Z=65 이고, 여기서, 0<Q<3.6 이다.

Description

Claims (9)

- 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법으로서,

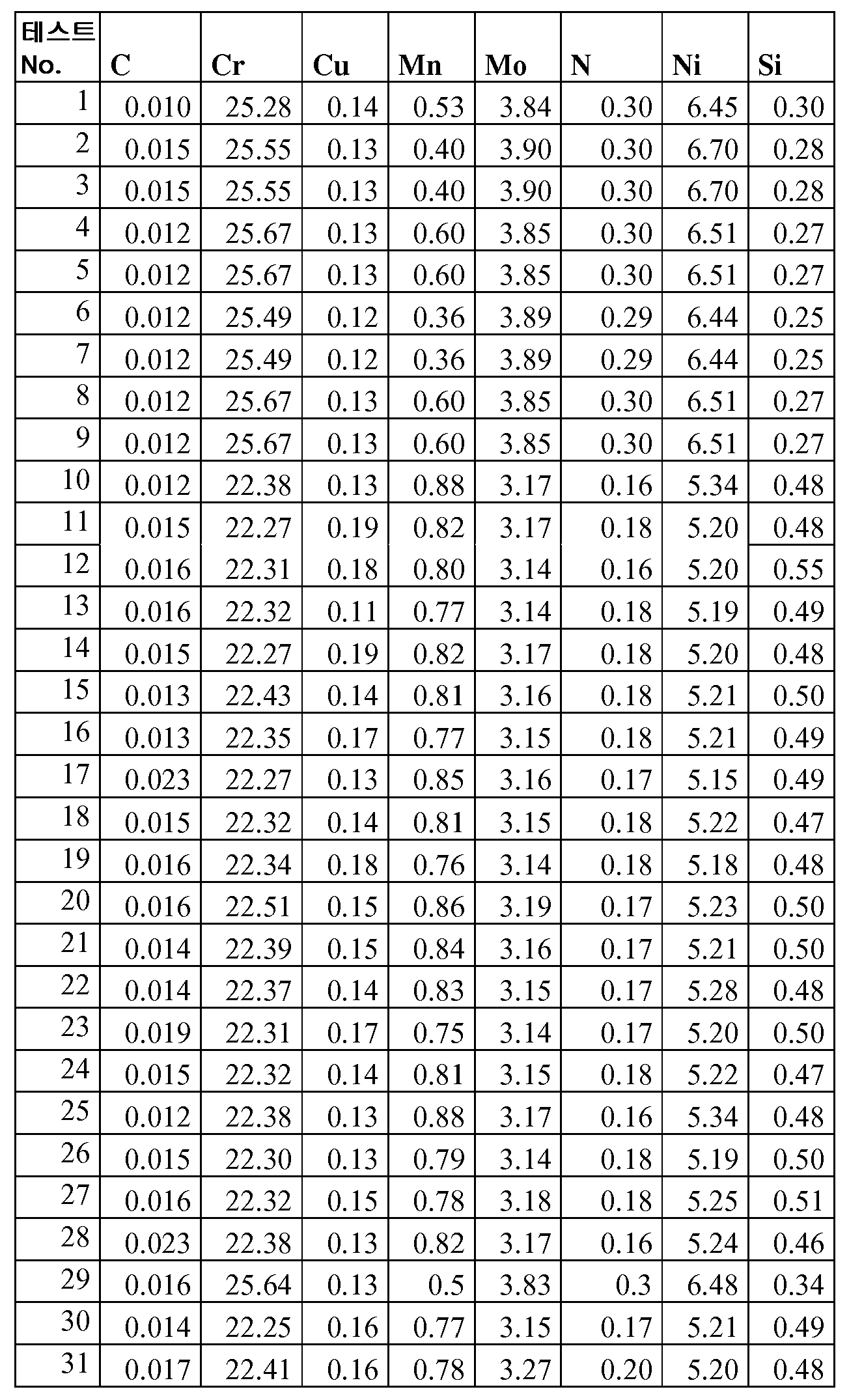

상기 듀플렉스 스테인레스 강은 (중량 % 로),

C 0-0.3;

Cr 22-26;

Cu 0-0.5;

Mn 0-1.2;

Mo 3.0-4.0;

N 0-0.35;

Ni 5.0-7.0;

Si 0.2-0.8;

잔부 Fe 및 불가피 불순물들을 갖고,

상기 방법은,

a) 상기 듀플렉스 스테인레스 강의 잉곳 또는 연속적으로 캐스팅된 빌렛을 제조하는 단계;

b) 튜브 내로 단계 a) 로부터 얻어진 상기 잉곳 또는 상기 빌렛을 열간 사출하는 단계; 및

c) 상기 튜브의 최종 치수로 단계 b) 로부터 얻어진 상기 튜브를 냉간 압연하는 단계를 포함하고;

냉간 압연된 상기 튜브의 외부 치수 (D) 및 벽 두께 (t) 는 각각 50-250 mm 및 5-25 mm 이고,

상기 냉간 압연하는 단계 동안, R 및 Q 는 다음의 식을 만족하도록 설정되고:

여기서,

- Rp0.2target 은 타겟팅된 항복 강도이고 800-1100 MPa 이고,

- Q = (W0 - W1)x(OD0-W0)/W0((OD0-W0)-(OD1-W1)) (2)

여기서, W1 은 냉간 압연 전에 튜브 벽 두께이고, W0 는 냉간 압연 후에 튜브 벽 두께이고, OD1 는 냉간 압연 전에 튜브의 외부 치수이고, OD0 는 냉간 압연 후에 튜브의 외부 치수이고,

- R 은 냉간 압하율이고 다음과 같이 규정되고:

- 여기서 A1 는 냉간 압연 전에 튜브 단면적이고 A0 는 냉간 압연 후에 튜브 단면적이고,

- Z=65 이고,

여기서, 0<Q<3.6 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항에 있어서,

0<Q<1 이면, 이때 25*Q<R<40*Q+20 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항에 있어서,

1≤Q≤2 이면, 이때 25*Q≤R≤60 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항에 있어서,

2<Q<3.6 이면, 이때 50<R<60 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항 내지 제 4 항 중 어느 한 항에 있어서,

상기 듀플렉스 스테인레스 강은 30-70 vol.% 오스테나이트 및 30-70 vol.% 페라이트를 포함하는, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항 내지 제 5 항 중 어느 한 항에 있어서,

상기 듀플렉스 스테인레스 강은 (중량 % 로),

C 0.008-0.03;

Cr 22-26;

Cu 0.1-0.2;

Mn 0.35-1.0;

Mo 3.0-4.0;

N 0.1-0.35;

Ni 5.0-7.0;

Si 0.2-0.7;

잔부 Fe 및 불가피 불순물들을 갖는, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항 내지 제 6 항 중 어느 한 항에 있어서,

Z=50 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법. - 제 1 항 내지 제 7 항 중 어느 한 항에 있어서,

Z=20 인, 듀플렉스 스테인레스 강 튜브를 제조하기 위한 방법.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP15203149 | 2015-12-30 | ||

| EP15203149.8 | 2015-12-30 | ||

| PCT/EP2016/082739 WO2017114847A1 (en) | 2015-12-30 | 2016-12-28 | A process of producing a duplex stainless steel tube |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098615A true KR20180098615A (ko) | 2018-09-04 |

| KR101968060B1 KR101968060B1 (ko) | 2019-04-10 |

Family

ID=55072483

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187021492A Expired - Fee Related KR101968060B1 (ko) | 2015-12-30 | 2016-12-28 | 듀플렉스 스테인레스 강 튜브를 제조하는 방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10704114B2 (ko) |

| EP (1) | EP3397406B1 (ko) |

| JP (1) | JP6550543B2 (ko) |

| KR (1) | KR101968060B1 (ko) |

| CN (1) | CN108472701B (ko) |

| ES (1) | ES2890331T3 (ko) |

| WO (1) | WO2017114847A1 (ko) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3640352A1 (en) | 2018-10-17 | 2020-04-22 | AB Sandvik Materials Technology | Method of producing tube of duplex stainless steel |

| CN111230406A (zh) * | 2018-11-28 | 2020-06-05 | 无锡市新峰管业有限公司 | 一种海洋环境下双相不锈钢管及其加工方法 |

| CN114289513B (zh) * | 2021-12-31 | 2024-12-24 | 江苏银环精密钢管有限公司 | 一种s32760超级双相不锈钢无缝管的制造方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6051081A (en) * | 1996-10-29 | 2000-04-18 | Tubacex, S.A. | Austenitic-ferritic steel of the superduplex type applicable to the fabrication of seamless tubes |

| KR20130109367A (ko) * | 2012-03-27 | 2013-10-08 | 주식회사 포스코 | 듀플렉스 스테인리스강의 제조방법 |

| JP2014040671A (ja) * | 2007-11-29 | 2014-03-06 | Ati Properties Inc | オーステナイト系のリーンステンレス鋼 |

| EP2853614A1 (en) * | 2012-08-31 | 2015-04-01 | Nippon Steel & Sumitomo Metal Corporation | Duplex stainless steel tube and method for producing same |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100554475C (zh) * | 2004-06-30 | 2009-10-28 | 住友金属工业株式会社 | Fe-Ni合金管坯及其制造方法 |

| JP5217277B2 (ja) * | 2007-07-20 | 2013-06-19 | 新日鐵住金株式会社 | 高合金管の製造方法 |

| JP5211841B2 (ja) * | 2007-07-20 | 2013-06-12 | 新日鐵住金株式会社 | 二相ステンレス鋼管の製造方法 |

| JP4420140B2 (ja) * | 2008-06-13 | 2010-02-24 | 住友金属工業株式会社 | 高合金継目無管の製造方法 |

| JP4462452B1 (ja) * | 2008-12-18 | 2010-05-12 | 住友金属工業株式会社 | 高合金管の製造方法 |

| WO2010082395A1 (ja) * | 2009-01-19 | 2010-07-22 | 住友金属工業株式会社 | 二相ステンレス鋼管の製造方法 |

| JP5137048B2 (ja) * | 2011-03-24 | 2013-02-06 | 新日鐵住金株式会社 | オーステナイト系合金管及びその製造方法 |

| DK2617858T3 (en) * | 2012-01-18 | 2015-10-05 | Sandvik Intellectual Property | Austenitic alloy |

| CN104962836A (zh) * | 2015-06-05 | 2015-10-07 | 山西太钢不锈钢股份有限公司 | 一种耐腐蚀铁基奥氏体油井管及其制造方法 |

-

2016

- 2016-12-28 JP JP2018534711A patent/JP6550543B2/ja not_active Expired - Fee Related

- 2016-12-28 EP EP16822199.2A patent/EP3397406B1/en active Active

- 2016-12-28 ES ES16822199T patent/ES2890331T3/es active Active

- 2016-12-28 US US16/066,156 patent/US10704114B2/en not_active Expired - Fee Related

- 2016-12-28 CN CN201680077169.4A patent/CN108472701B/zh not_active Expired - Fee Related

- 2016-12-28 WO PCT/EP2016/082739 patent/WO2017114847A1/en not_active Ceased

- 2016-12-28 KR KR1020187021492A patent/KR101968060B1/ko not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6051081A (en) * | 1996-10-29 | 2000-04-18 | Tubacex, S.A. | Austenitic-ferritic steel of the superduplex type applicable to the fabrication of seamless tubes |

| JP2014040671A (ja) * | 2007-11-29 | 2014-03-06 | Ati Properties Inc | オーステナイト系のリーンステンレス鋼 |

| KR20130109367A (ko) * | 2012-03-27 | 2013-10-08 | 주식회사 포스코 | 듀플렉스 스테인리스강의 제조방법 |

| EP2853614A1 (en) * | 2012-08-31 | 2015-04-01 | Nippon Steel & Sumitomo Metal Corporation | Duplex stainless steel tube and method for producing same |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2890331T3 (es) | 2022-01-18 |

| US10704114B2 (en) | 2020-07-07 |

| EP3397406B1 (en) | 2021-07-07 |

| EP3397406A1 (en) | 2018-11-07 |

| CN108472701B (zh) | 2020-02-18 |

| CN108472701A (zh) | 2018-08-31 |

| KR101968060B1 (ko) | 2019-04-10 |

| WO2017114847A1 (en) | 2017-07-06 |

| US20190010569A1 (en) | 2019-01-10 |

| JP6550543B2 (ja) | 2019-07-24 |

| JP2019505680A (ja) | 2019-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8333851B2 (en) | Method for producing two-phase stainless steel pipe | |

| US20180066344A1 (en) | Wire rod for use in bolts that has excellent acid pickling properties and resistance to delayed fracture after quenching and tempering, and bolt | |

| TW201538750A (zh) | 雙相不銹鋼 | |

| KR102583353B1 (ko) | 오스테나이트계 스테인리스 강 튜브의 제조 방법 | |

| KR101968060B1 (ko) | 듀플렉스 스테인레스 강 튜브를 제조하는 방법 | |

| CN111448326B (zh) | 具有优异的热加工性的通用铁素体不锈钢及其制造方法 | |

| US10329645B2 (en) | Steel for carburizing or carbonitriding use | |

| TW201608040A (zh) | 雙相不銹鋼 | |

| US10968504B2 (en) | Austenitic stainless alloy | |

| US20230287549A1 (en) | Austenitic stainless steel with improved deep drawing | |

| EP3797180B1 (en) | New austenitic alloy | |

| EP3752654B1 (en) | New duplex stainless steel | |

| CN111057963A (zh) | 生产双相不锈钢管的方法 | |

| KR102463015B1 (ko) | 열간가공성이 우수한 고강도 오스테나이트계 스테인리스강 | |

| CN119095999A (zh) | 新型双相不锈钢 | |

| KR20170121267A (ko) | 열간 압연 봉선재, 부품 및 열간 압연 봉선재의 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| A302 | Request for accelerated examination | ||

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PA0302 | Request for accelerated examination |

St.27 status event code: A-1-2-D10-D17-exm-PA0302 St.27 status event code: A-1-2-D10-D16-exm-PA0302 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 20240405 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 20240405 |