KR20140069043A - 포스트-cmp 세정 장치 및 방법 - Google Patents

포스트-cmp 세정 장치 및 방법 Download PDFInfo

- Publication number

- KR20140069043A KR20140069043A KR1020147008038A KR20147008038A KR20140069043A KR 20140069043 A KR20140069043 A KR 20140069043A KR 1020147008038 A KR1020147008038 A KR 1020147008038A KR 20147008038 A KR20147008038 A KR 20147008038A KR 20140069043 A KR20140069043 A KR 20140069043A

- Authority

- KR

- South Korea

- Prior art keywords

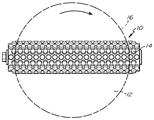

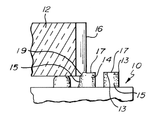

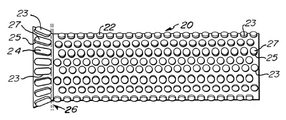

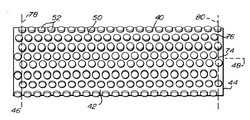

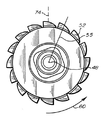

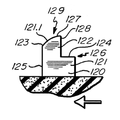

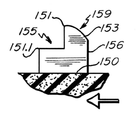

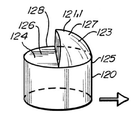

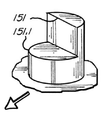

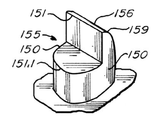

- nodules

- brush

- cylindrical base

- cylindrical

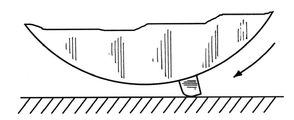

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H10P72/0412—

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67028—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like

- H01L21/6704—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing

- H01L21/67046—Apparatus for fluid treatment for cleaning followed by drying, rinsing, stripping, blasting or the like for wet cleaning or washing using mainly scrubbing means, e.g. brushes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02041—Cleaning

- H01L21/02057—Cleaning during device manufacture

- H01L21/02068—Cleaning during device manufacture during, before or after processing of conductive layers, e.g. polysilicon or amorphous silicon layers

- H01L21/02074—Cleaning during device manufacture during, before or after processing of conductive layers, e.g. polysilicon or amorphous silicon layers the processing being a planarization of conductive layers

-

- H10P70/277—

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Cleaning In General (AREA)

- Rolls And Other Rotary Bodies (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201161539342P | 2011-09-26 | 2011-09-26 | |

| US61/539,342 | 2011-09-26 | ||

| PCT/US2012/057337 WO2013049207A2 (en) | 2011-09-26 | 2012-09-26 | Post-cmp cleaning apparatus and method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20140069043A true KR20140069043A (ko) | 2014-06-09 |

Family

ID=47996722

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147008038A Withdrawn KR20140069043A (ko) | 2011-09-26 | 2012-09-26 | 포스트-cmp 세정 장치 및 방법 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20140230170A1 (enExample) |

| JP (1) | JP2014534615A (enExample) |

| KR (1) | KR20140069043A (enExample) |

| CN (1) | CN103918063A (enExample) |

| TW (1) | TW201318779A (enExample) |

| WO (1) | WO2013049207A2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20160052343A (ko) * | 2014-10-31 | 2016-05-12 | 가부시키가이샤 에바라 세이사꾸쇼 | 롤 부재, 펜슬 부재 및 그들 중 적어도 어느 한쪽을 포함하는 기판 처리 장치 |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10504753B2 (en) * | 2013-12-13 | 2019-12-10 | Taiwan Semiconductor Manufacturing Co., Ltd. | Brush cleaning apparatus, chemical-mechanical polishing (CMP) system and wafer processing method |

| US10790167B2 (en) | 2014-02-20 | 2020-09-29 | Entegris, Inc. | Nodule ratios for targeted enhanced cleaning performance |

| US9873180B2 (en) | 2014-10-17 | 2018-01-23 | Applied Materials, Inc. | CMP pad construction with composite material properties using additive manufacturing processes |

| KR102295988B1 (ko) | 2014-10-17 | 2021-09-01 | 어플라이드 머티어리얼스, 인코포레이티드 | 애디티브 제조 프로세스들을 이용한 복합 재료 특성들을 갖는 cmp 패드 구성 |

| US9776361B2 (en) | 2014-10-17 | 2017-10-03 | Applied Materials, Inc. | Polishing articles and integrated system and methods for manufacturing chemical mechanical polishing articles |

| US11745302B2 (en) | 2014-10-17 | 2023-09-05 | Applied Materials, Inc. | Methods and precursor formulations for forming advanced polishing pads by use of an additive manufacturing process |

| US10875153B2 (en) | 2014-10-17 | 2020-12-29 | Applied Materials, Inc. | Advanced polishing pad materials and formulations |

| KR102389613B1 (ko) | 2015-05-06 | 2022-04-22 | 삼성전자주식회사 | 기판 세정 장치 |

| CN113103145B (zh) | 2015-10-30 | 2023-04-11 | 应用材料公司 | 形成具有期望ζ电位的抛光制品的设备与方法 |

| US10593574B2 (en) | 2015-11-06 | 2020-03-17 | Applied Materials, Inc. | Techniques for combining CMP process tracking data with 3D printed CMP consumables |

| US10391605B2 (en) | 2016-01-19 | 2019-08-27 | Applied Materials, Inc. | Method and apparatus for forming porous advanced polishing pads using an additive manufacturing process |

| JP6643942B2 (ja) * | 2016-04-12 | 2020-02-12 | 株式会社荏原製作所 | 洗浄部材、基板洗浄装置及び基板処理装置 |

| US11923208B2 (en) * | 2017-05-19 | 2024-03-05 | Illinois Tool Works Inc. | Methods and apparatuses for chemical delivery for brush conditioning |

| US11471999B2 (en) | 2017-07-26 | 2022-10-18 | Applied Materials, Inc. | Integrated abrasive polishing pads and manufacturing methods |

| WO2019032286A1 (en) | 2017-08-07 | 2019-02-14 | Applied Materials, Inc. | ABRASIVE DISTRIBUTION POLISHING PADS AND METHODS OF MAKING SAME |

| WO2020050932A1 (en) | 2018-09-04 | 2020-03-12 | Applied Materials, Inc. | Formulations for advanced polishing pads |

| US11694910B2 (en) * | 2019-09-10 | 2023-07-04 | Illinois Tool Works Inc. | Brush with non-constant nodule density |

| US11470956B2 (en) | 2020-03-06 | 2022-10-18 | Applied Materials, Inc. | Brush, method of forming a brush, and structure embodied in a machine readable medium used in a design process |

| US11878389B2 (en) | 2021-02-10 | 2024-01-23 | Applied Materials, Inc. | Structures formed using an additive manufacturing process for regenerating surface texture in situ |

| JP2022134658A (ja) * | 2021-03-03 | 2022-09-15 | アイオン株式会社 | ブラシローラ |

| JP7714819B2 (ja) * | 2022-05-31 | 2025-07-29 | インテグリス・インコーポレーテッド | 半導体作製プロセスのための洗浄ブラシ |

| JP2024047416A (ja) * | 2022-09-26 | 2024-04-05 | 株式会社Screenホールディングス | 基板洗浄ブラシおよび基板洗浄装置 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS596974A (ja) * | 1982-07-05 | 1984-01-14 | カネボウ株式会社 | 洗浄方法 |

| US6299698B1 (en) * | 1998-07-10 | 2001-10-09 | Applied Materials, Inc. | Wafer edge scrubber and method |

| JP4554011B2 (ja) * | 1999-08-10 | 2010-09-29 | ルネサスエレクトロニクス株式会社 | 半導体集積回路装置の製造方法 |

| US6467120B1 (en) * | 1999-09-08 | 2002-10-22 | International Business Machines Corporation | Wafer cleaning brush profile modification |

| JP2001358110A (ja) * | 2000-06-13 | 2001-12-26 | Hitachi Ltd | スクラブ洗浄装置およびそれを用いた半導体装置の製造方法 |

| JP2003051481A (ja) * | 2001-08-07 | 2003-02-21 | Hitachi Ltd | 半導体集積回路装置の製造方法 |

| CN1863645B (zh) * | 2003-08-08 | 2011-11-30 | 安格斯公司 | 用于制作浇注在可旋转基体上的整体式多孔垫的方法和材料 |

| US7469443B2 (en) * | 2005-01-10 | 2008-12-30 | Intel Corporation | Brush for cleaning wafer |

| JP2008119621A (ja) * | 2006-11-14 | 2008-05-29 | Matsushita Electric Ind Co Ltd | 洗浄用ローラブラシ |

| JP2009117765A (ja) * | 2007-11-09 | 2009-05-28 | Aion Kk | 洗浄用スポンジローラ |

| KR101579572B1 (ko) * | 2008-06-30 | 2015-12-22 | 아이온 가부시키가이샤 | 세정용 스폰지 롤러 |

| USD682497S1 (en) * | 2010-12-21 | 2013-05-14 | Entegris, Inc. | Substrate cleaning brush |

-

2012

- 2012-09-26 CN CN201280045932.7A patent/CN103918063A/zh active Pending

- 2012-09-26 US US14/347,170 patent/US20140230170A1/en not_active Abandoned

- 2012-09-26 KR KR1020147008038A patent/KR20140069043A/ko not_active Withdrawn

- 2012-09-26 JP JP2014533684A patent/JP2014534615A/ja active Pending

- 2012-09-26 WO PCT/US2012/057337 patent/WO2013049207A2/en not_active Ceased

- 2012-09-26 TW TW101135344A patent/TW201318779A/zh unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20160052343A (ko) * | 2014-10-31 | 2016-05-12 | 가부시키가이샤 에바라 세이사꾸쇼 | 롤 부재, 펜슬 부재 및 그들 중 적어도 어느 한쪽을 포함하는 기판 처리 장치 |

| US11642704B2 (en) | 2014-10-31 | 2023-05-09 | Ebara Corporation | Roll-type processing member, pencil-type processing member, and substrate processing apparatus including any one of these |

Also Published As

| Publication number | Publication date |

|---|---|

| TW201318779A (zh) | 2013-05-16 |

| WO2013049207A3 (en) | 2013-07-11 |

| JP2014534615A (ja) | 2014-12-18 |

| US20140230170A1 (en) | 2014-08-21 |

| CN103918063A (zh) | 2014-07-09 |

| WO2013049207A2 (en) | 2013-04-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20140069043A (ko) | 포스트-cmp 세정 장치 및 방법 | |

| JP5977175B2 (ja) | Cmp後の洗浄ブラシ | |

| CN100366391C (zh) | 具有取决于工艺的槽结构的化学机械抛光基台 | |

| US7648410B2 (en) | Polishing pad and chemical mechanical polishing apparatus | |

| US6467120B1 (en) | Wafer cleaning brush profile modification | |

| US11694909B2 (en) | Brush cleaning apparatus, chemical-mechanical polishing (CMP) system and wafer processing method | |

| WO2003061904B1 (en) | Chemical mechanical polishing apparatus and method having a retaining ring with a contoured surface for slurry distribution | |

| WO2015057432A1 (en) | Cmp polishing pad having edge exclusion region of offset concentric groove pattern | |

| KR101929739B1 (ko) | 브러시 코어 및 브러시 구동 방법 | |

| US20250353138A1 (en) | Chemical-mechanical planarization pad and methods of use | |

| US7185384B2 (en) | Wafer cleaning brush | |

| KR20170077210A (ko) | 기판 세정 롤, 기판 세정 장치, 및 기판 세정 방법 | |

| TWI670763B (zh) | 一種用於在一化學機械研磨製程之後清潔晶圓之刷具與方法 | |

| WO2006026271A1 (en) | An optimized grooving structure for a cmp polishing pad | |

| US20090042494A1 (en) | Pad conditioner of semiconductor wafer polishing apparatus and manufacturing method thereof | |

| WO2003057405A1 (en) | Grooved rollers for a linear chemical mechanical planarization system | |

| US6101656A (en) | Wafer cleaning device | |

| KR20060116488A (ko) | 반도체 웨이퍼용 세정 브러쉬 | |

| CN223820307U (en) | Wafer fixing ring | |

| KR20090023778A (ko) | Cmp 패드 컨디셔닝 디스크 | |

| US6461441B1 (en) | Method of removing debris from cleaning pads in work piece cleaning equipment | |

| KR200195122Y1 (ko) | 반도체 웨이퍼 연마 패드 | |

| TW202237283A (zh) | 刷輥 | |

| TWM576921U (zh) | Cleaning brush structure | |

| KR20060070158A (ko) | 웨이퍼 세정장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| R17-X000 | Change to representative recorded |

St.27 status event code: A-3-3-R10-R17-oth-X000 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-3-3-R10-R18-oth-X000 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-3-3-R10-R18-oth-X000 |

|

| PC1203 | Withdrawal of no request for examination |

St.27 status event code: N-1-6-B10-B12-nap-PC1203 |

|

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid | ||

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-3-3-R10-R18-oth-X000 |

|

| P22-X000 | Classification modified |

St.27 status event code: A-2-2-P10-P22-nap-X000 |