KR20130064730A - 복합 층 - Google Patents

복합 층 Download PDFInfo

- Publication number

- KR20130064730A KR20130064730A KR1020127027301A KR20127027301A KR20130064730A KR 20130064730 A KR20130064730 A KR 20130064730A KR 1020127027301 A KR1020127027301 A KR 1020127027301A KR 20127027301 A KR20127027301 A KR 20127027301A KR 20130064730 A KR20130064730 A KR 20130064730A

- Authority

- KR

- South Korea

- Prior art keywords

- composite layer

- shims

- cavity

- die

- shim

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000002131 composite material Substances 0.000 title claims abstract description 79

- 239000000463 material Substances 0.000 claims abstract description 89

- 239000011159 matrix material Substances 0.000 claims abstract description 4

- 230000001070 adhesive effect Effects 0.000 claims description 58

- 239000000853 adhesive Substances 0.000 claims description 53

- 238000000034 method Methods 0.000 claims description 16

- 239000003795 chemical substances by application Substances 0.000 claims description 7

- 239000010410 layer Substances 0.000 description 62

- 238000001125 extrusion Methods 0.000 description 33

- 229920000642 polymer Polymers 0.000 description 27

- -1 polytetrafluoroethylene Polymers 0.000 description 20

- 229920001577 copolymer Polymers 0.000 description 13

- 239000004698 Polyethylene Substances 0.000 description 12

- 125000006850 spacer group Chemical group 0.000 description 12

- 239000000178 monomer Substances 0.000 description 10

- 229920000573 polyethylene Polymers 0.000 description 10

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 9

- 239000002861 polymer material Substances 0.000 description 9

- 239000003086 colorant Substances 0.000 description 8

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 7

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 7

- 239000004743 Polypropylene Substances 0.000 description 7

- 229920000139 polyethylene terephthalate Polymers 0.000 description 7

- 239000000203 mixture Substances 0.000 description 6

- 239000005020 polyethylene terephthalate Substances 0.000 description 6

- 210000003491 skin Anatomy 0.000 description 6

- 229910001220 stainless steel Inorganic materials 0.000 description 6

- 239000010935 stainless steel Substances 0.000 description 6

- 239000012530 fluid Substances 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- 229920001155 polypropylene Polymers 0.000 description 5

- GOXQRTZXKQZDDN-UHFFFAOYSA-N 2-Ethylhexyl acrylate Chemical compound CCCCC(CC)COC(=O)C=C GOXQRTZXKQZDDN-UHFFFAOYSA-N 0.000 description 4

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 4

- 230000008901 benefit Effects 0.000 description 4

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 229920001971 elastomer Polymers 0.000 description 4

- 239000008188 pellet Substances 0.000 description 4

- 229920000728 polyester Polymers 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 230000003287 optical effect Effects 0.000 description 3

- 229920001296 polysiloxane Polymers 0.000 description 3

- 239000004814 polyurethane Substances 0.000 description 3

- 229920002635 polyurethane Polymers 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- DXPPIEDUBFUSEZ-UHFFFAOYSA-N 6-methylheptyl prop-2-enoate Chemical compound CC(C)CCCCCOC(=O)C=C DXPPIEDUBFUSEZ-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 239000004793 Polystyrene Substances 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 239000002390 adhesive tape Substances 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 238000007796 conventional method Methods 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 239000000806 elastomer Substances 0.000 description 2

- 238000010894 electron beam technology Methods 0.000 description 2

- FJKIXWOMBXYWOQ-UHFFFAOYSA-N ethenoxyethane Chemical compound CCOC=C FJKIXWOMBXYWOQ-UHFFFAOYSA-N 0.000 description 2

- 230000009969 flowable effect Effects 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 229920000098 polyolefin Polymers 0.000 description 2

- 229920006124 polyolefin elastomer Polymers 0.000 description 2

- 229920002223 polystyrene Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 239000004810 polytetrafluoroethylene Substances 0.000 description 2

- 239000004800 polyvinyl chloride Substances 0.000 description 2

- 229920000915 polyvinyl chloride Polymers 0.000 description 2

- 239000005060 rubber Substances 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 241000282472 Canis lupus familiaris Species 0.000 description 1

- 241000723418 Carya Species 0.000 description 1

- 229920008347 Cellulose acetate propionate Polymers 0.000 description 1

- 229920002284 Cellulose triacetate Polymers 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 244000043261 Hevea brasiliensis Species 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 241001330988 Palmyra Species 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000005062 Polybutadiene Substances 0.000 description 1

- 239000004695 Polyether sulfone Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 229920002396 Polyurea Polymers 0.000 description 1

- BZHJMEDXRYGGRV-UHFFFAOYSA-N Vinyl chloride Chemical compound ClC=C BZHJMEDXRYGGRV-UHFFFAOYSA-N 0.000 description 1

- NNLVGZFZQQXQNW-ADJNRHBOSA-N [(2r,3r,4s,5r,6s)-4,5-diacetyloxy-3-[(2s,3r,4s,5r,6r)-3,4,5-triacetyloxy-6-(acetyloxymethyl)oxan-2-yl]oxy-6-[(2r,3r,4s,5r,6s)-4,5,6-triacetyloxy-2-(acetyloxymethyl)oxan-3-yl]oxyoxan-2-yl]methyl acetate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](OC(C)=O)[C@H]1OC(C)=O)O[C@H]1[C@@H]([C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](COC(C)=O)O1)OC(C)=O)COC(=O)C)[C@@H]1[C@@H](COC(C)=O)O[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@H]1OC(C)=O NNLVGZFZQQXQNW-ADJNRHBOSA-N 0.000 description 1

- 239000012080 ambient air Substances 0.000 description 1

- 229920001400 block copolymer Polymers 0.000 description 1

- 229920005549 butyl rubber Polymers 0.000 description 1

- 229920006217 cellulose acetate butyrate Polymers 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000001351 cycling effect Effects 0.000 description 1

- 239000000975 dye Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000004299 exfoliation Methods 0.000 description 1

- 230000001747 exhibiting effect Effects 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- LNMQRPPRQDGUDR-UHFFFAOYSA-N hexyl prop-2-enoate Chemical compound CCCCCCOC(=O)C=C LNMQRPPRQDGUDR-UHFFFAOYSA-N 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- 208000014674 injury Diseases 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- KYTZHLUVELPASH-UHFFFAOYSA-N naphthalene-1,2-dicarboxylic acid Chemical compound C1=CC=CC2=C(C(O)=O)C(C(=O)O)=CC=C21 KYTZHLUVELPASH-UHFFFAOYSA-N 0.000 description 1

- 229920003052 natural elastomer Polymers 0.000 description 1

- 229920001194 natural rubber Polymers 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000000049 pigment Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920001084 poly(chloroprene) Polymers 0.000 description 1

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 1

- 229920001200 poly(ethylene-vinyl acetate) Polymers 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920002857 polybutadiene Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 229920006393 polyether sulfone Polymers 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 229920003225 polyurethane elastomer Polymers 0.000 description 1

- SCUZVMOVTVSBLE-UHFFFAOYSA-N prop-2-enenitrile;styrene Chemical compound C=CC#N.C=CC1=CC=CC=C1 SCUZVMOVTVSBLE-UHFFFAOYSA-N 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 230000000171 quenching effect Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000003014 reinforcing effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 210000004927 skin cell Anatomy 0.000 description 1

- 229920000638 styrene acrylonitrile Polymers 0.000 description 1

- 229920006132 styrene block copolymer Polymers 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000002834 transmittance Methods 0.000 description 1

- 230000008733 trauma Effects 0.000 description 1

- 239000010981 turquoise Substances 0.000 description 1

- 238000012800 visualization Methods 0.000 description 1

- 229940089401 xylon Drugs 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

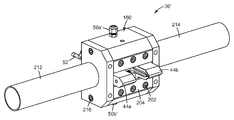

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

- B29C48/21—Articles comprising two or more components, e.g. co-extruded layers the components being layers the layers being joined at their surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/03—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor characterised by the shape of the extruded material at extrusion

- B29C48/07—Flat, e.g. panels

- B29C48/08—Flat, e.g. panels flexible, e.g. films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/16—Articles comprising two or more components, e.g. co-extruded layers

- B29C48/18—Articles comprising two or more components, e.g. co-extruded layers the components being layers

- B29C48/19—Articles comprising two or more components, e.g. co-extruded layers the components being layers the layers being joined at their edges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

- B29C48/305—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets

- B29C48/307—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets specially adapted for bringing together components, e.g. melts within the die

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C48/00—Extrusion moulding, i.e. expressing the moulding material through a die or nozzle which imparts the desired form; Apparatus therefor

- B29C48/25—Component parts, details or accessories; Auxiliary operations

- B29C48/30—Extrusion nozzles or dies

- B29C48/305—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets

- B29C48/31—Extrusion nozzles or dies having a wide opening, e.g. for forming sheets being adjustable, i.e. having adjustable exit sections

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/10—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material

- B32B3/14—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material characterised by a face layer formed of separate pieces of material which are juxtaposed side-by-side

- B32B3/16—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material characterised by a face layer formed of separate pieces of material which are juxtaposed side-by-side secured to a flexible backing

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/04—Homopolymers or copolymers of ethene

- C09J123/06—Polyethene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J123/00—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers

- C09J123/02—Adhesives based on homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Adhesives based on derivatives of such polymers not modified by chemical after-treatment

- C09J123/10—Homopolymers or copolymers of propene

- C09J123/12—Polypropene

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J133/00—Adhesives based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Adhesives based on derivatives of such polymers

- C09J133/04—Homopolymers or copolymers of esters

- C09J133/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, the oxygen atom being present only as part of the carboxyl radical

- C09J133/08—Homopolymers or copolymers of acrylic acid esters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/04—Polymers of ethylene

- B29K2023/06—PE, i.e. polyethylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/10—Polymers of propylene

- B29K2023/12—PP, i.e. polypropylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2033/00—Use of polymers of unsaturated acids or derivatives thereof as moulding material

- B29K2033/04—Polymers of esters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/0097—Glues or adhesives, e.g. hot melts or thermofusible adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/764—Photographic equipment or accessories

- B29L2031/7644—Films

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2405/00—Adhesive articles, e.g. adhesive tapes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24479—Structurally defined web or sheet [e.g., overall dimension, etc.] including variation in thickness

- Y10T428/24612—Composite web or sheet

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Extrusion Moulding Of Plastics Or The Like (AREA)

- Laminated Bodies (AREA)

- Adhesive Tapes (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US31749010P | 2010-03-25 | 2010-03-25 | |

| US61/317,490 | 2010-03-25 | ||

| PCT/US2011/027549 WO2011119325A2 (en) | 2010-03-25 | 2011-03-08 | Composite layer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20130064730A true KR20130064730A (ko) | 2013-06-18 |

Family

ID=44120908

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020127027301A Ceased KR20130064730A (ko) | 2010-03-25 | 2011-03-08 | 복합 층 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US20130004729A1 (enExample) |

| EP (1) | EP2550156A2 (enExample) |

| JP (1) | JP5969456B2 (enExample) |

| KR (1) | KR20130064730A (enExample) |

| CN (2) | CN105399971B (enExample) |

| BR (1) | BR112012024365A2 (enExample) |

| WO (1) | WO2011119325A2 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011097436A1 (en) | 2010-02-08 | 2011-08-11 | 3M Innovative Properties Company | Method of co-extruding, co-extrusion die, and extruded articles made therefrom |

| US8758882B2 (en) * | 2010-03-25 | 2014-06-24 | 3M Innovative Properties Company | Composite layer |

| WO2011119323A1 (en) | 2010-03-25 | 2011-09-29 | 3M Innovative Properties Company | Extrusion die element, extrusion die and method for making multiple stripe extrudate |

| US9724865B2 (en) | 2011-10-05 | 2017-08-08 | 3M Innovative Properties Company | Three-dimensional polymeric strand netting, dies, and methods of making the same |

| EP2830863B1 (en) | 2012-03-26 | 2016-05-25 | 3M Innovative Properties Company | Films comprising an array of openings and methods of making the same |

| US9944043B2 (en) | 2012-10-02 | 2018-04-17 | 3M Innovative Properties Company | Laminates and methods of making the same |

| US10272655B2 (en) | 2012-10-02 | 2019-04-30 | 3M Innovative Properties Company | Film with alternating stripes and strands and apparatus and method for making the same |

| US20140248471A1 (en) | 2013-03-01 | 2014-09-04 | 3M Innovative Properties Company | Film with Layered Segments and Apparatus and Method for Making the Same |

| BR112015022744A2 (pt) | 2013-03-13 | 2017-07-18 | 3M Innovative Properties Co | enredamentos, matrizes e métodos de fabricação dos mesmos |

| US9944764B2 (en) | 2013-05-23 | 2018-04-17 | 3M Innovative Properties Company | Reticulated thermoplastic film and method of making the same |

| US9649824B2 (en) | 2013-05-23 | 2017-05-16 | 3M Innovative Properties Company | Laminates including a reticulated thermoplastic film and method of making the same |

| US10099408B2 (en) | 2013-06-27 | 2018-10-16 | 3M Innovative Properties Company | Polymeric layers and methods of making the same |

| CN104869754B (zh) * | 2014-02-25 | 2018-06-26 | 财团法人工业技术研究院 | 嵌有导线的软性基板及其制造方法 |

| EP3110617A4 (en) | 2014-02-28 | 2017-11-22 | 3M Innovative Properties Company | Polymeric netting of strands and first and second ribbons and methods of making the same |

| MX361639B (es) | 2014-02-28 | 2018-12-13 | 3M Innovative Properties Co | Medio de filtración que incluye malla polimérica de cintas y hebras. |

| JP7530542B2 (ja) * | 2020-03-19 | 2024-08-08 | グンゼ株式会社 | 部分機能性フィルム |

| JP7593741B2 (ja) * | 2020-03-26 | 2024-12-03 | ノードソン コーポレーション | ノズル、接着剤塗布ヘッド、接着剤塗布装置及びおむつ製造方法 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2031387A (en) * | 1934-08-22 | 1936-02-18 | Schwarz Arthur | Nozzle |

| US2884126A (en) | 1955-11-18 | 1959-04-28 | Minnesota Mining & Mfg | Pressure-sensitive adhesive sheet material |

| US3485912A (en) * | 1965-02-09 | 1969-12-23 | Dow Chemical Co | Composite article formation |

| US3770357A (en) * | 1971-11-15 | 1973-11-06 | American Optical Corp | Extrusion die |

| US5080957A (en) * | 1989-08-01 | 1992-01-14 | Minnesota Mining And Manufacturing Company | Tape having partially embedded ribs |

| CA2116679C (en) * | 1991-10-01 | 2003-11-04 | David B. Herridge | Coextruded pressure-sensitive adhesive tape and method of making |

| US5585178A (en) * | 1991-12-31 | 1996-12-17 | Minnesota Mining & Manufacturing Company | Composite adhesive tape |

| US5679379A (en) * | 1995-01-09 | 1997-10-21 | Fabbricante; Anthony S. | Disposable extrusion apparatus with pressure balancing modular die units for the production of nonwoven webs |

| US5648166A (en) | 1995-02-21 | 1997-07-15 | Minnesota Mining And Manufacturing Company | Pressure-sensitive adhesives and tape articles |

| WO1997000168A1 (en) * | 1995-06-14 | 1997-01-03 | Mitsubishi Rayon Co., Ltd. | Resin sheet, method and apparatus for producing the same, surface light source, and laminated body |

| US5866265A (en) * | 1996-03-08 | 1999-02-02 | The Goodyear Tire & Rubber Company | Rubber article having a surface design for high abrasion resistance |

| JPH09300425A (ja) * | 1996-05-20 | 1997-11-25 | Mitsubishi Rayon Co Ltd | 複合シートの製造装置および製造方法 |

| US5902540A (en) * | 1996-10-08 | 1999-05-11 | Illinois Tool Works Inc. | Meltblowing method and apparatus |

| US6187432B1 (en) * | 1997-03-11 | 2001-02-13 | Avery Dennison Corporation | Composite pressure sensitive adhesive |

| AU9491098A (en) * | 1997-09-18 | 1999-04-05 | D.W. Wallcovering, Inc. | Repositionable article |

| US6171985B1 (en) | 1997-12-01 | 2001-01-09 | 3M Innovative Properties Company | Low trauma adhesive article |

| US6927315B1 (en) * | 1999-07-30 | 2005-08-09 | 3M Innovative Properties Company | Adhesive composite having distinct phases |

| WO2001045918A1 (en) * | 1999-12-20 | 2001-06-28 | The Goodyear Tire & Rubber Company | An apparatus and method for extruding a multilayered elastomer product |

| DE10139653A1 (de) * | 2001-08-11 | 2003-02-20 | Tesa Ag | Etikett mit erhöhter Fälschungssicherheit |

| US6949283B2 (en) * | 2001-12-19 | 2005-09-27 | 3M Innovative Properties Company | Polymeric coextruded multilayer articles |

| US20050003035A1 (en) * | 2003-04-11 | 2005-01-06 | Jerry Zucker | Method for forming polymer materials utilizing modular die units |

| US20070154683A1 (en) * | 2005-12-29 | 2007-07-05 | 3M Innovative Properties Company | Microstriped film |

| US20080078500A1 (en) * | 2006-10-02 | 2008-04-03 | 3M Innovative Properties Company | Method of manufacturing structured release liner |

| US7780812B2 (en) * | 2006-11-01 | 2010-08-24 | Palo Alto Research Center Incorporated | Extrusion head with planarized edge surface |

| US8226391B2 (en) * | 2006-11-01 | 2012-07-24 | Solarworld Innovations Gmbh | Micro-extrusion printhead nozzle with tapered cross-section |

| US8322025B2 (en) * | 2006-11-01 | 2012-12-04 | Solarworld Innovations Gmbh | Apparatus for forming a plurality of high-aspect ratio gridline structures |

| JP2009072986A (ja) * | 2007-09-19 | 2009-04-09 | Idemitsu Technofine Co Ltd | 積層体 |

| US20090162595A1 (en) * | 2007-12-19 | 2009-06-25 | Chan Ko | Striped adhesive construction and method and die for making same |

| DE102008024804A1 (de) * | 2008-05-23 | 2009-11-26 | Ewald Dörken Ag | Flächiges Klebemittel, wie Klebeband, Klebefolie oder Kleberand, insbesondere zur Verwendung im Baubereich |

| CA2732976A1 (en) * | 2008-08-05 | 2010-02-11 | Giesecke & Devrient Gmbh | Security arrangement |

| US9643394B2 (en) * | 2011-02-01 | 2017-05-09 | Palo Alto Research Center Incorporated | Oblique angle micromachining of fluidic structures |

-

2011

- 2011-03-08 CN CN201510745005.1A patent/CN105399971B/zh not_active Expired - Fee Related

- 2011-03-08 EP EP11710593A patent/EP2550156A2/en not_active Withdrawn

- 2011-03-08 US US13/635,701 patent/US20130004729A1/en not_active Abandoned

- 2011-03-08 WO PCT/US2011/027549 patent/WO2011119325A2/en not_active Ceased

- 2011-03-08 BR BR112012024365A patent/BR112012024365A2/pt not_active Application Discontinuation

- 2011-03-08 CN CN201180023024.3A patent/CN102883877B/zh not_active Expired - Fee Related

- 2011-03-08 KR KR1020127027301A patent/KR20130064730A/ko not_active Ceased

- 2011-03-08 JP JP2013501287A patent/JP5969456B2/ja not_active Expired - Fee Related

-

2017

- 2017-03-28 US US15/471,831 patent/US20170197347A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| CN105399971A (zh) | 2016-03-16 |

| WO2011119325A2 (en) | 2011-09-29 |

| JP2013523484A (ja) | 2013-06-17 |

| JP5969456B2 (ja) | 2016-08-17 |

| US20170197347A1 (en) | 2017-07-13 |

| CN102883877B (zh) | 2016-03-16 |

| US20130004729A1 (en) | 2013-01-03 |

| CN102883877A (zh) | 2013-01-16 |

| EP2550156A2 (en) | 2013-01-30 |

| BR112012024365A2 (pt) | 2017-07-18 |

| WO2011119325A3 (en) | 2012-02-23 |

| CN105399971B (zh) | 2019-03-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20130064730A (ko) | 복합 층 | |

| KR20130064729A (ko) | 복합 층 | |

| CN102905871B (zh) | 挤出模头元件、挤出模头和用于制备多条带挤出物的方法 | |

| US4405547A (en) | Method of coextruding diverse materials | |

| EP0050476B1 (en) | Coextrusion device and method | |

| CN102271893A (zh) | 共挤出模头、使用该模头的挤出方法以及由其制成的挤出制品 | |

| CN102869496B (zh) | 复合层 | |

| CN102905882A (zh) | 复合层 | |

| US4784815A (en) | Edge-laminating apparatus and process | |

| JP2928108B2 (ja) | 複合樹脂シートの製造装置及びその製造方法 | |

| TW201716241A (zh) | 旋轉變色陣列以及其製備和使用方法 | |

| US12023841B2 (en) | Coextruded polymeric article and method of making the same | |

| JP3589606B2 (ja) | 表皮木目模様の形成方法及びそのダイス構造 | |

| US11975469B2 (en) | Coextruded polymeric nettings and method of making the same | |

| CA1200357A (en) | Extruding laminated sheet with alteration of stream dimensions in die | |

| CN113508032B (zh) | 共挤出聚合物结网及其制造方法 | |

| JPH08132508A (ja) | 複合樹脂シートの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20121019 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20160216 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20170522 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20170828 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20170522 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |