KR101390132B1 - 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 - Google Patents

1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 Download PDFInfo

- Publication number

- KR101390132B1 KR101390132B1 KR20120067579A KR20120067579A KR101390132B1 KR 101390132 B1 KR101390132 B1 KR 101390132B1 KR 20120067579 A KR20120067579 A KR 20120067579A KR 20120067579 A KR20120067579 A KR 20120067579A KR 101390132 B1 KR101390132 B1 KR 101390132B1

- Authority

- KR

- South Korea

- Prior art keywords

- strength

- cement

- type

- concrete

- concrete composition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000203 mixture Substances 0.000 title claims abstract description 33

- 239000011372 high-strength concrete Substances 0.000 title claims abstract description 25

- 239000011398 Portland cement Substances 0.000 title description 3

- 239000004568 cement Substances 0.000 claims abstract description 48

- 239000004567 concrete Substances 0.000 claims abstract description 31

- 239000000843 powder Substances 0.000 claims abstract description 24

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 21

- 239000010959 steel Substances 0.000 claims abstract description 21

- 239000002893 slag Substances 0.000 claims abstract description 18

- 229910001341 Crude steel Inorganic materials 0.000 claims abstract description 17

- 239000010881 fly ash Substances 0.000 claims abstract description 17

- 239000000654 additive Substances 0.000 claims abstract description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 21

- 239000011230 binding agent Substances 0.000 claims description 16

- 239000002436 steel type Substances 0.000 claims description 9

- 230000000996 additive effect Effects 0.000 claims description 5

- 238000002156 mixing Methods 0.000 abstract description 4

- 238000010276 construction Methods 0.000 abstract description 3

- 238000012360 testing method Methods 0.000 description 21

- 230000000052 comparative effect Effects 0.000 description 12

- 239000000463 material Substances 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 7

- 239000003638 chemical reducing agent Substances 0.000 description 6

- 238000013461 design Methods 0.000 description 6

- 239000002245 particle Substances 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- 230000007774 longterm Effects 0.000 description 5

- 229910021487 silica fume Inorganic materials 0.000 description 5

- 239000002253 acid Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 3

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 238000010998 test method Methods 0.000 description 3

- 229910001208 Crucible steel Inorganic materials 0.000 description 2

- 239000004952 Polyamide Substances 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- -1 alkylaryl sulfonic acid Chemical compound 0.000 description 2

- 125000000129 anionic group Chemical group 0.000 description 2

- 238000009529 body temperature measurement Methods 0.000 description 2

- 125000002091 cationic group Chemical group 0.000 description 2

- 238000005345 coagulation Methods 0.000 description 2

- 230000015271 coagulation Effects 0.000 description 2

- 230000006866 deterioration Effects 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 238000009472 formulation Methods 0.000 description 2

- 230000036571 hydration Effects 0.000 description 2

- 238000006703 hydration reaction Methods 0.000 description 2

- 150000002500 ions Chemical class 0.000 description 2

- 238000007726 management method Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920002647 polyamide Polymers 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- LSNNMFCWUKXFEE-UHFFFAOYSA-M Bisulfite Chemical compound OS([O-])=O LSNNMFCWUKXFEE-UHFFFAOYSA-M 0.000 description 1

- IAYPIBMASNFSPL-UHFFFAOYSA-N Ethylene oxide Chemical compound C1CO1 IAYPIBMASNFSPL-UHFFFAOYSA-N 0.000 description 1

- 229920001732 Lignosulfonate Polymers 0.000 description 1

- 229920000877 Melamine resin Polymers 0.000 description 1

- 229920003171 Poly (ethylene oxide) Polymers 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 150000001346 alkyl aryl ethers Chemical class 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- AXCZMVOFGPJBDE-UHFFFAOYSA-L calcium dihydroxide Chemical compound [OH-].[OH-].[Ca+2] AXCZMVOFGPJBDE-UHFFFAOYSA-L 0.000 description 1

- 239000000920 calcium hydroxide Substances 0.000 description 1

- 229910001861 calcium hydroxide Inorganic materials 0.000 description 1

- OSGAYBCDTDRGGQ-UHFFFAOYSA-L calcium sulfate Chemical compound [Ca+2].[O-]S([O-])(=O)=O OSGAYBCDTDRGGQ-UHFFFAOYSA-L 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000010883 coal ash Substances 0.000 description 1

- 239000002817 coal dust Substances 0.000 description 1

- 238000013329 compounding Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 230000002209 hydrophobic effect Effects 0.000 description 1

- JDSHMPZPIAZGSV-UHFFFAOYSA-N melamine Chemical compound NC1=NC(N)=NC(N)=N1 JDSHMPZPIAZGSV-UHFFFAOYSA-N 0.000 description 1

- 239000002736 nonionic surfactant Substances 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 230000000171 quenching effect Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 238000007788 roughening Methods 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 238000009628 steelmaking Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 150000003871 sulfonates Chemical class 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 150000003467 sulfuric acid derivatives Chemical class 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B18/00—Use of agglomerated or waste materials or refuse as fillers for mortars, concrete or artificial stone; Treatment of agglomerated or waste materials or refuse, specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B18/04—Waste materials; Refuse

- C04B18/14—Waste materials; Refuse from metallurgical processes

- C04B18/141—Slags

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B18/00—Use of agglomerated or waste materials or refuse as fillers for mortars, concrete or artificial stone; Treatment of agglomerated or waste materials or refuse, specially adapted to enhance their filling properties in mortars, concrete or artificial stone

- C04B18/04—Waste materials; Refuse

- C04B18/06—Combustion residues, e.g. purification products of smoke, fumes or exhaust gases

- C04B18/08—Flue dust, i.e. fly ash

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B28/00—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements

- C04B28/02—Compositions of mortars, concrete or artificial stone, containing inorganic binders or the reaction product of an inorganic and an organic binder, e.g. polycarboxylate cements containing hydraulic cements other than calcium sulfates

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2111/00—Mortars, concrete or artificial stone or mixtures to prepare them, characterised by specific function, property or use

- C04B2111/00017—Aspects relating to the protection of the environment

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2111/00—Mortars, concrete or artificial stone or mixtures to prepare them, characterised by specific function, property or use

- C04B2111/00034—Physico-chemical characteristics of the mixtures

- C04B2111/00068—Mortar or concrete mixtures with an unusual water/cement ratio

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2201/00—Mortars, concrete or artificial stone characterised by specific physical values

- C04B2201/05—Materials having an early high strength, e.g. allowing fast demoulding or formless casting

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2201/00—Mortars, concrete or artificial stone characterised by specific physical values

- C04B2201/50—Mortars, concrete or artificial stone characterised by specific physical values for the mechanical strength

- C04B2201/52—High compression strength concretes, i.e. with a compression strength higher than about 55 N/mm2, e.g. reactive powder concrete [RPC]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/91—Use of waste materials as fillers for mortars or concrete

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Environmental & Geological Engineering (AREA)

- Civil Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Inorganic Chemistry (AREA)

- Combustion & Propulsion (AREA)

- Curing Cements, Concrete, And Artificial Stone (AREA)

Abstract

Description

도 1은 본 발명의 100MPa 고강도 콘크리트의 슬럼프 플로우 실험사진.

도 2는 본 발명의 실험방법에 따라 콘크리트 시험체를 시험하기 전,후의 모습을 도시한 사진.

도 3은 본 발명의 1종 조강형 시멘트를 사용한 고강도 콘크리트로 만든 시험체의 구성 및 온도측정 취치를 나타낸 수직단면도와 수평단면도.

| 시험요인 | 시험수준 | 평가항목 |

| 비교예 | 시중유통 고강도 배합(60,80,100MPa) | 조기강도(양생조건20℃) 장기강도 |

| 실시예 | 1종조강형시멘트Base고강도배합(60,80,100MPa) |

| 구분(MPa) |

W/B (%) |

S/a (%) |

단위재료량(kg/㎥) | |||||||||

| W | C1 | C2 | BFS | FA | SF | Ω | S | G | ||||

| 비교예 |

60 | 26.2 | 46.0 | 163 | 392 | | 180 | 50 | | | 715 | 849 |

| 80 | 23.3 | 45.2 | 163 | 399 | | 210 | 56 | | 35 | 670 | 822 | |

| 100-1 | 20.3 | 36.5 | 163 | 418 | | 257 | 64 | | 64 | 507 | 899 | |

| 100-2 | 20.3 | 35.6 | 163 | 418 | | 257 | 64 | 64 | | 488 | 900 | |

| 실시예 | 60 | 28.5 | 47.5 | 163 | | 360 | 166 | 46 | | | 759 | 849 |

| 80 | 25.1 | 46.8 | 163 | | 403 | 195 | 52 | | | 716 | 823 | |

| 100 | 20.9 | 37.0 | 163 | | 406 | 312 | 62 | | | 522 | 899 | |

| 설계강도 (MPa) |

수준 |

압축강도(MPa) | |||||

| 18Hr | 24Hr | 3d | 7d | 28d | 56d | ||

| 60 |

비교예 | 6.1 | 19.1 | 42.0 | 68.7 | 81.4 | |

| 실시예 | 19.2 | 28.4 | 42.2 | 68.7 | 81.4 | ||

| 80 |

비교예 | 4.7 | 17.5 | 51.9 | 82.2 | 86.6 | |

| 실시예 | 24.3 | 34.3 | 52.4 | 81.1 | 93.0 | ||

| 100 |

비교예Ω | | 14.6 | 61.4 | 81.0 | 96.4 | 96.6 |

| 비교예(SF) | | 8.4 | 56.0 | 75.1 | 96.0 | 98.1 | |

| 실시예 | 10.6 | 27.1 | 62.6 | 82.4 | 97.5 | 102 | |

| 규격 |

W/B (%) |

S/a (%) |

단위재료량(kg/㎥) | ||||||||

| W | B | Ce | BFS | FA | PA | S | G | Ad | |||

| 20-50-600 | 34.8 | 47.9 | 160 | 460 | 359 | 64 | 37 | 0.6 | 819 | 901 | 6.67 |

| 20-60-600 | 28.5 | 45.0 | 160 | 561 | 365 | 152 | 45 | 0.8 | 727 | 899 | 7.40 |

| 20-70-600 | 26.6 | 43.6 | 160 | 602 | 361 | 192 | 48 | 0.9 | 688 | 901 | 8.12 |

| 20-80-600 | 24.6 | 42.0 | 160 | 650 | 364 | 234 | 52 | 1.0 | 644 | 900 | 8.78 |

| 20-100-600 | 20.5 | 37.2 | 160 | 780 | 406 | 312 | 62 | 1.5 | 527 | 900 | 10.9 |

| 0-lot(sec) | Slump Flow(mm) | Air(%) | T 500 ( sec ) | |||||

| 규격 | 0분 | 60분 | 0분 | 60분 | 0분 | 60분 | 0분 | 60분 |

| 20-50-600 | 3.6 | 7.9 | 630x630 | 600x590 | 4.8 | 3.7 | 2.0 | 3.6 |

| 20-60-600 | 4.5 | | 640x630 | | 4.3 | | 3.5 | |

| 20-70-600 | 8.7 | | 670x660 | | 4.1 | | 5.0 | |

| 20-80-600 | 9.9 | | 650x630 | | 3.7 | | 4.4 | |

| 20-100-600 | 14.8 | 9.6 | 620x620 | 630x630 | 4.2 | 3.9 | 4.5 | 4.0 |

| 설계강도 (MPa) |

압축강도(MPa) | |||||||

| 15Hr | 18Hr | 24Hr | 3d | 7d | 28d | 56d | 91d | |

| 50 | 5.72 | 12.4 | 15.6 | 25.8 | 36.0 | 51.7 | 2.8 | |

| 60 | 5.12 | 12.2 | 17.7 | 27.0 | 40.8 | 60.2 | 2.4 | |

| 70 | 2.97 | 12.4 | 19.8 | 36.5 | 58.7 | 75.5 | 7.2 | |

| 80 | 3.74 | 13.2 | 20.6 | 36.0 | 65.2 | 81.4 | 5.1 | |

| 100 | 3.68 | 9.54 | 23.2 | 52.0 | 77.7 | 95.2 | 8.6 | 102 |

| 압축강도 (MPa) |

시험체 A 주철근 | 시험체 B 주철근 | 비고 | ||

| 평균온도(℃) | 최고온도(℃) | 평균온도(℃) | 최고온도(℃) | ||

| 538 | 649 | 538 | 649 | 성능기준 | |

| 50 | 456 | 472 | 531 | 568 | |

| 60 | 495 | 481 | 576 | 550 | |

| 70 | 528 | 508 | 599 | 606 | |

| 80 | 514 | 523 | 575 | 585 | |

| 100 | 480 | 461 | 558 | 539 | |

Claims (5)

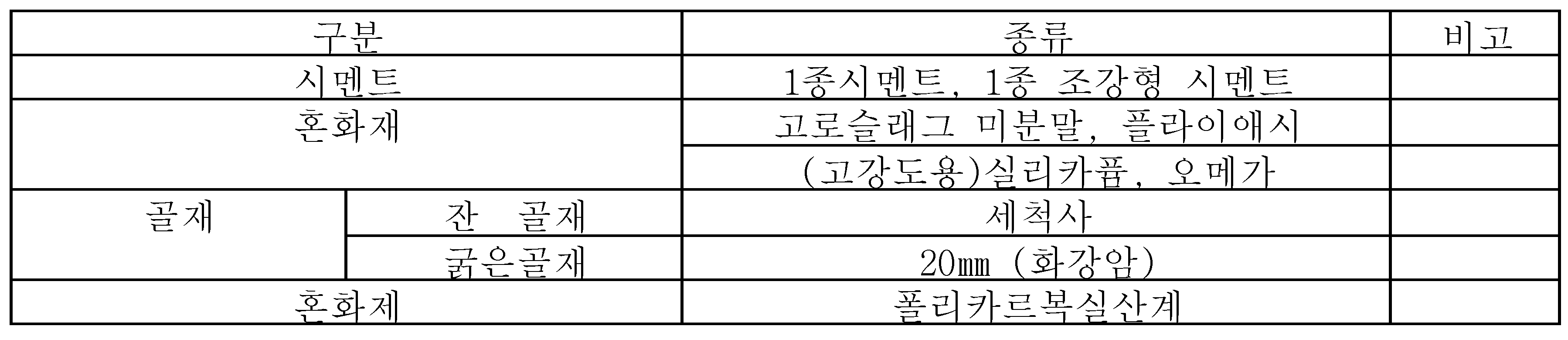

- 콘크리트 조성물의 단위체적에 대하여,

1종 조강형 시멘트를 포함하는 결합재 570 내지 770㎏/㎥과;

물 160 내지 165㎏/㎥과;

잔골재 530 내지 720㎏/㎥과;

굵은 골재 820 내지 900㎏/㎥ 을 포함하여 구성되고,

물결합재비(W/B)는 21~29%, 잔골재율(S/a)은 37-46%이며,

상기 1종 조강형 시멘트는 4,000 내지 4,500㎠/g의 분말도를 가지며 조강형 무기첨가재가 함유되고,

상기 1종 조강형 시멘트를 포함하는 결합재는,

1종 조강형 시멘트 300 내지 500㎏/㎥과;

고로슬래그 미분말 60 내지 350㎏/㎥과;

플라이애시 30 내지 100㎏/㎥;으로 구성된 것을 특징으로 하는 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물. - 삭제

- 삭제

- 삭제

- 제1항의 조성물에 의해 제조되고,

슬럼프 플로우가 500 내지 700mm이고, 압축강도가 50~100MPa인 것을 특징으로 하는 1종 조강형 시멘트를 사용한 고강도 콘크리트.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR20120067579A KR101390132B1 (ko) | 2012-06-22 | 2012-06-22 | 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR20120067579A KR101390132B1 (ko) | 2012-06-22 | 2012-06-22 | 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20140015648A KR20140015648A (ko) | 2014-02-07 |

| KR101390132B1 true KR101390132B1 (ko) | 2014-04-28 |

Family

ID=50264963

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR20120067579A Active KR101390132B1 (ko) | 2012-06-22 | 2012-06-22 | 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR101390132B1 (ko) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102526859B1 (ko) | 2022-05-16 | 2023-04-28 | (주)자연콘이엔씨 | Pc용 콘크리트 조성물 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA3158926A1 (en) | 2014-06-25 | 2015-12-30 | CR Minerals Company, LLC | Pozzolanic compositions containing coal ash and remediation agents for use in cementitious materials |

| KR101705242B1 (ko) * | 2015-05-27 | 2017-02-22 | 한국건설기술연구원 | 시공성을 향상시킨 초고성능 섬유보강 콘크리트의 제조방법 |

| US10457601B2 (en) | 2017-02-24 | 2019-10-29 | CR Minerals Company, LLC | Settable compositions comprising remediated fly ash (RFA) and methods of cementing in subterranean formations |

| KR101993873B1 (ko) * | 2017-06-14 | 2019-06-28 | 삼성물산(주) | 분체량 절감을 위한 조강형 저수축 콘크리트 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0812464A (ja) * | 1994-06-22 | 1996-01-16 | Shimizu Corp | 気泡コンクリートおよびそれを用いたプレキャストコンクリート部材 |

| JPH09241062A (ja) * | 1996-03-05 | 1997-09-16 | Nof Corp | コンクリート組成物及びコンクリート |

| KR100893495B1 (ko) | 2008-01-09 | 2009-04-17 | 한일시멘트 (주) | 자기충전용 저발열 고강도 콘크리트 조성물 및 그 제조방법 |

| KR101154699B1 (ko) * | 2009-12-30 | 2012-06-08 | 대림산업 주식회사 | 조기강도 발현 성능을 가지는 콘크리트 조성물 |

-

2012

- 2012-06-22 KR KR20120067579A patent/KR101390132B1/ko active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0812464A (ja) * | 1994-06-22 | 1996-01-16 | Shimizu Corp | 気泡コンクリートおよびそれを用いたプレキャストコンクリート部材 |

| JPH09241062A (ja) * | 1996-03-05 | 1997-09-16 | Nof Corp | コンクリート組成物及びコンクリート |

| KR100893495B1 (ko) | 2008-01-09 | 2009-04-17 | 한일시멘트 (주) | 자기충전용 저발열 고강도 콘크리트 조성물 및 그 제조방법 |

| KR101154699B1 (ko) * | 2009-12-30 | 2012-06-08 | 대림산업 주식회사 | 조기강도 발현 성능을 가지는 콘크리트 조성물 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR102526859B1 (ko) | 2022-05-16 | 2023-04-28 | (주)자연콘이엔씨 | Pc용 콘크리트 조성물 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20140015648A (ko) | 2014-02-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6528880B2 (ja) | 高強度セメントモルタル組成物 | |

| RU2705646C1 (ru) | Бесцементное вяжущее вещество и его применение | |

| KR100917117B1 (ko) | 철근이음매용 충전재 및 이를 이용한 철근이음매충전시공방법 | |

| JP6530890B2 (ja) | 高強度セメントモルタル組成物及び高強度セメントモルタル硬化体の製造方法 | |

| KR101818143B1 (ko) | 무수축 무시멘트 모르타르 조성물 | |

| KR100873514B1 (ko) | 초고강도 콘크리트용 결합재 및 이를 이용한 콘크리트의제조방법 | |

| JP6205843B2 (ja) | 高強度セメントペースト組成物及び高強度セメントペースト硬化体の製造方法 | |

| KR101390132B1 (ko) | 1종 조강형 시멘트를 사용한 고강도 콘크리트 조성물 및 콘크리트 | |

| KR101779565B1 (ko) | 레미콘용 친환경 시멘트 콘크리트 조성물 | |

| Reddy et al. | Experimental studies on compressive strength of ternary blended concretes at different levels of micro silica and ggbs | |

| CN106186958B (zh) | 一种再生微粉轻骨料高强混凝土及其制备方法 | |

| KR101365684B1 (ko) | 고강도 드라이 콘크리트 믹스 조성물 | |

| KR20160144049A (ko) | 건식 무시멘트 콘크리트를 사용한 축사 바닥판 및 그 제조 방법 | |

| KR101015066B1 (ko) | 고강도 경량 무수축 충진모르타르 | |

| JP6417891B2 (ja) | 高強度コンクリート組成物及び高強度コンクリート硬化体の製造方法 | |

| JP2015009993A (ja) | 高強度モルタル組成物の製造方法 | |

| JP5612504B2 (ja) | 高強度モルタル組成物 | |

| KR101861228B1 (ko) | 초기 강도가 향상된 콘크리트 조성물 | |

| JP6417890B2 (ja) | 高強度コンクリート組成物及び高強度コンクリート硬化体の製造方法 | |

| KR101989503B1 (ko) | 프리캐스트 경량콘크리트 및 이의 제조방법 | |

| Umar et al. | Experiemental study on strength of concrete using silica fumes as supplementary cementitious material | |

| Abd Elaty et al. | Improvement the setting time and strength gain of the fly ash-based geopolymer mortars by using mineral additives | |

| KR102028612B1 (ko) | 오니를 활용한 고강도 경량 콘크리트 조성물 | |

| KR100568933B1 (ko) | 경량콘크리트 및 그 제조 방법 | |

| Sutikulsombat et al. | Development of Thai lignite fly ash and metakaolin for pervious geopolymer concrete |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20120622 |

|

| PA0201 | Request for examination | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20130902 Patent event code: PE09021S01D |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

Patent event code: PE07011S01D Comment text: Decision to Grant Registration Patent event date: 20140207 |

|

| PG1501 | Laying open of application | ||

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

Comment text: Registration of Establishment Patent event date: 20140422 Patent event code: PR07011E01D |

|

| PR1002 | Payment of registration fee |

Payment date: 20140422 End annual number: 3 Start annual number: 1 |

|

| PG1601 | Publication of registration | ||

| FPAY | Annual fee payment |

Payment date: 20170418 Year of fee payment: 4 |

|

| PR1001 | Payment of annual fee |

Payment date: 20170418 Start annual number: 4 End annual number: 4 |

|

| FPAY | Annual fee payment |

Payment date: 20180521 Year of fee payment: 5 |

|

| PR1001 | Payment of annual fee |

Payment date: 20180521 Start annual number: 5 End annual number: 5 |

|

| FPAY | Annual fee payment |

Payment date: 20190329 Year of fee payment: 6 |

|

| PR1001 | Payment of annual fee |

Payment date: 20190329 Start annual number: 6 End annual number: 6 |

|

| PR1001 | Payment of annual fee |

Payment date: 20200413 Start annual number: 7 End annual number: 7 |

|

| PR1001 | Payment of annual fee |

Payment date: 20210112 Start annual number: 8 End annual number: 8 |

|

| PR1001 | Payment of annual fee |

Payment date: 20220413 Start annual number: 9 End annual number: 9 |

|

| PR1001 | Payment of annual fee |

Payment date: 20230419 Start annual number: 10 End annual number: 10 |

|

| PR1001 | Payment of annual fee |

Payment date: 20240326 Start annual number: 11 End annual number: 11 |

|

| PR1001 | Payment of annual fee |

Payment date: 20250326 Start annual number: 12 End annual number: 12 |