KR101063107B1 - 피스턴과 피스턴의 제조방법 - Google Patents

피스턴과 피스턴의 제조방법 Download PDFInfo

- Publication number

- KR101063107B1 KR101063107B1 KR1020057008128A KR20057008128A KR101063107B1 KR 101063107 B1 KR101063107 B1 KR 101063107B1 KR 1020057008128 A KR1020057008128 A KR 1020057008128A KR 20057008128 A KR20057008128 A KR 20057008128A KR 101063107 B1 KR101063107 B1 KR 101063107B1

- Authority

- KR

- South Korea

- Prior art keywords

- piston portion

- piston

- joining surfaces

- joining

- joint

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K13/00—Welding by high-frequency current heating

- B23K13/01—Welding by high-frequency current heating by induction heating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

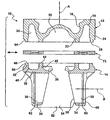

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/003—Multi-part pistons the parts being connected by casting, brazing, welding or clamping

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B3/00—Engines characterised by air compression and subsequent fuel addition

- F02B3/06—Engines characterised by air compression and subsequent fuel addition with compression ignition

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/003—Multi-part pistons the parts being connected by casting, brazing, welding or clamping

- F02F2003/0061—Multi-part pistons the parts being connected by casting, brazing, welding or clamping by welding

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- General Engineering & Computer Science (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US42408902P | 2002-11-06 | 2002-11-06 | |

| US60/424,089 | 2002-11-06 | ||

| US10/701,274 | 2003-11-04 | ||

| US10/701,274 US6825450B2 (en) | 2002-11-06 | 2003-11-04 | Piston and method of manufacture |

| PCT/US2003/035461 WO2004044409A2 (en) | 2002-11-06 | 2003-11-05 | Piston and method of manufacture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20050073622A KR20050073622A (ko) | 2005-07-14 |

| KR101063107B1 true KR101063107B1 (ko) | 2011-09-07 |

Family

ID=32314522

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020057008128A Expired - Fee Related KR101063107B1 (ko) | 2002-11-06 | 2003-11-05 | 피스턴과 피스턴의 제조방법 |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US6825450B2 (enExample) |

| EP (1) | EP1559297B1 (enExample) |

| JP (7) | JP4583178B2 (enExample) |

| KR (1) | KR101063107B1 (enExample) |

| AU (1) | AU2003295410A1 (enExample) |

| BR (1) | BRPI0315466B1 (enExample) |

| CA (1) | CA2505113A1 (enExample) |

| MX (1) | MXPA05004775A (enExample) |

| WO (1) | WO2004044409A2 (enExample) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6825450B2 (en) * | 2002-11-06 | 2004-11-30 | Federal-Mogul World Wide, Inc. | Piston and method of manufacture |

| US6973723B2 (en) * | 2003-01-08 | 2005-12-13 | International Engine Intellectual Property Company, Llc | Piston formed by powder metallurgical methods |

| US7005620B2 (en) * | 2003-11-04 | 2006-02-28 | Federal-Mogul World Wide, Inc. | Piston and method of manufacture |

| US7509890B2 (en) * | 2004-05-27 | 2009-03-31 | International Engine Intellectual Property Company, Llc | Non-homogeneous engine component formed by powder metallurgy |

| US7299715B2 (en) * | 2004-05-27 | 2007-11-27 | International Engine Intellectual Property Company, Llc | Non-homogeneous engine component formed by powder metallurgy |

| US6997158B1 (en) * | 2004-10-07 | 2006-02-14 | International Engine Intellectual Property Company, Llc | Diesel combustion chamber |

| US20060207424A1 (en) * | 2005-03-18 | 2006-09-21 | Federal--Mogul World Wide, Inc. | Piston and method of manufacture |

| US7654240B2 (en) * | 2006-08-18 | 2010-02-02 | Caterpillar Inc. | Engine piston having an insulating air gap |

| US7647911B2 (en) * | 2007-08-08 | 2010-01-19 | Federal-Mogul World Wide, Inc. | Small end con rod guidance piston |

| DE102008045456A1 (de) * | 2008-09-02 | 2010-03-04 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor |

| DE102010033879A1 (de) | 2010-08-10 | 2012-02-16 | Mahle International Gmbh | Verfahren zur Herstellung eines Kolbens für einen Verbrennungsmotor sowie Kolben für einen Verbrennungsmotor |

| DE102010033881A1 (de) * | 2010-08-10 | 2012-02-16 | Mahle International Gmbh | Kolben für einen Verbrennungsmotor und Verfahren zu seiner Herstellung |

| US9856820B2 (en) | 2010-10-05 | 2018-01-02 | Mahle International Gmbh | Piston assembly |

| EP2697016B1 (en) | 2011-04-15 | 2019-03-13 | Tenneco Inc. | Method of making a piston |

| US8973484B2 (en) | 2011-07-01 | 2015-03-10 | Mahle Industries Inc. | Piston with cooling gallery |

| DE102012214681A1 (de) * | 2012-08-17 | 2014-02-20 | Ks Kolbenschmidt Gmbh | Kolben mit einer lokalen Ringnut- und/oder Muldenrandverstärkung |

| EP2946100B1 (en) * | 2013-01-21 | 2016-11-23 | Federal-Mogul Corporation | Piston and method of making a piston |

| KR101449304B1 (ko) | 2013-06-27 | 2014-10-08 | 현대자동차주식회사 | 자동차 엔진용 피스톤의 제조 방법 |

| WO2015143059A1 (en) | 2014-03-21 | 2015-09-24 | Inductoheat, Inc. | Double-sided flat inductor assembly |

| US9909527B2 (en) | 2014-08-27 | 2018-03-06 | Federal-Mogul Llc | Hybrid induction welding process applied to piston manufacturing |

| DE102016120023A1 (de) * | 2015-10-21 | 2017-04-27 | Ks Kolbenschmidt Gmbh | Mehrfach gefügter Kolben mittels kombiniertem Hybridschweißverfahren |

| US10926350B2 (en) * | 2017-07-28 | 2021-02-23 | Spinduction Weld, Inc. | Integrated heat treatment apparatus and method for autogenous welding |

| GB2590701B (en) * | 2019-12-27 | 2022-06-22 | Caterpillar Motoren Gmbh & Co | Piston for an internal combustion engine |

| KR102885961B1 (ko) * | 2024-02-16 | 2025-11-12 | 강재원 | 양변기 세척밸브용 피스톤 제조방법 |

Family Cites Families (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2892914A (en) * | 1958-07-02 | 1959-06-30 | Magnetic Heating Corp | Methods and apparatus for butt welding |

| DE1262071B (de) * | 1965-03-13 | 1968-02-29 | Mahle Kg | Kolben fuer Brennkraftmaschinen mit einem im Bereich der Ringzone liegenden, ringfoermigen Hohlraum |

| US3872275A (en) * | 1973-12-12 | 1975-03-18 | Thermatool Corp | Forge welding with induction coil heating |

| US4012616A (en) * | 1975-01-02 | 1977-03-15 | General Electric Company | Method for metal bonding |

| JPS60166157A (ja) * | 1984-02-09 | 1985-08-29 | Ishikawajima Harima Heavy Ind Co Ltd | ピストンヘツドの製作方法 |

| JPS6139453U (ja) | 1984-08-17 | 1986-03-12 | 三菱自動車工業株式会社 | 電子ビ−ム溶接ピストン |

| US4706550A (en) * | 1986-01-09 | 1987-11-17 | The United States Of America As Represented By The Secretary Of The Navy | Metal matrix composite piston head and method of fabrication |

| US4734552A (en) * | 1986-03-27 | 1988-03-29 | Fmc Corporation | Induction heated pressure welding |

| US4687892A (en) * | 1986-08-11 | 1987-08-18 | Fmc Corporation | Inert atmosphere control for induction heated pressure welding system |

| US4875616A (en) * | 1988-08-10 | 1989-10-24 | America Matrix, Inc. | Method of producing a high temperature, high strength bond between a ceramic shape and metal shape |

| JPH0365840U (enExample) * | 1989-10-30 | 1991-06-26 | ||

| BR9001859A (pt) * | 1990-04-17 | 1991-11-12 | Metal Leve Sa | Processo de fabricacao de embolo e embolo |

| BR9001916A (pt) * | 1990-04-20 | 1991-11-12 | Metal Leve Sa | Processo de obtencao de embolo refrigerado e embolo refrigerado |

| BR9004990A (pt) * | 1990-09-28 | 1992-03-31 | Metal Leve Sa | Processo de fabricacao de cabeca de embolo articulado e embolo articulado |

| BR9005370A (pt) * | 1990-10-18 | 1992-06-16 | Metal Leve Sa | Processo de fabricacao de embolo refrigerado |

| BR9005371A (pt) * | 1990-10-18 | 1992-06-16 | Metal Leve Sa | Processo de fabricacao de embolo com galeria de refrigeracao |

| JPH04321759A (ja) * | 1991-04-23 | 1992-11-11 | Yanmar Diesel Engine Co Ltd | 内燃機関用ピストン |

| US5549335A (en) * | 1994-04-06 | 1996-08-27 | Peerless Of America, Incorporated | Solderless metallurgical joint |

| JP3557813B2 (ja) * | 1996-10-22 | 2004-08-25 | Jfeスチール株式会社 | 鋼管の製造方法 |

| JP3757506B2 (ja) * | 1996-12-24 | 2006-03-22 | 株式会社日立製作所 | 耐熱合金の接合法 |

| IT1293667B1 (it) * | 1997-08-01 | 1999-03-08 | Fiat Ricerche | Sistema di raffreddamento per un motore di autoveicolo. |

| JP3740858B2 (ja) * | 1997-09-16 | 2006-02-01 | マツダ株式会社 | 接合金属部材及び該部材の接合方法 |

| FR2779489B1 (fr) * | 1998-06-09 | 2001-04-06 | Valeo | Dispositif de commande hydraulique de freinage ou d'un embrayage, notamment pour vehicule automobile |

| US6260472B1 (en) * | 1998-07-28 | 2001-07-17 | Federal-Mogul World Wide, Inc. | One-piece integral skirt piston and method of making the same |

| US6291806B1 (en) * | 1998-10-01 | 2001-09-18 | Usf Filtration And Separations Group, Inc. | Process for bonding workpieces |

| US6155157A (en) * | 1998-10-06 | 2000-12-05 | Caterpillar Inc. | Method and apparatus for making a two piece unitary piston |

| US6279455B1 (en) * | 1998-10-06 | 2001-08-28 | Caterpillar Inc. | Method and apparatus for making a two piece unitary piston |

| US6112642A (en) * | 1998-10-06 | 2000-09-05 | Caterpillar Inc. | Method and apparatus for making a two piece unitary piston |

| AU764537B2 (en) * | 1998-11-02 | 2003-08-21 | Industrial Field Robotics | Improved method of solid state welding and welded parts |

| JP2000303904A (ja) * | 1999-04-21 | 2000-10-31 | Riken Tanzou Kk | 内燃機関ピストンの製造方法 |

| JP2001107803A (ja) * | 1999-10-08 | 2001-04-17 | Riken Tanzou Kk | 内燃機関ピストンの製造方法 |

| EP1084793A1 (en) * | 1999-09-20 | 2001-03-21 | Riken Forge Co., Ltd | Method of manufacturing piston of internal combustion engine |

| US6244161B1 (en) * | 1999-10-07 | 2001-06-12 | Cummins Engine Company, Inc. | High temperature-resistant material for articulated pistons |

| EP1222364B2 (en) * | 1999-10-08 | 2018-03-28 | Federal-Mogul Corporation | Dual gallery piston |

| AU2459201A (en) * | 1999-12-30 | 2001-07-16 | Federal Mogul Corporation | Piston having uncoupled skirt |

| EP1268991B1 (en) * | 2000-03-28 | 2006-07-05 | Federal-Mogul Corporation | Heavy duty piston having oil splash deflector |

| GB2365507B (en) * | 2000-08-02 | 2004-09-15 | Federal Mogul Technology Ltd | Engine piston and manufacture |

| GB2368550B (en) * | 2000-09-07 | 2004-09-01 | Rolls Royce Plc | Method and apparatus for friction welding |

| DE60139329D1 (de) * | 2000-10-18 | 2009-09-03 | Federal Mogul Corp | Mehraxial geschmiedeter kolben |

| US6499387B2 (en) * | 2001-03-06 | 2002-12-31 | Federal-Mogul World Wide, Inc. | Unified multi-piece piston and method of manufacture |

| US6508162B2 (en) * | 2001-05-10 | 2003-01-21 | Federal-Mogul World Wide, Inc. | Dual alloy piston and method of manufacture |

| US6526871B1 (en) * | 2001-08-24 | 2003-03-04 | Federal-Mogul World Wide, Inc. | Monobloc piston for diesel engines |

| US6588408B2 (en) * | 2001-09-18 | 2003-07-08 | Federal-Mogul World Wide, Inc. | Cylinder liner for diesel engines with EGR and method of manufacture |

| US6508240B1 (en) * | 2001-09-18 | 2003-01-21 | Federal-Mogul World Wide, Inc. | Cylinder liner having EGR coating |

| US6513477B1 (en) * | 2001-09-19 | 2003-02-04 | Federal-Mogul World Wide, Inc. | Closed gallery piston having pin bore lubrication |

| US6491013B1 (en) * | 2001-09-19 | 2002-12-10 | Federal-Mogul World Wide, Inc. | Closed gallery piston having reinforced oil hole |

| US6539910B1 (en) * | 2001-09-19 | 2003-04-01 | Federal-Mogul World Wide, Inc. | Closed gallery piston having con rod lubrication |

| US6557514B1 (en) * | 2001-10-23 | 2003-05-06 | Federal-Mogul World Wide, Inc. | Closed gallery monobloc piston having oil drainage groove |

| US6571684B1 (en) * | 2002-01-09 | 2003-06-03 | Federal-Mogul World Wide, Inc. | Crosshead piston and bearing assemblies |

| US6825450B2 (en) * | 2002-11-06 | 2004-11-30 | Federal-Mogul World Wide, Inc. | Piston and method of manufacture |

-

2003

- 2003-11-04 US US10/701,274 patent/US6825450B2/en not_active Expired - Lifetime

- 2003-11-05 WO PCT/US2003/035461 patent/WO2004044409A2/en not_active Ceased

- 2003-11-05 EP EP03786596.1A patent/EP1559297B1/en not_active Expired - Lifetime

- 2003-11-05 MX MXPA05004775A patent/MXPA05004775A/es active IP Right Grant

- 2003-11-05 CA CA002505113A patent/CA2505113A1/en not_active Abandoned

- 2003-11-05 AU AU2003295410A patent/AU2003295410A1/en not_active Abandoned

- 2003-11-05 KR KR1020057008128A patent/KR101063107B1/ko not_active Expired - Fee Related

- 2003-11-05 JP JP2004551829A patent/JP4583178B2/ja not_active Expired - Fee Related

- 2003-11-05 BR BRPI0315466A patent/BRPI0315466B1/pt not_active IP Right Cessation

-

2004

- 2004-07-26 US US10/898,878 patent/US20040262297A1/en not_active Abandoned

-

2010

- 2010-07-14 JP JP2010159944A patent/JP2010247236A/ja active Pending

-

2011

- 2011-02-17 JP JP2011032102A patent/JP5351192B2/ja not_active Expired - Fee Related

-

2012

- 2012-02-24 JP JP2012038758A patent/JP5411308B2/ja not_active Expired - Fee Related

- 2012-02-24 JP JP2012038754A patent/JP2012152825A/ja active Pending

-

2013

- 2013-02-06 JP JP2013021351A patent/JP2013091109A/ja not_active Withdrawn

- 2013-02-12 JP JP2013024337A patent/JP2013091110A/ja not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| JP2012152826A (ja) | 2012-08-16 |

| US6825450B2 (en) | 2004-11-30 |

| US20040262297A1 (en) | 2004-12-30 |

| CA2505113A1 (en) | 2004-05-27 |

| JP2012152825A (ja) | 2012-08-16 |

| JP2006507943A (ja) | 2006-03-09 |

| EP1559297A4 (en) | 2010-01-20 |

| AU2003295410A1 (en) | 2004-06-03 |

| US20040149739A1 (en) | 2004-08-05 |

| WO2004044409A2 (en) | 2004-05-27 |

| AU2003295410A8 (en) | 2004-06-03 |

| MXPA05004775A (es) | 2005-07-22 |

| JP2011101905A (ja) | 2011-05-26 |

| JP4583178B2 (ja) | 2010-11-17 |

| JP2013091110A (ja) | 2013-05-16 |

| JP5351192B2 (ja) | 2013-11-27 |

| JP5411308B2 (ja) | 2014-02-12 |

| KR20050073622A (ko) | 2005-07-14 |

| BR0315466A (pt) | 2005-08-23 |

| BRPI0315466B1 (pt) | 2017-05-30 |

| WO2004044409A3 (en) | 2005-03-31 |

| EP1559297A2 (en) | 2005-08-03 |

| JP2010247236A (ja) | 2010-11-04 |

| JP2013091109A (ja) | 2013-05-16 |

| EP1559297B1 (en) | 2013-05-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101063107B1 (ko) | 피스턴과 피스턴의 제조방법 | |

| US7005620B2 (en) | Piston and method of manufacture | |

| US20060207424A1 (en) | Piston and method of manufacture | |

| KR101752216B1 (ko) | 보강된 이중 갤러리 피스톤 및 그 제작 방법 | |

| JP5984809B2 (ja) | 内燃機関用のピストン並びにピストンを製造する方法 | |

| GB2244223A (en) | Method of the manufacture of a cooled engine piston | |

| EP3186027B1 (en) | Hybrid induction welding process applied to piston manufacturing | |

| CN100544526C (zh) | 一种活塞制造方法 | |

| US20150176522A1 (en) | Piston for internal combustion engines | |

| CN108779738B (zh) | 复杂形状的锻造活塞油道 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| A201 | Request for examination | ||

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| T11-X000 | Administrative time limit extension requested |

St.27 status event code: U-3-3-T10-T11-oth-X000 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| FPAY | Annual fee payment |

Payment date: 20140730 Year of fee payment: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |

|

| FPAY | Annual fee payment |

Payment date: 20160629 Year of fee payment: 6 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |

|

| PN2301 | Change of applicant |

St.27 status event code: A-5-5-R10-R13-asn-PN2301 St.27 status event code: A-5-5-R10-R11-asn-PN2301 |

|

| FPAY | Annual fee payment |

Payment date: 20170629 Year of fee payment: 7 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 7 |

|

| FPAY | Annual fee payment |

Payment date: 20180628 Year of fee payment: 8 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 8 |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: A-4-4-U10-U13-oth-PC1903 Not in force date: 20190901 Payment event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE |

|

| PC1903 | Unpaid annual fee |

St.27 status event code: N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text: Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date: 20190901 |