JP7616631B2 - 延性に優れた高強度鋼 - Google Patents

延性に優れた高強度鋼 Download PDFInfo

- Publication number

- JP7616631B2 JP7616631B2 JP2020116997A JP2020116997A JP7616631B2 JP 7616631 B2 JP7616631 B2 JP 7616631B2 JP 2020116997 A JP2020116997 A JP 2020116997A JP 2020116997 A JP2020116997 A JP 2020116997A JP 7616631 B2 JP7616631 B2 JP 7616631B2

- Authority

- JP

- Japan

- Prior art keywords

- steel

- strength

- martensite phase

- ductility

- phase

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910000831 Steel Inorganic materials 0.000 title claims description 220

- 239000010959 steel Substances 0.000 title claims description 220

- 229910000734 martensite Inorganic materials 0.000 claims description 137

- 150000003568 thioethers Chemical class 0.000 claims description 50

- 229910052750 molybdenum Inorganic materials 0.000 claims description 8

- 150000004767 nitrides Chemical class 0.000 claims description 7

- 239000012535 impurity Substances 0.000 claims description 6

- 229910052782 aluminium Inorganic materials 0.000 claims description 5

- 229910052802 copper Inorganic materials 0.000 claims description 5

- 229910052748 manganese Inorganic materials 0.000 claims description 5

- 229910052758 niobium Inorganic materials 0.000 claims description 5

- 229910052717 sulfur Inorganic materials 0.000 claims description 5

- 229910052719 titanium Inorganic materials 0.000 claims description 5

- 229910052720 vanadium Inorganic materials 0.000 claims description 5

- 229910052796 boron Inorganic materials 0.000 claims description 4

- 229910052759 nickel Inorganic materials 0.000 claims description 4

- 229910052710 silicon Inorganic materials 0.000 claims description 4

- -1 composed of them Chemical class 0.000 claims description 3

- 229910052799 carbon Inorganic materials 0.000 claims description 2

- 239000002245 particle Substances 0.000 claims 1

- 229910000859 α-Fe Inorganic materials 0.000 description 50

- 238000005516 engineering process Methods 0.000 description 37

- 239000000463 material Substances 0.000 description 34

- 238000010438 heat treatment Methods 0.000 description 26

- 229910001566 austenite Inorganic materials 0.000 description 22

- 229910052751 metal Inorganic materials 0.000 description 17

- 239000002184 metal Substances 0.000 description 17

- 238000005496 tempering Methods 0.000 description 17

- 230000000694 effects Effects 0.000 description 16

- 238000004519 manufacturing process Methods 0.000 description 15

- 238000000034 method Methods 0.000 description 15

- 239000011651 chromium Substances 0.000 description 13

- 239000011572 manganese Substances 0.000 description 12

- 239000010936 titanium Substances 0.000 description 10

- 238000009864 tensile test Methods 0.000 description 9

- 230000006872 improvement Effects 0.000 description 8

- 239000010955 niobium Substances 0.000 description 8

- 230000008569 process Effects 0.000 description 8

- 239000010949 copper Substances 0.000 description 7

- 229910052804 chromium Inorganic materials 0.000 description 6

- PXHVJJICTQNCMI-UHFFFAOYSA-N nickel Substances [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 6

- 230000009466 transformation Effects 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 238000001816 cooling Methods 0.000 description 5

- 230000007423 decrease Effects 0.000 description 5

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 239000002436 steel type Substances 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 229910045601 alloy Inorganic materials 0.000 description 3

- 239000000956 alloy Substances 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 238000007796 conventional method Methods 0.000 description 3

- 229910052742 iron Inorganic materials 0.000 description 3

- 229910052698 phosphorus Inorganic materials 0.000 description 3

- 238000001556 precipitation Methods 0.000 description 3

- 238000010791 quenching Methods 0.000 description 3

- 230000000171 quenching effect Effects 0.000 description 3

- 238000005204 segregation Methods 0.000 description 3

- 230000007547 defect Effects 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 238000007731 hot pressing Methods 0.000 description 2

- 238000010191 image analysis Methods 0.000 description 2

- 238000007726 management method Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000002844 melting Methods 0.000 description 2

- 230000008018 melting Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- 239000006104 solid solution Substances 0.000 description 2

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 229910000915 Free machining steel Inorganic materials 0.000 description 1

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- 238000005275 alloying Methods 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000012141 concentrate Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009749 continuous casting Methods 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000011574 phosphorus Substances 0.000 description 1

- 239000002244 precipitate Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Landscapes

- Heat Treatment Of Sheet Steel (AREA)

Description

Claims (3)

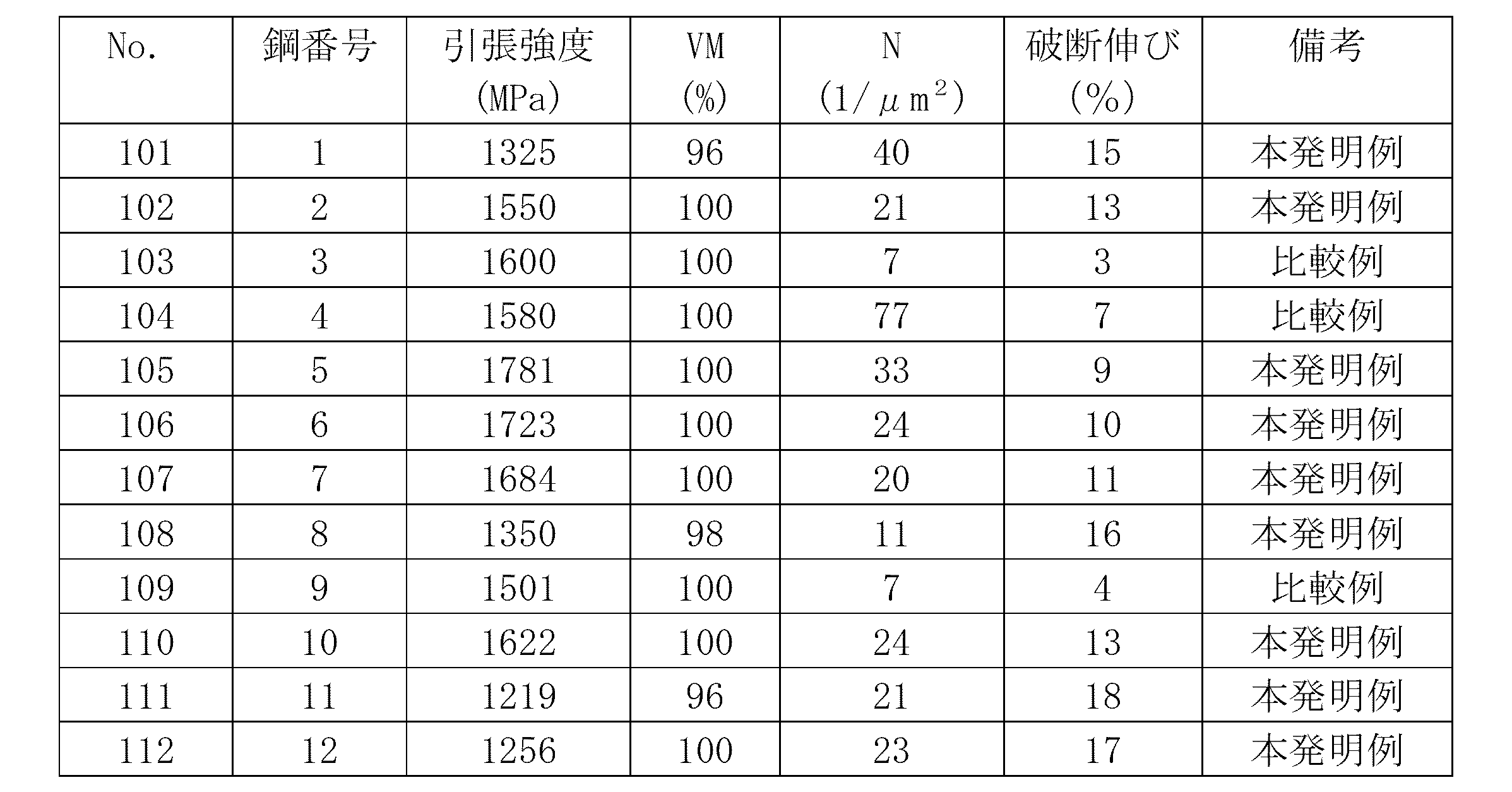

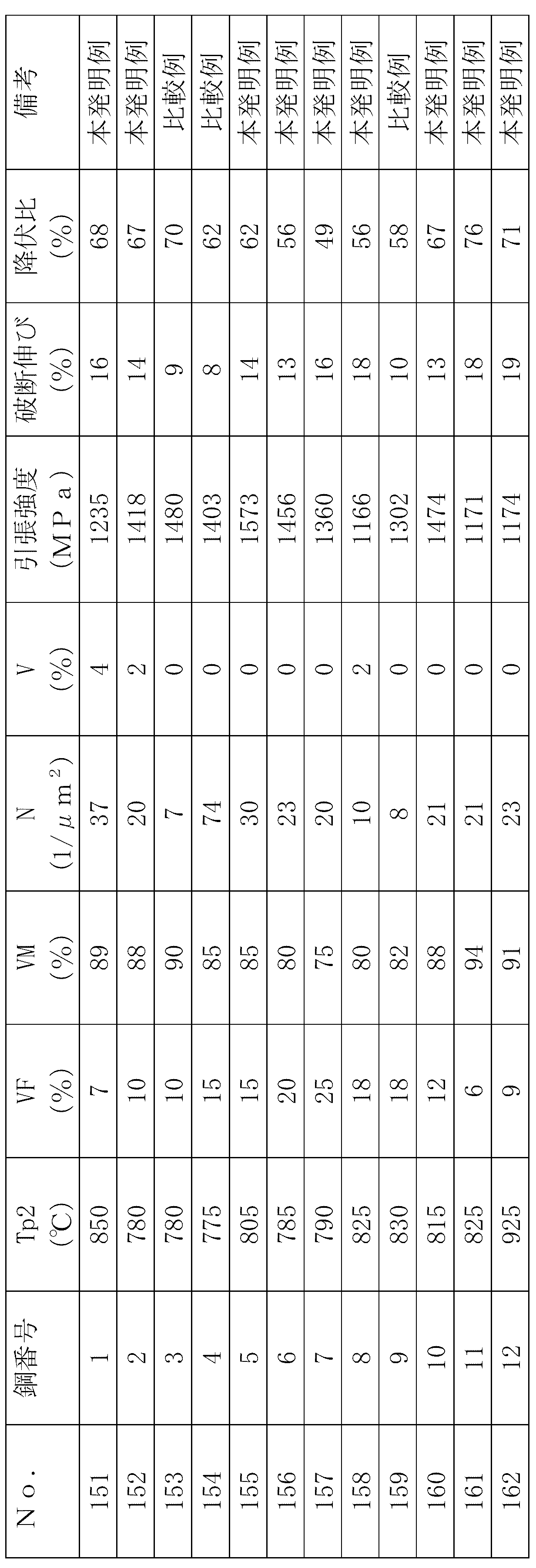

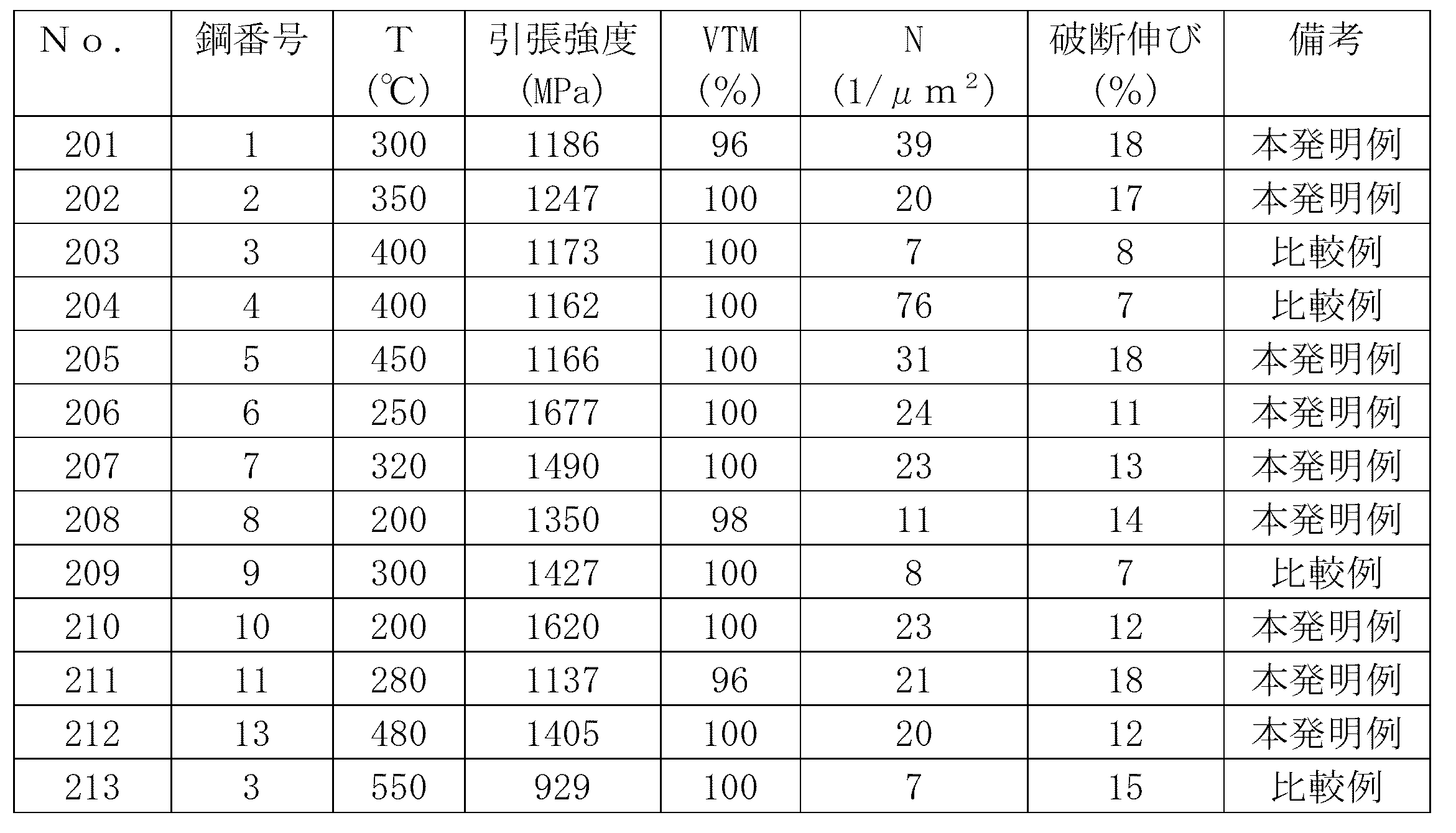

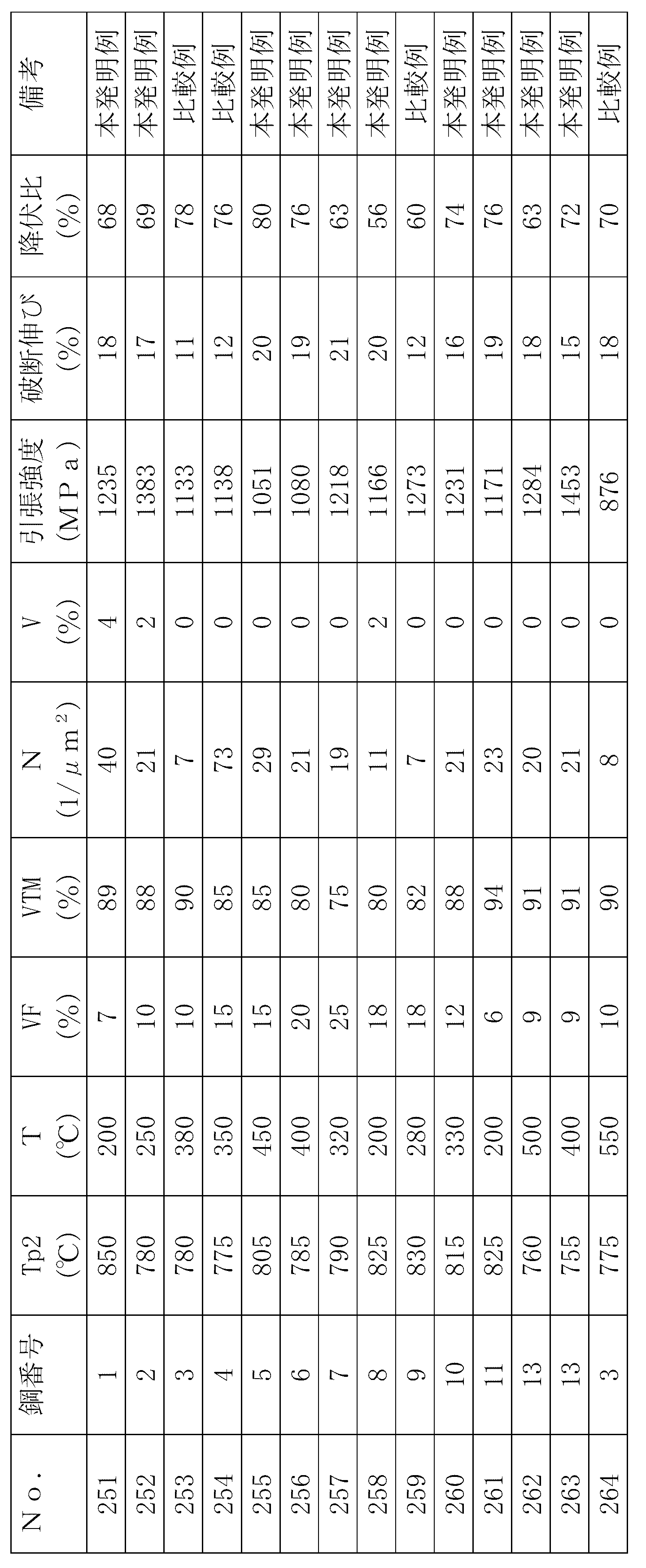

- 引張強度が1200MPa以上、かつマルテンサイト相の体積率が95%以上である高強度鋼であって、

質量比で、S:0.014~0.03%、C:0.20~0.45%、Si:0.1~2.0%、Mn:0.6~2.5%、P:0.03%以下、Al:0.005~0.1%を含有し、残部がFeおよび不可避不純物からなり、破断伸びが8%以上であることを特徴とする高強度鋼。 - MnSまたはFeSまたはそれらを主体とした硫化物、さらには酸化物、窒化物と複合化された硫化物のうち、アスペクト比が3以下であるもののうち円換算直径が0.03μm以上かつ0.2μm以下である硫化物が、1μm2当たり10個以上50個以下でマルテンサイト相中に存在することを特徴とする、請求項1に記載の鋼強度鋼。

- 質量比で、Cr:0.01~0.5%、Mo:0.01~0.5%、Cu:0.05~0.5%、Ni:0.05~0.5%、Nb:0.005~0.08%、V:0.01~0.2%、Ti:0.005~0.08%、B:0.0003~0.0040%のいずれか1種もしくは2種以上をさらに含有する、請求項1又は2に記載の高強度鋼。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020116997A JP7616631B2 (ja) | 2020-07-07 | 2020-07-07 | 延性に優れた高強度鋼 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020116997A JP7616631B2 (ja) | 2020-07-07 | 2020-07-07 | 延性に優れた高強度鋼 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2022014599A JP2022014599A (ja) | 2022-01-20 |

| JP7616631B2 true JP7616631B2 (ja) | 2025-01-17 |

Family

ID=80120322

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020116997A Active JP7616631B2 (ja) | 2020-07-07 | 2020-07-07 | 延性に優れた高強度鋼 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP7616631B2 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20250029951A (ko) | 2022-07-11 | 2025-03-05 | 덴카 주식회사 | 바니시 및 그 경화체 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011158818A1 (ja) | 2010-06-14 | 2011-12-22 | 新日本製鐵株式会社 | ホットスタンプ成形体、ホットスタンプ用鋼板の製造方法及びホットスタンプ成形体の製造方法 |

| JP2012162798A (ja) | 2011-01-18 | 2012-08-30 | Kobe Steel Ltd | 耐遅れ破壊性に優れたボロン添加高強度ボルト用鋼および高強度ボルト |

| WO2013105631A1 (ja) | 2012-01-13 | 2013-07-18 | 新日鐵住金株式会社 | ホットスタンプ成形体及びその製造方法 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10298664A (ja) * | 1997-04-23 | 1998-11-10 | Nippon Steel Corp | 高一様伸び低降伏比高張力鋼材の製造方法 |

-

2020

- 2020-07-07 JP JP2020116997A patent/JP7616631B2/ja active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011158818A1 (ja) | 2010-06-14 | 2011-12-22 | 新日本製鐵株式会社 | ホットスタンプ成形体、ホットスタンプ用鋼板の製造方法及びホットスタンプ成形体の製造方法 |

| JP2012162798A (ja) | 2011-01-18 | 2012-08-30 | Kobe Steel Ltd | 耐遅れ破壊性に優れたボロン添加高強度ボルト用鋼および高強度ボルト |

| WO2013105631A1 (ja) | 2012-01-13 | 2013-07-18 | 新日鐵住金株式会社 | ホットスタンプ成形体及びその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2022014599A (ja) | 2022-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102470965B1 (ko) | 우수한 인성, 연성 및 강도를 갖는 강 시트 및 이의 제조 방법 | |

| JP7087078B2 (ja) | 衝突特性及び成形性に優れた高強度鋼板及びその製造方法 | |

| CN1075117C (zh) | 具有优良韧性和焊接性的超高强度二次硬化钢 | |

| CN110100032B (zh) | 屈服比低且均匀延伸率优异的回火马氏体钢及其制造方法 | |

| CA2962472C (en) | High-toughness hot-rolled high-strength steel with yield strength of grade 800 mpa and preparation method thereof | |

| TWI460288B (zh) | 具有優異加工性之高降伏比的高強度冷軋鋼板及其製造方法 | |

| JP7232252B2 (ja) | 冷間圧延熱処理鋼板及びその製造方法 | |

| CN108368594B (zh) | 具有优异的低温应变时效冲击特性和焊接热影响区冲击特性的高强度钢材及其制造方法 | |

| EP1675970A1 (en) | A cold-rolled steel sheet having a tensile strength of 780 mpa or more an excellent local formability and a suppressed increase in weld hardness | |

| WO2012002566A1 (ja) | 加工性に優れた高強度鋼板およびその製造方法 | |

| WO2017212885A1 (ja) | 成形性に優れた高強度冷延鋼板及びその製造方法 | |

| JP2022537932A (ja) | 冷間圧延マルテンサイト鋼及びそのマルテンサイト鋼の方法 | |

| JP2017218672A (ja) | 成形性に優れた高強度冷延鋼板及びその製造方法 | |

| JP6852806B2 (ja) | 低温用ニッケル含有鋼 | |

| JP5302840B2 (ja) | 伸びと伸びフランジ性のバランスに優れた高強度冷延鋼板 | |

| CN114761584B (zh) | 经热处理的冷轧钢板及其制造方法 | |

| CN115151672A (zh) | 钢板、构件和它们的制造方法 | |

| JP7616631B2 (ja) | 延性に優れた高強度鋼 | |

| US20210071278A1 (en) | High yield ratio-type high-strength steel sheet and method for manufacturing same | |

| CN119137303A (zh) | 经冷轧的马氏体钢及其生产方法 | |

| JP2017197792A (ja) | 液体水素用Ni鋼 | |

| JP2017197793A (ja) | 液体水素用Ni鋼 | |

| JP7533408B2 (ja) | 鋼板およびその製造方法 | |

| JP5935678B2 (ja) | 高靭性高張力鋼およびその製造方法 | |

| JP6620659B2 (ja) | 液体水素用Ni鋼 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20230421 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20240425 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240514 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20240709 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240913 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20241203 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20241223 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7616631 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |