JP7535865B2 - 流体動圧軸受装置 - Google Patents

流体動圧軸受装置 Download PDFInfo

- Publication number

- JP7535865B2 JP7535865B2 JP2020050522A JP2020050522A JP7535865B2 JP 7535865 B2 JP7535865 B2 JP 7535865B2 JP 2020050522 A JP2020050522 A JP 2020050522A JP 2020050522 A JP2020050522 A JP 2020050522A JP 7535865 B2 JP7535865 B2 JP 7535865B2

- Authority

- JP

- Japan

- Prior art keywords

- shaft member

- groove portion

- dynamic pressure

- bearing

- polygonal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000012530 fluid Substances 0.000 title claims description 39

- 239000010687 lubricating oil Substances 0.000 claims description 38

- 230000002093 peripheral effect Effects 0.000 description 23

- 230000000694 effects Effects 0.000 description 12

- 239000003921 oil Substances 0.000 description 10

- 239000002184 metal Substances 0.000 description 7

- 229910052751 metal Inorganic materials 0.000 description 7

- 230000007423 decrease Effects 0.000 description 6

- 230000005484 gravity Effects 0.000 description 5

- 238000005461 lubrication Methods 0.000 description 4

- 239000011347 resin Substances 0.000 description 4

- 229920005989 resin Polymers 0.000 description 4

- 229910001369 Brass Inorganic materials 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 239000010951 brass Substances 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- 230000002159 abnormal effect Effects 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- IYRDVAUFQZOLSB-UHFFFAOYSA-N copper iron Chemical compound [Fe].[Cu] IYRDVAUFQZOLSB-UHFFFAOYSA-N 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

Images

Landscapes

- Sliding-Contact Bearings (AREA)

Description

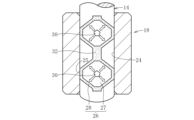

18 軸受部材(軸受スリーブ)

24 内周面

25 外周面

26 ラジアル動圧発生部(動圧溝)

27 多角形丘部(八角形丘部)

28 多角形溝部(八角形溝部)

30 溝部

31 丘部

32 連結溝部(第一の連結溝部)

33 連結溝部(第二の連結溝部)

Claims (5)

- 軸部材と、内周に前記軸部材が挿入された軸受部材と、軸部材の外周面と前記軸受部材の内周面との間のラジアル軸受隙間に生じる流体膜の圧力でもって軸部材を相対回転自在に非接触で支持するラジアル動圧発生部とを備えた流体動圧軸受装置であって、

前記ラジアル動圧発生部は、前記軸受部材の内周面および前記軸部材の外周面のいずれか一方にパターン配置された多数の多角形丘部と、各多角形丘部を囲繞するように形成された多角形溝部と、軸方向に隣接した前記多角形溝部を連結する、軸方向に沿う連結溝部とを備え、

前記連結溝部は前記各多角形丘部を横切っていないことを特徴とする流体動圧軸受装置。 - 前記ラジアル動圧発生部は、前記多角形丘部における表面開孔率よりも、前記多角形溝部における表面開孔率を大きくした請求項1に記載の流体動圧軸受装置。

- 前記ラジアル動圧発生部は、前記多角形丘部の中心に、潤滑油を供給するための溝部が形成されている請求項1又は2に記載の流体動圧軸受装置。

- 前記ラジアル動圧発生部は、前記多角形溝部からの潤滑油の流出を阻止する丘部が形成されている請求項1~3のいずれか一項に記載の流体動圧軸受装置。

- 前記連結溝部の周方向に垂直な平面での断面積を前記多角形溝部の断面積よりも大きくした請求項1~4のいずれか一項に記載の流体動圧軸受装置。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202080023337.8A CN113614395B (zh) | 2019-03-26 | 2020-03-25 | 流体动压轴承装置 |

| PCT/JP2020/013255 WO2020196599A1 (ja) | 2019-03-26 | 2020-03-25 | 流体動圧軸受装置 |

| US17/435,492 US11959513B2 (en) | 2019-03-26 | 2020-03-25 | Fluid dynamic bearing device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019059055 | 2019-03-26 | ||

| JP2019059055 | 2019-03-26 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2020165533A JP2020165533A (ja) | 2020-10-08 |

| JP7535865B2 true JP7535865B2 (ja) | 2024-08-19 |

Family

ID=72717402

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2020050522A Active JP7535865B2 (ja) | 2019-03-26 | 2020-03-23 | 流体動圧軸受装置 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP7535865B2 (ja) |

| CN (1) | CN113614395B (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7213329B1 (ja) | 2021-11-29 | 2023-01-26 | シチズンファインデバイス株式会社 | 軸受け部材 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020009243A1 (en) | 1997-03-06 | 2002-01-24 | Ntn Corporation | Hydrodynamic type porous oil-impregnated bearing |

| JP2004257510A (ja) | 2003-02-27 | 2004-09-16 | Matsushita Electric Ind Co Ltd | 流体軸受装置及び加工方法 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2578711A (en) * | 1947-06-27 | 1951-12-18 | Cincinnati Milling Machine Co | Bearing |

| NL152774A (ja) * | 1950-01-24 | |||

| DE2100365B2 (de) * | 1971-01-07 | 1981-09-17 | Ekkehard Dr.-Ing. 7100 Heilbronn Grau | Gleitlager mit Schmiernutensystem |

| JPS5838646B2 (ja) * | 1973-10-30 | 1983-08-24 | 豊田工機株式会社 | リユウタイジクウケ オヨビ ソノ セイゾウホウホウ |

| JPS5214160A (en) * | 1975-07-23 | 1977-02-02 | Akashi Seisakusho Co Ltd | Static pressure bearing of pressure distribution adjusting type |

| US4671676A (en) * | 1985-09-03 | 1987-06-09 | Rockwell International Corporation | Hydrostatic bearing |

| JPH0312971Y2 (ja) * | 1987-11-13 | 1991-03-26 | ||

| GB2235736B (en) * | 1989-08-09 | 1993-09-15 | Nippon Seiko Kk | Bearing with dynamic pressure grooves and method for manufacturing the same |

| JPH11132227A (ja) * | 1997-10-30 | 1999-05-18 | Nippon Densan Corp | 動圧流体軸受およびこれを備えたモータ |

| JP2000018251A (ja) * | 1998-07-01 | 2000-01-18 | Mitsubishi Heavy Ind Ltd | 静圧軸受装置 |

| US7165889B2 (en) * | 2005-01-27 | 2007-01-23 | Siemens Power Generation, Inc. | Bearing oil lift pocket |

| FR2882409B1 (fr) * | 2005-02-21 | 2008-09-05 | Ct Stephanois De Recherches | Organe de guidage autolubrifiant |

| CN200975415Y (zh) * | 2006-10-10 | 2007-11-14 | 周竝贤 | 改良型储油轴承 |

| TW200920962A (en) * | 2007-11-09 | 2009-05-16 | Metal Ind Res & Dev Ct | Hydrodynamic bearing |

| CN102840241A (zh) * | 2011-06-20 | 2012-12-26 | 吴江同新自润滑轴承厂 | 轴套结构 |

| TWM487376U (zh) * | 2014-03-10 | 2014-10-01 | Wei-Yung Lin | 粉末冶金含油的動壓軸承 |

| KR20160139508A (ko) * | 2015-05-27 | 2016-12-07 | 주식회사 티엠시 | 아크형 양단부를 가진 장방형 요홈 형상의 오일 저장소를 내주면에 구비한 원통형 슬라이딩 베어링 |

| CN107791146A (zh) * | 2017-11-21 | 2018-03-13 | 江阴兴澄特种钢铁有限公司 | 一种可用于轧辊磨床的润滑系统 |

| CN207485846U (zh) * | 2017-11-29 | 2018-06-12 | 浙江大学 | 一种仿生螺旋槽止推轴承 |

-

2020

- 2020-03-23 JP JP2020050522A patent/JP7535865B2/ja active Active

- 2020-03-25 CN CN202080023337.8A patent/CN113614395B/zh active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020009243A1 (en) | 1997-03-06 | 2002-01-24 | Ntn Corporation | Hydrodynamic type porous oil-impregnated bearing |

| JP2004257510A (ja) | 2003-02-27 | 2004-09-16 | Matsushita Electric Ind Co Ltd | 流体軸受装置及び加工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113614395A (zh) | 2021-11-05 |

| CN113614395B (zh) | 2025-03-07 |

| JP2020165533A (ja) | 2020-10-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6402385B1 (en) | Dynamic pressure bearing apparatus | |

| CN104411988B (zh) | 流体动压轴承装置以及具备该流体动压轴承装置的电动机 | |

| JP5674495B2 (ja) | 流体動圧軸受装置 | |

| WO2016084937A1 (ja) | ジャーナル軸受、回転機械 | |

| JP7535865B2 (ja) | 流体動圧軸受装置 | |

| JP2007177808A (ja) | 動圧軸受ユニット | |

| JP4360482B2 (ja) | 動圧軸受装置 | |

| JP2006234161A (ja) | 焼結合金動圧軸受及びそれを備えたモータ | |

| JP2004036891A (ja) | スピンドルモータの回転軸受用の流体軸受システム | |

| JP3637632B2 (ja) | 電動機 | |

| WO2020196599A1 (ja) | 流体動圧軸受装置 | |

| JP3602707B2 (ja) | 動圧軸受モータ | |

| JP2017180672A (ja) | フォイル軸受 | |

| JP2017053398A (ja) | 流体動圧軸受装置及びこれを備えるモータ | |

| WO2012144288A1 (ja) | 流体動圧軸受装置 | |

| WO2022064956A1 (ja) | 流体動圧軸受装置 | |

| JPS6044620A (ja) | 動圧軸受装置 | |

| JP7759178B2 (ja) | 動圧軸受、流体動圧軸受装置、及びモータ | |

| JP6502036B2 (ja) | 流体動圧軸受装置及びこれを備えるモータ | |

| JP5687104B2 (ja) | 軸流ファンモータ | |

| JP2006329391A (ja) | 動圧軸受装置 | |

| JP2006112614A (ja) | 動圧軸受装置 | |

| JP2004316924A (ja) | 動圧型焼結含油軸受ユニット | |

| JPH07241054A (ja) | 小形モータ用の滑り軸受 | |

| JP2004197889A (ja) | 動圧軸受装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20220916 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20230804 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20231002 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20231122 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240112 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20240221 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20240419 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20240711 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20240806 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 7535865 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |