JP6991908B2 - 筒状体 - Google Patents

筒状体 Download PDFInfo

- Publication number

- JP6991908B2 JP6991908B2 JP2018054407A JP2018054407A JP6991908B2 JP 6991908 B2 JP6991908 B2 JP 6991908B2 JP 2018054407 A JP2018054407 A JP 2018054407A JP 2018054407 A JP2018054407 A JP 2018054407A JP 6991908 B2 JP6991908 B2 JP 6991908B2

- Authority

- JP

- Japan

- Prior art keywords

- belt

- tubular body

- cast iron

- ductile cast

- guide roller

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910001141 Ductile iron Inorganic materials 0.000 claims description 41

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 17

- 229910002804 graphite Inorganic materials 0.000 claims description 17

- 239000010439 graphite Substances 0.000 claims description 17

- 239000000463 material Substances 0.000 description 13

- 230000002093 peripheral effect Effects 0.000 description 10

- 238000000034 method Methods 0.000 description 8

- 229910001562 pearlite Inorganic materials 0.000 description 8

- 229910000859 α-Fe Inorganic materials 0.000 description 8

- 229910000831 Steel Inorganic materials 0.000 description 7

- 239000002245 particle Substances 0.000 description 7

- 239000010959 steel Substances 0.000 description 7

- 238000012360 testing method Methods 0.000 description 7

- 238000009750 centrifugal casting Methods 0.000 description 5

- 102200082816 rs34868397 Human genes 0.000 description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- 238000002474 experimental method Methods 0.000 description 3

- 229910001018 Cast iron Inorganic materials 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000009977 dual effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000010791 quenching Methods 0.000 description 2

- 230000000171 quenching effect Effects 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000004323 axial length Effects 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 239000007769 metal material Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000004576 sand Substances 0.000 description 1

- 239000010865 sewage Substances 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Landscapes

- Structure Of Belt Conveyors (AREA)

- Rollers For Roller Conveyors For Transfer (AREA)

- Pulleys (AREA)

Description

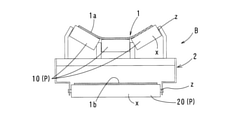

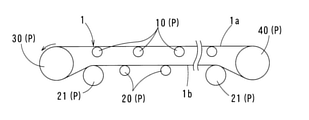

1a 搬送側ベルト

1b リターン側ベルト

2 フレーム

10 搬送側案内ローラ

20 リターン側案内ローラ

21 反転部案内ローラ

30 駆動プーリ

40 従動プーリ

B ベルトコンベヤ

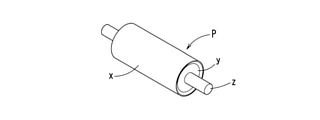

P 筒状体

x 外周部

y 支持部

z 回転軸

Claims (5)

- 他の部材と接触しながら軸周り回転することでその表面に三元アブレシブ摩耗が生じ得る筒状体(P)をダクタイル鋳鉄製としたことを特徴とする筒状体。

- 前記他の部材は、ベルトコンベヤ(B)の無端状のコンベヤベルト(1)であり、前記筒状体(P)は前記コンベヤベルト(1)の表面に接触するものである請求項1に記載の筒状体。

- 前記筒状体(P)は、前記コンベヤベルト(1)の表面に接触する駆動プーリ(30)、従動プーリ(40)及び案内ローラ(10,20,21)の一部又は全部である

請求項2に記載の筒状体。 - 前記筒状体(P)を構成するダクタイル鋳鉄は、黒鉛粒数が300個/mm2以上、黒鉛粒径が15μm以下、黒鉛粒が占める面積率が8%以上12%未満である

請求項1から3のいずれか一つに記載の筒状体。 - 請求項1から4のいずれか一つに記載の筒状体を、駆動プーリ(30)、従動プーリ(40)及び案内ローラ(10,20,21)の一部又は全部に用いたベルトコンベヤ。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018054407A JP6991908B2 (ja) | 2018-03-22 | 2018-03-22 | 筒状体 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2018054407A JP6991908B2 (ja) | 2018-03-22 | 2018-03-22 | 筒状体 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019167183A JP2019167183A (ja) | 2019-10-03 |

| JP6991908B2 true JP6991908B2 (ja) | 2022-01-13 |

Family

ID=68107095

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018054407A Active JP6991908B2 (ja) | 2018-03-22 | 2018-03-22 | 筒状体 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6991908B2 (ja) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7615998B2 (ja) | 2021-10-01 | 2025-01-17 | 株式会社ダイフク | 搬送コンベヤ及び当該搬送コンベヤを備えた搬送装置 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006175494A (ja) | 2004-12-24 | 2006-07-06 | Mie Katan Kogyo Kk | ダクタイル鋳鉄のフェライト地鋳物の製造方法 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5652174Y2 (ja) * | 1978-12-26 | 1981-12-05 | ||

| JPS61159551A (ja) * | 1985-01-07 | 1986-07-19 | Mitsubishi Heavy Ind Ltd | 搬送用ロ−ラ |

-

2018

- 2018-03-22 JP JP2018054407A patent/JP6991908B2/ja active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2006175494A (ja) | 2004-12-24 | 2006-07-06 | Mie Katan Kogyo Kk | ダクタイル鋳鉄のフェライト地鋳物の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2019167183A (ja) | 2019-10-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| GB1571233A (en) | Arrangement for conveying and rotating material | |

| US6915745B2 (en) | Self-lubricating overhead conveyor system | |

| JP6991908B2 (ja) | 筒状体 | |

| US3848744A (en) | Green pellet sizing screen | |

| US4193493A (en) | Roller conveyor | |

| KR20120139652A (ko) | 부시 베어링 | |

| KR200233688Y1 (ko) | 컨베이어용 롤러 | |

| CN113993797B (zh) | 用于输送带系统的运载滚轮 | |

| KR101770037B1 (ko) | 컨베이어용 프릭션 롤러 | |

| US20050023112A1 (en) | Track system for tow-line conveyors | |

| KR101703692B1 (ko) | 플로팅 실 | |

| US1332176A (en) | High-speed roller-bearing | |

| KR20120062141A (ko) | 부시 베어링 | |

| RU2097296C1 (ru) | Ролик ленточного конвейера | |

| CN117446418B (zh) | 一种转轮、刮板以及物料输送装置 | |

| US1636051A (en) | Conveyer mechanism and particularly conveyer pulley supports | |

| WO2010097957A1 (ja) | 付着物除去装置 | |

| JP7640775B1 (ja) | 改善長尺リターンローラー及びそれを含む長尺リターンローラー群 | |

| Sapate et al. | Metallurgical investigation of failure of coal mill drag chain pin | |

| JP6403110B2 (ja) | 自動調芯プーリを備えたベルトコンベア | |

| RU224905U1 (ru) | Устройство для очистки конвейерной ленты | |

| CN203806536U (zh) | 板式给矿机的链板组件 | |

| CN222934606U (zh) | 一种螺纹多楔带头滚筒 | |

| RU2487827C2 (ru) | Ролик ленточного конвейера | |

| JP2009018929A (ja) | ローラフォロア及びこれを備えた真空搬送装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20201217 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20210927 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20211109 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20211208 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6991908 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |