JP6987643B2 - メタルボンド研磨物品の製造方法及びメタルボンド研磨物品 - Google Patents

メタルボンド研磨物品の製造方法及びメタルボンド研磨物品 Download PDFInfo

- Publication number

- JP6987643B2 JP6987643B2 JP2017566775A JP2017566775A JP6987643B2 JP 6987643 B2 JP6987643 B2 JP 6987643B2 JP 2017566775 A JP2017566775 A JP 2017566775A JP 2017566775 A JP2017566775 A JP 2017566775A JP 6987643 B2 JP6987643 B2 JP 6987643B2

- Authority

- JP

- Japan

- Prior art keywords

- particles

- metal

- polishing

- powder particles

- polished article

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910052751 metal Inorganic materials 0.000 title claims description 114

- 239000002184 metal Substances 0.000 title claims description 114

- 238000004519 manufacturing process Methods 0.000 title claims description 75

- 239000002245 particle Substances 0.000 claims description 196

- 239000000843 powder Substances 0.000 claims description 131

- 238000005498 polishing Methods 0.000 claims description 72

- 239000011230 binding agent Substances 0.000 claims description 71

- 239000000463 material Substances 0.000 claims description 70

- 239000007788 liquid Substances 0.000 claims description 60

- 238000000034 method Methods 0.000 claims description 57

- 239000002243 precursor Substances 0.000 claims description 50

- 238000002844 melting Methods 0.000 claims description 42

- 230000008018 melting Effects 0.000 claims description 42

- 239000002923 metal particle Substances 0.000 claims description 27

- 238000001816 cooling Methods 0.000 claims description 25

- 230000008569 process Effects 0.000 claims description 25

- 239000003870 refractory metal Substances 0.000 claims description 19

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 18

- 239000000126 substance Substances 0.000 claims description 15

- 229910003460 diamond Inorganic materials 0.000 claims description 14

- 239000010432 diamond Substances 0.000 claims description 14

- 239000011159 matrix material Substances 0.000 claims description 10

- 229920000642 polymer Polymers 0.000 claims description 10

- 229910052582 BN Inorganic materials 0.000 claims description 9

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 claims description 9

- 238000010438 heat treatment Methods 0.000 claims description 9

- 229910044991 metal oxide Inorganic materials 0.000 claims description 7

- 150000004706 metal oxides Chemical class 0.000 claims description 7

- 238000000151 deposition Methods 0.000 claims description 6

- 230000004907 flux Effects 0.000 claims description 6

- 239000011224 oxide ceramic Substances 0.000 claims description 6

- 238000001723 curing Methods 0.000 claims description 4

- 238000000227 grinding Methods 0.000 claims description 4

- 230000008016 vaporization Effects 0.000 claims description 4

- 238000013007 heat curing Methods 0.000 claims description 3

- 238000003847 radiation curing Methods 0.000 claims description 3

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 11

- 239000000203 mixture Substances 0.000 description 11

- 238000007639 printing Methods 0.000 description 10

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- -1 1390 to 1425 ° C) Substances 0.000 description 7

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 7

- 229910001220 stainless steel Inorganic materials 0.000 description 7

- 239000010935 stainless steel Substances 0.000 description 7

- 229910000906 Bronze Inorganic materials 0.000 description 6

- PEDCQBHIVMGVHV-UHFFFAOYSA-N Glycerine Chemical compound OCC(O)CO PEDCQBHIVMGVHV-UHFFFAOYSA-N 0.000 description 6

- DNIAPMSPPWPWGF-UHFFFAOYSA-N Propylene glycol Chemical compound CC(O)CO DNIAPMSPPWPWGF-UHFFFAOYSA-N 0.000 description 6

- 229910045601 alloy Inorganic materials 0.000 description 6

- 239000000956 alloy Substances 0.000 description 6

- 239000010974 bronze Substances 0.000 description 6

- KUNSUQLRTQLHQQ-UHFFFAOYSA-N copper tin Chemical compound [Cu].[Sn] KUNSUQLRTQLHQQ-UHFFFAOYSA-N 0.000 description 6

- 238000001035 drying Methods 0.000 description 6

- 238000002347 injection Methods 0.000 description 6

- 239000007924 injection Substances 0.000 description 6

- 239000003960 organic solvent Substances 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- 238000010146 3D printing Methods 0.000 description 5

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 5

- 239000011651 chromium Substances 0.000 description 5

- 239000010949 copper Substances 0.000 description 5

- 101100433746 Arabidopsis thaliana ABCG29 gene Proteins 0.000 description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 4

- 101100054289 Oryza sativa subsp. japonica ABCG34 gene Proteins 0.000 description 4

- 101100107601 Oryza sativa subsp. japonica ABCG45 gene Proteins 0.000 description 4

- 101150088582 PDR1 gene Proteins 0.000 description 4

- 101100400877 Trichophyton rubrum (strain ATCC MYA-4607 / CBS 118892) MDR1 gene Proteins 0.000 description 4

- 239000006061 abrasive grain Substances 0.000 description 4

- 238000009825 accumulation Methods 0.000 description 4

- 229910052782 aluminium Inorganic materials 0.000 description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 4

- 229910052802 copper Inorganic materials 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 235000019441 ethanol Nutrition 0.000 description 4

- 150000002739 metals Chemical class 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 229910052759 nickel Inorganic materials 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 238000005245 sintering Methods 0.000 description 4

- 239000002904 solvent Substances 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 3

- XEKOWRVHYACXOJ-UHFFFAOYSA-N Ethyl acetate Chemical compound CCOC(C)=O XEKOWRVHYACXOJ-UHFFFAOYSA-N 0.000 description 3

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 3

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 3

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 3

- 229910000831 Steel Inorganic materials 0.000 description 3

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 3

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 3

- 239000012298 atmosphere Substances 0.000 description 3

- 229910052804 chromium Inorganic materials 0.000 description 3

- 229910017052 cobalt Inorganic materials 0.000 description 3

- 239000010941 cobalt Substances 0.000 description 3

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 3

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 3

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 3

- 229910052737 gold Inorganic materials 0.000 description 3

- 239000010931 gold Substances 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 3

- 229910052742 iron Inorganic materials 0.000 description 3

- 229910052749 magnesium Inorganic materials 0.000 description 3

- 239000011777 magnesium Substances 0.000 description 3

- 238000003801 milling Methods 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 3

- 239000011148 porous material Substances 0.000 description 3

- 230000000717 retained effect Effects 0.000 description 3

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 3

- 229910010271 silicon carbide Inorganic materials 0.000 description 3

- 229910052709 silver Inorganic materials 0.000 description 3

- 239000004332 silver Substances 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 229910052718 tin Inorganic materials 0.000 description 3

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 3

- 229910052721 tungsten Inorganic materials 0.000 description 3

- 239000010937 tungsten Substances 0.000 description 3

- 229910052725 zinc Inorganic materials 0.000 description 3

- 239000011701 zinc Substances 0.000 description 3

- ARXKVVRQIIOZGF-UHFFFAOYSA-N 1,2,4-butanetriol Chemical compound OCCC(O)CO ARXKVVRQIIOZGF-UHFFFAOYSA-N 0.000 description 2

- ARXJGSRGQADJSQ-UHFFFAOYSA-N 1-methoxypropan-2-ol Chemical compound COCC(C)O ARXJGSRGQADJSQ-UHFFFAOYSA-N 0.000 description 2

- XNWFRZJHXBZDAG-UHFFFAOYSA-N 2-METHOXYETHANOL Chemical compound COCCO XNWFRZJHXBZDAG-UHFFFAOYSA-N 0.000 description 2

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 2

- SVTBMSDMJJWYQN-UHFFFAOYSA-N 2-methylpentane-2,4-diol Chemical compound CC(O)CC(C)(C)O SVTBMSDMJJWYQN-UHFFFAOYSA-N 0.000 description 2

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 2

- 101100433754 Arabidopsis thaliana ABCG30 gene Proteins 0.000 description 2

- 101100433757 Arabidopsis thaliana ABCG32 gene Proteins 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- 229910052580 B4C Inorganic materials 0.000 description 2

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 2

- IAZDPXIOMUYVGZ-UHFFFAOYSA-N Dimethylsulphoxide Chemical compound CS(C)=O IAZDPXIOMUYVGZ-UHFFFAOYSA-N 0.000 description 2

- 101100381989 Emericella nidulans (strain FGSC A4 / ATCC 38163 / CBS 112.46 / NRRL 194 / M139) broA gene Proteins 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 2

- SECXISVLQFMRJM-UHFFFAOYSA-N N-Methylpyrrolidone Chemical compound CN1CCCC1=O SECXISVLQFMRJM-UHFFFAOYSA-N 0.000 description 2

- 101100054291 Oryza sativa subsp. japonica ABCG35 gene Proteins 0.000 description 2

- 101100054296 Oryza sativa subsp. japonica ABCG37 gene Proteins 0.000 description 2

- 101100107593 Oryza sativa subsp. japonica ABCG40 gene Proteins 0.000 description 2

- 101100107595 Oryza sativa subsp. japonica ABCG41 gene Proteins 0.000 description 2

- 101150024488 PDR2 gene Proteins 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- 101100491255 Saccharomyces cerevisiae (strain ATCC 204508 / S288c) YAP1 gene Proteins 0.000 description 2

- 101100321174 Saccharomyces cerevisiae (strain ATCC 204508 / S288c) YRR1 gene Proteins 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- DKGAVHZHDRPRBM-UHFFFAOYSA-N Tert-Butanol Chemical compound CC(C)(C)O DKGAVHZHDRPRBM-UHFFFAOYSA-N 0.000 description 2

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 239000000654 additive Substances 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- 229920006187 aquazol Polymers 0.000 description 2

- 239000012861 aquazol Substances 0.000 description 2

- 229910052796 boron Inorganic materials 0.000 description 2

- INAHAJYZKVIDIZ-UHFFFAOYSA-N boron carbide Chemical compound B12B3B4C32B41 INAHAJYZKVIDIZ-UHFFFAOYSA-N 0.000 description 2

- 239000010951 brass Substances 0.000 description 2

- 238000005219 brazing Methods 0.000 description 2

- 101150068326 bro1 gene Proteins 0.000 description 2

- BTANRVKWQNVYAZ-UHFFFAOYSA-N butan-2-ol Chemical compound CCC(C)O BTANRVKWQNVYAZ-UHFFFAOYSA-N 0.000 description 2

- WERYXYBDKMZEQL-UHFFFAOYSA-N butane-1,4-diol Chemical compound OCCCCO WERYXYBDKMZEQL-UHFFFAOYSA-N 0.000 description 2

- 229910052799 carbon Inorganic materials 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 229920001577 copolymer Polymers 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 239000003822 epoxy resin Substances 0.000 description 2

- LZCLXQDLBQLTDK-UHFFFAOYSA-N ethyl 2-hydroxypropanoate Chemical compound CCOC(=O)C(C)O LZCLXQDLBQLTDK-UHFFFAOYSA-N 0.000 description 2

- 239000010419 fine particle Substances 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 2

- 239000000411 inducer Substances 0.000 description 2

- ZXEKIIBDNHEJCQ-UHFFFAOYSA-N isobutanol Chemical compound CC(C)CO ZXEKIIBDNHEJCQ-UHFFFAOYSA-N 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- 239000013528 metallic particle Substances 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 239000011733 molybdenum Substances 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 239000002105 nanoparticle Substances 0.000 description 2

- 229910052758 niobium Inorganic materials 0.000 description 2

- 239000010955 niobium Substances 0.000 description 2

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 description 2

- 239000012299 nitrogen atmosphere Substances 0.000 description 2

- 238000011022 operating instruction Methods 0.000 description 2

- 230000000737 periodic effect Effects 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 229920000647 polyepoxide Polymers 0.000 description 2

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 2

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 2

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 2

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000004094 surface-active agent Substances 0.000 description 2

- 229910052715 tantalum Inorganic materials 0.000 description 2

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 2

- 239000010936 titanium Substances 0.000 description 2

- 229910052719 titanium Inorganic materials 0.000 description 2

- MTPVUVINMAGMJL-UHFFFAOYSA-N trimethyl(1,1,2,2,2-pentafluoroethyl)silane Chemical compound C[Si](C)(C)C(F)(F)C(F)(F)F MTPVUVINMAGMJL-UHFFFAOYSA-N 0.000 description 2

- 229910052720 vanadium Inorganic materials 0.000 description 2

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 description 2

- 238000009834 vaporization Methods 0.000 description 2

- PUPZLCDOIYMWBV-UHFFFAOYSA-N (+/-)-1,3-Butanediol Chemical compound CC(O)CCO PUPZLCDOIYMWBV-UHFFFAOYSA-N 0.000 description 1

- ZWVMLYRJXORSEP-UHFFFAOYSA-N 1,2,6-Hexanetriol Chemical compound OCCCCC(O)CO ZWVMLYRJXORSEP-UHFFFAOYSA-N 0.000 description 1

- 229940043375 1,5-pentanediol Drugs 0.000 description 1

- LAVARTIQQDZFNT-UHFFFAOYSA-N 1-(1-methoxypropan-2-yloxy)propan-2-yl acetate Chemical compound COCC(C)OCC(C)OC(C)=O LAVARTIQQDZFNT-UHFFFAOYSA-N 0.000 description 1

- RWNUSVWFHDHRCJ-UHFFFAOYSA-N 1-butoxypropan-2-ol Chemical compound CCCCOCC(C)O RWNUSVWFHDHRCJ-UHFFFAOYSA-N 0.000 description 1

- OQUIHNRSFOIOFU-UHFFFAOYSA-N 1-methoxy-2-(2-methoxypropoxy)propane Chemical class COCC(C)OCC(C)OC OQUIHNRSFOIOFU-UHFFFAOYSA-N 0.000 description 1

- FENFUOGYJVOCRY-UHFFFAOYSA-N 1-propoxypropan-2-ol Chemical compound CCCOCC(C)O FENFUOGYJVOCRY-UHFFFAOYSA-N 0.000 description 1

- OAYXUHPQHDHDDZ-UHFFFAOYSA-N 2-(2-butoxyethoxy)ethanol Chemical compound CCCCOCCOCCO OAYXUHPQHDHDDZ-UHFFFAOYSA-N 0.000 description 1

- WMDZKDKPYCNCDZ-UHFFFAOYSA-N 2-(2-butoxypropoxy)propan-1-ol Chemical compound CCCCOC(C)COC(C)CO WMDZKDKPYCNCDZ-UHFFFAOYSA-N 0.000 description 1

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- SBASXUCJHJRPEV-UHFFFAOYSA-N 2-(2-methoxyethoxy)ethanol Chemical compound COCCOCCO SBASXUCJHJRPEV-UHFFFAOYSA-N 0.000 description 1

- CUDYYMUUJHLCGZ-UHFFFAOYSA-N 2-(2-methoxypropoxy)propan-1-ol Chemical compound COC(C)COC(C)CO CUDYYMUUJHLCGZ-UHFFFAOYSA-N 0.000 description 1

- XYVAYAJYLWYJJN-UHFFFAOYSA-N 2-(2-propoxypropoxy)propan-1-ol Chemical compound CCCOC(C)COC(C)CO XYVAYAJYLWYJJN-UHFFFAOYSA-N 0.000 description 1

- JDSQBDGCMUXRBM-UHFFFAOYSA-N 2-[2-(2-butoxypropoxy)propoxy]propan-1-ol Chemical compound CCCCOC(C)COC(C)COC(C)CO JDSQBDGCMUXRBM-UHFFFAOYSA-N 0.000 description 1

- WAEVWDZKMBQDEJ-UHFFFAOYSA-N 2-[2-(2-methoxypropoxy)propoxy]propan-1-ol Chemical compound COC(C)COC(C)COC(C)CO WAEVWDZKMBQDEJ-UHFFFAOYSA-N 0.000 description 1

- FYYLCPPEQLPTIQ-UHFFFAOYSA-N 2-[2-(2-propoxypropoxy)propoxy]propan-1-ol Chemical compound CCCOC(C)COC(C)COC(C)CO FYYLCPPEQLPTIQ-UHFFFAOYSA-N 0.000 description 1

- POAOYUHQDCAZBD-UHFFFAOYSA-N 2-butoxyethanol Chemical compound CCCCOCCO POAOYUHQDCAZBD-UHFFFAOYSA-N 0.000 description 1

- RSROEZYGRKHVMN-UHFFFAOYSA-N 2-ethyl-2-(hydroxymethyl)propane-1,3-diol;oxirane Chemical compound C1CO1.CCC(CO)(CO)CO RSROEZYGRKHVMN-UHFFFAOYSA-N 0.000 description 1

- OMIGHNLMNHATMP-UHFFFAOYSA-N 2-hydroxyethyl prop-2-enoate Chemical class OCCOC(=O)C=C OMIGHNLMNHATMP-UHFFFAOYSA-N 0.000 description 1

- QCDWFXQBSFUVSP-UHFFFAOYSA-N 2-phenoxyethanol Chemical compound OCCOC1=CC=CC=C1 QCDWFXQBSFUVSP-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 101100433755 Arabidopsis thaliana ABCG31 gene Proteins 0.000 description 1

- QYEXBYZXHDUPRC-UHFFFAOYSA-N B#[Ti]#B Chemical compound B#[Ti]#B QYEXBYZXHDUPRC-UHFFFAOYSA-N 0.000 description 1

- 239000004375 Dextrin Substances 0.000 description 1

- 229920001353 Dextrin Polymers 0.000 description 1

- 229920002907 Guar gum Polymers 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 229930194542 Keto Natural products 0.000 description 1

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- 229910000792 Monel Inorganic materials 0.000 description 1

- 101100054294 Oryza sativa subsp. japonica ABCG36 gene Proteins 0.000 description 1

- 101100107604 Oryza sativa subsp. japonica ABCG48 gene Proteins 0.000 description 1

- 101150078988 PDR3 gene Proteins 0.000 description 1

- ALQSHHUCVQOPAS-UHFFFAOYSA-N Pentane-1,5-diol Chemical compound OCCCCCO ALQSHHUCVQOPAS-UHFFFAOYSA-N 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- 241000183024 Populus tremula Species 0.000 description 1

- 229910000676 Si alloy Inorganic materials 0.000 description 1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- NINIDFKCEFEMDL-UHFFFAOYSA-N Sulfur Chemical compound [S] NINIDFKCEFEMDL-UHFFFAOYSA-N 0.000 description 1

- 229910033181 TiB2 Inorganic materials 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- NRTOMJZYCJJWKI-UHFFFAOYSA-N Titanium nitride Chemical compound [Ti]#N NRTOMJZYCJJWKI-UHFFFAOYSA-N 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- MCMNRKCIXSYSNV-UHFFFAOYSA-N ZrO2 Inorganic materials O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 1

- 239000003082 abrasive agent Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000012190 activator Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 238000005054 agglomeration Methods 0.000 description 1

- 230000002776 aggregation Effects 0.000 description 1

- 239000003570 air Substances 0.000 description 1

- 150000005215 alkyl ethers Chemical class 0.000 description 1

- WATWJIUSRGPENY-UHFFFAOYSA-N antimony atom Chemical compound [Sb] WATWJIUSRGPENY-UHFFFAOYSA-N 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 229910052793 cadmium Inorganic materials 0.000 description 1

- BDOSMKKIYDKNTQ-UHFFFAOYSA-N cadmium atom Chemical compound [Cd] BDOSMKKIYDKNTQ-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 229910000420 cerium oxide Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000004320 controlled atmosphere Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 235000019425 dextrin Nutrition 0.000 description 1

- SWXVUIWOUIDPGS-UHFFFAOYSA-N diacetone alcohol Natural products CC(=O)CC(C)(C)O SWXVUIWOUIDPGS-UHFFFAOYSA-N 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- XXJWXESWEXIICW-UHFFFAOYSA-N diethylene glycol monoethyl ether Chemical compound CCOCCOCCO XXJWXESWEXIICW-UHFFFAOYSA-N 0.000 description 1

- USIUVYZYUHIAEV-UHFFFAOYSA-N diphenyl ether Chemical class C=1C=CC=CC=1OC1=CC=CC=C1 USIUVYZYUHIAEV-UHFFFAOYSA-N 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 150000002170 ethers Chemical class 0.000 description 1

- 229940116333 ethyl lactate Drugs 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000005755 formation reaction Methods 0.000 description 1

- 229910021485 fumed silica Inorganic materials 0.000 description 1

- 239000002223 garnet Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000005469 granulation Methods 0.000 description 1

- 230000003179 granulation Effects 0.000 description 1

- 229910002804 graphite Inorganic materials 0.000 description 1

- 239000010439 graphite Substances 0.000 description 1

- 239000000665 guar gum Substances 0.000 description 1

- 235000010417 guar gum Nutrition 0.000 description 1

- 229960002154 guar gum Drugs 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 229940051250 hexylene glycol Drugs 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- XLSMFKSTNGKWQX-UHFFFAOYSA-N hydroxyacetone Chemical compound CC(=O)CO XLSMFKSTNGKWQX-UHFFFAOYSA-N 0.000 description 1

- 229910001026 inconel Inorganic materials 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 230000008595 infiltration Effects 0.000 description 1

- 238000001764 infiltration Methods 0.000 description 1

- 239000000976 ink Substances 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 229940035429 isobutyl alcohol Drugs 0.000 description 1

- 238000010030 laminating Methods 0.000 description 1

- 239000011133 lead Substances 0.000 description 1

- FPYJFEHAWHCUMM-UHFFFAOYSA-N maleic anhydride Chemical compound O=C1OC(=O)C=C1 FPYJFEHAWHCUMM-UHFFFAOYSA-N 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000011572 manganese Substances 0.000 description 1

- 239000002082 metal nanoparticle Substances 0.000 description 1

- 229920000609 methyl cellulose Polymers 0.000 description 1

- XJRBAMWJDBPFIM-UHFFFAOYSA-N methyl vinyl ether Chemical compound COC=C XJRBAMWJDBPFIM-UHFFFAOYSA-N 0.000 description 1

- 239000001923 methylcellulose Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000006082 mold release agent Substances 0.000 description 1

- 229920005615 natural polymer Polymers 0.000 description 1

- 229910001120 nichrome Inorganic materials 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 229910052755 nonmetal Inorganic materials 0.000 description 1

- 150000002843 nonmetals Chemical class 0.000 description 1

- QIQXTHQIDYTFRH-UHFFFAOYSA-N octadecanoic acid Chemical compound CCCCCCCCCCCCCCCCCC(O)=O QIQXTHQIDYTFRH-UHFFFAOYSA-N 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- 239000011146 organic particle Substances 0.000 description 1

- 229920000620 organic polymer Polymers 0.000 description 1

- BMMGVYCKOGBVEV-UHFFFAOYSA-N oxo(oxoceriooxy)cerium Chemical compound [Ce]=O.O=[Ce]=O BMMGVYCKOGBVEV-UHFFFAOYSA-N 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 239000011941 photocatalyst Substances 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920002432 poly(vinyl methyl ether) polymer Polymers 0.000 description 1

- 229920002401 polyacrylamide Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- LLHKCFNBLRBOGN-UHFFFAOYSA-N propylene glycol methyl ether acetate Chemical compound COCC(C)OC(C)=O LLHKCFNBLRBOGN-UHFFFAOYSA-N 0.000 description 1

- HNJBEVLQSNELDL-UHFFFAOYSA-N pyrrolidin-2-one Chemical compound O=C1CCCN1 HNJBEVLQSNELDL-UHFFFAOYSA-N 0.000 description 1

- 238000010791 quenching Methods 0.000 description 1

- 230000000171 quenching effect Effects 0.000 description 1

- 150000003254 radicals Chemical class 0.000 description 1

- 238000001878 scanning electron micrograph Methods 0.000 description 1

- 238000007873 sieving Methods 0.000 description 1

- 239000000779 smoke Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000011877 solvent mixture Substances 0.000 description 1

- 238000001694 spray drying Methods 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 150000005846 sugar alcohols Polymers 0.000 description 1

- HXJUTPCZVOIRIF-UHFFFAOYSA-N sulfolane Chemical compound O=S1(=O)CCCC1 HXJUTPCZVOIRIF-UHFFFAOYSA-N 0.000 description 1

- 229910052717 sulfur Inorganic materials 0.000 description 1

- 239000011593 sulfur Substances 0.000 description 1

- 230000003685 thermal hair damage Effects 0.000 description 1

- 239000011135 tin Substances 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 1

- JLGLQAWTXXGVEM-UHFFFAOYSA-N triethylene glycol monomethyl ether Chemical group COCCOCCOCCO JLGLQAWTXXGVEM-UHFFFAOYSA-N 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

- 239000000230 xanthan gum Substances 0.000 description 1

- 235000010493 xanthan gum Nutrition 0.000 description 1

- 229920001285 xanthan gum Polymers 0.000 description 1

- 229940082509 xanthan gum Drugs 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/04—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially inorganic

- B24D3/06—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially inorganic metallic or mixture of metals with ceramic materials, e.g. hard metals, "cermets", cements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D18/00—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for

- B24D18/0009—Manufacture of grinding tools or other grinding devices, e.g. wheels, not otherwise provided for using moulds or presses

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C3/00—Dental tools or instruments

- A61C3/02—Tooth drilling or cutting instruments; Instruments acting like a sandblast machine

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/10—Formation of a green body

- B22F10/14—Formation of a green body by jetting of binder onto a bed of metal powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/004—Filling molds with powder

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B22F3/26—Impregnating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F5/10—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product of articles with cavities or holes, not otherwise provided for in the preceding subgroups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B1/00—Processes of grinding or polishing; Use of auxiliary equipment in connection with such processes

- B24B1/04—Processes of grinding or polishing; Use of auxiliary equipment in connection with such processes subjecting the grinding or polishing tools, the abrading or polishing medium or work to vibration, e.g. grinding with ultrasonic frequency

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D3/00—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents

- B24D3/02—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent

- B24D3/20—Physical features of abrasive bodies, or sheets, e.g. abrasive surfaces of special nature; Abrasive bodies or sheets characterised by their constituents the constituent being used as bonding agent and being essentially organic

- B24D3/28—Resins or natural or synthetic macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C26/00—Alloys containing diamond or cubic or wurtzitic boron nitride, fullerenes or carbon nanotubes

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C32/00—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ

- C22C32/001—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with only oxides

- C22C32/0015—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with only oxides with only single oxides as main non-metallic constituents

- C22C32/0026—Matrix based on Ni, Co, Cr or alloys thereof

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C32/00—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ

- C22C32/001—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with only oxides

- C22C32/0015—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with only oxides with only single oxides as main non-metallic constituents

- C22C32/0031—Matrix based on refractory metals, W, Mo, Nb, Hf, Ta, Zr, Ti, V or alloys thereof

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C32/00—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ

- C22C32/0047—Non-ferrous alloys containing at least 5% by weight but less than 50% by weight of oxides, carbides, borides, nitrides, silicides or other metal compounds, e.g. oxynitrides, sulfides, whether added as such or formed in situ with carbides, nitrides, borides or silicides as the main non-metallic constituents

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0207—Using a mixture of prealloyed powders or a master alloy

- C22C33/0228—Using a mixture of prealloyed powders or a master alloy comprising other non-metallic compounds or more than 5% of graphite

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0257—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements

- C22C33/0278—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5%

- C22C33/0285—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5% with Cr, Co, or Ni having a minimum content higher than 5%

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

- A61C3/00—Dental tools or instruments

- A61C3/06—Tooth grinding or polishing discs; Holders therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F5/00—Manufacture of workpieces or articles from metallic powder characterised by the special shape of the product

- B22F2005/002—Tools other than cutting tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2998/00—Supplementary information concerning processes or compositions relating to powder metallurgy

- B22F2998/10—Processes characterised by the sequence of their steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y40/00—Auxiliary operations or equipment, e.g. for material handling

- B33Y40/20—Post-treatment, e.g. curing, coating or polishing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y80/00—Products made by additive manufacturing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Ceramic Engineering (AREA)

- Inorganic Chemistry (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Epidemiology (AREA)

- Dentistry (AREA)

- Polishing Bodies And Polishing Tools (AREA)

Description

a)

i)固まっていない粉末粒子の層を限られた領域に堆積する工程であり、固まっていない粉末粒子は、高融点金属粒子及び研磨粒子を含み、固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)液状バインダ前駆体物質を、少なくとも1つの所定の領域にある固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子の層を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、研磨物品プリフォームは、所定の形状を有し、各工程a)では、固まっていない粉末粒子は、独立して選択され、液状バインダ前駆体物質は、独立して選択される、工程と、

c)残った固まっていない粉末粒子の実質的に全てを研磨物品プリフォームから分離する工程と、

d)研磨物品プリフォームに融解した低融点金属を注入する工程であり、高融点金属粒子の少なくとも一部は、融解した低融点金属により接触したときに完全には融解しない、工程と、

e)融解した低融点金属を固化して、メタルボンド研磨物品を提供する工程と、

を含む、製造方法である。

a)

i)固まっていない粉末粒子の層を限られた領域に堆積する工程であり、固まっていない粉末粒子は、金属粒子及び研磨粒子を含み、固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)液状バインダ前駆体物質を、少なくとも1つの所定の領域にある固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、研磨物品プリフォームは、所定の形状を有し、各工程a)では、固まっていない粉末粒子は、独立して選択され、液状バインダ前駆体物質は、独立して選択される、工程と、

c)残った固まっていない粉末粒子の実質的に全てを研磨物品プリフォームから分離する工程と、

d)研磨物品プリフォームを加熱して、メタルボンド研磨物品を提供する工程と、

を含む、製造方法である。

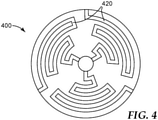

メタルボンド研磨物品前駆体の少なくとも一部を通って延びる少なくとも1つの蛇行状の冷却通路、又は

メタルボンド研磨物品前駆体の少なくとも一部を通って延びる少なくとも1つの弓状の冷却通路のうちの少なくとも1つを更に備える、メタルボンド研磨物品前駆体を提供する。

第1の実施形態では、本開示は、メタルボンド研磨物品の製造方法を提供する。この製造方法は、逐次的な工程を含み、逐次的な工程は、

a)

i)固まっていない粉末粒子の層を限られた領域に堆積させる工程であり、固まっていない粉末粒子は、高融点金属粒子及び研磨粒子を含み、固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)液状バインダ前駆体物質を、少なくとも1つの所定の領域にある固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子の層を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、研磨物品プリフォームは、所定の形状を有し、各工程a)では、固まっていない粉末粒子は、独立して選択され、液状バインダ前駆体物質は、独立して選択される、工程と、

c)残った固まっていない粉末粒子の実質的に全てを研磨物品プリフォームから分離する工程と、

d)研磨物品プリフォームに融解した低融点金属を注入する工程であり、高融点金属粒子の少なくとも一部は、融解した低融点金属により接触したときに完全には融解しない、工程と、

e)融解した低融点金属を固化して、メタルボンド研磨物品を提供する工程と、

を含む、製造方法である。

a)

i)固まっていない粉末粒子の層を限られた領域に堆積させる工程であり、固まっていない粉末粒子は、金属粒子及び研磨粒子を含み、固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)液状バインダ前駆体物質を、少なくとも1つの所定の領域にある固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、研磨物品プリフォームは、所定の形状を有し、各工程a)では、固まっていない粉末粒子は、独立して選択され、液状バインダ前駆体物質は、独立して選択される、工程と、

c)残った固まっていない粉末粒子の実質的に全てを研磨物品プリフォームから分離する工程と、

d)研磨物品プリフォームを加熱して、メタルボンド研磨物品を提供する工程と、

を含む、製造方法である。

メタルボンド研磨物品前駆体の少なくとも一部を通って延びる少なくとも1つの蛇行状の冷却通路、又は

メタルボンド研磨物品前駆体の少なくとも一部を通って延びる少なくとも1つの弓状の冷却通路のうちの少なくとも1つを更に備える、メタルボンド研磨物品前駆体を提供する。

混合物重量基準で89%のPDR1及び11%のPDR2を混合して、プリント材料(400g)を準備した。The ExOne Company(North Huntingdon,Pennsylvania)から入手したX1−Lab 3Dプリンタの形成ボックスにプリント材料を詰めた。プリンタのバインダ供給ボトルにBINを詰めた。ステンレス鋼用の以下の操作パラメータを使用して、製造者の操作指示書によるプリント手順及び順序によって、3Dプリンティングを実行した。層厚100ミクロン、スプレッダスピード25mm/秒、プリント飽和度70%レベル、90%ヒータ出力時の乾燥時間60秒。プリントプロセス中、粉末混合物は、良好に展開し、均一な平坦層を形成した。ダイヤモンド砥粒は、一様に分布しているように見えた。プリンティングが終了した後、物体及び周囲の粉末を含む粉末床をプリンタから取り出し、周囲雰囲気オーブン(ambient atmosphere oven)内に配置して195℃で2時間硬化させた。プリントされ硬化した物体を粉末床から取り出し、固まっていない粉末を柔らかな起毛ブラシを使用して除去した。

混合物重量基準で70%のPDR1、11%のPDR2及び19%のBRO2を混合して、プリント材料(400g)を準備した。The ExOne Companyから入手したX1−Lab 3Dプリンタの形成ボックスにプリント材料を詰めた。プリンタのバインダ供給ボトルにBINを詰めた。ステンレス鋼用の以下の操作パラメータを使用して、製造者の操作指示書によるプリント手順及び順序によって、3Dプリンティングを実行した。層厚100ミクロン、スプレッダスピード5mm/秒、プリント飽和度100%レベル、90%ヒータ出力時の乾燥時間60秒。プリンティングが終了した後、物体及び周囲の粉末を含む粉末床をプリンタから取り出し、周囲雰囲気オーブン内に配置して195℃で2時間硬化させた。23℃まで冷却した後に、次いで、プリントされ硬化したディスクを粉末床から取り出し、固まっていない粉末を柔らかな起毛ブラシを使用して除去した。得られた研磨物品は、外径22mm、中心穴直径1.5mm、及び厚さ0.6mmの平坦なダイヤモンド切削ディスクであった。

混合物重量基準で45%のPDR1、25%のPDR3及び30%のBRO2を混合して、プリント材料(400g)を準備した。The ExOne Companyから入手したX1−Lab 3Dプリンタの形成ボックスにプリント材料を詰めた。プリンタのバインダ供給ボトルにBINを詰めた。歯科用バーヘッドの前駆体部分を図2の歯科用バーヘッド210の形状(外径5mm、内径3mm)にプリントするために、ステンレス鋼用の以下の操作パラメータを使用して、製造者の操作指示書による印刷手順及び順序によって、3Dプリンティングを実行した。層厚200ミクロン、スプレッダスピード5mm/秒、プリント飽和度120%レベル、90%ヒータ出力時の乾燥時間120秒。粉末混合物は、良好に展開し、均一な平坦層を形成した。ダイヤモンド砥粒は、一様に分布しているように見えた。プリントプロセスが終了した後、物体及び周囲の粉末を含む粉末床をプリンタから取り出し、周囲雰囲気オーブン内に配置して195℃で2時間硬化させた。23℃まで冷却した後に、次いで、プリントされ硬化した歯科用バーヘッド前駆体を粉末床から取り出し、固まっていない粉末を柔らかな起毛ブラシを使用して除去した。

実施例3の歯科用バーを、力を調節して試験材にバーを押し付けることができる試験装置であるDremelドリルに挿入した。試験材は、Filtek Supreme Ultra Universal(3M ESPE(Saint Paul,Minnesota))の歯科用修復化合物質を、15×25×1.8mmサイズのブロックに鋳造し、出力84に設定されたUV−Vis LED SourceモデルCF2000(Clearstone Tech製(Hopkins,Minnesota))を使用して、2つの主面のそれぞれを20秒間の露出で光硬化したブロックであった。試験材の1つの主面に熱電対を取り付けた。ドリルを10000RPMの回転スピードに設定し、力を200gfに設定した。熱電対とは反対側にある材料の主面にバーを60秒間押し進め、0秒後、30秒後、45秒後及び60秒後それぞれの温度上昇を記録した。バーが物質を除去し、切込みを形成するのが観察された。バーを取り外して、走査型電子顕微鏡(SEM)を使用して100倍に拡大して確認した。バーに削り屑の蓄積がないことを観察した。

Claims (29)

- メタルボンド研磨物品の製造方法であって、前記製造方法は、逐次的な工程を含み、前記逐次的な工程は、

a)

i)固まっていない粉末粒子の層を限られた領域に堆積する工程であり、前記固まっていない粉末粒子は、高融点金属粒子及び研磨粒子を含み、前記固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)前記固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)前記液状バインダ前駆体物質を、気化、熱硬化、化学硬化、及び/又は、放射線硬化によって、前記少なくとも1つの所定の領域にある前記固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子の層を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、積層された前記結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、前記研磨物品プリフォームは、所定の形状を有し、各工程a)では、前記固まっていない粉末粒子は、独立して選択され、前記液状バインダ前駆体物質は、独立して選択される、工程と、

c)前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離する工程と、

d)前記研磨物品プリフォームを加熱して前記バインダ物質の少なくとも一部分をバーンアウトするステップと、

e)前記研磨物品プリフォームに融解した低融点金属を注入する工程であり、前記高融点金属粒子の少なくとも一部は、前記融解した低融点金属と接触したときに完全には融解しない、工程と、

f)前記融解した低融点金属を固化して、前記メタルボンド研磨物品を提供する工程と、を含む、製造方法。 - 前記固まっていない粉末粒子は、融剤粒子を更に含む、請求項1に記載の製造方法。

- 前記研磨粒子は、ダイヤモンド粒子又は立方窒化ホウ素粒子のうちの少なくとも1つを含む、請求項1又は2に記載の製造方法。

- 前記研磨粒子は、金属酸化物セラミック粒子を含む、請求項1又は2に記載の製造方法。

- 前記メタルボンド研磨物品は、前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離することによって形成される空間部分の少なくとも一部である、少なくとも1つの冷却通路を含む、請求項1〜4のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、研磨パッド、研磨研削ビット、研磨セグメント、及び研磨ホイールから成る群から選択される、請求項1〜5のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、歯科用回転ツールの研磨部の少なくとも一部分を構成する、請求項1〜5のいずれか一項に記載の製造方法。

- 前記液状バインダ前駆体物質は、溶存ポリマーを含有する液状ビヒクルを含む、請求項1〜7のいずれか一項に記載の製造方法。

- 前記液状ビヒクルは、主に水を含む、請求項8に記載の製造方法。

- 前記高融点金属粒子が、前記融解した低融点金属の温度よりも少なくとも50℃高い融点を有する、請求項1〜9のいずれか一項に記載の製造方法。

- メタルボンド研磨物品の製造方法であって、前記方法は、逐次的な工程を含み、前記逐次的な工程は、

a)

i)固まっていない粉末粒子の層を限られた領域に堆積する工程であり、前記固まっていない粉末粒子は、金属粒子及び研磨粒子を含み、前記固まっていない粉末粒子の層は、実質的に均一な厚さを有する、工程、

ii)前記固まっていない粉末粒子の層の少なくとも1つの所定の領域に液状バインダ前駆体物質を噴射する工程、並びに

iii)前記液状バインダ前駆体物質を、気化、熱硬化、化学硬化、及び/又は、放射線硬化によって、前記少なくとも1つの所定の領域にある前記固まっていない粉末粒子を一緒に結合するバインダ物質に転換して、結合した粉末粒子を形成する工程、を逐次的に行うサブプロセスと、

b)工程a)を独立して複数回実施して、積層された前記結合した粉末粒子及び残った固まっていない粉末粒子を含む研磨物品プリフォームを生成する工程であり、前記研磨物品プリフォームは、所定の形状を有し、各工程a)では、前記固まっていない粉末粒子は、独立して選択され、前記液状バインダ前駆体物質は、独立して選択される、工程と、

c)前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離する工程と、

d)前記研磨物品プリフォームを加熱して前記バインダ物質の少なくとも一部分をバーンアウトし、前記メタルボンド研磨物品を提供する工程と、を含む、製造方法。 - 前記固まっていない粉末粒子は、融剤粒子を更に含む、請求項11に記載の製造方法。

- 前記研磨粒子は、ダイヤモンド粒子又は立方窒化ホウ素粒子のうちの少なくとも1つを含む、請求項11又は12に記載の製造方法。

- 前記研磨粒子は、金属酸化物セラミック粒子を含む、請求項11又は12に記載の製造方法。

- 前記金属粒子は、高融点金属粒子と低融点金属粒子との組合せを含み、前記高融点金属粒子は、前記融解した低温金属の温度よりも少なくとも50℃高い融点を有する、請求項11〜14のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離することによって形成される空間部分の少なくとも一部である、少なくとも1つの冷却通路を含む、請求項11〜15のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、研磨パッド、研磨研削ビット、研磨セグメント、及び研磨ホイールから成る群から選択される、請求項11〜16のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、歯科用回転ツールの研磨部の少なくとも一部分を構成する、請求項11〜16のいずれか一項に記載の製造方法。

- 前記液状バインダ前駆体物質は、溶存ポリマーを含有する液状ビヒクルを含む、請求項11〜18のいずれか一項に記載の製造方法。

- 前記液状ビヒクルは、主に水を含む、請求項19に記載の製造方法。

- 前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離することによって形成される空間部分の少なくとも一部である、前記メタルボンド研磨物品の少なくとも一部を通って延びる少なくとも1つの蛇行状の冷却通路を形成し、前記メタルボンド研磨物品は、研磨粒子を内部に保持する金属性バインダ物質を含む、請求項1〜20のいずれか一項に記載の製造方法。

- 前記残った固まっていない粉末粒子の実質的に全てを前記研磨物品プリフォームから分離することによって形成される空間部分の少なくとも一部である、前記メタルボンド研磨物品の少なくとも一部を通って延びる少なくとも1つの弓状の冷却通路を形成し、前記メタルボンド研磨物品は、研磨粒子を内部に保持する金属性バインダ物質を含む、請求項1〜20のいずれか一項に記載の製造方法。

- 前記研磨粒子は、第1の研磨粒子及び第2の研磨粒子を含み、前記第1の研磨粒子及び前記第2の研磨粒子が、前記メタルボンド研磨物品内の分散した所定の異なる領域に配置されている、請求項21又は22に記載の製造方法。

- 前記異なる領域は層である、請求項23に記載の製造方法。

- 前記研磨粒子は、ダイヤモンド粒子又は立方窒化ホウ素粒子のうちの少なくとも1つを含む、請求項21〜24のいずれか一項に記載の製造方法。

- 前記研磨粒子は、金属酸化物セラミック粒子を含む、請求項21〜25のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、研磨パッド、研磨研削ビット、研磨セグメント、及び研磨ホイールから成る群から選択される、請求項21〜26のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、15〜50体積パーセントの空隙率を有する多孔性の金属含有マトリックスを含む、請求項21〜27のいずれか一項に記載の製造方法。

- 前記メタルボンド研磨物品は、歯科用ツールの少なくとも一部分を含む、請求項21〜27のいずれか一項に記載の製造方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562184689P | 2015-06-25 | 2015-06-25 | |

| US62/184,689 | 2015-06-25 | ||

| PCT/US2016/037767 WO2016209696A1 (en) | 2015-06-25 | 2016-06-16 | Methods of making metal bond abrasive articles and metal bond abrasive articles |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2018519176A JP2018519176A (ja) | 2018-07-19 |

| JP6987643B2 true JP6987643B2 (ja) | 2022-01-05 |

Family

ID=57586133

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017566775A Active JP6987643B2 (ja) | 2015-06-25 | 2016-06-16 | メタルボンド研磨物品の製造方法及びメタルボンド研磨物品 |

Country Status (6)

| Country | Link |

|---|---|

| US (2) | US10888973B2 (ja) |

| EP (1) | EP3313617B1 (ja) |

| JP (1) | JP6987643B2 (ja) |

| CN (1) | CN107896491B (ja) |

| PL (1) | PL3313617T3 (ja) |

| WO (1) | WO2016209696A1 (ja) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11072053B2 (en) | 2016-01-21 | 2021-07-27 | 3M Innovative Properties Company | Methods of making metal bond and vitreous bond abrasive articles, and abrasive article precursors |

| EP3436269A4 (en) | 2016-03-30 | 2019-11-20 | 3M Innovative Properties Company | METHOD FOR PRODUCING A METAL BOND AND GLASS-TYPE GRINDING MATERIALS AND GRINDING PROCESSORS |

| CN108015906A (zh) | 2016-10-28 | 2018-05-11 | 圣戈班磨料磨具有限公司 | 空芯钻头及其制造方法 |

| JP7134971B2 (ja) * | 2016-12-23 | 2022-09-12 | スリーエム イノベイティブ プロパティズ カンパニー | ポリマーボンド研磨物品及びそれらの製造方法 |

| EP3589450A4 (en) * | 2017-02-28 | 2021-04-07 | 3M Innovative Properties Company | METAL-BOND ABRASIVE ARTICLES AND METHODS FOR MANUFACTURING METAL-BONDED ABRASIVE ARTICLES |

| CN110799287A (zh) | 2017-06-28 | 2020-02-14 | 惠普发展公司,有限责任合伙企业 | 三维打印 |

| US11404180B2 (en) | 2017-10-09 | 2022-08-02 | Ut-Battelle, Llc | Method for producing collimators and other components from neutron absorbing materials using additive manufacturing |

| US10654259B2 (en) * | 2017-10-24 | 2020-05-19 | Global Circuit Innovations Incorporated | Conductive diamond application method |

| WO2020102025A1 (en) | 2018-11-12 | 2020-05-22 | Desktop Metal, Inc. | Techniques for controlling build material flow characteristics in additive manufacturing and related systems and methods |

| WO2020222725A1 (en) * | 2019-04-27 | 2020-11-05 | Hewlett-Packard Development Company, L.P. | Three-dimensional printing |

| US11538597B2 (en) * | 2019-06-28 | 2022-12-27 | Ut-Battelle, Llc | Additive manufacturing of composite neutron absorbing components |

| CN112140015A (zh) * | 2019-06-28 | 2020-12-29 | 圣戈班磨料磨具有限公司 | 磨料制品及其形成方法 |

| WO2021001730A1 (en) * | 2019-07-02 | 2021-01-07 | 3M Innovative Properties Company | Methods of making metal bond abrasive articles and metal bond abrasive articles |

| EP3785825A1 (en) * | 2019-08-30 | 2021-03-03 | 3M Innovative Properties Company | Powder blend for use in additive manufacturing |

| EP4051741A1 (en) | 2019-10-28 | 2022-09-07 | 3M Innovative Properties Company | System and methods of finishing a metallic surface |

| US20210171814A1 (en) * | 2019-12-10 | 2021-06-10 | Saint-Gobain Abrasives, Inc. | Fixed abrasive article |

| CN110948407B (zh) * | 2019-12-13 | 2022-05-17 | 黄石海纳新材料科技股份有限公司 | 一种磨具的制备方法 |

| US11319613B2 (en) | 2020-08-18 | 2022-05-03 | Enviro Metals, LLC | Metal refinement |

| WO2023130059A1 (en) | 2021-12-30 | 2023-07-06 | Saint-Gobain Abrasives, Inc. | Abrasive articles and methods for forming same |

| CN114932223B (zh) * | 2022-06-07 | 2024-01-09 | 江苏精研科技股份有限公司 | 一种金属基复合材料的共烧结制备方法 |

| US20240325129A1 (en) * | 2023-03-29 | 2024-10-03 | Kabushiki Kaisha Shofu | Dental polishing instrument |

Family Cites Families (76)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2367404A (en) | 1943-07-09 | 1945-01-16 | Fish Schurman Corp | Abrasive composition of matter and method of forming same |

| US4314827A (en) | 1979-06-29 | 1982-02-09 | Minnesota Mining And Manufacturing Company | Non-fused aluminum oxide-based abrasive mineral |

| US4623364A (en) | 1984-03-23 | 1986-11-18 | Norton Company | Abrasive material and method for preparing the same |

| US4574003A (en) | 1984-05-03 | 1986-03-04 | Minnesota Mining And Manufacturing Co. | Process for improved densification of sol-gel produced alumina-based ceramics |

| US4718005A (en) | 1984-05-03 | 1988-01-05 | International Business Machines Corporation | Distributed control of alias name usage in networks |

| US5227104A (en) | 1984-06-14 | 1993-07-13 | Norton Company | High solids content gels and a process for producing them |

| CA1254238A (en) | 1985-04-30 | 1989-05-16 | Alvin P. Gerk | Process for durable sol-gel produced alumina-based ceramics, abrasive grain and abrasive products |

| US4770671A (en) | 1985-12-30 | 1988-09-13 | Minnesota Mining And Manufacturing Company | Abrasive grits formed of ceramic containing oxides of aluminum and yttrium, method of making and using the same and products made therewith |

| AU613584B2 (en) * | 1986-09-15 | 1991-08-08 | Abrasive Technology N.A. Inc. | A flexible abrasive coated article and method of making it |

| US4960441A (en) | 1987-05-11 | 1990-10-02 | Norton Company | Sintered alumina-zirconia ceramic bodies |

| US4881951A (en) | 1987-05-27 | 1989-11-21 | Minnesota Mining And Manufacturing Co. | Abrasive grits formed of ceramic containing oxides of aluminum and rare earth metal, method of making and products made therewith |

| US5011508A (en) | 1988-10-14 | 1991-04-30 | Minnesota Mining And Manufacturing Company | Shelling-resistant abrasive grain, a method of making the same, and abrasive products |

| JPH02237759A (ja) * | 1989-03-10 | 1990-09-20 | Sanwa Daiyamondo Kogyo Kk | カッターおよびその製造方法 |

| US5387380A (en) | 1989-12-08 | 1995-02-07 | Massachusetts Institute Of Technology | Three-dimensional printing techniques |

| US5204055A (en) * | 1989-12-08 | 1993-04-20 | Massachusetts Institute Of Technology | Three-dimensional printing techniques |

| US5449388A (en) * | 1990-05-21 | 1995-09-12 | Wiand; Ronald C. | Injection molded abrasive article and process |

| US5139978A (en) | 1990-07-16 | 1992-08-18 | Minnesota Mining And Manufacturing Company | Impregnation method for transformation of transition alumina to a alpha alumina |

| US5090968A (en) | 1991-01-08 | 1992-02-25 | Norton Company | Process for the manufacture of filamentary abrasive particles |

| US5178849A (en) | 1991-03-22 | 1993-01-12 | Norton Company | Process for manufacturing alpha alumina from dispersible boehmite |

| JPH04372366A (ja) * | 1991-06-17 | 1992-12-25 | I N R Kenkyusho:Kk | 研削工具及びその製造方法 |

| JP2835210B2 (ja) | 1991-06-19 | 1998-12-14 | 古河電気工業株式会社 | 半田付け用加熱炉 |

| US5252264A (en) * | 1991-11-08 | 1993-10-12 | Dtm Corporation | Apparatus and method for producing parts with multi-directional powder delivery |

| US5178644A (en) | 1992-01-23 | 1993-01-12 | Cincinnati Milacron Inc. | Method for making vitreous bonded abrasive article and article made by the method |

| US5282875A (en) | 1992-03-18 | 1994-02-01 | Cincinnati Milacron Inc. | High density sol-gel alumina-based abrasive vitreous bonded grinding wheel |

| US5201916A (en) | 1992-07-23 | 1993-04-13 | Minnesota Mining And Manufacturing Company | Shaped abrasive particles and method of making same |

| US5366523A (en) | 1992-07-23 | 1994-11-22 | Minnesota Mining And Manufacturing Company | Abrasive article containing shaped abrasive particles |

| JP3052603B2 (ja) * | 1992-09-17 | 2000-06-19 | 三菱マテリアル株式会社 | 多孔質メタルボンド砥石 |

| EP0662110B1 (en) | 1992-09-25 | 1999-11-24 | Minnesota Mining And Manufacturing Company | Abrasive grain including rare earth oxide therein |

| DE69309478T2 (de) | 1992-09-25 | 1997-07-10 | Minnesota Mining & Mfg | Aluminiumoxid und zirconiumoxid enthaltendes schleifkorn |

| ATE137792T1 (de) | 1992-09-25 | 1996-05-15 | Minnesota Mining & Mfg | Verfahren zur herstellung von aluminiumoxid und ceroxid enthaltendem schleifkorn |

| US5490882A (en) | 1992-11-30 | 1996-02-13 | Massachusetts Institute Of Technology | Process for removing loose powder particles from interior passages of a body |

| AU1370595A (en) | 1993-12-28 | 1995-07-17 | Minnesota Mining And Manufacturing Company | Alpha alumina-based abrasive grain having an as sintered outer surface |

| US5839329A (en) | 1994-03-16 | 1998-11-24 | Baker Hughes Incorporated | Method for infiltrating preformed components and component assemblies |

| US6209420B1 (en) | 1994-03-16 | 2001-04-03 | Baker Hughes Incorporated | Method of manufacturing bits, bit components and other articles of manufacture |

| JPH0811051A (ja) * | 1994-06-28 | 1996-01-16 | Sony Corp | 研磨布 |

| US5725162A (en) | 1995-04-05 | 1998-03-10 | Saint Gobain/Norton Industrial Ceramics Corporation | Firing sol-gel alumina particles |

| US5660621A (en) * | 1995-12-29 | 1997-08-26 | Massachusetts Institute Of Technology | Binder composition for use in three dimensional printing |

| US5776214A (en) | 1996-09-18 | 1998-07-07 | Minnesota Mining And Manufacturing Company | Method for making abrasive grain and abrasive articles |

| US5766277A (en) | 1996-09-20 | 1998-06-16 | Minnesota Mining And Manufacturing Company | Coated abrasive article and method of making same |

| NL1006059C2 (nl) | 1997-05-14 | 1998-11-17 | Geest Adrianus F Van Der | Werkwijze en inrichting voor het vervaardigen van een vormlichaam. |

| DE19834559A1 (de) * | 1998-07-31 | 2000-02-03 | Friedrich Schiller Uni Jena Bu | Verfahren zur Herstellung von Werkzeugen für die Bearbeitung von Oberflächen |

| DE19909882C2 (de) * | 1999-03-06 | 2002-01-10 | Fraunhofer Ges Forschung | Material zur schichtweisen Herstellung von Werkzeugen, Formen oder Bauteilen durch das Lasersinterverfahren |

| US6645412B2 (en) | 1999-04-20 | 2003-11-11 | Stratasys, Inc. | Process of making a three-dimensional object |

| US6123744A (en) | 1999-06-02 | 2000-09-26 | Milacron Inc. | Vitreous bond compositions for abrasive articles |

| US6376590B2 (en) | 1999-10-28 | 2002-04-23 | 3M Innovative Properties Company | Zirconia sol, process of making and composite material |

| WO2001034371A2 (en) * | 1999-11-05 | 2001-05-17 | Z Corporation | Material systems and methods of three-dimensional printing |

| US6413286B1 (en) * | 2000-05-03 | 2002-07-02 | Saint-Gobain Abrasives Technology Company | Production tool process |

| US6551366B1 (en) | 2000-11-10 | 2003-04-22 | 3M Innovative Properties Company | Spray drying methods of making agglomerate abrasive grains and abrasive articles |

| US20020095875A1 (en) | 2000-12-04 | 2002-07-25 | D'evelyn Mark Philip | Abrasive diamond composite and method of making thereof |

| US6575353B2 (en) | 2001-02-20 | 2003-06-10 | 3M Innovative Properties Company | Reducing metals as a brazing flux |

| US6593391B2 (en) * | 2001-03-27 | 2003-07-15 | General Electric Company | Abrasive-filled thermoset composition and its preparation, and abrasive-filled articles and their preparation |

| WO2005021248A1 (ja) * | 2003-08-27 | 2005-03-10 | Fuji Photo Film Co., Ltd. | 三次元造形物の製造方法 |

| DE10361895B4 (de) * | 2003-12-30 | 2013-02-07 | Technische Universität Kaiserslautern | Hochleistungs-Schleifscheibe |

| US8870571B2 (en) | 2004-09-24 | 2014-10-28 | Spectrum Systems, Llc | Rotary dental tool and method of manufacture |

| US7524345B2 (en) | 2005-02-22 | 2009-04-28 | Saint-Gobain Abrasives, Inc. | Rapid tooling system and methods for manufacturing abrasive articles |

| US7875091B2 (en) * | 2005-02-22 | 2011-01-25 | Saint-Gobain Abrasives, Inc. | Rapid tooling system and methods for manufacturing abrasive articles |

| US7867302B2 (en) | 2005-02-22 | 2011-01-11 | Saint-Gobain Abrasives, Inc. | Rapid tooling system and methods for manufacturing abrasive articles |

| US20070020457A1 (en) | 2005-07-21 | 2007-01-25 | 3M Innovative Properties Company | Composite particle comprising an abrasive grit |

| US7399330B2 (en) | 2005-10-18 | 2008-07-15 | 3M Innovative Properties Company | Agglomerate abrasive grains and methods of making the same |

| EP2001656B1 (en) | 2006-04-06 | 2014-10-15 | 3D Systems Incorporated | KiT FOR THE PRODUCTION OF THREE-DIMENSIONAL OBJECTS BY USE OF ELECTROMAGNETIC RADIATION |

| WO2007121052A2 (en) | 2006-04-13 | 2007-10-25 | 3M Innovative Properties Company | Metal-coated superabrasive material and methods of making the same |

| US10040216B2 (en) | 2007-04-04 | 2018-08-07 | The Exone Company | Powder particle layerwise three-dimensional printing process |

| KR101524123B1 (ko) * | 2008-08-08 | 2015-06-01 | 생-고뱅 어브레이시브즈, 인코포레이티드 | 연마 부품을 캐리어에 결합하기 위해 연속적인 금속 상을 가지는 연마 공구들 |

| FR2939075B1 (fr) | 2008-12-01 | 2010-12-17 | Rhodia Operations | Realisation d'article par fusion selective de couches de poudre de polymere |

| US8991211B1 (en) | 2009-11-01 | 2015-03-31 | The Exone Company | Three-dimensional printing glass articles |

| FR2955330B1 (fr) | 2010-01-19 | 2012-01-20 | Arkema France | Composition de poudre thermoplastique et objets tridimensionnels fabriques par frittage d'une telle composition |

| CN101804603B (zh) | 2010-04-29 | 2012-05-30 | 沈阳理工大学 | 锡固结金刚石磨料仿生抛光盘及制造方法 |

| TWI544064B (zh) | 2010-09-03 | 2016-08-01 | 聖高拜磨料有限公司 | 粘結的磨料物品及形成方法 |

| US9156999B2 (en) * | 2011-07-28 | 2015-10-13 | Hewlett-Packard Development Company, L.P. | Liquid inkjettable materials for three-dimensional printing |

| FR2979269B1 (fr) | 2011-08-24 | 2014-05-16 | Lorraine Inst Nat Polytech | Procede de fabrication d'une piece comprenant de l'aluminium |

| US9067299B2 (en) | 2012-04-25 | 2015-06-30 | Applied Materials, Inc. | Printed chemical mechanical polishing pad |

| US10471571B2 (en) | 2013-03-12 | 2019-11-12 | 3M Innovative Properties Company | Bonded abrasive article |

| JP6550374B2 (ja) | 2013-04-05 | 2019-07-24 | スリーエム イノベイティブ プロパティズ カンパニー | 焼結された研磨粒子、それを作製する方法、及びそれを含む研磨物品 |

| WO2015048768A1 (en) | 2013-09-30 | 2015-04-02 | Saint-Gobain Ceramics & Plastics, Inc. | Shaped abrasive particles and methods of forming same |

| JP6290428B2 (ja) | 2013-12-31 | 2018-03-07 | サンーゴバン アブレイシブズ,インコーポレイティド | 成形研磨粒子を含む研磨物品 |

| WO2016210057A1 (en) | 2015-06-25 | 2016-12-29 | 3M Innovative Properties Company | Vitreous bond abrasive articles and methods of making the same |

-

2016

- 2016-06-16 US US15/573,254 patent/US10888973B2/en active Active

- 2016-06-16 WO PCT/US2016/037767 patent/WO2016209696A1/en active Application Filing

- 2016-06-16 JP JP2017566775A patent/JP6987643B2/ja active Active

- 2016-06-16 EP EP16815079.5A patent/EP3313617B1/en active Active

- 2016-06-16 CN CN201680037153.0A patent/CN107896491B/zh active Active

- 2016-06-16 PL PL16815079.5T patent/PL3313617T3/pl unknown

-

2020

- 2020-12-11 US US17/247,442 patent/US11597058B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN107896491B (zh) | 2020-12-29 |

| JP2018519176A (ja) | 2018-07-19 |

| US20210094149A1 (en) | 2021-04-01 |

| US11597058B2 (en) | 2023-03-07 |

| EP3313617B1 (en) | 2023-06-14 |

| PL3313617T3 (pl) | 2023-08-14 |

| EP3313617A1 (en) | 2018-05-02 |

| US10888973B2 (en) | 2021-01-12 |

| WO2016209696A1 (en) | 2016-12-29 |

| EP3313617A4 (en) | 2019-02-27 |

| CN107896491A (zh) | 2018-04-10 |

| US20180126515A1 (en) | 2018-05-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6987643B2 (ja) | メタルボンド研磨物品の製造方法及びメタルボンド研磨物品 | |

| JP7458693B2 (ja) | ガラス質ボンド研磨物品及びその製造方法 | |

| US11383350B2 (en) | Metal bond abrasive articles and methods of making metal bond abrasive articles | |

| KR102427116B1 (ko) | 배향된 연마 입자를 포함하는 접합된 연마 용품, 및 그의 제조 방법 | |

| JP6926094B2 (ja) | メタルボンド及びガラス質ボンド研磨物品の製造方法、並びに研磨物品前駆体 | |

| WO2021001730A1 (en) | Methods of making metal bond abrasive articles and metal bond abrasive articles | |

| US20230219195A1 (en) | Polymer bond abrasive articles and methods of making them | |

| CN114144282B (zh) | 具有内部冷却剂特征的磨料制品及其制造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190614 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200626 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200714 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20201002 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210427 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210511 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20211102 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20211201 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6987643 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |