JP6619399B2 - 数値制御工作機械にてワークピースを加工する方法、装置、工作機械、及びコンピュータプログラム製品 - Google Patents

数値制御工作機械にてワークピースを加工する方法、装置、工作機械、及びコンピュータプログラム製品 Download PDFInfo

- Publication number

- JP6619399B2 JP6619399B2 JP2017149869A JP2017149869A JP6619399B2 JP 6619399 B2 JP6619399 B2 JP 6619399B2 JP 2017149869 A JP2017149869 A JP 2017149869A JP 2017149869 A JP2017149869 A JP 2017149869A JP 6619399 B2 JP6619399 B2 JP 6619399B2

- Authority

- JP

- Japan

- Prior art keywords

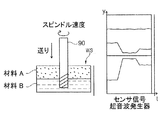

- workpiece

- tool

- sensor signal

- ultrasonic generator

- machine tool

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/416—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by control of velocity, acceleration or deceleration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q17/00—Arrangements for observing, indicating or measuring on machine tools

- B23Q17/20—Arrangements for observing, indicating or measuring on machine tools for indicating or measuring workpiece characteristics, e.g. contour, dimension, hardness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B49/00—Measuring or gauging equipment on boring machines for positioning or guiding the drill; Devices for indicating failure of drills during boring; Centering devices for holes to be bored

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B37/00—Boring by making use of ultrasonic energy

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q15/00—Automatic control or regulation of feed movement, cutting velocity or position of tool or work

- B23Q15/007—Automatic control or regulation of feed movement, cutting velocity or position of tool or work while the tool acts upon the workpiece

- B23Q15/013—Control or regulation of feed movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q15/00—Automatic control or regulation of feed movement, cutting velocity or position of tool or work

- B23Q15/007—Automatic control or regulation of feed movement, cutting velocity or position of tool or work while the tool acts upon the workpiece

- B23Q15/12—Adaptive control, i.e. adjusting itself to have a performance which is optimum according to a preassigned criterion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q15/00—Automatic control or regulation of feed movement, cutting velocity or position of tool or work

- B23Q15/007—Automatic control or regulation of feed movement, cutting velocity or position of tool or work while the tool acts upon the workpiece

- B23Q15/18—Compensation of tool-deflection due to temperature or force

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23Q—DETAILS, COMPONENTS, OR ACCESSORIES FOR MACHINE TOOLS, e.g. ARRANGEMENTS FOR COPYING OR CONTROLLING; MACHINE TOOLS IN GENERAL CHARACTERISED BY THE CONSTRUCTION OF PARTICULAR DETAILS OR COMPONENTS; COMBINATIONS OR ASSOCIATIONS OF METAL-WORKING MACHINES, NOT DIRECTED TO A PARTICULAR RESULT

- B23Q17/00—Arrangements for observing, indicating or measuring on machine tools

- B23Q17/09—Arrangements for observing, indicating or measuring on machine tools for indicating or measuring cutting pressure or for determining cutting-tool condition, e.g. cutting ability, load on tool

- B23Q17/0952—Arrangements for observing, indicating or measuring on machine tools for indicating or measuring cutting pressure or for determining cutting-tool condition, e.g. cutting ability, load on tool during machining

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B17/00—Measuring arrangements characterised by the use of infrasonic, sonic or ultrasonic vibrations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2260/00—Details of constructional elements

- B23B2260/128—Sensors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2270/00—Details of turning, boring or drilling machines, processes or tools not otherwise provided for

- B23B2270/10—Use of ultrasound

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23B—TURNING; BORING

- B23B2270/00—Details of turning, boring or drilling machines, processes or tools not otherwise provided for

- B23B2270/48—Measuring or detecting

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/45—Nc applications

- G05B2219/45206—Ultrasonic drill, mill, machining

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Human Computer Interaction (AREA)

- Manufacturing & Machinery (AREA)

- Automation & Control Theory (AREA)

- Automatic Control Of Machine Tools (AREA)

- Numerical Control (AREA)

- Machine Tool Sensing Apparatuses (AREA)

- Drilling And Boring (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016214699.8 | 2016-08-08 | ||

| DE102016214699.8A DE102016214699A1 (de) | 2016-08-08 | 2016-08-08 | Verfahren und Vorrichtung zur Bearbeitung eines Werkstücks an einer numerisch gesteuerten Werkzeugmaschine |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2018039107A JP2018039107A (ja) | 2018-03-15 |

| JP2018039107A5 JP2018039107A5 (enExample) | 2019-07-11 |

| JP6619399B2 true JP6619399B2 (ja) | 2019-12-11 |

Family

ID=59649494

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017149869A Active JP6619399B2 (ja) | 2016-08-08 | 2017-08-02 | 数値制御工作機械にてワークピースを加工する方法、装置、工作機械、及びコンピュータプログラム製品 |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US10678219B2 (enExample) |

| EP (1) | EP3281741B1 (enExample) |

| JP (1) | JP6619399B2 (enExample) |

| CN (1) | CN107695793B (enExample) |

| CA (1) | CA2975574C (enExample) |

| DE (1) | DE102016214699A1 (enExample) |

| ES (1) | ES2904283T3 (enExample) |

| PL (1) | PL3281741T3 (enExample) |

| PT (1) | PT3281741T (enExample) |

| RU (1) | RU2700628C2 (enExample) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102017208909A1 (de) | 2017-05-26 | 2018-11-29 | Trumpf Werkzeugmaschinen Gmbh + Co. Kg | Verfahren zum Bestimmen von Materialeigenschaften eines Werkstücks durch Audioanalyse einer Werkstückbearbeitung sowie Stanzmaschine und Computerprogrammprodukt |

| WO2019147536A1 (en) | 2018-01-23 | 2019-08-01 | Quantum Impact, LLC | Method and apparatus for machining a workpiece |

| CN109894923B (zh) * | 2019-03-07 | 2020-11-27 | 中南大学 | 一种超声振动辅助加工中刀具稳定性控制方法 |

| EP3715978A1 (de) * | 2019-03-26 | 2020-09-30 | Siemens Aktiengesellschaft | Verfahren zum betreiben einer werkzeugmaschine sowie werkzeugmaschine |

| DE102019003921B4 (de) * | 2019-06-05 | 2021-05-06 | Hufschmied Zerspanungssysteme Gmbh | Werkstückprüfverfahren und Werkstückprüfsystem |

| DE102019209191B4 (de) * | 2019-06-25 | 2025-05-22 | Dmg Mori Ultrasonic Lasertec Gmbh | Verfahren und vorrichtung zum steuern einer ultraschall-werkzeugeinheit für die spanende bearbeitung an einer werkzeugmaschine |

| CN111609000B (zh) * | 2020-05-18 | 2025-07-11 | 广州市优尚家具有限公司 | 一种隐藏式铝合金家具扣件 |

| CN111843615B (zh) * | 2020-06-29 | 2021-07-20 | 中南大学 | 一种超声振动辅助加工中材料的断裂韧性的快速识别方法 |

| CN113714856B (zh) * | 2021-07-26 | 2023-06-27 | 豪丰茂五金制品(太仓)有限公司 | 一种数控机床的超声自动检测系统及其工作方法 |

| CN116140658A (zh) * | 2021-11-23 | 2023-05-23 | 济南大学 | 一种通过超声振动抑制车削中杆类零件自激振动的方法 |

| MX2024009784A (es) | 2022-03-22 | 2024-08-19 | Schunk Sonosystems Gmbh | Metodo para controlar un generador de ultrasonidos y generador de ultrasonidos. |

| CN115570447A (zh) * | 2022-10-11 | 2023-01-06 | 上海诺倬力机电科技有限公司 | 一种数控机床防碰撞用监测方法、系统、终端及介质 |

| US20240165764A1 (en) * | 2022-11-23 | 2024-05-23 | Raytheon Technologies Corporation | Adaptive vibration amplitude for impact grinding of ceramic matrix composite components |

| CN119328904B (zh) * | 2024-10-31 | 2025-11-14 | 中国一冶集团有限公司 | 一种自动化水电开槽系统及方法 |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8810976D0 (en) * | 1988-05-10 | 1988-06-15 | Sra Dev Ltd | Cutting brittle materials |

| US5257531A (en) * | 1992-08-17 | 1993-11-02 | Masashi Motosugi | Apparatus for monitoring machining state of drill |

| US5940787A (en) * | 1993-12-10 | 1999-08-17 | U.S. Tech Corporation | Apparatuses and methods of monitoring the condition of tools and workpieces |

| TW320591B (enExample) * | 1995-04-26 | 1997-11-21 | Fujitsu Ltd | |

| US5808396A (en) * | 1996-12-18 | 1998-09-15 | Alcon Laboratories, Inc. | System and method for tuning and controlling an ultrasonic handpiece |

| US6051500A (en) * | 1998-05-19 | 2000-04-18 | Lucent Technologies Inc. | Device and method for polishing a semiconductor substrate |

| DE19960824C2 (de) * | 1999-12-16 | 2003-08-21 | Hilti Ag | Verfahren und Einrichtung zur Untersuchung und Identifizierung der Art eines Untergrunds |

| US6637986B2 (en) * | 2001-11-26 | 2003-10-28 | Delphi Technologies, Inc. | Drilling apparatus and method |

| JP2005224891A (ja) * | 2004-02-12 | 2005-08-25 | Kyoritsu Seiki Kk | ドリルホルダー |

| ATE395999T1 (de) | 2004-07-02 | 2008-06-15 | Sauer Gmbh | Schwingkopf-werkzeug |

| ES2659512T3 (es) * | 2004-12-13 | 2018-03-16 | Fritz Studer Ag | Unidad de herramienta para el mecanizado rotativo asistido por ultrasonido |

| JP2008140037A (ja) * | 2006-11-30 | 2008-06-19 | Matsushita Electric Works Ltd | 加工監視装置 |

| DE102007013055B4 (de) * | 2007-03-19 | 2015-11-26 | Sauer Ultrasonic Gmbh | Verfahren und Vorrichtung zum Bestimmen der Frequenzkennlinie und zum Betreiben eines Ultraschallwerkzeugs |

| DE102007042280A1 (de) * | 2007-09-06 | 2009-03-12 | Komet Group Holding Gmbh | Bohrwerkzeug für Werkzeugmaschinen sowie Verfahren zu dessen Herstellung |

| US8180479B2 (en) * | 2008-02-05 | 2012-05-15 | The Boeing Company | Adaptive control of composite plycutting |

| US8317437B2 (en) * | 2008-08-01 | 2012-11-27 | The Boeing Company | Adaptive positive feed drilling system |

| FR2944722B1 (fr) * | 2009-04-28 | 2014-10-10 | Arts | Tete de percage a vibrations axiales |

| JP5622463B2 (ja) * | 2010-07-09 | 2014-11-12 | 株式会社スギノマシン | 穴あけ加工制御方法および穴あけ加工装置 |

| JP5573459B2 (ja) * | 2010-07-27 | 2014-08-20 | 株式会社ジェイテクト | 研削方法および研削盤 |

| DE102010048636B4 (de) * | 2010-10-15 | 2017-11-16 | Sauer Ultrasonic Gmbh | Werkzeugmaschine und Verfahren zur Bearbeitung eines Werkstücks mit einem Werkzeug |

| JP5747576B2 (ja) * | 2011-03-11 | 2015-07-15 | トヨタ紡織株式会社 | 超音波切断装置及びこれを用いる車両用内装材の製造方法 |

| EP2803455A1 (de) * | 2013-05-13 | 2014-11-19 | A O Schallinox GmbH | Vorrichtung zum Schneiden eines Prozessguts |

| CN104552422A (zh) * | 2013-10-29 | 2015-04-29 | 青岛天恒机械有限公司 | 复合材料的超声辅助切削加工技术 |

| CN104647147A (zh) * | 2013-11-25 | 2015-05-27 | 大连康赛谱科技发展有限公司 | 一种碳纤维复合材料旋转超声铣磨加工装置及方法 |

| KR101561531B1 (ko) * | 2014-04-25 | 2015-11-02 | 한국기계연구원 | 초음파 밀링 가공 장치 |

| DE102015105338A1 (de) * | 2015-04-08 | 2016-10-27 | Lti Motion Gmbh | Werkzeugantrieb mit Spindelwelle und Betriebsverfahren |

| JP6695102B2 (ja) * | 2015-05-26 | 2020-05-20 | 株式会社ディスコ | 加工システム |

| US10232446B2 (en) * | 2015-11-16 | 2019-03-19 | Apex Brands, Inc. | Adaptive drilling with piezo-electric feed oscillator |

-

2016

- 2016-08-08 DE DE102016214699.8A patent/DE102016214699A1/de not_active Ceased

-

2017

- 2017-08-02 JP JP2017149869A patent/JP6619399B2/ja active Active

- 2017-08-04 CA CA2975574A patent/CA2975574C/en not_active Expired - Fee Related

- 2017-08-04 RU RU2017127899A patent/RU2700628C2/ru active

- 2017-08-08 EP EP17185214.8A patent/EP3281741B1/de active Active

- 2017-08-08 PL PL17185214T patent/PL3281741T3/pl unknown

- 2017-08-08 ES ES17185214T patent/ES2904283T3/es active Active

- 2017-08-08 US US15/671,517 patent/US10678219B2/en active Active

- 2017-08-08 CN CN201710672201.XA patent/CN107695793B/zh active Active

- 2017-08-08 PT PT171852148T patent/PT3281741T/pt unknown

Also Published As

| Publication number | Publication date |

|---|---|

| RU2017127899A (ru) | 2019-02-04 |

| DE102016214699A1 (de) | 2018-02-08 |

| CN107695793B (zh) | 2021-11-23 |

| RU2700628C2 (ru) | 2019-09-19 |

| US20180039255A1 (en) | 2018-02-08 |

| PL3281741T3 (pl) | 2022-03-07 |

| JP2018039107A (ja) | 2018-03-15 |

| US10678219B2 (en) | 2020-06-09 |

| CA2975574C (en) | 2019-06-18 |

| ES2904283T3 (es) | 2022-04-04 |

| PT3281741T (pt) | 2022-02-14 |

| CN107695793A (zh) | 2018-02-16 |

| CA2975574A1 (en) | 2018-02-08 |

| RU2017127899A3 (enExample) | 2019-02-04 |

| EP3281741B1 (de) | 2021-12-15 |

| EP3281741A1 (de) | 2018-02-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6619399B2 (ja) | 数値制御工作機械にてワークピースを加工する方法、装置、工作機械、及びコンピュータプログラム製品 | |

| JP6718953B2 (ja) | 機械加工のために超音波振動状態に設定された工具の共振周波数を測定するための方法およびデバイス | |

| JP6616488B2 (ja) | 工具の超音波振動を発生させ、振動パラメータを測定するためのデバイス | |

| KR102168075B1 (ko) | 공구의 진동 진폭을 결정하기 위한 방법 및 디바이스 | |

| CN104889869B (zh) | 切削装置 | |

| JP2018039107A5 (enExample) | ||

| CN103052457B (zh) | 机床及工件加工方法 | |

| JP6223239B2 (ja) | 切削装置 | |

| JP7346085B2 (ja) | 工作機械の構造的特徴を決定するためのシステムおよび方法 | |

| JP7503581B2 (ja) | 工作機械上での機械加工のための超音波工具ユニットを制御するための方法および装置 | |

| JP4614337B2 (ja) | 工具の先端位置検出方法、ワークの加工方法および摩耗状態検出方法 | |

| CN104889868B (zh) | 切削装置 | |

| US20240383088A1 (en) | Method of operating a machine tool apparatus | |

| Tryshyn et al. | Experimental Studies of Vibration Excitation During Turning | |

| RU2379737C2 (ru) | Способ поддержания предельно допустимых технологических режимов | |

| TW202024579A (zh) | 用以量測一旋轉物件於加工期間所具有之超音波振動的方法及超音波振動量測模組 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20171221 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20181130 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20181212 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20190311 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20190510 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20190607 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20191030 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20191114 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6619399 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |