JP6234905B2 - Elevator car - Google Patents

Elevator car Download PDFInfo

- Publication number

- JP6234905B2 JP6234905B2 JP2014191397A JP2014191397A JP6234905B2 JP 6234905 B2 JP6234905 B2 JP 6234905B2 JP 2014191397 A JP2014191397 A JP 2014191397A JP 2014191397 A JP2014191397 A JP 2014191397A JP 6234905 B2 JP6234905 B2 JP 6234905B2

- Authority

- JP

- Japan

- Prior art keywords

- floor

- car

- horizontal portion

- design surface

- skirting board

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Cage And Drive Apparatuses For Elevators (AREA)

Description

本発明は、かご室内に幅木が設けられたエレベータの乗りかごに関する。 The present invention relates to an elevator car provided with baseboards in a car room.

エレベータの乗りかご内には、側板とかご床を支持する床枠とのボルト締結部を覆う為に幅木が設置されている。この幅木の取り付け作業性を向上する技術が特許文献1に開示されている。特許文献1では、幅木は、塗装された鋼板、あるいは、印刷された鋼板を折り曲げることにより、乗りかごの内側に露出される意匠面となる側面と、床枠に固定するための上部折り曲げ部とが一体に形成されている。そして、上部折り曲げ部に、複数個の長穴を設けると共に、床枠の内側周面に複数個の保持手段、例えば板ばねを設置し、この板ばねを上部折り曲げ部に設けられた長穴に挿入することで、幅木を床枠に固定することが記載されている。

A baseboard is installed in the elevator car to cover the bolt fastening portion between the side plate and the floor frame that supports the car floor.

しかしながら、前述のような板ばねを幅木に設けられた長穴に挿入することで幅木を固定する構成では、軽量化や原価の低減のため、幅木となる鋼板の板厚寸法を薄くすることが難しいという課題があった。すなわち、鋼板の板厚寸法を薄くすると、幅木としての断面性能/剛性が落ちてしまい、幅木固定の為に必要とされる板ばねのばね圧に対応することができなくなる。 However, in the configuration in which the skirting board is fixed by inserting the leaf spring as described above into the long hole provided in the skirting board, the thickness of the steel plate used as the skirting board is reduced in order to reduce weight and cost. There was a problem that it was difficult to do. That is, when the plate thickness dimension of the steel plate is reduced, the cross-sectional performance / rigidity as a base plate is lowered, and it becomes impossible to cope with the spring pressure of the plate spring required for fixing the base plate.

また、断面性能/剛性を確保するために板厚寸法を所定値以上にすると、幅木は鋼板を折り曲げ成型するものであるため、比較的厚い板厚寸法でも折り曲げ成型が可能な鋼板を選択する必要がある。そのため、幅木の素材が限定されてしまうという問題があった。 In addition, if the plate thickness dimension is set to a predetermined value or more in order to ensure the cross-sectional performance / rigidity, the baseboard folds the steel plate, so a steel plate that can be bent even with a relatively thick plate thickness is selected. There is a need. For this reason, there is a problem that the material of the baseboard is limited.

そこで、本発明は、幅木の断面性能/剛性を確保しつつ、幅木となる鋼板の板厚寸法を薄くすることができるエレベータの乗りかごを提供することを目的とする。 Accordingly, an object of the present invention is to provide an elevator car that can reduce the plate thickness of a steel plate to be a baseboard while ensuring the cross-sectional performance / rigidity of the baseboard.

上記課題を解決するために、例えば特許請求の範囲に記載の構成を採用する。本願は、上記課題を解決する手段を複数含んでいるが、その一例を挙げるならば、かご室の床面となるかご床と、かご室を介してかご床と対向する位置に設けられた天井と、かご室の側面を囲むようにかご床の周囲に立設された複数の側板と、かご床及び側板を支持する床枠と、側板とかご床との間に設けられる幅木と、幅木をかご床側に付勢するばね部材とを有するエレベータの乗りかごにおいて、幅木は、かご室側に配置される意匠面を有する意匠面部と、意匠面部の上部側から水平方向に延設され、ばね部材が嵌合する複数の嵌合孔を有する上部水平部と、意匠面部の下部側から水平方向に延設され、かご床に接する下部水平部と、上部水平部及び下部水平部の間において上下方向に延在するように設けられる補強部とを備え、意匠面部、上部水平部、下部水平部及び補強部は一枚の鋼板を折り曲げることにより一体に形成されていることを特徴とする。 In order to solve the above problems, for example, the configuration described in the claims is adopted. The present application includes a plurality of means for solving the above-described problems. For example, a car floor that serves as a floor surface of a car room and a ceiling provided at a position facing the car floor through the car room. A plurality of side plates standing around the car floor so as to surround the side of the car room, a floor frame supporting the car floor and the side plates, a baseboard provided between the side plate and the car floor, and a width In an elevator car having a spring member that biases the wood toward the car floor, the baseboard extends in the horizontal direction from the design surface part having the design surface arranged on the car room side and the upper side of the design surface part An upper horizontal portion having a plurality of fitting holes into which the spring member is fitted, a lower horizontal portion extending in a horizontal direction from the lower side of the design surface portion, and in contact with the car floor, and an upper horizontal portion and a lower horizontal portion. And a reinforcing surface provided so as to extend in the vertical direction between, and the design surface , Upper horizontal portion, a lower horizontal portion and the reinforcing portion is characterized by being formed integrally by bending a single steel plate.

本発明によれば、エレベータの乗りかごにおいて、幅木の断面性能/剛性を確保しつつ、幅木となる鋼板の板厚寸法を低減することができる。 ADVANTAGE OF THE INVENTION According to this invention, the board thickness dimension of the steel plate used as a base board can be reduced, ensuring the cross-sectional performance / rigidity of a base board in the elevator car.

以下、本発明の実施形態に係るエレベータの乗りかごの一例を、図面を参照しながら説明する。なお、本発明は以下の例に限定されるものではない。 Hereinafter, an example of an elevator car according to an embodiment of the present invention will be described with reference to the drawings. In addition, this invention is not limited to the following examples.

《第1の実施形態》

[エレベータの乗りかごの内部の構成]

図1に、本発明の第1の実施形態に係るエレベータの乗りかごの内部の様子を示す概略構成を示し、図2に、要部の断面構成を示す。図1に示すように、本実施形態のエレベータの乗りかご1は、かご床2と、側板3と、扉部10と、天井4と、かご床2と側板3との間に設けられる幅木7とを備え、これらに囲まれる空間が乗客等を収容できるかご室となる。

<< First Embodiment >>

[Inside elevator car configuration]

FIG. 1 shows a schematic configuration showing an internal state of an elevator car according to the first embodiment of the present invention, and FIG. 2 shows a cross-sectional configuration of a main part. As shown in FIG. 1, an

かご床2は、図2に示すように、かご室側の面が水平な床面となる台状の部材で構成され、かご室側に面する側の床面には、タイルなどで構成された床板23が設けられている。本実施形態では、かご床は、床面が四角形状の板状のかご床本体21と、かご床本体21の径よりも小さい径を有する台状の部材で構成された土台部22とで構成され、土台部22上面にかご床本体21が設けられた構成とされている。天井4は、かご室を介してかご床2と対向する位置に設けられている。側板3は、かご室の側面を囲むようにかご床2の周囲に立設され、扉部10を除く位置に複数設けられる。詳述すると、側板3は、扉部10が設けられる前面に対向する背面と、対向して設けられる2つの側面に設けられる。扉部10は、かご室の前面に設けられ、開閉可能に設けられている。扉部10はかご室への出入り口となる。

As shown in FIG. 2, the

[要部の構成]

次に、エレベータの乗りかご1の要部について説明する。図2に示すように、エレベータの乗りかご1は、かご床2及び側板3を支持する床枠5と、かご床2と側板3との間に設けられる幅木7と、幅木7を固定するためのばね部材8とを備える。

[Configuration of main parts]

Next, the main part of the

[床枠]

まず、床枠5について説明する。床枠5は、かご床2を支持する側に水平面を備える底部51と、底部51の側面から底部51の水平面に対して側板3が配置される方向に延在する側壁部52と、側壁部52の底部51側とは反対側の端部においてかご室側に延在する水平面を備える上端部55とを備える。側壁部52は、かご床2のかご床本体21と土台部22との間の段差部の形状に沿うように設けられた段差部52aを有している。本実施形態では、かご床2の土台部22の底面が床枠5の底部51に当接し、かご床2のかご床本体21の底面が床枠5の段差部52aの水平面に当接することで、かご床2が床枠5に支持される。すなわち、本実施形態では、かご床2にかかる荷重は、床枠5の底部51及び段差部52aによって受けられる。

[Floor frame]

First, the floor frame 5 will be described. The floor frame 5 includes a

また、床枠5の上端部55のかご室側に向かう方向の幅の長さは、側板3の厚みとほぼ同じに形成されており、上端部55の所望の位置には、側板3を床枠5の上端部55に固定するためのボルト締結孔53が設けられている。本実施形態では、側板3と床枠5の上端部55とが、ボルト締結孔53においてボルト6とナット(図示を省略する)で締め付けられることによって固定される。これにより、側板3が床枠5の上端部55に支持される。

Further, the length of the width of the

さらに、床枠5の側壁部52には、段差部52aと上端部55との間の領域の所望の位置に、ばね部材8を固定するためのボルト締結孔54が設けられている。ボルト締結孔54では、側壁部52のかご室側にばね部材8がボルト9(本発明の固定部)とナット(図示を省略する)によって固定される。

Further, the

[幅木]

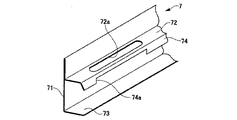

次に、幅木7について説明する。本実施形態では、幅木7の構造が特徴を有する。図3は、幅木7の概略斜視図である。また、図4は、かご室の側面と背面とに取り付けられる2本の幅木7(7A,7B)をかご室の内側から透過して見た構成図であり、図5は、ばね部材8が取り付けられる側から見た幅木7の概略斜視図である。また、図6は、ばね部材8が取り付けられる側から見た幅木7の概略構成図である。以下の説明において、背面の幅木7と側面の幅木7とを区別する場合には、それぞれ「背面幅木7A」、「側面幅木7B」と記載し、区別しない場合には「幅木7」と記載する。

[Baseboard]

Next, the

幅木7は、かご室側において、床枠5の上端部55と側板3とのボルト締結孔53を被覆するために床枠5と側板3との間に設けられる。本実施形態では、幅木7は、扉部10が設けられる位置を除くかご床2の3つの辺にそれぞれ一つずつ設けられており、それぞれの幅木7は、側板3が設けられるかご床2の一辺に対応する長さに形成されている。図2及び図3に示すように、幅木7は、意匠面部71と、下部水平部73と、上部水平部72と、補強部74とを備え、これらは一枚の鋼板を折り曲げることによって一体に形成されている。

The

意匠面部71は、かご室側に露出される意匠面71aを有している。意匠面71aは、図2に示すように側板3のかご室側の面とほぼ平行な面である。かご床2の床面に直交する方向における意匠面部71の長さ、すなわち意匠面部71の短手方向の長さは、床面に配置された床板23と側板3との間の長さとほぼ等しく構成される。また、図4に示すように、背面幅木7Aにおいては、意匠面部71の短手方向に直交する長手方向の長さは対応する床面の辺と同じ長さに構成され、側面幅木7Bにおいては、意匠面部71の長手方向の長さは対応する床面の辺よりも若干長く構成されている。

The

下部水平部73は、意匠面部71の下部側(かご床2側)の端部からかご室とは反対側に延在して設けられている。意匠面71aに直交する方向における下部水平部73の長さは、幅木7を床枠5に取り付けたときに下部水平部73の端部が床枠5の側壁部52に当接する長さに構成されている。

The lower

上部水平部72は、下部水平部73よりも上部側(側板3側)であって、後述するばね部材8のばね部81が配置される位置に設けられ、意匠面部71から床枠5の側壁部52側に延在する水平面を有するように構成されている。また、上部水平部72の側壁部52に固定されるばね部81に対向する位置には、後述するばね部材8のばね部81が嵌合する嵌合孔72aが設けられている。したがって、上部水平部72における意匠面71aに直交する方向の長さは、ばね部材8のばね部81が嵌合する嵌合孔72aを形成できる程度の幅に構成されている。

The upper

補強部74は、上部水平部72の側壁部52側の端部から鉛直下方向に延在して設けられ、意匠面71aと平行な平面を有するように構成されている。補強部74は幅木7の断面性能/剛性を向上させるために設けられる部位である。また、補強部74の、側壁部52に設けられるボルト締結孔54に対向する位置には切り欠き部74aが設けられている。切り欠き部74aは、ボルト締結孔54に取り付けられるボルト9が補強部74に当たるのを回避する為に設けられている。

The reinforcing

また、本実施形態では、下部水平部73、上部水平部72及び補強部74の長手方向の両端部は、図5に示すように、意匠面部71側から側壁部52側に向かうに連れて長手方向の長さが短くなるようなテーパ状に形成されている。本実施形態では、例えば下部水平部73は、所定の角度βで長手方向の長さが意匠面部71の長手方向の長さより短くなるように構成され、上部水平部72及び補強部74は、所定の角度αで長手方向の長さが意匠面部71の長さより短くなるように構成されている。

Moreover, in this embodiment, the both ends of the longitudinal direction of the lower

本実施形態では、下部水平部73、上部水平部72及び補強部74の長手方向の両端部をテーパ状に形成し、意匠面部71の長手方向の長さよりも短くすることによって、隣接する他の部材との緩衝を避けることができるので幅木7の取り付け時における取り扱いが容易になる。また、図4及び図5に示すように幅木7の角部が鈍角になるため、幅木7の取り扱い時の安全性を向上させることができる。

In the present embodiment, both ends in the longitudinal direction of the lower

図7は、本実施形態の幅木7の展開図である。本実施形態では、幅木7は、図6に示すような厚さ0.7mmの鋼板を折り曲げることによって形成されている。また、本実施形態における幅木7は、図6に示すように、長手方向の両端部において、下部水平部73、上部水平部72及び補強部74となる部分を面取りし、図6に示す形状の板状部材を折り曲げ加工することによって下部水平部73、上部水平部72及び補強部74の長手方向の両端部をテーパ状にすることができる。幅木7を構成する鋼板の材料としては、例えば、ステンレス鋼板を用いることができる。また、幅木7としては、塗装や印刷が施された各種鋼板を用いることができる。

FIG. 7 is a development view of the

[ばね部材]

次に、ばね部材8について説明する。ばね部材8は、平面が矩形状の板状部材で構成された取り付け部82と、取り付け部82の一端から延在して設けられたばね部81とを備えたいわゆる板ばねであり、取り付け部82及びばね部81は、一枚の板状部材を折り曲げることによって一体に形成されている。取り付け部82には、ばね部81が設けられる方向と直交する方向に並列した2つの長穴82aが形成されている。長穴82aは、ばね部81が設けられる方向に長い角丸長方形状(小判型)に形成されている。また、取り付け部82のばね部81とは反対側の端部は、ばね部81とほぼ並行となるように折り曲げられている。

[Spring member]

Next, the

ばね部81は、取り付け部82の平面に直交する方向に延在して設けられており、その断面形状は、取り付け部82側に窪み部が形成されるような断面凹形状に形成されている。断面凹形状に形成されたばね部81は、前述した幅木7の上部水平部72に設けられた嵌合孔72aに嵌合可能な大きさに形成されている。また、取り付け部82の平面に直交する方向におけるばね部81の幅は、側壁部52と幅木7の意匠面部71との間の隙間に収まる幅に構成されている。

The

本実施形態では、取り付け部82を側壁部52のかご室側に当接させ、取り付け部82の長穴82aと側壁部52に設けられたボルト締結孔54とを位置あわせし、その後、ボルト9とナット(図示を省略する)で両者を固定する。このとき、ばね部材8のばね部81が幅木7の上部水平部72に設けられた嵌合孔72aに嵌合すると共に、ばね部81が上部水平部72を鉛直下方向に付勢することができる高さとなるように、ばね部材8の高さを調整する。本実施形態では、取り付け部82のボルト9が挿入される穴を長穴82aとすることにより、かご床2の床面に配置される床板23の厚さに応じて、ばね部材8の取り付け位置を調整することができる。

In the present embodiment, the

〈幅木の取り付け方法〉

次に、本実施形態における幅木7の取り付け方法について説明する。まず、床枠5の側壁部52の所望の位置にばね部材8をボルト9とナット(図示を省略する)を用いて固定する。この場合、前述したように、床板23の厚みに応じてばね部材8が丁度いい高さとなるようにばね部材8を取り付ける。この高さは、ばね部材8のばね部81が幅木7の上部水平部72の嵌合孔72aに嵌合可能であると共に、ばね部81が上部水平部72を鉛直下方向に付勢可能な高さであり、ばね部81の最も低い位置が上部水平部72の高さよりも低くなる位置である。

<Attaching the skirting board>

Next, the attachment method of the

その後、幅木7の上部水平部72に設けられた嵌合孔72aにばね部材8のばね部81を嵌合させながら幅木7を床枠5に嵌め込む。これにより、ばね部材8のばね部81によって幅木7の上部水平部72は鉛直下方向に付勢されることに伴って下部水平部73がかご床2の床面側に押し付けられ、幅木7が床枠5に固定される。本実施形態では、幅木7が取り付けられる床枠5の3つの辺のうち、まず、扉部10を挟んで対向する2つの辺、すなわちかご室の両側面に側面幅木7Bを嵌め込み、次に、扉部10に対向する辺、すなわちかご室の背面側に背面幅木7Aを嵌め込む。なお、扉部10側にも幅木7を嵌め込む必要がある場合には、側面幅木7Bを嵌め込んだ後に、前面幅木を嵌め込む。

Thereafter, the

このとき、側面幅木7Bの長手方向の長さは床枠5の辺(かご室の辺)よりも少し長く形成されており、背面幅木7Aの長手方向の長さは床枠5の辺(かご室の辺)と同じに形成されている。したがって、図4に示すように、側面幅木7Bの意匠面部71に背面幅木7Aの両端部が当接する形で背面幅木7Aが床枠(図2参照)に嵌め込まれる。このため、側面幅木7Bと背面幅木7Aとの間の隙間調整が容易になる。以上の作業により、幅木7の取り付けが完了する。そして、幅木7が取り付けられることにより、図2に示すように、床枠5と側板3とを固定するボルト9が被覆され、側板3と床板23との間の隙間がかご室側から見えなくなるように隠される。

At this time, the length in the longitudinal direction of the

本実施形態では、幅木7において補強部74が設けられることにより、幅木7の断面性能/剛性を向上させることができる。したがって、補強部74を設けることにより、幅木7を形成するための鋼板の厚みを従来のものよりも薄くした場合にも、幅木7に必要な所望の断面性能/剛性を確保することができるため、幅木7の軽量化及び原価低減を図ることができる。

In the present embodiment, the cross section performance / rigidity of the

従来の幅木7では、所望の断面剛性を得るために1.2mm以上の厚みの鋼板を用いる必要があった。一方で、幅木7は一枚の板状部材を折り曲げることによって所定の形状に加工されるが、厚みが1.2mm以上のステンレス鋼板を用いた場合、曲げ成型が困難となり、一枚の板状部材を折り曲げて形成する幅木は実用化することができなかった。すなわち、幅木7において、補強部74が設けられていない場合には、厚みが1.2mmよりも小さい鋼板を用いた場合には、ばね部材8に耐え得る剛性が得られず、厚みを1.2mm以上にした場合には曲げ成型ができないという問題があった。

In the

これに対し、本実施形態では、補強部74を設けることにより、曲げ成型が可能な厚み0.7mmのステンレス鋼板を用いた場合にも必要な断面性能/剛性を確保することができることが検証により判明している。このように、本実施形態では、鋼板の板厚寸法を低減できることから、折り曲げ成型が容易となり、幅木7として使用可能な素材の選択肢を広げることができる。

On the other hand, in the present embodiment, it is verified by providing the reinforcing

本実施形態では、補強部74は、上部水平部72の端部から鉛直下方向に延びるように形成されているが、下部水平部73の床枠5側の端部から鉛直上方向に延びるように形成してもよい。すなわち、補強部74はその延在方向が、上部水平部72と下部水平部73との間の上下方向であればよい。ところで、幅木7の断面性能/剛性を向上させる方法として、下部水平部73や上部水平部72の短手方向の長さを長くする方法も考えられる。しかしながら、下部水平部73や上部水平部72の短手方向の長さを長くするよりも、上部水平部72及び下部水平部73間において上下方向に延在する補強部74を設ける方が、下部水平部73や上部水平部72の短手方向の長さを長くするよりも、意匠面部71を曲がりにくくすることができる。したがって、補強部74は、上部水平部72又は下部水平部73の端部から上下方向に延びるように形成することが好ましい。

In the present embodiment, the reinforcing

また、本実施形態のように、補強部74を上部水平部72の端部から鉛直下方向に延びるように設けることにより、ばね部材8に対する幅木7の強度も高めることができる。すなわち、幅木7を固定する際、ばね部材8によって上部水平部72が鉛直方向に付勢されることで幅木7が固定されるが、上部水平部72側に補強部74を設けることで、ばね部材8からの押圧力に対する上部水平部72の強度を高めることができる。なお、本実施形態では、補強部74はその平面が意匠面71aと平行であり、鉛直方向に延びるように形成されているが、必ずしも鉛直方向である必要はない。例えば、補強部74は、上部水平部72と下部水平部73との間で上下方向に延在していればよく、意匠面71aに対して斜め方向に延在していてもよい。

Further, by providing the reinforcing

また、本実施形態では、補強部74に切り欠き部74aが設けられる。これにより、幅木7を取り付ける際に、ばね部材8を固定するためのボルト9に補強部74が当たるのを回避することができる。本実施形態では、切り欠き部74aは一方が開口した矩形状に形成されているが、穴状に形成してもよく、ボルト9が補強部74に当たるのを回避できる形状であればいかなる形状であってもよい。

In the present embodiment, the reinforcing

《第2の実施形態》

次に、本発明の第2の実施形態に係るエレベータの乗りかごについて説明する。本実施形態のエレベータの乗りかごは、幅木の構成(特に、側面幅木の構成)が第1の実施形態と異なる。図8は、本実施形態の幅木70の概略構成図である。本実施形態のエレベータの乗りかごの全体の構成については第1の実施形態と同様であるから説明を省略し、また、図8において、図5に対応する部分には同一符号を付し重複説明を省略する。

<< Second Embodiment >>

Next, an elevator car according to the second embodiment of the present invention will be described. The elevator car according to the present embodiment is different from the first embodiment in the configuration of baseboards (particularly, the configuration of side baseboards). FIG. 8 is a schematic configuration diagram of the skirting

ところで、図4に示すような側面幅木7Bは、対向する2つの側面に設けられるが、側面幅木7Bのうち一方の幅木7を左側幅木、他方の幅木7を右側幅木としたとき、通常は左側幅木と右側幅木の長手方向の長さは同じである。したがって、左側幅木と右側幅木として同じものを用いることができれば、コストの低減や作業効率の向上に繋がる。しかしながら、幅木7を固定するためのばね部材8の床枠5への固定位置は、幅木7の長手方向の中心部に設けられるとは限らない。例えば、左側幅木及び右側幅木を固定するばね部材8が、それぞれ、幅木7の長手方向の中心部よりも扉部10側手前に対向するように配置された場合(すなわち、左右勝手違いでばね部材8が配置された場合)、左側幅木と右側幅木とでは、嵌合孔72a及び切り欠き部74aの位置を異なる位置に配置する必要がある。したがって、左側幅木と右側幅木とを共通の部材とすることができない。

By the way,

そこで、本実施形態では、図8に示すように、1つの幅木70に、左側幅木として用いる場合に使用可能な嵌合孔76及び切り欠き部78と、右側幅木として用いる場合に使用可能な嵌合孔77及び切り欠き部79の両方を予め形成する。そうすると、図8に示すように、幅木70を、例えば右側幅木として用いる場合には、左側幅木用の嵌合孔77及び切り欠き部79は使用されない。逆に、幅木70を、左側幅木として用いる場合には、右側幅木用の嵌合孔76及び切り欠き部78は使用されない。

Therefore, in the present embodiment, as shown in FIG. 8, a

本実施形態では、側面に使用される幅木70において、左右勝手違いに取り付けられたばね部材8に対応可能な嵌合孔76,77及び切り欠き部78,79を設けることにより、左側幅木と右側幅木とで共通の部材を用いることができる。これにより、コストの低減や作業効率の向上を図ることができる。

In the present embodiment, in the

以上、本発明について、実施形態に基づいて説明したが、本発明は上述の実施形態に記載した構成に限定されるものではなく、その趣旨を逸脱しない範囲において適宜その構成を変更することができるものである。例えば、上述した実施形態例は、本発明を分かりやすく説明するために詳細に説明したものであり、必ずしも説明した全ての構成を備えるものに限定されるものではない。また、ある実施形態の構成の一部を他の実施形態の構成に置き換えることが可能であり、また、ある実施形態の構成について他の実施形態の構成を加えることも可能である。また、各実施形態の構成の一部について、他の構成の追加・削除・置換をすることが可能である。 As described above, the present invention has been described based on the embodiment. However, the present invention is not limited to the configuration described in the above-described embodiment, and the configuration can be appropriately changed without departing from the gist thereof. Is. For example, the above-described exemplary embodiments have been described in detail for easy understanding of the present invention, and are not necessarily limited to those having all the configurations described. Further, a part of the configuration of an embodiment can be replaced with the configuration of another embodiment, and the configuration of another embodiment can be added to the configuration of an embodiment. In addition, it is possible to add, delete, and replace other configurations for a part of the configuration of each embodiment.

1…乗りかご、2…かご床、3…側板、4…天井、5…床枠、6…ボルト、7,70…幅木、7A…背面幅木、7B…側面幅木、8…ばね部材、9…ボルト、10…扉部、21…床本体、22…土台部、23…床板、51…底部、52…側壁部、53…ボルト締結孔、54…ボルト締結孔、55…上端部、71…意匠面部、71a…意匠面、72…上部水平部、72a,76,77…嵌合孔、73…下部水平部、74…補強部、74a,78,79…切り欠き部、81…ばね部、82…取り付け部、82a…長穴

DESCRIPTION OF

Claims (4)

かご室を介して前記かご床と対向する位置に設けられた天井と、

かご室の側面を囲むように前記かご床の周囲に立設された複数の側板と、

前記かご床及び前記側板を支持する床枠と、

前記側板と前記かご床との間に設けられる幅木と、

前記幅木を前記かご床側に付勢するばね部材とを有するエレベータの乗りかごにおいて、

前記幅木は、かご室側に配置される意匠面を有する意匠面部と、前記意匠面部の上部側から水平方向に延設され、前記ばね部材が嵌合する複数の嵌合孔を有する上部水平部と、前記意匠面部の下部側から水平方向に延設され、前記かご床に接する下部水平部と、前記上部水平部及び前記下部水平部の間において上下方向に延在するように設けられる補強部とを備え、前記意匠面部、前記上部水平部、前記下部水平部及び前記補強部は一枚の鋼板を折り曲げることにより一体に形成されている

ことを特徴とするエレベータの乗りかご。 A car floor to be the floor of the car room;

A ceiling provided at a position facing the car floor via a car room;

A plurality of side plates erected around the car floor so as to surround a side surface of the car room;

A floor frame that supports the car floor and the side plates;

A skirting board provided between the side plate and the car floor;

In an elevator car having a spring member that biases the skirting board toward the car floor,

The base board has a design surface portion having a design surface disposed on the cab side, and an upper horizontal portion extending in a horizontal direction from the upper side of the design surface portion and having a plurality of fitting holes into which the spring member is fitted. And a reinforcement that is provided so as to extend in the vertical direction between the lower horizontal portion that extends in the horizontal direction from the lower portion side of the design surface portion and contacts the car floor, and between the upper horizontal portion and the lower horizontal portion. And the design surface portion, the upper horizontal portion, the lower horizontal portion, and the reinforcing portion are integrally formed by bending a single steel plate.

請求項1に記載のエレベータの乗りかご。 The elevator car according to claim 1, wherein the reinforcing portion extends from an end portion of the upper horizontal portion opposite to the design surface portion side toward the lower horizontal portion side.

前記補強部の前記固定部に対向する部分には前記固定部と前記補強部との接触を回避するための切り欠き部が設けられている

請求項1又は2に記載のエレベータの乗りかご。 The spring member is fixed to the floor frame by a fixing portion,

The elevator car according to claim 1, wherein a portion of the reinforcing portion that faces the fixed portion is provided with a notch for avoiding contact between the fixed portion and the reinforcing portion.

請求項1〜3のいずれか一項に記載のエレベータの乗りかご。 The longitudinal ends of the lower horizontal portion, the upper horizontal portion, and the reinforcing portion are formed in a taper shape such that the length in the longitudinal direction becomes shorter toward the direction away from the design surface side. The elevator car as described in any one of -3.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014191397A JP6234905B2 (en) | 2014-09-19 | 2014-09-19 | Elevator car |

| CN201510471374.6A CN106185552B (en) | 2014-09-19 | 2015-08-04 | The car of elevator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014191397A JP6234905B2 (en) | 2014-09-19 | 2014-09-19 | Elevator car |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016060613A JP2016060613A (en) | 2016-04-25 |

| JP2016060613A5 JP2016060613A5 (en) | 2016-12-28 |

| JP6234905B2 true JP6234905B2 (en) | 2017-11-22 |

Family

ID=55795674

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014191397A Active JP6234905B2 (en) | 2014-09-19 | 2014-09-19 | Elevator car |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6234905B2 (en) |

| CN (1) | CN106185552B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101810812B1 (en) * | 2017-01-20 | 2018-01-25 | 윤일식 | Device for Coupling Wall-decoration Boards of an Elevator |

| CN107043063B (en) * | 2017-05-15 | 2023-02-07 | 通祐电梯有限公司 | Quick-mounting skirting board for elevator car |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5935494Y2 (en) * | 1979-05-22 | 1984-10-01 | 三菱電機株式会社 | elevator car room |

| JP3539745B2 (en) * | 1993-06-14 | 2004-07-07 | 株式会社日立ビルシステム | Elevator car side plate |

| JP3382044B2 (en) * | 1995-01-12 | 2003-03-04 | 株式会社東芝 | Elevator cab |

| JPH1036043A (en) * | 1996-07-19 | 1998-02-10 | Hitachi Building Syst Co Ltd | Car of elevator |

| JPH11322233A (en) * | 1998-05-15 | 1999-11-24 | Hitachi Building Systems Co Ltd | Side plate of elevator car |

| JP2002114469A (en) * | 2000-10-05 | 2002-04-16 | Hitachi Ltd | Car baseboard structure of elevator |

| JP2006137513A (en) * | 2004-11-11 | 2006-06-01 | Hitachi Ltd | Elevator car and elevator device |

| JP2008024384A (en) * | 2006-07-18 | 2008-02-07 | Mitsubishi Electric Corp | Elevator cage |

| JP5130800B2 (en) * | 2007-06-27 | 2013-01-30 | 三菱電機株式会社 | Elevator car room |

| CN201169477Y (en) * | 2007-11-14 | 2008-12-24 | 上海德圣米高电梯有限公司 | Embarkation elevator car suitable for outdoor operating |

| JP5344426B2 (en) * | 2009-01-14 | 2013-11-20 | 東芝エレベータ株式会社 | Elevator car |

| CN201825621U (en) * | 2010-06-29 | 2011-05-11 | 江南嘉捷电梯股份有限公司 | Connecting structure for upper car wall plate and end part rib of elevator car |

-

2014

- 2014-09-19 JP JP2014191397A patent/JP6234905B2/en active Active

-

2015

- 2015-08-04 CN CN201510471374.6A patent/CN106185552B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN106185552A (en) | 2016-12-07 |

| JP2016060613A (en) | 2016-04-25 |

| CN106185552B (en) | 2018-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6138258B2 (en) | Elevator guide rail fixing device | |

| KR100827716B1 (en) | Bracket for window and door frames | |

| KR101173795B1 (en) | Assemblable Truss Structure | |

| JP6234905B2 (en) | Elevator car | |

| US10519006B2 (en) | Elevator guide rail bracket and method for securing a guide rail | |

| JP2008149888A (en) | Support structure for power plant | |

| JP5599415B2 (en) | Elevator car frame | |

| JP5330134B2 (en) | Suspended ceiling structure and construction method | |

| US9446794B2 (en) | Fender panel support structure for vehicle | |

| JP4902597B2 (en) | Elevator car structure | |

| JP2009107403A (en) | Floor member structure of cargo bed of truck | |

| JP7121806B2 (en) | Elevator equipment assembly method | |

| JP6633747B2 (en) | Elevator cab wall | |

| JP6340222B2 (en) | Mounting bracket for diagonal reinforcement members | |

| JP5405931B2 (en) | Ceiling edge with shape retaining member, ceiling edge unit and ceiling surface structure | |

| JP5864192B2 (en) | Three-way elevator | |

| JP2011143808A (en) | Railroad vehicle body structure | |

| JP4967262B2 (en) | Seismic isolation elevator plate | |

| JP6242176B2 (en) | Elevator car floor and manufacturing method thereof | |

| JP6672571B2 (en) | Suspension bracket reinforcement structure | |

| KR200461677Y1 (en) | Dust and noise reduction panel for construction work | |

| JP2013166616A (en) | Elevator | |

| JP2013006699A (en) | Support structure of elevator rail | |

| JP7288179B2 (en) | Joint structure | |

| JP2008196125A (en) | Mounting structure of wall panel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20161111 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20161111 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20170928 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20171017 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20171025 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6234905 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |