JP6185931B2 - 二輪車用タイヤ - Google Patents

二輪車用タイヤ Download PDFInfo

- Publication number

- JP6185931B2 JP6185931B2 JP2014549598A JP2014549598A JP6185931B2 JP 6185931 B2 JP6185931 B2 JP 6185931B2 JP 2014549598 A JP2014549598 A JP 2014549598A JP 2014549598 A JP2014549598 A JP 2014549598A JP 6185931 B2 JP6185931 B2 JP 6185931B2

- Authority

- JP

- Japan

- Prior art keywords

- tire

- core

- cord

- belt structure

- metal wire

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000002184 metal Substances 0.000 claims description 78

- 230000003014 reinforcing effect Effects 0.000 claims description 37

- 238000004804 winding Methods 0.000 claims description 21

- 239000007769 metal material Substances 0.000 claims description 13

- -1 polyethylene terephthalate Polymers 0.000 claims description 10

- 239000000203 mixture Substances 0.000 claims description 8

- 239000011368 organic material Substances 0.000 claims description 8

- 239000000835 fiber Substances 0.000 claims description 7

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 7

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 7

- 239000002657 fibrous material Substances 0.000 claims description 6

- 239000004760 aramid Substances 0.000 claims description 5

- 229920003235 aromatic polyamide Polymers 0.000 claims description 5

- 229910010272 inorganic material Inorganic materials 0.000 claims description 5

- 239000011147 inorganic material Substances 0.000 claims description 5

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 claims description 4

- 229910052796 boron Inorganic materials 0.000 claims description 4

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 claims description 4

- 239000011112 polyethylene naphthalate Substances 0.000 claims description 4

- 229920002748 Basalt fiber Polymers 0.000 claims description 3

- 229920000049 Carbon (fiber) Polymers 0.000 claims description 3

- 229920000742 Cotton Polymers 0.000 claims description 3

- 239000004952 Polyamide Substances 0.000 claims description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 claims description 3

- 239000004917 carbon fiber Substances 0.000 claims description 3

- 239000003365 glass fiber Substances 0.000 claims description 3

- 229920002647 polyamide Polymers 0.000 claims description 3

- 229920001470 polyketone Polymers 0.000 claims description 3

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 3

- 229920001290 polyvinyl ester Polymers 0.000 claims description 3

- 239000004627 regenerated cellulose Substances 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 21

- 239000000463 material Substances 0.000 description 16

- 239000004753 textile Substances 0.000 description 12

- 229910000831 Steel Inorganic materials 0.000 description 9

- 239000011324 bead Substances 0.000 description 9

- 229920001971 elastomer Polymers 0.000 description 9

- 239000010959 steel Substances 0.000 description 9

- 238000004519 manufacturing process Methods 0.000 description 7

- 230000002787 reinforcement Effects 0.000 description 7

- 230000000052 comparative effect Effects 0.000 description 6

- 239000000806 elastomer Substances 0.000 description 6

- 239000013536 elastomeric material Substances 0.000 description 6

- 239000000945 filler Substances 0.000 description 6

- 230000004044 response Effects 0.000 description 6

- 230000014509 gene expression Effects 0.000 description 5

- 238000012360 testing method Methods 0.000 description 5

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 238000000034 method Methods 0.000 description 4

- 230000009257 reactivity Effects 0.000 description 4

- 229920000433 Lyocell Polymers 0.000 description 3

- 229920000297 Rayon Polymers 0.000 description 3

- 238000010521 absorption reaction Methods 0.000 description 3

- 230000001133 acceleration Effects 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 239000002964 rayon Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 239000002131 composite material Substances 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000004971 Cross linker Substances 0.000 description 1

- 229920000271 Kevlar® Polymers 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000008094 contradictory effect Effects 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000003562 lightweight material Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000012763 reinforcing filler Substances 0.000 description 1

- 230000003938 response to stress Effects 0.000 description 1

- 230000004043 responsiveness Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 230000035945 sensitivity Effects 0.000 description 1

- 230000001502 supplementing effect Effects 0.000 description 1

- 239000013585 weight reducing agent Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/005—Reinforcements made of different materials, e.g. hybrid or composite cords

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/0007—Reinforcements made of metallic elements, e.g. cords, yarns, filaments or fibres made from metal

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/0042—Reinforcements made of synthetic materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/02—Carcasses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/22—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel the plies being arranged with all cords disposed along the circumference of the tyre

- B60C9/2204—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel the plies being arranged with all cords disposed along the circumference of the tyre obtained by circumferentially narrow strip winding

-

- D—TEXTILES; PAPER

- D02—YARNS; MECHANICAL FINISHING OF YARNS OR ROPES; WARPING OR BEAMING

- D02G—CRIMPING OR CURLING FIBRES, FILAMENTS, THREADS, OR YARNS; YARNS OR THREADS

- D02G3/00—Yarns or threads, e.g. fancy yarns; Processes or apparatus for the production thereof, not otherwise provided for

- D02G3/44—Yarns or threads characterised by the purpose for which they are designed

- D02G3/48—Tyre cords

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0606—Reinforcing cords for rubber or plastic articles

- D07B1/062—Reinforcing cords for rubber or plastic articles the reinforcing cords being characterised by the strand configuration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C2009/2074—Physical properties or dimension of the belt cord

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/22—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel the plies being arranged with all cords disposed along the circumference of the tyre

- B60C2009/2252—Physical properties or dimension of the zero degree ply cords

- B60C2009/2257—Diameters of the cords; Linear density thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/18—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers

- B60C9/20—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel

- B60C9/22—Structure or arrangement of belts or breakers, crown-reinforcing or cushioning layers built-up from rubberised plies each having all cords arranged substantially parallel the plies being arranged with all cords disposed along the circumference of the tyre

- B60C2009/2252—Physical properties or dimension of the zero degree ply cords

- B60C2009/2285—Twist structures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C2200/00—Tyres specially adapted for particular applications

- B60C2200/10—Tyres specially adapted for particular applications for motorcycles, scooters or the like

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2024—Strands twisted

- D07B2201/2029—Open winding

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2047—Cores

- D07B2201/2052—Cores characterised by their structure

- D07B2201/2053—Cores characterised by their structure being homogeneous

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2047—Cores

- D07B2201/2052—Cores characterised by their structure

- D07B2201/2055—Cores characterised by their structure comprising filaments or fibers

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2047—Cores

- D07B2201/2052—Cores characterised by their structure

- D07B2201/2055—Cores characterised by their structure comprising filaments or fibers

- D07B2201/2057—Cores characterised by their structure comprising filaments or fibers resulting in a twisted structure

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Tires In General (AREA)

- Ropes Or Cables (AREA)

Description

本発明は、二輪車用タイヤに関する。

− カーカス構造と、

− カーカス構造に対して半径方向外側位置に配置されたベルト構造と、

− ベルト構造に対して半径方向外側位置に配置されたトレッドバンドと、

を含み、

前記ベルト構造は実質的な周方向に沿って配向された隣接するコイルに従い前記カーカス構造に巻かれた少なくとも1つの補強コードを含み、

前記少なくとも1つの補強コードが、

− 非金属材料で作製されたコアと、

− 実質的に互いに平行し、前記コアに所定の巻線ピッチで螺旋状に巻回された複数の金属ワイヤと、

を含む、二輪車用タイヤに関する。

Claims (14)

- − カーカス構造(2)と、

− 前記カーカス構造(2)に対して半径方向外側位置に配置されたベルト構造(10)と、

− 前記ベルト構造(10)に対して半径方向外側位置に配置されたトレッドバンド(20)と、

を含み、

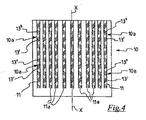

前記ベルト構造(10)が、周方向に沿って配向された隣接するコイル(11a)に従い前記カーカス構造(2)に巻かれた少なくとも1つの補強コード(11)を含み、

前記少なくとも1つの補強コード(11)が、

− 非金属材料で作製されたコア(12)と、

− 互いに平行し、且つ前記コア(12)に所定の巻線ピッチで螺旋状に巻回された複数の金属ワイヤ(13)と、

を含み、

前記金属ワイヤ(13)が、前記補強コード(11)の任意の断面において、それらが前記コア(12)に外接する理想的円周(C)のある角度部分だけに配されるように前記コア(12)の周りに配置されており、

前記コア(12)が、互いに撚り合わせられた少なくとも2つの細長要素(12a、12b)、又は、単独で撚られた単一の細長要素を含む、

二輪車用のタイヤ(100)。 - 前記角度部分が40°〜270°に含まれる角度によって画定される、請求項1に記載のタイヤ(100)。

- 前記コア(12)の直径と、前記金属ワイヤ(13)の直径と、前記金属ワイヤ(13)の前記巻線ピッチとが、前記金属ワイヤ(13)が周方向に対して10°〜40°に含まれる角度で傾斜するように選択される、請求項1又は2に記載のタイヤ。

- 前記金属ワイヤ(13)の数が2〜8に含まれる、請求項1〜3のいずれか一項に記載のタイヤ(100)。

- 前記金属ワイヤ(13)の数が5に等しい、請求項1〜4のいずれか一項に記載のタイヤ(100)。

- 前記金属ワイヤ(13)の直径が0.12mm〜0.35mmに含まれる、請求項1〜5のいずれか一項に記載のタイヤ(100)。

- 前記金属ワイヤ(13)が相接の状態にある、請求項1〜6のいずれか一項に記載のタイヤ(100)。

- 前記少なくとも1つの補強コード(11)が0.5mm〜2.5mmに含まれる直径を有する、請求項1〜7のいずれか一項に記載のタイヤ(100)。

- 前記巻線ピッチが3mm〜16mmに含まれる、請求項1〜8のいずれか一項に記載のタイヤ(100)。

- 前記少なくとも1つの補強コード(11)が2.5%超の破断点伸度を有する、請求項1〜9のいずれか一項に記載のタイヤ(100)。

- 前記少なくとも1つの補強コード(11)が0.5%超の部分荷重伸度を有する、請求項1〜10のいずれか一項に記載のタイヤ(100)。

- 前記コア(12)が繊維質材料を含む、請求項1〜11のいずれか一項に記載のタイヤ(100)。

- 前記繊維質材料が、ガラス繊維及び/又は炭素繊維及び/又は玄武岩繊維及び/又はホウ素繊維の中から選択された無機材料を含む、請求項12に記載のタイヤ(100)。

- 前記繊維質材料が、ポリエチレンテレフタレート、ポリアミド、芳香族ポリアミド、ポリビニルエステル、ポリビニルアルコール、ポリエチレンナフタレート、ポリケトン、再生セルロースの糸、綿及びそれらの混成物又は混合物の中から選択された有機材料を含む、請求項12に記載のタイヤ(100)。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ITMI20112394 | 2011-12-27 | ||

| ITMI2011A002394 | 2011-12-27 | ||

| US201161581912P | 2011-12-30 | 2011-12-30 | |

| US61/581,912 | 2011-12-30 | ||

| PCT/IB2012/057593 WO2013098738A1 (en) | 2011-12-27 | 2012-12-21 | Tyre for motorcycles |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2015506303A JP2015506303A (ja) | 2015-03-02 |

| JP2015506303A5 JP2015506303A5 (ja) | 2015-12-24 |

| JP6185931B2 true JP6185931B2 (ja) | 2017-08-23 |

Family

ID=45571687

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014549598A Active JP6185931B2 (ja) | 2011-12-27 | 2012-12-21 | 二輪車用タイヤ |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20150122395A1 (ja) |

| EP (1) | EP2748015B1 (ja) |

| JP (1) | JP6185931B2 (ja) |

| CN (1) | CN103958218B (ja) |

| BR (1) | BR112014014311B1 (ja) |

| WO (1) | WO2013098738A1 (ja) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| LU92527B1 (fr) * | 2012-12-25 | 2014-12-22 | Kordsa Global Endustriyel Iplik Ve Kord Bezi Sanayi Ve Ticaret As | Structure de câbles hybride |

| US20160318343A1 (en) * | 2013-12-23 | 2016-11-03 | Pirelli Tyre S.P.A. | Tyre for heavy load vehicle wheels |

| AU2017248361B2 (en) * | 2016-04-08 | 2019-08-15 | Gates Corporation, a Delaware Corporation | Hybrid cable for reinforcing polymeric articles and reinforced articles |

| IT201600117754A1 (it) * | 2016-11-22 | 2018-05-22 | Pirelli | Pneumatico per motoveicoli |

| JP2018083594A (ja) * | 2016-11-25 | 2018-05-31 | 株式会社ブリヂストン | タイヤ |

| WO2020026178A1 (en) * | 2018-08-03 | 2020-02-06 | Pirelli Tyre S.P.A. | Tyre for vehicle wheels |

| CN109049759A (zh) * | 2018-09-25 | 2018-12-21 | 北航(四川)西部国际创新港科技有限公司 | 复合材料轮毂及其制造方法 |

| US20220169078A1 (en) * | 2019-04-17 | 2022-06-02 | Pirelli Tyre S.P.A. | Hybrid cord and tyre with such cord |

| CN114786961B (zh) * | 2019-12-17 | 2024-07-09 | 倍耐力轮胎股份公司 | 用于车轮轮胎的金属增强帘线 |

| CN114829703B (zh) * | 2019-12-17 | 2024-07-30 | 倍耐力轮胎股份公司 | 用于车辆车轮的轮胎的金属增强帘线 |

| IT202000014521A1 (it) | 2020-06-17 | 2021-12-17 | Pirelli | Pneumatico per ruote di veicoli |

| CN118043518A (zh) | 2021-09-28 | 2024-05-14 | 贝卡尔特公司 | 具有经适应的伸长性能的钢帘线 |

| CN114083940B (zh) * | 2021-11-30 | 2023-09-15 | 蓉驿时代科技有限公司 | 一种全方位防护自修复轮胎及其制备方法 |

| WO2024127732A1 (ja) * | 2022-12-14 | 2024-06-20 | 株式会社ブリヂストン | 自動二輪車用タイヤ |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2260660B1 (ja) | 1974-02-12 | 1976-11-26 | Michelin & Cie | |

| IT1248851B (it) | 1990-06-14 | 1995-01-30 | Pirelli | Procedimento per la fabbricazione di pneumatici per veicoli a due ruote e pneumatici cosi' prodotti |

| JPH0641881A (ja) * | 1992-05-20 | 1994-02-15 | Bridgestone Corp | エラストマー製品補強用複合コード |

| JP3411615B2 (ja) * | 1993-04-14 | 2003-06-03 | 株式会社ブリヂストン | 空気入りラジアルタイヤ |

| JP3294378B2 (ja) * | 1993-04-21 | 2002-06-24 | 住友ゴム工業株式会社 | 空気入りタイヤ |

| JPH0796712A (ja) * | 1993-09-30 | 1995-04-11 | Bridgestone Corp | 二輪自動車用空気入りラジアルタイヤ |

| JP3471863B2 (ja) * | 1993-09-30 | 2003-12-02 | 株式会社ブリヂストン | 二輪自動車用空気入りラジアルタイヤ |

| DE10144833A1 (de) | 2001-09-12 | 2003-04-30 | Continental Ag | Verstärkungskord |

| DE102004036129A1 (de) * | 2004-07-24 | 2006-02-16 | Continental Aktiengesellschaft | Verstärkungscord für elastomere Erzeugnisse |

| JP4755488B2 (ja) * | 2005-11-25 | 2011-08-24 | 住友ゴム工業株式会社 | 自動二輪車用ラジアルタイヤ、及びそれに用いるバンドコード |

| FR2897076B1 (fr) | 2006-02-09 | 2008-04-18 | Michelin Soc Tech | Cable composite elastique pour pneumatique. |

| EP2091762B1 (en) * | 2006-11-22 | 2010-04-21 | Pirelli Tyre S.p.A. | Tire with light weight bead core |

| DE102007026774A1 (de) * | 2007-06-09 | 2008-12-11 | Continental Aktiengesellschaft | Verstärkungshybridkord für elastomere Erzeugnisse, insbesondere als Karkasslage oder Gürtellage von Fahrzeugluftreifen |

| EP2300659B1 (en) * | 2008-04-21 | 2019-06-19 | Pirelli Tyre S.p.A. | Metallic cord comprising preformed and non-preformed wires |

| CN102046396B (zh) * | 2008-05-28 | 2014-06-18 | 倍耐力轮胎股份公司 | 摩托车轮胎 |

| JP4814979B2 (ja) * | 2009-06-12 | 2011-11-16 | 住友ゴム工業株式会社 | タイヤ用コード及びそれを用いた空気入りタイヤ |

-

2012

- 2012-12-21 WO PCT/IB2012/057593 patent/WO2013098738A1/en active Application Filing

- 2012-12-21 EP EP12823044.8A patent/EP2748015B1/en active Active

- 2012-12-21 US US14/366,510 patent/US20150122395A1/en not_active Abandoned

- 2012-12-21 CN CN201280058148.XA patent/CN103958218B/zh active Active

- 2012-12-21 JP JP2014549598A patent/JP6185931B2/ja active Active

- 2012-12-21 BR BR112014014311-0A patent/BR112014014311B1/pt active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| EP2748015A1 (en) | 2014-07-02 |

| WO2013098738A1 (en) | 2013-07-04 |

| CN103958218A (zh) | 2014-07-30 |

| JP2015506303A (ja) | 2015-03-02 |

| US20150122395A1 (en) | 2015-05-07 |

| CN103958218B (zh) | 2018-09-18 |

| EP2748015B1 (en) | 2017-03-29 |

| BR112014014311B1 (pt) | 2020-10-13 |

| BR112014014311A2 (pt) | 2017-06-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6185931B2 (ja) | 二輪車用タイヤ | |

| JP3294378B2 (ja) | 空気入りタイヤ | |

| US5975175A (en) | Pair of high-tranverse-curvature tires for two-wheeled vehicles having different belt structures and method of controlling the behavior of such vehicles on a bend | |

| CN109219529B (zh) | 用于重载车辆车轮的轮胎 | |

| JP5868085B2 (ja) | 空気入りタイヤの形成方法 | |

| RU2694685C1 (ru) | Гибридный корд как усилитель каркаса в диагональных шинах | |

| EP0928704B1 (en) | High transverse curvature tyre for two-wheeled vehicles | |

| WO2011024447A1 (ja) | ランフラットタイヤ | |

| CN109952209B (zh) | 摩托车轮胎 | |

| CN105934354B (zh) | 用于重载车轮的轮胎 | |

| CN104066595A (zh) | 用于摩托车的轮胎 | |

| US6412533B1 (en) | High transverse-curvature tire for two-wheeled vehicles including specified belt structure | |

| JP3764245B2 (ja) | 空気入りタイヤ | |

| EP3898276B1 (en) | Tyre for vehicle wheels | |

| JP6577345B2 (ja) | 空気入りタイヤ | |

| EP3829898B1 (en) | Tyre for vehicle wheels | |

| EP0928703A1 (en) | High transverse curvature tire for two-wheeled vehicles and method for its manufacture | |

| EP3956157A1 (en) | Hybrid cord and tyre with such cord | |

| JP6848262B2 (ja) | 空気入りタイヤ | |

| JP4805021B2 (ja) | 空気入りタイヤ | |

| JP5519165B2 (ja) | 二輪車用空気入りタイヤ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20151104 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20151104 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20161026 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161028 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20170116 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170322 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170720 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170728 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6185931 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |