JP6169727B2 - Air compressor equipment - Google Patents

Air compressor equipment Download PDFInfo

- Publication number

- JP6169727B2 JP6169727B2 JP2015555532A JP2015555532A JP6169727B2 JP 6169727 B2 JP6169727 B2 JP 6169727B2 JP 2015555532 A JP2015555532 A JP 2015555532A JP 2015555532 A JP2015555532 A JP 2015555532A JP 6169727 B2 JP6169727 B2 JP 6169727B2

- Authority

- JP

- Japan

- Prior art keywords

- air

- air compressor

- hat

- storage unit

- manifold

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003860 storage Methods 0.000 claims description 26

- 230000006835 compression Effects 0.000 claims description 17

- 238000007906 compression Methods 0.000 claims description 17

- 238000002347 injection Methods 0.000 claims description 6

- 239000007924 injection Substances 0.000 claims description 6

- 238000003825 pressing Methods 0.000 claims description 4

- 238000009434 installation Methods 0.000 claims description 2

- 230000033001 locomotion Effects 0.000 description 5

- 238000010586 diagram Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000009172 bursting Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B35/00—Piston pumps specially adapted for elastic fluids and characterised by the driving means to their working members, or by combination with, or adaptation to, specific driving engines or motors, not otherwise provided for

- F04B35/04—Piston pumps specially adapted for elastic fluids and characterised by the driving means to their working members, or by combination with, or adaptation to, specific driving engines or motors, not otherwise provided for the means being electric

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/0005—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00 adaptations of pistons

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B39/00—Component parts, details, or accessories, of pumps or pumping systems specially adapted for elastic fluids, not otherwise provided for in, or of interest apart from, groups F04B25/00 - F04B37/00

- F04B39/12—Casings; Cylinders; Cylinder heads; Fluid connections

- F04B39/122—Cylinder block

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/02—Stopping, starting, unloading or idling control

- F04B49/03—Stopping, starting, unloading or idling control by means of valves

- F04B49/035—Bypassing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04B—POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS

- F04B49/00—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00

- F04B49/22—Control, e.g. of pump delivery, or pump pressure of, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for, or of interest apart from, groups F04B1/00 - F04B47/00 by means of valves

- F04B49/24—Bypassing

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

- Compressor (AREA)

- Filling Or Discharging Of Gas Storage Vessels (AREA)

Description

本発明は、機械式安全弁を取り付ける必要がなく、空気圧縮機が動作段階で圧力を安全値範囲内に保持し、タイヤに気体を注入する際、タイヤ圧が安全値を超えないようにしてタイヤを保護する空気圧縮機装置を提供する。 The present invention eliminates the need for attaching a mechanical safety valve, maintains the pressure within a safe value range during the operation stage of the air compressor, and prevents the tire pressure from exceeding the safe value when injecting gas into the tire. An air compressor device for protecting the air is provided.

本発明者は長年、小型の空気圧縮機の研究開発に力を注ぎ、手間と時間がかかって複雑な構造であった初期の空気圧縮機を、構造が簡素で、容易かつ速やかに組立てることができる製品へ転換した。米国特許第7462018号明細書の排出管(outlet tube)には、複数のダクト(duct)が設けられ、そのうち1つのダクト(duct)には、機械式圧力安全弁(safety valve)が取り付けられる。空気圧縮機のピストンがシリンダー内で直線運動を行い、上死点に達すると、当該案のピストン中のピストンヘッドの頂平面がシリンダーの圧縮室の頂壁面に完全に当接され、ピストンの上動行程の動作において、シリンダーの圧縮室と連通する排気用の排出管に圧縮空気が完全に進入するが、不適切な気体注入により空気圧縮機が被測定タイヤの設定タイヤ圧より高くなると、付加的な機械式圧力安全弁(safety valve)により自動的に圧力を下げなければならないが、機械式圧力安全弁(safety valve)が古すぎると詰まって故障し、使用者がタイヤに気体を注入する際、タイヤに注入する気体が多すぎるとタイヤが容易にパンクしてしまう危険性があった。

(発明の内容)

The present inventor has been devoted to research and development of a small air compressor for many years, and it is possible to assemble an early air compressor, which has been complicated and time-consuming and time-consuming, with a simple structure and easily and quickly. Converted to a product that can be used. The outlet tube of U.S. Pat. No. 7,46,018 is provided with a plurality of ducts, one of which is fitted with a mechanical pressure relief valve. When the piston of the air compressor moves linearly in the cylinder and reaches top dead center, the top surface of the piston head in the proposed piston is completely abutted against the top wall of the compression chamber of the cylinder, In the operation of the stroke, the compressed air completely enters the exhaust discharge pipe communicating with the compression chamber of the cylinder, but it is added if the air compressor becomes higher than the set tire pressure of the measured tire due to improper gas injection. The pressure must be automatically reduced by a mechanical safety valve, but if the mechanical pressure valve is too old, it will clog and fail, and when the user injects gas into the tire, If too much gas was injected into the tire, there was a risk that the tire would easily puncture.

(Content of invention)

本発明の目的は、機械式圧力安全弁を取り付けずに、空気圧縮機が動作段階にあるとき、圧力を安全値範囲内に維持し、タイヤに気体を注入する際、タイヤ圧が安全値を超えてタイヤが破裂してしまう問題が生じることを防ぐ、空気圧縮機装置を提供することにある。 The object of the present invention is to maintain a pressure within a safe value range when the air compressor is in an operating stage without attaching a mechanical pressure safety valve, and when injecting gas into the tire, the tire pressure exceeds the safe value. Another object of the present invention is to provide an air compressor device that prevents the tire from bursting.

上述の目的を達成するために、本発明の解決手段は:

空気圧縮機装置が、ボックス体を含み、その内部には、電源がオンされると空気圧力を発生させる空気圧縮機が設けられ、空気圧縮機は、モータが作動する際、ピストン本体のピストンヘッドがシリンダー内で往復運動し、シリンダー内の圧縮空気が押し出されて空気圧縮機の空気貯蔵ユニット内に進入し、空気貯蔵ユニット上には、空気貯蔵ユニットと連通する複数のマニホールドが設けられる。

In order to achieve the above object, the solution of the present invention is:

An air compressor device includes a box body, and an air compressor that generates air pressure when a power source is turned on is provided in the air compressor device. Reciprocates in the cylinder, the compressed air in the cylinder is pushed out and enters the air storage unit of the air compressor, and a plurality of manifolds communicating with the air storage unit are provided on the air storage unit.

空気圧縮機のシリンダーの外壁には、副気室を有するマニホールドが設けられ、副気室は、シリンダーの圧縮室と流通するが、排気用の空気貯蔵ユニットとは連通せず、空気圧縮機のピストンヘッドの頂面が、シリンダーの圧縮室の頂壁面に完全に当接されると、圧縮空気の一部が副気室内に進入し、ピストン本体の下動行程の動作がスムーズになるとともに、空気圧縮機に圧力安全弁を設置しなくとも、気体注入する際、安全圧力値範囲を超えることがない。 A manifold having a sub air chamber is provided on the outer wall of the cylinder of the air compressor, and the sub air chamber circulates with the cylinder compression chamber, but does not communicate with the exhaust air storage unit. When the top surface of the piston head is completely brought into contact with the top wall surface of the compression chamber of the cylinder, a part of the compressed air enters the auxiliary air chamber, and the operation of the downward movement of the piston body becomes smooth, Even if a pressure safety valve is not installed in the air compressor, the safe pressure value range is not exceeded when gas is injected.

上述の構造を採用した後、本発明に係る空気圧縮機装置は、空気圧縮機のシリンダーの外壁に、副気室を有するマニホールドが設けられ、副気室は、シリンダーの圧縮室と流通するが、排気用の空気貯蔵ユニットと連通せず、空気圧縮機のピストンヘッドの頂面が、シリンダーの圧縮室の頂壁面に完全に当接されると、圧縮空気の一部が副気室内に進入し、ピストン本体の下動行程の動作がスムーズになるとともに、空気圧縮機に圧力安全弁を設置しなくとも、気体注入する際、安全圧力値範囲を超えることがない。 After adopting the above-described structure, the air compressor apparatus according to the present invention is provided with a manifold having a sub air chamber on the outer wall of the cylinder of the air compressor, and the sub air chamber circulates with the compression chamber of the cylinder. When the top surface of the piston head of the air compressor is completely in contact with the top wall of the compression chamber of the cylinder without communicating with the air storage unit for exhaust, a part of the compressed air enters the auxiliary air chamber. In addition, the operation of the downward stroke of the piston body becomes smooth, and even if a pressure safety valve is not installed in the air compressor, the safe pressure value range is not exceeded when gas is injected.

従来技術と比べ、本発明に係る空気圧縮機装置は、機械式圧力安全弁を取り付ける必要がなく、空気圧縮機が動作段階で圧力を安全値範囲内に保持し、タイヤに気体を注入する際、タイヤ圧が安全値を超えないようにしてタイヤを保護する目的を達成する。本発明は、製造コストを減らすことができる上、ピストン本体の下動行程の動作をスムーズにすることもできる。

(実施方式)

Compared with the prior art, the air compressor device according to the present invention does not need to be equipped with a mechanical pressure safety valve, the air compressor keeps the pressure within the safe value range during the operation stage, and when injecting gas into the tire, To achieve the purpose of protecting the tire so that the tire pressure does not exceed a safe value. According to the present invention, the manufacturing cost can be reduced, and the operation of the downward movement of the piston body can be made smooth.

(Implementation method)

本発明の技術手段をさらに説明するために、以下、具体的な実施例により本発明を詳細に説明する。 In order to further explain the technical means of the present invention, the present invention will be described in detail below by means of specific examples.

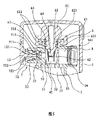

まず、図1〜図4を参照する。図1〜図4に示すように、本発明の空気圧縮機装置は、ボックス体1を含む。ボックス体1上には、押しボタン式のスイッチ11と、ボタン12と、中空状の透孔13とが設けられる。ボックス体1内には、空気圧縮機が設けられる。空気圧縮機は、ピストン本体25が動作するシリンダー3と、モータ21を固定するメインフレーム20とが一体成形された構造である。

First, reference will be made to FIGS. As shown in FIGS. 1 to 4, the air compressor device of the present invention includes a

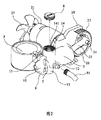

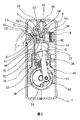

メインフレーム20には、空気圧縮機の動力機構が固定されてもよい。動力機構は、モータ21と、伝動用のピニオン22と、ギア23と、クランクピン24を有する重量回転盤28と、放熱用の放熱ファン27とを含む。モータ21により空気圧縮機の動力機構を駆動し、ピストン本体25のピストンヘッド26がシリンダー3のインナーチャンバ34内で往復圧縮動作を行い、圧縮された空気が空気孔32を介して弁体41を押動してばね42を圧縮し、圧縮された空気が空気貯蔵ユニット5内に進入する。

A power mechanism of an air compressor may be fixed to the

空気貯蔵ユニット5上には、空気貯蔵ユニット5と連通する複数のマニホールド52,53,55が設けられる(図8を同時に参照する)。マニホールド52には、ホース91が接続される。マニホールド53は、ガス抜き弁7の設置に応用される。マニホールド55には、圧力計9が設置される。本発明の最も重要な構造特徴は、シリンダー3の外壁にマニホールド54が設けられている点である。マニホールド54内には、流通口35を介してシリンダー3の圧縮室33と連通する副気室541が設けられているが、副気室541は、排気用として用いられる空気貯蔵ユニット5のチャンバ51と連通せず、マニホールド54の外端開口には、螺合可能な調節弁8が設けられる。調節弁8の螺合深さを調整することにより、副気室541の容積を調整することができる。

On the air storage unit 5, a plurality of

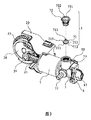

図4〜図7を同時に参照する。空気貯蔵ユニット5は、底部50においてシリンダー3の頂壁31と隣接し、共用の中間壁30が形成される。中間壁30上には、空気孔32及び流通口35が形成される。空気孔32は、シリンダー3中のインナーチャンバ34の圧縮室33と、空気貯蔵ユニット5のチャンバ51とを連通させ、流通口35によりシリンダー3のインナーチャンバ34の圧縮室33とマニホールド54の副気室541とが連通する。弁体41は、前述の中間壁30の空気孔32上端に設置される。矩形状を呈するトップカバー6(図5を参照する)は、その上端に回転ハンドル61が設けられる。トップカバー6の中心部からは円筒柱62が下方へ延び、円筒柱62上からは互いに離間した複数の環状ショルダ621が外方へ延び、トップカバー6と環状ショルダ621との間には、複数の凹状環溝622が形成される。円筒柱62は、底端縁63を有する。底端縁63には、円筒柱62の内心へ向かう凸状の押圧部64が形成される。複数のシールリング65は、前述の円筒柱62上の環状ショルダ621に嵌合される。

Please refer to FIGS. 4 to 7 at the same time. The air storage unit 5 is adjacent to the

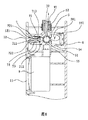

前述のトップカバー6は、前述の空気貯蔵ユニット5上に対応して結合される。図2に示すように、回転ハンドル61を回転させると、トップカバー6が空気貯蔵ユニット5上に強固に係合され、緩む虞がない。ばね42は、一端が前述の弁体41上に設置され、他端がトップカバー6の円筒柱62上の環状ショルダ621に当接される。

The aforementioned

図3及び図5を同時に参照する。ガス抜き弁7は、中空状のハット型ソフトキャップ71と、ナット72と、を含む。中空状のハット型ソフトキャップ71は、一端に前端部711が設けられ、他端に外リングが設けられ、外リングには互いに離間した複数のバンプ712が設けられ、互いに離間したバンプ712間には、流通溝713が形成される。ナット72の一端は開口721を有し、ナット72の他端は内口径が開口721より小さな透孔722から延びる。このときハット型ソフトキャップ71をマニホールド53に装入してから、ナット72の透孔722の端部をハット型ソフトキャップ71に当接させてマニホールド53内に結合させ、この段階でハット型ソフトキャップ71の一端の外リングがマニホールド53の内壁に当接され、ハット型ソフトキャップ71の他端がナット725の透孔722の端部に当接される。前述のボックス体1のボタン12の内側のプッシュバー121は、ナット72に挿通され、ハット型ソフトキャップ71の前端部711に対応する。ボタン12を押下すると、ガス抜き弁7のハット型ソフトキャップ71の前端部711が押圧され、ハット型ソフトキャップ51が圧縮されて変形し、気体被注入物の過剰な圧力は、図5及び図6に示すように、ガス抜き弁7に取り付けられたマニホールド53から排出される。調節弁8は、マニホールド54内に螺合され、回転することにより副気室541の内容積を調整することができる。

Please refer to FIG. 3 and FIG. 5 simultaneously. The

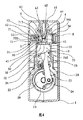

本発明のピストン本体25は、シリンダー3のインナーチャンバ34内で行う往復直線運動が上死点に達すると、ピストンヘッド26の頂面260がシリンダー3の圧縮室33の頂壁31に完全に当接され(図7参照)、このとき大部分の圧縮空気がシリンダー3の頂壁31に形成された空気孔32を介して弁体41が圧縮押動されるとばね42が圧縮され、圧縮された空気が空気貯蔵ユニット5のチャンバ51内に進入し、各マニホールド52,53,55を介して異なる性質、機能のオブジェクトに接続される。しかし、シリンダー3から出力される圧縮空気中には、依然として一部の空気が流通口35を介してマニホールド54の副気室541内へ進入し、副気室541内に収容される空気量により、空気圧縮機が気体を注入する際、圧力値が安全範囲を超えることがなく、ピストン本体25の下動行程を開始する際、動作がスムーズとなる。前述の弁体41は、駆動されてトップカバー6の円筒柱62の底端の押圧部64により制限されると、その動作状態を図7及び図8に示す。

When the reciprocating linear motion performed in the

図6及び図7を参照する。気体被注入物の内部圧力が安全圧力値の範囲を超えた場合、使用者はガス抜き弁7を操作して圧力を開放する。

Please refer to FIG. 6 and FIG. When the internal pressure of the gas injection object exceeds the range of the safe pressure value, the user operates the

以上を要約すると、本発明のシリンダー3の外側には、副気室541を有するマニホールド54が設けられる。副気室541は、流通口35を介してシリンダー3の圧縮室33と連通する。シリンダー3の外側に延びた空気貯蔵ユニット5は、空気孔32を介してシリンダー3の圧縮室33と連通するが、副気室541と空気貯蔵ユニット5のチャンバ51とは連通せず、大部分の圧縮空気は、空気貯蔵ユニット5に設けたダクトからその他の機能の部材及び気体被注入物に至るまで出力され、残部の圧縮空気は、副気室541内に進入して残留するが、このような構造設計は、圧力安全弁を設けなくともピストン本体25が動作する際に圧力値が安全範囲を超える気体注入が行われることを防ぐとともに、ピストン本体25の下動行程の動作がスムーズとなり、進歩性を備える。

In summary, a manifold 54 having a

上述の実施例及び図面は、本発明の製品形態及び様式を限定するものではなく、当業者が行う適宜変更又は修正も全て本発明の特許請求の範囲から外れるものではない。 The above-described embodiments and drawings do not limit the product form and style of the present invention, and any appropriate changes or modifications made by those skilled in the art do not depart from the scope of the claims of the present invention.

1 ボックス体

11 スイッチ

12 ボタン

121 プッシュバー

13 透孔

20 メインフレーム

21 モータ

22 ピニオン

23 ギア

24 クランクピン

25 ピストン本体

26 ピストンヘッド

260 頂面

27 放熱ファン

28 重量回転盤

3 シリンダー

30 中間

31 壁頂壁

32 空気孔

33 圧縮室

34 インナーチャンバ

35 流通口

41 弁体

42 ばね

5 空気貯蔵ユニット

51 チャンバ

52 マニホールド

53 マニホールド

54 マニホールド

55 マニホールド

541 副気室

6 トップカバー

61 回転ハンドル

62 円筒柱

621 環状ショルダ

622 環溝

63 底端縁

64 押圧部

65 シールリング

7 ガス抜き弁

71 ハット型ソフトキャップ

711 前端部

712 バンプ

713 流通溝

72 ナット

721 開口

722 透孔

8 調節弁

9 圧力計

91 ホース

DESCRIPTION OF

Claims (3)

ボックス体を含み、その内部には、電源がオンされると空気圧力を発生させる空気圧縮機が設けられ、

前記空気圧縮機は、モータが作動する際、ピストン本体のピストンヘッドがシリンダー内で往復運動し、前記シリンダー内の圧縮空気が押し出されて前記空気圧縮機の空気貯蔵ユニット内に進入し、

前記空気貯蔵ユニット上には、複数のマニホールドが設けられ、少なくとも一つの前記マニホールドが副気室を有し、

前記副気室は、前記シリンダーの圧縮室と流通するが、排気用の前記空気貯蔵ユニットと連通せず、

前記マニホールド内には、調整式の調整弁が設けられ、前記調整弁により前記副気室の内容積を調整し、

前記空気圧縮機の前記ピストンヘッドの頂面が、前記シリンダーの前記圧縮室の頂壁面に完全に当接されると、圧縮空気の一部が前記副気室内に進入し、前記ピストン本体の下動行程の動作がスムーズになるとともに、前記空気圧縮機に圧力安全弁を設置しなくとも、気体注入する際、安全圧力値範囲を超えることがないことを特徴とする空気圧縮機装置。 An air compressor device,

Including the box body, inside it is provided with an air compressor that generates air pressure when the power is turned on,

In the air compressor, when the motor operates, the piston head of the piston body reciprocates in the cylinder, the compressed air in the cylinder is pushed out and enters the air storage unit of the air compressor,

Wherein the on air storage unit is provided with a multiple manifold, at least one of said manifold has a sub air chamber,

The auxiliary air chamber circulates with the compression chamber of the cylinder, but does not communicate with the air storage unit for exhaust,

An adjustment type adjustment valve is provided in the manifold, and the internal volume of the auxiliary air chamber is adjusted by the adjustment valve,

When the top surface of the piston head of the air compressor is completely brought into contact with the top wall surface of the compression chamber of the cylinder, a part of the compressed air enters the sub air chamber and An air compressor apparatus characterized in that the operation of the moving stroke becomes smooth and that the safe pressure value range is not exceeded when gas is injected without installing a pressure safety valve in the air compressor.

前記空気貯蔵ユニット上の前記マニホールドをガス抜き弁の設置に応用し、

前記ガス抜き弁は、中空状のハット型ソフトキャップを含み、前記ハット型ソフトキャップは、一端に前端部が設けられ、他端に外リングが設けられ、前記外リングには互いに離間した複数のバンプが設けられ、前記互いに離間したバンプ間には、流通溝が形成され、ナットの一端は開口を有し、前記ナットの他端は内口径が前記開口より小さな透孔から延び、

前記ハット型ソフトキャップが前記マニホールド内に装入され、前記ナットの前記透孔の端部を前記ハット型ソフトキャップに当接させて前記マニホールド内に結合させ、前記ハット型ソフトキャップの他端の前記外リングが前記マニホールドの内壁に当接され、前記ハット型ソフトキャップの他端が前記ナットの前記透孔の端部に当接され、前記ボックス体中の前記ボタン内側のプッシュバーが前記ナットに挿通され、前記ハット型ソフトキャップの前端部に対応し、前記ボタンを押下すると、前記ガス抜き弁の前記ハット型ソフトキャップの前端部に押圧され、前記ハット型ソフトキャップが圧縮されて変形し、気体被注入物の過剰な圧力が流通溝、透孔を介して下がることを特徴とする請求項1に記載の空気圧縮機装置。 A button is provided on the box body,

Applying the manifold on the air storage unit to the installation of a vent valve;

The gas vent valve includes a hollow hat-type soft cap, and the hat-type soft cap has a front end provided at one end, an outer ring provided at the other end, and the outer ring includes a plurality of spaced apart ones. Bumps are provided, a flow groove is formed between the bumps spaced apart from each other, one end of the nut has an opening, and the other end of the nut extends from a through hole having an inner diameter smaller than the opening,

The hat type soft cap is charged into the manifold, the end portion of the through hole of the nut is brought into contact with the hat soft cap is coupled into the manifold, the other end of the hat-type soft cap The outer ring is in contact with the inner wall of the manifold, the other end of the hat-type soft cap is in contact with the end of the through hole of the nut, and the push bar inside the button in the box body is the nut When the button is pressed, the front end of the hat-type soft cap of the gas vent valve is pressed against the front end of the hat-type soft cap, and the hat-type soft cap is compressed and deformed. The air compressor apparatus according to claim 1, wherein an excessive pressure of the gas injection object is lowered through the flow groove and the through hole.

前記中間壁の前記空気孔の上端には、弁体が設置され、

矩形状を呈するトップカバーは、上端に回転ハンドルが設けられ、前記トップカバーの中心部からは円筒柱が下方へ延び、前記円筒柱上には互いに離間した複数の環状ショルダが外方へ延びて延設され、前記トップカバーと前記環状ショルダとの間には、複数の凹状環溝が形成され、前記円筒柱は、底端縁を有し、前記底端縁には、前記円筒柱の内心へ向かう凸状の押圧部が形成され、

前記円筒柱上の前記環状ショルダには、複数のシールリングが嵌合され、

前記トップカバーは、前記空気貯蔵ユニット上に対応して結合され、回転ハンドルを回転させると前記トップカバーが前記空気貯蔵ユニット上に強固に係合され、

ばねは、一端が前記弁体上に設けられ、他端が前記トップカバーの前記円筒柱上の前記環状ショルダに当接されることを特徴とする請求項1に記載の空気圧縮機装置。 A common intermediate wall is formed adjacent to the top wall of the cylinder at the bottom of the air storage unit, an air hole is formed on the intermediate wall, and the inner chamber of the cylinder is formed through the air hole. The compression chamber communicates with the chamber of the air storage unit;

A valve body is installed at the upper end of the air hole of the intermediate wall,

The top cover having a rectangular shape is provided with a rotary handle at the upper end, a cylindrical column extends downward from the center of the top cover, and a plurality of annular shoulders spaced apart from each other extend outward on the cylindrical column. A plurality of concave annular grooves are formed between the top cover and the annular shoulder, the cylindrical column has a bottom end edge, and the bottom end edge has an inner center of the cylindrical column. A convex pressing part toward the

A plurality of seal rings are fitted to the annular shoulder on the cylindrical column,

The top cover is correspondingly coupled on the air storage unit, and when the rotary handle is rotated, the top cover is firmly engaged on the air storage unit,

2. The air compressor device according to claim 1, wherein one end of the spring is provided on the valve body, and the other end abuts on the annular shoulder on the cylindrical column of the top cover.

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/CN2013/071532 WO2014121497A1 (en) | 2013-02-07 | 2013-02-07 | Air compressor apparatus |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2016505115A JP2016505115A (en) | 2016-02-18 |

| JP2016505115A5 JP2016505115A5 (en) | 2017-04-06 |

| JP6169727B2 true JP6169727B2 (en) | 2017-07-26 |

Family

ID=51299204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015555532A Active JP6169727B2 (en) | 2013-02-07 | 2013-02-07 | Air compressor equipment |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP2955381B1 (en) |

| JP (1) | JP6169727B2 (en) |

| KR (1) | KR101801627B1 (en) |

| CN (1) | CN104903579B (en) |

| DK (1) | DK2955381T3 (en) |

| HU (1) | HUE037832T2 (en) |

| PL (1) | PL2955381T3 (en) |

| WO (1) | WO2014121497A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI626377B (en) * | 2016-02-26 | 2018-06-11 | 周文三 | Improved air compressor |

| CN111207055A (en) * | 2020-01-10 | 2020-05-29 | 浙江多加机电科技股份有限公司 | Low-voltage pressure-relief inflator pump device |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US302978A (en) * | 1884-08-05 | Air-compressor | ||

| US2329401A (en) * | 1941-10-01 | 1943-09-14 | Ingersoll Rand Co | Unloader for compressors |

| JPH0411286U (en) * | 1990-05-21 | 1992-01-30 | ||

| US5902097A (en) * | 1997-05-19 | 1999-05-11 | Wu; Scott | Pumping device with a clamping nozzle for various valves |

| KR100248835B1 (en) * | 1997-11-15 | 2000-04-01 | 정몽규 | Radiator cap |

| FR2793284B1 (en) * | 1999-05-05 | 2005-10-14 | Renault Vehicules Ind | PISTON AIR COMPRESSOR |

| BR0004859A (en) * | 2000-10-05 | 2002-05-07 | Brasil Compressores Sa | Piston stroke limiting device in reciprocating compressor |

| US7462018B2 (en) * | 2002-08-12 | 2008-12-09 | Wen San Chou | Air compressor having stable configuration |

| CN100372711C (en) * | 2004-04-08 | 2008-03-05 | 周文三 | Small and simple aerating device |

| JP4420740B2 (en) * | 2004-05-27 | 2010-02-24 | 株式会社ブリヂストン | Pump-up device |

| US7240642B2 (en) * | 2005-08-16 | 2007-07-10 | Wen San Chou | Air compressor having changeable structure |

| US20070098583A1 (en) * | 2005-08-23 | 2007-05-03 | Chou Wen S | Air compressor having detachable structure |

| DE102008057826A1 (en) * | 2008-11-18 | 2010-06-02 | Jhou, Wen-San, An-Din | Air compression-assembly for inflating e.g. different air devices, with air, has control device coupled to air compression devices to control air compression devices for generating and supplying compressed air to air tank |

| TWI430899B (en) * | 2010-03-10 | 2014-03-21 | Wen San Chou | Device for sealing and inflating inflatable object |

| CN102465860B (en) * | 2010-11-09 | 2015-11-25 | 周文三 | A kind of air compressor |

| JP5438702B2 (en) * | 2011-02-17 | 2014-03-12 | 住友ゴム工業株式会社 | Compressor device |

-

2013

- 2013-02-07 HU HUE13874544A patent/HUE037832T2/en unknown

- 2013-02-07 WO PCT/CN2013/071532 patent/WO2014121497A1/en active Application Filing

- 2013-02-07 DK DK13874544.3T patent/DK2955381T3/en active

- 2013-02-07 JP JP2015555532A patent/JP6169727B2/en active Active

- 2013-02-07 EP EP13874544.3A patent/EP2955381B1/en active Active

- 2013-02-07 CN CN201380069838.XA patent/CN104903579B/en active Active

- 2013-02-07 PL PL13874544T patent/PL2955381T3/en unknown

- 2013-02-07 KR KR1020157017326A patent/KR101801627B1/en active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| EP2955381A4 (en) | 2016-11-02 |

| CN104903579A (en) | 2015-09-09 |

| PL2955381T3 (en) | 2018-07-31 |

| CN104903579B (en) | 2017-05-31 |

| DK2955381T3 (en) | 2018-04-23 |

| EP2955381A1 (en) | 2015-12-16 |

| JP2016505115A (en) | 2016-02-18 |

| KR101801627B1 (en) | 2017-11-27 |

| EP2955381B1 (en) | 2018-01-10 |

| WO2014121497A1 (en) | 2014-08-14 |

| KR20150090227A (en) | 2015-08-05 |

| HUE037832T2 (en) | 2018-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI604129B (en) | Air compressor | |

| JP3201612U (en) | Air compressor coupling structure | |

| JP6120928B2 (en) | Air compressor structure | |

| JP2022166841A (en) | Porous piston body in cylinder of air compressor | |

| JP6169727B2 (en) | Air compressor equipment | |

| JP2022167842A (en) | Air stop sheet of piston body of cylinder | |

| JP6169726B2 (en) | Air compressor structure | |

| JP3205431U (en) | Compressor cylinder exhaust structure of air compressor | |

| TWI548812B (en) | Air compressor device | |

| JP6178866B2 (en) | Air compressor equipment | |

| JP6067143B2 (en) | Piston body structure of air compressor | |

| TWI598511B (en) | Air compressor device | |

| TWI568934B (en) | Piston assembly of air compressor | |

| KR101257829B1 (en) | Air compressor | |

| EP4289561A1 (en) | Pneumatic nailing gun with adjustable nailing force | |

| TWI526619B (en) | Air compressor device | |

| TWM507975U (en) | Improved combination structure of an air compressor | |

| TWM504152U (en) | Air compressor | |

| KR20150000311U (en) | Portable air pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20150804 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20160414 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20160426 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20160720 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20161206 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20170306 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20170606 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20170628 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6169727 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |