JP5803316B2 - 構造物の製造方法 - Google Patents

構造物の製造方法 Download PDFInfo

- Publication number

- JP5803316B2 JP5803316B2 JP2011134937A JP2011134937A JP5803316B2 JP 5803316 B2 JP5803316 B2 JP 5803316B2 JP 2011134937 A JP2011134937 A JP 2011134937A JP 2011134937 A JP2011134937 A JP 2011134937A JP 5803316 B2 JP5803316 B2 JP 5803316B2

- Authority

- JP

- Japan

- Prior art keywords

- region

- opening

- stage

- shape

- opening area

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

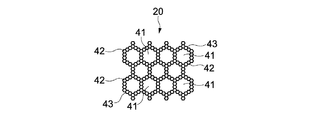

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/10—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material

- B32B3/12—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a discontinuous layer, i.e. formed of separate pieces of material characterised by a layer of regularly- arranged cells, e.g. a honeycomb structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/124—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified

- B29C64/129—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified characterised by the energy source therefor, e.g. by global irradiation combined with a mask

- B29C64/135—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified characterised by the energy source therefor, e.g. by global irradiation combined with a mask the energy source being concentrated, e.g. scanning lasers or focused light sources

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C67/00—Shaping techniques not covered by groups B29C39/00 - B29C65/00, B29C70/00 or B29C73/00

- B29C67/20—Shaping techniques not covered by groups B29C39/00 - B29C65/00, B29C70/00 or B29C73/00 for porous or cellular articles, e.g. of foam plastics, coarse-pored

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D99/00—Subject matter not provided for in other groups of this subclass

- B29D99/0089—Producing honeycomb structures

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24149—Honeycomb-like

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24273—Structurally defined web or sheet [e.g., overall dimension, etc.] including aperture

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Filtering Materials (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011134937A JP5803316B2 (ja) | 2011-06-17 | 2011-06-17 | 構造物の製造方法 |

| US14/124,530 US20140113105A1 (en) | 2011-06-17 | 2012-06-11 | Structure and method of producing the same |

| CN201280028384.7A CN103608166B (zh) | 2011-06-17 | 2012-06-11 | 结构体及其生产方法 |

| PCT/JP2012/003780 WO2012172770A1 (ja) | 2011-06-17 | 2012-06-11 | 構造物及びその製造方法 |

| EP12799786.4A EP2722159A4 (en) | 2011-06-17 | 2012-06-11 | STRUCTURE AND MANUFACTURING METHOD THEREFOR |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011134937A JP5803316B2 (ja) | 2011-06-17 | 2011-06-17 | 構造物の製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2013000998A JP2013000998A (ja) | 2013-01-07 |

| JP2013000998A5 JP2013000998A5 (enExample) | 2014-07-17 |

| JP5803316B2 true JP5803316B2 (ja) | 2015-11-04 |

Family

ID=47356777

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011134937A Expired - Fee Related JP5803316B2 (ja) | 2011-06-17 | 2011-06-17 | 構造物の製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20140113105A1 (enExample) |

| EP (1) | EP2722159A4 (enExample) |

| JP (1) | JP5803316B2 (enExample) |

| CN (1) | CN103608166B (enExample) |

| WO (1) | WO2012172770A1 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE112014001464T5 (de) * | 2013-03-15 | 2016-02-18 | Pyrotek Incorporated | Keramikfilter |

| TWI609769B (zh) | 2014-06-03 | 2018-01-01 | 三緯國際立體列印科技股份有限公司 | 立體結構與立體列印方法 |

| EP3017932A1 (en) * | 2014-10-07 | 2016-05-11 | Kapsch TrafficCom AG | Method of producing a core for a construction element and 3D-printer therefore |

| FR3027554B1 (fr) * | 2014-10-27 | 2020-02-07 | Centre National De La Recherche Scientifique | Procede d'impression en trois dimensions |

| MX2018000874A (es) * | 2015-07-22 | 2018-08-15 | Ask Chemicals Lp | Filtro de ceramica y metodo para formar el filtro. |

| US11230053B2 (en) | 2016-01-21 | 2022-01-25 | 3M Innovative Properties Company | Additive processing of fluoropolymers |

| US20200164572A1 (en) * | 2017-06-30 | 2020-05-28 | 3M Innovative Properties Company | Three-dimensional article and method of making a three-dimensional article |

| DE102018206120A1 (de) * | 2018-04-20 | 2019-10-24 | Faurecia Innenraum Systeme Gmbh | Verbundteil, insbesondere Innenverkleidungsteil, und Verfahren zu dessen Herstellung |

| JP2021130227A (ja) * | 2020-02-19 | 2021-09-09 | 株式会社リコー | フィルタおよびその製造方法、水の浄化装置、発電装置、並びに発電システム |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4416676A (en) * | 1982-02-22 | 1983-11-22 | Corning Glass Works | Honeycomb filter and method of making it |

| FR2691818B1 (fr) * | 1992-06-02 | 1997-01-03 | Alsthom Cge Alcatel | Procede de fabrication d'un objet fractal par stereolithographie et objet fractal obtenu par un tel procede. |

| JP2002347125A (ja) * | 2001-05-24 | 2002-12-04 | Nakakin:Kk | 光造形物 |

| JP2002349246A (ja) * | 2001-05-25 | 2002-12-04 | Nippon Steel Chem Co Ltd | 排ガスの微粒子除去装置及び方法 |

| JP2003200398A (ja) * | 2001-10-30 | 2003-07-15 | Sony Corp | 多重化階層構造体およびその製造方法ならびに機能材料およびその製造方法ならびに電子装置およびその製造方法ならびにらせん構造体 |

| WO2004024295A1 (ja) * | 2002-09-13 | 2004-03-25 | Ibiden Co., Ltd. | ハニカム構造体 |

| US20040121120A1 (en) * | 2002-12-20 | 2004-06-24 | The Procter & Gamble Company | Apparatus for making a polymeric web exhibiting a soft and silky tactile impression |

| ES2546329T3 (es) * | 2003-07-24 | 2015-09-22 | Tecomet Inc. | Espumas no aleatorias ensambladas |

| US7688279B2 (en) * | 2003-09-08 | 2010-03-30 | Juridical Foundation Osaka Industrial Promotion Organization | Fractal structure, super structure of fractal structures, method for manufacturing the same and applications |

| JP5040152B2 (ja) * | 2006-04-12 | 2012-10-03 | 東洋製罐株式会社 | 構造体、構造体の形成方法及び構造体形成装置 |

| US7785520B2 (en) * | 2006-12-15 | 2010-08-31 | E.I. Du Pont De Nemours And Company | Processes for making shaped honeycomb and honeycombs made thereby |

| US8828517B2 (en) * | 2009-03-23 | 2014-09-09 | Solexel, Inc. | Structure and method for improving solar cell efficiency and mechanical strength |

| JP2011098484A (ja) * | 2009-11-05 | 2011-05-19 | Sony Corp | 3次元光造形装置、3次元光造形方法及び造形物 |

-

2011

- 2011-06-17 JP JP2011134937A patent/JP5803316B2/ja not_active Expired - Fee Related

-

2012

- 2012-06-11 WO PCT/JP2012/003780 patent/WO2012172770A1/ja not_active Ceased

- 2012-06-11 CN CN201280028384.7A patent/CN103608166B/zh not_active Expired - Fee Related

- 2012-06-11 EP EP12799786.4A patent/EP2722159A4/en not_active Withdrawn

- 2012-06-11 US US14/124,530 patent/US20140113105A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013000998A (ja) | 2013-01-07 |

| CN103608166A (zh) | 2014-02-26 |

| US20140113105A1 (en) | 2014-04-24 |

| EP2722159A4 (en) | 2015-02-18 |

| EP2722159A1 (en) | 2014-04-23 |

| WO2012172770A1 (ja) | 2012-12-20 |

| CN103608166B (zh) | 2016-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5803316B2 (ja) | 構造物の製造方法 | |

| JP5884321B2 (ja) | 構造物の製造方法 | |

| JP2012240216A (ja) | 3次元造形装置、造形物及び造形物の製造方法 | |

| ES2754073T3 (es) | Dispositivo y procedimiento para generar estructuras tridimensionales | |

| JP2012040757A (ja) | 3次元造形装置、造形物及び造形物の製造方法 | |

| JP2011098484A (ja) | 3次元光造形装置、3次元光造形方法及び造形物 | |

| KR100976864B1 (ko) | 레이져 어블레이션을 이용한 초발수성 표면 가공방법과듀얼 스케일의 미세구조를 갖는 초발수성 표면의 고체기재 | |

| JP2006068762A (ja) | レーザー加工方法およびレーザー加工装置 | |

| US11097482B2 (en) | System and method for forming nano-structures on substrates to provide predetermined physical characteristics to the substrates | |

| JP6020672B2 (ja) | 3次元造形装置及び造形物の製造方法 | |

| JP6344447B2 (ja) | 3次元造形装置及び造形物の製造方法 | |

| JP6451420B2 (ja) | 接合構造体の製造方法 | |

| US12036725B2 (en) | Shaping apparatus, droplet moving device, object production method, shaping method, droplet moving method, shaping program, and droplet moving program | |

| US11465355B2 (en) | Modeling apparatus and manufacturing method for a modeled object | |

| JP6862795B2 (ja) | 造形装置及び造形物の製造方法 | |

| Jariwala et al. | A film fabrication process on transparent substrate using mask projection micro-stereolithography | |

| Choi et al. | Curing characteristics of three-dimensional microstructures using dynamic pattern projection | |

| HK1250154A1 (zh) | 用於本体或表面的激光辅助加工的装置和方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140604 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20140604 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20150317 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20150327 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20150804 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20150817 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 5803316 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |