JP5117857B2 - リン酸アルミニウム組成物、コーティング及び関連複合体 - Google Patents

リン酸アルミニウム組成物、コーティング及び関連複合体 Download PDFInfo

- Publication number

- JP5117857B2 JP5117857B2 JP2007534922A JP2007534922A JP5117857B2 JP 5117857 B2 JP5117857 B2 JP 5117857B2 JP 2007534922 A JP2007534922 A JP 2007534922A JP 2007534922 A JP2007534922 A JP 2007534922A JP 5117857 B2 JP5117857 B2 JP 5117857B2

- Authority

- JP

- Japan

- Prior art keywords

- coating

- inventive material

- coatings

- present

- inventive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000576 coating method Methods 0.000 title claims description 306

- 239000002131 composite material Substances 0.000 title claims description 31

- 239000000203 mixture Substances 0.000 title description 50

- ILRRQNADMUWWFW-UHFFFAOYSA-K aluminium phosphate Chemical compound O1[Al]2OP1(=O)O2 ILRRQNADMUWWFW-UHFFFAOYSA-K 0.000 title description 29

- 239000011248 coating agent Substances 0.000 claims description 217

- 239000000758 substrate Substances 0.000 claims description 128

- 229910052751 metal Inorganic materials 0.000 claims description 48

- 239000002184 metal Substances 0.000 claims description 48

- 230000004888 barrier function Effects 0.000 claims description 32

- -1 aluminum phosphate compound Chemical class 0.000 claims description 30

- 229920003023 plastic Polymers 0.000 claims description 29

- 239000004033 plastic Substances 0.000 claims description 29

- 229910052698 phosphorus Inorganic materials 0.000 claims description 16

- 239000011574 phosphorus Substances 0.000 claims description 14

- 229920001721 polyimide Polymers 0.000 claims description 14

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims description 12

- 229910045601 alloy Inorganic materials 0.000 claims description 12

- 239000000956 alloy Substances 0.000 claims description 12

- 229910052782 aluminium Inorganic materials 0.000 claims description 12

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 10

- 239000004642 Polyimide Substances 0.000 claims description 9

- 239000011888 foil Substances 0.000 claims description 9

- 229920000515 polycarbonate Polymers 0.000 claims description 9

- 239000004417 polycarbonate Substances 0.000 claims description 9

- 150000001875 compounds Chemical class 0.000 claims description 8

- 238000004519 manufacturing process Methods 0.000 claims description 8

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 7

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 230000005693 optoelectronics Effects 0.000 claims description 6

- 229920000728 polyester Polymers 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 239000010936 titanium Substances 0.000 claims description 5

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 4

- 229910052719 titanium Inorganic materials 0.000 claims description 4

- 229910052759 nickel Inorganic materials 0.000 claims description 3

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 claims description 2

- 239000011777 magnesium Substances 0.000 claims description 2

- 229910052749 magnesium Inorganic materials 0.000 claims description 2

- 238000010276 construction Methods 0.000 claims 1

- 239000000463 material Substances 0.000 description 288

- 239000010410 layer Substances 0.000 description 65

- 238000000034 method Methods 0.000 description 61

- 229920000642 polymer Polymers 0.000 description 61

- 239000000243 solution Substances 0.000 description 60

- 239000010408 film Substances 0.000 description 53

- 239000011521 glass Substances 0.000 description 41

- 239000002243 precursor Substances 0.000 description 37

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 31

- 229910010271 silicon carbide Inorganic materials 0.000 description 30

- 239000007787 solid Substances 0.000 description 24

- 239000000126 substance Substances 0.000 description 24

- 239000000523 sample Substances 0.000 description 23

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 22

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 21

- 238000001723 curing Methods 0.000 description 20

- 230000003287 optical effect Effects 0.000 description 19

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 18

- 230000007547 defect Effects 0.000 description 18

- 239000010935 stainless steel Substances 0.000 description 18

- 229910001220 stainless steel Inorganic materials 0.000 description 18

- 238000010438 heat treatment Methods 0.000 description 17

- 238000012545 processing Methods 0.000 description 17

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 16

- 230000008569 process Effects 0.000 description 16

- 239000000047 product Substances 0.000 description 16

- 235000013305 food Nutrition 0.000 description 15

- 239000007789 gas Substances 0.000 description 15

- 239000002904 solvent Substances 0.000 description 15

- 229910019142 PO4 Inorganic materials 0.000 description 13

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 13

- 239000000919 ceramic Substances 0.000 description 13

- 238000006243 chemical reaction Methods 0.000 description 13

- 230000000694 effects Effects 0.000 description 13

- 230000006870 function Effects 0.000 description 13

- 150000002739 metals Chemical class 0.000 description 13

- 229910052760 oxygen Inorganic materials 0.000 description 13

- 235000021317 phosphate Nutrition 0.000 description 13

- 239000010452 phosphate Substances 0.000 description 13

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 12

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 12

- 239000000853 adhesive Substances 0.000 description 12

- 230000001070 adhesive effect Effects 0.000 description 12

- 238000000151 deposition Methods 0.000 description 12

- 238000005516 engineering process Methods 0.000 description 12

- 230000003647 oxidation Effects 0.000 description 12

- 238000007254 oxidation reaction Methods 0.000 description 12

- 239000001301 oxygen Substances 0.000 description 12

- 239000002245 particle Substances 0.000 description 12

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 11

- 230000006378 damage Effects 0.000 description 11

- 230000007613 environmental effect Effects 0.000 description 11

- 238000000465 moulding Methods 0.000 description 11

- NBIIXXVUZAFLBC-UHFFFAOYSA-K phosphate Chemical compound [O-]P([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-K 0.000 description 11

- 239000004065 semiconductor Substances 0.000 description 11

- 229910052710 silicon Inorganic materials 0.000 description 11

- 239000010703 silicon Substances 0.000 description 11

- 235000012239 silicon dioxide Nutrition 0.000 description 11

- 238000005507 spraying Methods 0.000 description 11

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 description 10

- 239000000654 additive Substances 0.000 description 10

- 230000015572 biosynthetic process Effects 0.000 description 10

- 230000007797 corrosion Effects 0.000 description 10

- 238000005260 corrosion Methods 0.000 description 10

- 230000002829 reductive effect Effects 0.000 description 10

- 229910052594 sapphire Inorganic materials 0.000 description 10

- 239000010980 sapphire Substances 0.000 description 10

- 239000004698 Polyethylene Substances 0.000 description 9

- 239000008199 coating composition Substances 0.000 description 9

- 210000003298 dental enamel Anatomy 0.000 description 9

- 238000009792 diffusion process Methods 0.000 description 9

- 230000001737 promoting effect Effects 0.000 description 9

- 238000007789 sealing Methods 0.000 description 9

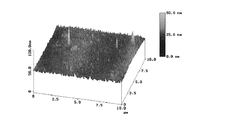

- 230000003746 surface roughness Effects 0.000 description 9

- 239000010409 thin film Substances 0.000 description 9

- 238000004140 cleaning Methods 0.000 description 8

- 230000001965 increasing effect Effects 0.000 description 8

- 238000012986 modification Methods 0.000 description 8

- 230000004048 modification Effects 0.000 description 8

- 230000005855 radiation Effects 0.000 description 8

- 239000011787 zinc oxide Substances 0.000 description 8

- 238000005299 abrasion Methods 0.000 description 7

- 238000010521 absorption reaction Methods 0.000 description 7

- 230000008901 benefit Effects 0.000 description 7

- 229920000620 organic polymer Polymers 0.000 description 7

- 238000011282 treatment Methods 0.000 description 7

- 238000007792 addition Methods 0.000 description 6

- 238000003618 dip coating Methods 0.000 description 6

- 239000007943 implant Substances 0.000 description 6

- 229910052757 nitrogen Inorganic materials 0.000 description 6

- 238000004806 packaging method and process Methods 0.000 description 6

- 230000035699 permeability Effects 0.000 description 6

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 6

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 6

- 229920005989 resin Polymers 0.000 description 6

- 239000011347 resin Substances 0.000 description 6

- 239000011343 solid material Substances 0.000 description 6

- 241000894007 species Species 0.000 description 6

- 239000007921 spray Substances 0.000 description 6

- 238000012360 testing method Methods 0.000 description 6

- 238000009736 wetting Methods 0.000 description 6

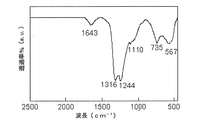

- 238000005033 Fourier transform infrared spectroscopy Methods 0.000 description 5

- 239000004743 Polypropylene Substances 0.000 description 5

- 229910000147 aluminium phosphate Inorganic materials 0.000 description 5

- 230000008021 deposition Effects 0.000 description 5

- 238000009472 formulation Methods 0.000 description 5

- 239000005350 fused silica glass Substances 0.000 description 5

- 239000001257 hydrogen Substances 0.000 description 5

- 229910052739 hydrogen Inorganic materials 0.000 description 5

- 229920000573 polyethylene Polymers 0.000 description 5

- 229920000139 polyethylene terephthalate Polymers 0.000 description 5

- 239000005020 polyethylene terephthalate Substances 0.000 description 5

- 239000011148 porous material Substances 0.000 description 5

- 230000001681 protective effect Effects 0.000 description 5

- 239000010453 quartz Substances 0.000 description 5

- 239000000377 silicon dioxide Substances 0.000 description 5

- 238000004381 surface treatment Methods 0.000 description 5

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 4

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 4

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 4

- 239000004952 Polyamide Substances 0.000 description 4

- 229910004298 SiO 2 Inorganic materials 0.000 description 4

- BLRPTPMANUNPDV-UHFFFAOYSA-N Silane Chemical compound [SiH4] BLRPTPMANUNPDV-UHFFFAOYSA-N 0.000 description 4

- 230000009471 action Effects 0.000 description 4

- 125000004429 atom Chemical group 0.000 description 4

- 238000000089 atomic force micrograph Methods 0.000 description 4

- 229920002678 cellulose Polymers 0.000 description 4

- 239000003795 chemical substances by application Substances 0.000 description 4

- 239000003599 detergent Substances 0.000 description 4

- 238000007598 dipping method Methods 0.000 description 4

- 238000002474 experimental method Methods 0.000 description 4

- 239000010438 granite Substances 0.000 description 4

- 230000002209 hydrophobic effect Effects 0.000 description 4

- 239000011261 inert gas Substances 0.000 description 4

- ZXEKIIBDNHEJCQ-UHFFFAOYSA-N isobutanol Chemical compound CC(C)CO ZXEKIIBDNHEJCQ-UHFFFAOYSA-N 0.000 description 4

- 239000007788 liquid Substances 0.000 description 4

- 229910044991 metal oxide Inorganic materials 0.000 description 4

- 150000004706 metal oxides Chemical class 0.000 description 4

- 239000012044 organic layer Substances 0.000 description 4

- 230000036961 partial effect Effects 0.000 description 4

- 238000005498 polishing Methods 0.000 description 4

- 229920002647 polyamide Polymers 0.000 description 4

- 229920001601 polyetherimide Polymers 0.000 description 4

- 238000002310 reflectometry Methods 0.000 description 4

- 229910000077 silane Inorganic materials 0.000 description 4

- 239000011734 sodium Substances 0.000 description 4

- 229910052708 sodium Inorganic materials 0.000 description 4

- 229920001169 thermoplastic Polymers 0.000 description 4

- 239000004416 thermosoftening plastic Substances 0.000 description 4

- 238000000411 transmission spectrum Methods 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- QTBSBXVTEAMEQO-UHFFFAOYSA-N Acetic acid Chemical compound CC(O)=O QTBSBXVTEAMEQO-UHFFFAOYSA-N 0.000 description 3

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 3

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 239000004697 Polyetherimide Substances 0.000 description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 3

- 229910010413 TiO 2 Inorganic materials 0.000 description 3

- 238000000862 absorption spectrum Methods 0.000 description 3

- 239000000443 aerosol Substances 0.000 description 3

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical class [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 3

- 238000000137 annealing Methods 0.000 description 3

- 230000000844 anti-bacterial effect Effects 0.000 description 3

- 239000013011 aqueous formulation Substances 0.000 description 3

- 238000000149 argon plasma sintering Methods 0.000 description 3

- 230000009286 beneficial effect Effects 0.000 description 3

- 239000011230 binding agent Substances 0.000 description 3

- 230000000975 bioactive effect Effects 0.000 description 3

- 239000010839 body fluid Substances 0.000 description 3

- 210000001124 body fluid Anatomy 0.000 description 3

- 230000001680 brushing effect Effects 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 230000015556 catabolic process Effects 0.000 description 3

- 239000001913 cellulose Substances 0.000 description 3

- 239000011651 chromium Substances 0.000 description 3

- 229910052804 chromium Inorganic materials 0.000 description 3

- KRKNYBCHXYNGOX-UHFFFAOYSA-N citric acid Chemical compound OC(=O)CC(O)(C(O)=O)CC(O)=O KRKNYBCHXYNGOX-UHFFFAOYSA-N 0.000 description 3

- 239000011247 coating layer Substances 0.000 description 3

- 229920001577 copolymer Polymers 0.000 description 3

- 229910052802 copper Inorganic materials 0.000 description 3

- 239000010949 copper Substances 0.000 description 3

- 238000005336 cracking Methods 0.000 description 3

- 239000008367 deionised water Substances 0.000 description 3

- 229910021641 deionized water Inorganic materials 0.000 description 3

- 239000010432 diamond Substances 0.000 description 3

- 229910003460 diamond Inorganic materials 0.000 description 3

- 239000003502 gasoline Substances 0.000 description 3

- 150000002500 ions Chemical class 0.000 description 3

- 230000000670 limiting effect Effects 0.000 description 3

- 239000010687 lubricating oil Substances 0.000 description 3

- 238000002844 melting Methods 0.000 description 3

- 230000008018 melting Effects 0.000 description 3

- 229910001092 metal group alloy Inorganic materials 0.000 description 3

- 244000005700 microbiome Species 0.000 description 3

- 239000002105 nanoparticle Substances 0.000 description 3

- 239000003960 organic solvent Substances 0.000 description 3

- 238000009304 pastoral farming Methods 0.000 description 3

- 150000003014 phosphoric acid esters Chemical class 0.000 description 3

- 229910052573 porcelain Inorganic materials 0.000 description 3

- 239000011253 protective coating Substances 0.000 description 3

- 230000009467 reduction Effects 0.000 description 3

- 229910052709 silver Inorganic materials 0.000 description 3

- 239000004332 silver Substances 0.000 description 3

- 239000002002 slurry Substances 0.000 description 3

- 238000001228 spectrum Methods 0.000 description 3

- 238000003860 storage Methods 0.000 description 3

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 2

- JBRZTFJDHDCESZ-UHFFFAOYSA-N AsGa Chemical compound [As]#[Ga] JBRZTFJDHDCESZ-UHFFFAOYSA-N 0.000 description 2

- FERIUCNNQQJTOY-UHFFFAOYSA-M Butyrate Chemical compound CCCC([O-])=O FERIUCNNQQJTOY-UHFFFAOYSA-M 0.000 description 2

- FERIUCNNQQJTOY-UHFFFAOYSA-N Butyric acid Natural products CCCC(O)=O FERIUCNNQQJTOY-UHFFFAOYSA-N 0.000 description 2

- 229920002284 Cellulose triacetate Polymers 0.000 description 2

- 229910000684 Cobalt-chrome Inorganic materials 0.000 description 2

- 238000001157 Fourier transform infrared spectrum Methods 0.000 description 2

- 229910001218 Gallium arsenide Inorganic materials 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 235000007688 Lycopersicon esculentum Nutrition 0.000 description 2

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 2

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 2

- FAPWRFPIFSIZLT-UHFFFAOYSA-M Sodium chloride Chemical compound [Na+].[Cl-] FAPWRFPIFSIZLT-UHFFFAOYSA-M 0.000 description 2

- 240000003768 Solanum lycopersicum Species 0.000 description 2

- 238000003917 TEM image Methods 0.000 description 2

- 239000004809 Teflon Substances 0.000 description 2

- 229920006362 Teflon® Polymers 0.000 description 2

- NNLVGZFZQQXQNW-ADJNRHBOSA-N [(2r,3r,4s,5r,6s)-4,5-diacetyloxy-3-[(2s,3r,4s,5r,6r)-3,4,5-triacetyloxy-6-(acetyloxymethyl)oxan-2-yl]oxy-6-[(2r,3r,4s,5r,6s)-4,5,6-triacetyloxy-2-(acetyloxymethyl)oxan-3-yl]oxyoxan-2-yl]methyl acetate Chemical compound O([C@@H]1O[C@@H]([C@H]([C@H](OC(C)=O)[C@H]1OC(C)=O)O[C@H]1[C@@H]([C@@H](OC(C)=O)[C@H](OC(C)=O)[C@@H](COC(C)=O)O1)OC(C)=O)COC(=O)C)[C@@H]1[C@@H](COC(C)=O)O[C@@H](OC(C)=O)[C@H](OC(C)=O)[C@H]1OC(C)=O NNLVGZFZQQXQNW-ADJNRHBOSA-N 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 230000000996 additive effect Effects 0.000 description 2

- 239000002318 adhesion promoter Substances 0.000 description 2

- 230000001476 alcoholic effect Effects 0.000 description 2

- 150000001298 alcohols Chemical class 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 230000003667 anti-reflective effect Effects 0.000 description 2

- 239000012298 atmosphere Substances 0.000 description 2

- 230000001580 bacterial effect Effects 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 239000000560 biocompatible material Substances 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 238000000071 blow moulding Methods 0.000 description 2

- 239000001569 carbon dioxide Substances 0.000 description 2

- 229910002092 carbon dioxide Inorganic materials 0.000 description 2

- 229910010293 ceramic material Inorganic materials 0.000 description 2

- 150000004770 chalcogenides Chemical class 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- DBULDCSVZCUQIR-UHFFFAOYSA-N chromium(3+);trisulfide Chemical compound [S-2].[S-2].[S-2].[Cr+3].[Cr+3] DBULDCSVZCUQIR-UHFFFAOYSA-N 0.000 description 2

- 239000010952 cobalt-chrome Substances 0.000 description 2

- 238000009833 condensation Methods 0.000 description 2

- 230000005494 condensation Effects 0.000 description 2

- 238000011109 contamination Methods 0.000 description 2

- 238000010411 cooking Methods 0.000 description 2

- 238000006731 degradation reaction Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 201000010099 disease Diseases 0.000 description 2

- 208000037265 diseases, disorders, signs and symptoms Diseases 0.000 description 2

- 238000002524 electron diffraction data Methods 0.000 description 2

- 230000005496 eutectics Effects 0.000 description 2

- 239000004744 fabric Substances 0.000 description 2

- 239000012847 fine chemical Substances 0.000 description 2

- 230000009969 flowable effect Effects 0.000 description 2

- 239000000499 gel Substances 0.000 description 2

- 239000002241 glass-ceramic Substances 0.000 description 2

- 150000002431 hydrogen Chemical class 0.000 description 2

- 229910052588 hydroxylapatite Inorganic materials 0.000 description 2

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 239000011229 interlayer Substances 0.000 description 2

- 229940035429 isobutyl alcohol Drugs 0.000 description 2

- 239000004922 lacquer Substances 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 238000005461 lubrication Methods 0.000 description 2

- 239000004579 marble Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 229910021645 metal ion Inorganic materials 0.000 description 2

- 229910001463 metal phosphate Inorganic materials 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000006259 organic additive Substances 0.000 description 2

- 230000001590 oxidative effect Effects 0.000 description 2

- XYJRXVWERLGGKC-UHFFFAOYSA-D pentacalcium;hydroxide;triphosphate Chemical compound [OH-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O XYJRXVWERLGGKC-UHFFFAOYSA-D 0.000 description 2

- TZMFJUDUGYTVRY-UHFFFAOYSA-N pentane-2,3-dione Chemical group CCC(=O)C(C)=O TZMFJUDUGYTVRY-UHFFFAOYSA-N 0.000 description 2

- 125000002467 phosphate group Chemical group [H]OP(=O)(O[H])O[*] 0.000 description 2

- 238000001782 photodegradation Methods 0.000 description 2

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 2

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 2

- 229920002492 poly(sulfone) Polymers 0.000 description 2

- 229920000570 polyether Polymers 0.000 description 2

- 239000011112 polyethylene naphthalate Substances 0.000 description 2

- 239000002861 polymer material Substances 0.000 description 2

- 229920000307 polymer substrate Polymers 0.000 description 2

- 238000006116 polymerization reaction Methods 0.000 description 2

- 229920000098 polyolefin Polymers 0.000 description 2

- 229920001155 polypropylene Polymers 0.000 description 2

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 2

- 238000004064 recycling Methods 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 150000003839 salts Chemical class 0.000 description 2

- 238000001878 scanning electron micrograph Methods 0.000 description 2

- 239000000565 sealant Substances 0.000 description 2

- 239000013545 self-assembled monolayer Substances 0.000 description 2

- 229910001415 sodium ion Inorganic materials 0.000 description 2

- 230000035882 stress Effects 0.000 description 2

- 239000004094 surface-active agent Substances 0.000 description 2

- 238000003786 synthesis reaction Methods 0.000 description 2

- DLYUQMMRRRQYAE-UHFFFAOYSA-N tetraphosphorus decaoxide Chemical compound O1P(O2)(=O)OP3(=O)OP1(=O)OP2(=O)O3 DLYUQMMRRRQYAE-UHFFFAOYSA-N 0.000 description 2

- 210000003813 thumb Anatomy 0.000 description 2

- 210000001519 tissue Anatomy 0.000 description 2

- 238000002834 transmittance Methods 0.000 description 2

- 238000002525 ultrasonication Methods 0.000 description 2

- 229920002554 vinyl polymer Polymers 0.000 description 2

- 238000001429 visible spectrum Methods 0.000 description 2

- BNGXYYYYKUGPPF-UHFFFAOYSA-M (3-methylphenyl)methyl-triphenylphosphanium;chloride Chemical compound [Cl-].CC1=CC=CC(C[P+](C=2C=CC=CC=2)(C=2C=CC=CC=2)C=2C=CC=CC=2)=C1 BNGXYYYYKUGPPF-UHFFFAOYSA-M 0.000 description 1

- WRIDQFICGBMAFQ-UHFFFAOYSA-N (E)-8-Octadecenoic acid Natural products CCCCCCCCCC=CCCCCCCC(O)=O WRIDQFICGBMAFQ-UHFFFAOYSA-N 0.000 description 1

- XQUPVDVFXZDTLT-UHFFFAOYSA-N 1-[4-[[4-(2,5-dioxopyrrol-1-yl)phenyl]methyl]phenyl]pyrrole-2,5-dione Chemical compound O=C1C=CC(=O)N1C(C=C1)=CC=C1CC1=CC=C(N2C(C=CC2=O)=O)C=C1 XQUPVDVFXZDTLT-UHFFFAOYSA-N 0.000 description 1

- LQJBNNIYVWPHFW-UHFFFAOYSA-N 20:1omega9c fatty acid Natural products CCCCCCCCCCC=CCCCCCCCC(O)=O LQJBNNIYVWPHFW-UHFFFAOYSA-N 0.000 description 1

- QSBYPNXLFMSGKH-UHFFFAOYSA-N 9-Heptadecensaeure Natural products CCCCCCCC=CCCCCCCCC(O)=O QSBYPNXLFMSGKH-UHFFFAOYSA-N 0.000 description 1

- 229910017119 AlPO Inorganic materials 0.000 description 1

- 229910052582 BN Inorganic materials 0.000 description 1

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 1

- 229910001369 Brass Inorganic materials 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 235000005979 Citrus limon Nutrition 0.000 description 1

- 244000131522 Citrus pyriformis Species 0.000 description 1

- 240000007154 Coffea arabica Species 0.000 description 1

- 241000270281 Coluber constrictor Species 0.000 description 1

- VQTUBCCKSQIDNK-UHFFFAOYSA-N Isobutene Chemical compound CC(C)=C VQTUBCCKSQIDNK-UHFFFAOYSA-N 0.000 description 1

- 229920000106 Liquid crystal polymer Polymers 0.000 description 1

- 239000004977 Liquid-crystal polymers (LCPs) Substances 0.000 description 1

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- 239000000020 Nitrocellulose Substances 0.000 description 1

- 239000005642 Oleic acid Substances 0.000 description 1

- ZQPPMHVWECSIRJ-UHFFFAOYSA-N Oleic acid Natural products CCCCCCCCC=CCCCCCCCC(O)=O ZQPPMHVWECSIRJ-UHFFFAOYSA-N 0.000 description 1

- 208000018262 Peripheral vascular disease Diseases 0.000 description 1

- NBIIXXVUZAFLBC-UHFFFAOYSA-L Phosphate ion(2-) Chemical compound OP([O-])([O-])=O NBIIXXVUZAFLBC-UHFFFAOYSA-L 0.000 description 1

- ABLZXFCXXLZCGV-UHFFFAOYSA-N Phosphorous acid Chemical compound OP(O)=O ABLZXFCXXLZCGV-UHFFFAOYSA-N 0.000 description 1

- 239000004962 Polyamide-imide Substances 0.000 description 1

- 239000005062 Polybutadiene Substances 0.000 description 1

- 229920000331 Polyhydroxybutyrate Polymers 0.000 description 1

- 229920000265 Polyparaphenylene Polymers 0.000 description 1

- 239000004721 Polyphenylene oxide Substances 0.000 description 1

- 229920000388 Polyphosphate Polymers 0.000 description 1

- 239000004793 Polystyrene Substances 0.000 description 1

- 239000004372 Polyvinyl alcohol Substances 0.000 description 1

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- PMZURENOXWZQFD-UHFFFAOYSA-L Sodium Sulfate Chemical compound [Na+].[Na+].[O-]S([O-])(=O)=O PMZURENOXWZQFD-UHFFFAOYSA-L 0.000 description 1

- FKNQFGJONOIPTF-UHFFFAOYSA-N Sodium cation Chemical compound [Na+] FKNQFGJONOIPTF-UHFFFAOYSA-N 0.000 description 1

- 229920010524 Syndiotactic polystyrene Polymers 0.000 description 1

- 244000269722 Thea sinensis Species 0.000 description 1

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 1

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 1

- GEIAQOFPUVMAGM-UHFFFAOYSA-N ZrO Inorganic materials [Zr]=O GEIAQOFPUVMAGM-UHFFFAOYSA-N 0.000 description 1

- LYSCPVVGYLJURL-UHFFFAOYSA-K [O-]P([O-])([O-])=O.OP(O)(O)=O.[Al+3].P Chemical compound [O-]P([O-])([O-])=O.OP(O)(O)=O.[Al+3].P LYSCPVVGYLJURL-UHFFFAOYSA-K 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000003570 air Substances 0.000 description 1

- 239000003513 alkali Substances 0.000 description 1

- 125000000217 alkyl group Chemical group 0.000 description 1

- HSFWRNGVRCDJHI-UHFFFAOYSA-N alpha-acetylene Natural products C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 1

- 150000004645 aluminates Chemical group 0.000 description 1

- 229910000323 aluminium silicate Inorganic materials 0.000 description 1

- 230000000845 anti-microbial effect Effects 0.000 description 1

- 239000004599 antimicrobial Substances 0.000 description 1

- 239000003963 antioxidant agent Substances 0.000 description 1

- 230000003078 antioxidant effect Effects 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 125000003118 aryl group Chemical group 0.000 description 1

- 238000000889 atomisation Methods 0.000 description 1

- 230000010065 bacterial adhesion Effects 0.000 description 1

- 235000013361 beverage Nutrition 0.000 description 1

- 230000008512 biological response Effects 0.000 description 1

- YXTPWUNVHCYOSP-UHFFFAOYSA-N bis($l^{2}-silanylidene)molybdenum Chemical compound [Si]=[Mo]=[Si] YXTPWUNVHCYOSP-UHFFFAOYSA-N 0.000 description 1

- 239000008280 blood Substances 0.000 description 1

- 210000004369 blood Anatomy 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 210000000988 bone and bone Anatomy 0.000 description 1

- BGECDVWSWDRFSP-UHFFFAOYSA-N borazine Chemical compound B1NBNBN1 BGECDVWSWDRFSP-UHFFFAOYSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- 235000014121 butter Nutrition 0.000 description 1

- 125000004063 butyryl group Chemical group O=C([*])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 239000001506 calcium phosphate Substances 0.000 description 1

- 229910000389 calcium phosphate Inorganic materials 0.000 description 1

- 235000011010 calcium phosphates Nutrition 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 239000003518 caustics Substances 0.000 description 1

- 239000012707 chemical precursor Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- ITVPBBDAZKBMRP-UHFFFAOYSA-N chloro-dioxido-oxo-$l^{5}-phosphane;hydron Chemical class OP(O)(Cl)=O ITVPBBDAZKBMRP-UHFFFAOYSA-N 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000000748 compression moulding Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 239000013068 control sample Substances 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000005536 corrosion prevention Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 238000004031 devitrification Methods 0.000 description 1

- 229920005994 diacetyl cellulose Polymers 0.000 description 1

- MNNHAPBLZZVQHP-UHFFFAOYSA-N diammonium hydrogen phosphate Chemical compound [NH4+].[NH4+].OP([O-])([O-])=O MNNHAPBLZZVQHP-UHFFFAOYSA-N 0.000 description 1

- 229910000388 diammonium phosphate Inorganic materials 0.000 description 1

- 235000019838 diammonium phosphate Nutrition 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 229910052571 earthenware Inorganic materials 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 238000010292 electrical insulation Methods 0.000 description 1

- 230000005670 electromagnetic radiation Effects 0.000 description 1

- 238000004049 embossing Methods 0.000 description 1

- 238000005538 encapsulation Methods 0.000 description 1

- 239000011439 engineered stone Substances 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 150000002148 esters Chemical group 0.000 description 1

- IDGUHHHQCWSQLU-UHFFFAOYSA-N ethanol;hydrate Chemical compound O.CCO IDGUHHHQCWSQLU-UHFFFAOYSA-N 0.000 description 1

- UHPJWJRERDJHOJ-UHFFFAOYSA-N ethene;naphthalene-1-carboxylic acid Chemical compound C=C.C1=CC=C2C(C(=O)O)=CC=CC2=C1 UHPJWJRERDJHOJ-UHFFFAOYSA-N 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 238000009501 film coating Methods 0.000 description 1

- 238000007730 finishing process Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 description 1

- XPBBUZJBQWWFFJ-UHFFFAOYSA-N fluorosilane Chemical compound [SiH3]F XPBBUZJBQWWFFJ-UHFFFAOYSA-N 0.000 description 1

- OQZCSNDVOWYALR-UHFFFAOYSA-N flurochloridone Chemical compound FC(F)(F)C1=CC=CC(N2C(C(Cl)C(CCl)C2)=O)=C1 OQZCSNDVOWYALR-UHFFFAOYSA-N 0.000 description 1

- 239000005003 food packaging material Substances 0.000 description 1

- 239000003205 fragrance Substances 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 230000005802 health problem Effects 0.000 description 1

- 238000002173 high-resolution transmission electron microscopy Methods 0.000 description 1

- 239000000017 hydrogel Substances 0.000 description 1

- GBHRVZIGDIUCJB-UHFFFAOYSA-N hydrogenphosphite Chemical compound OP([O-])[O-] GBHRVZIGDIUCJB-UHFFFAOYSA-N 0.000 description 1

- 230000003301 hydrolyzing effect Effects 0.000 description 1

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 208000015181 infectious disease Diseases 0.000 description 1

- 238000002329 infrared spectrum Methods 0.000 description 1

- 238000001746 injection moulding Methods 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 229910052816 inorganic phosphate Inorganic materials 0.000 description 1

- 229920000592 inorganic polymer Polymers 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- GKOZUEZYRPOHIO-UHFFFAOYSA-N iridium atom Chemical compound [Ir] GKOZUEZYRPOHIO-UHFFFAOYSA-N 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- QXJSBBXBKPUZAA-UHFFFAOYSA-N isooleic acid Natural products CCCCCCCC=CCCCCCCCCC(O)=O QXJSBBXBKPUZAA-UHFFFAOYSA-N 0.000 description 1

- 235000015094 jam Nutrition 0.000 description 1

- 235000008960 ketchup Nutrition 0.000 description 1

- 150000002576 ketones Chemical class 0.000 description 1

- 238000002032 lab-on-a-chip Methods 0.000 description 1

- 238000002372 labelling Methods 0.000 description 1

- 238000013035 low temperature curing Methods 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 229920002521 macromolecule Polymers 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000011572 manganese Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 238000002493 microarray Methods 0.000 description 1

- 239000012569 microbial contaminant Substances 0.000 description 1

- 235000013336 milk Nutrition 0.000 description 1

- 239000008267 milk Substances 0.000 description 1

- 210000004080 milk Anatomy 0.000 description 1

- 229910003465 moissanite Inorganic materials 0.000 description 1

- CWQXQMHSOZUFJS-UHFFFAOYSA-N molybdenum disulfide Chemical compound S=[Mo]=S CWQXQMHSOZUFJS-UHFFFAOYSA-N 0.000 description 1

- 229910021344 molybdenum silicide Inorganic materials 0.000 description 1

- GKTNLYAAZKKMTQ-UHFFFAOYSA-N n-[bis(dimethylamino)phosphinimyl]-n-methylmethanamine Chemical compound CN(C)P(=N)(N(C)C)N(C)C GKTNLYAAZKKMTQ-UHFFFAOYSA-N 0.000 description 1

- 150000002823 nitrates Chemical class 0.000 description 1

- 229920001220 nitrocellulos Polymers 0.000 description 1

- 229910000510 noble metal Inorganic materials 0.000 description 1

- 231100000252 nontoxic Toxicity 0.000 description 1

- 230000003000 nontoxic effect Effects 0.000 description 1

- ZQPPMHVWECSIRJ-KTKRTIGZSA-N oleic acid Chemical compound CCCCCCCC\C=C/CCCCCCCC(O)=O ZQPPMHVWECSIRJ-KTKRTIGZSA-N 0.000 description 1

- 235000021313 oleic acid Nutrition 0.000 description 1

- 239000004006 olive oil Substances 0.000 description 1

- 235000008390 olive oil Nutrition 0.000 description 1

- 125000000962 organic group Chemical group 0.000 description 1

- 239000011368 organic material Substances 0.000 description 1

- 125000002524 organometallic group Chemical group 0.000 description 1

- 230000000399 orthopedic effect Effects 0.000 description 1

- 229910052762 osmium Inorganic materials 0.000 description 1

- SYQBFIAQOQZEGI-UHFFFAOYSA-N osmium atom Chemical compound [Os] SYQBFIAQOQZEGI-UHFFFAOYSA-N 0.000 description 1

- 230000003204 osmotic effect Effects 0.000 description 1

- 125000004430 oxygen atom Chemical group O* 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 235000021485 packed food Nutrition 0.000 description 1

- 229910052763 palladium Inorganic materials 0.000 description 1

- 239000012466 permeate Substances 0.000 description 1

- 239000005365 phosphate glass Substances 0.000 description 1

- 150000003003 phosphines Chemical class 0.000 description 1

- UEZVMMHDMIWARA-UHFFFAOYSA-M phosphonate Chemical compound [O-]P(=O)=O UEZVMMHDMIWARA-UHFFFAOYSA-M 0.000 description 1

- 125000004437 phosphorous atom Chemical group 0.000 description 1

- 230000001699 photocatalysis Effects 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000000053 physical method Methods 0.000 description 1

- 238000005240 physical vapour deposition Methods 0.000 description 1

- 238000001020 plasma etching Methods 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229910052697 platinum Inorganic materials 0.000 description 1

- 229920003192 poly(bis maleimide) Polymers 0.000 description 1

- 229920001643 poly(ether ketone) Polymers 0.000 description 1

- 239000005015 poly(hydroxybutyrate) Substances 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920002312 polyamide-imide Polymers 0.000 description 1

- 229920001230 polyarylate Polymers 0.000 description 1

- 229920002480 polybenzimidazole Polymers 0.000 description 1

- 229920002857 polybutadiene Polymers 0.000 description 1

- 229920001707 polybutylene terephthalate Polymers 0.000 description 1

- 229920006289 polycarbonate film Polymers 0.000 description 1

- 229920002721 polycyanoacrylate Polymers 0.000 description 1

- 229920000193 polymethacrylate Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 239000011116 polymethylpentene Substances 0.000 description 1

- 229920000306 polymethylpentene Polymers 0.000 description 1

- 239000001205 polyphosphate Substances 0.000 description 1

- 235000011176 polyphosphates Nutrition 0.000 description 1

- 229920001296 polysiloxane Polymers 0.000 description 1

- 229920002223 polystyrene Polymers 0.000 description 1

- 229920001021 polysulfide Polymers 0.000 description 1

- 239000005077 polysulfide Substances 0.000 description 1

- 150000008117 polysulfides Polymers 0.000 description 1

- 239000004810 polytetrafluoroethylene Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 239000001267 polyvinylpyrrolidone Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000004663 powder metallurgy Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 125000001501 propionyl group Chemical group O=C([*])C([H])([H])C([H])([H])[H] 0.000 description 1

- 230000009993 protective function Effects 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 238000010107 reaction injection moulding Methods 0.000 description 1

- 238000007430 reference method Methods 0.000 description 1

- 238000000985 reflectance spectrum Methods 0.000 description 1

- 238000002407 reforming Methods 0.000 description 1

- 230000008929 regeneration Effects 0.000 description 1

- 238000011069 regeneration method Methods 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 229910052702 rhenium Inorganic materials 0.000 description 1

- WUAPFZMCVAUBPE-UHFFFAOYSA-N rhenium atom Chemical compound [Re] WUAPFZMCVAUBPE-UHFFFAOYSA-N 0.000 description 1

- 238000001175 rotational moulding Methods 0.000 description 1

- 229910052707 ruthenium Inorganic materials 0.000 description 1

- 235000015067 sauces Nutrition 0.000 description 1

- 239000002094 self assembled monolayer Substances 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000011780 sodium chloride Substances 0.000 description 1

- 229910052938 sodium sulfate Inorganic materials 0.000 description 1

- 235000011152 sodium sulphate Nutrition 0.000 description 1

- 238000003980 solgel method Methods 0.000 description 1

- 238000000527 sonication Methods 0.000 description 1

- 238000004528 spin coating Methods 0.000 description 1

- 238000010186 staining Methods 0.000 description 1

- 150000004763 sulfides Chemical class 0.000 description 1

- 229910000601 superalloy Inorganic materials 0.000 description 1

- 230000000153 supplemental effect Effects 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 238000010189 synthetic method Methods 0.000 description 1

- KKEYFWRCBNTPAC-UHFFFAOYSA-L terephthalate(2-) Chemical compound [O-]C(=O)C1=CC=C(C([O-])=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-L 0.000 description 1

- ISIJQEHRDSCQIU-UHFFFAOYSA-N tert-butyl 2,7-diazaspiro[4.5]decane-7-carboxylate Chemical compound C1N(C(=O)OC(C)(C)C)CCCC11CNCC1 ISIJQEHRDSCQIU-UHFFFAOYSA-N 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 238000003856 thermoforming Methods 0.000 description 1

- 239000012815 thermoplastic material Substances 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- 230000001988 toxicity Effects 0.000 description 1

- 231100000419 toxicity Toxicity 0.000 description 1

- 238000001721 transfer moulding Methods 0.000 description 1

- 229920006352 transparent thermoplastic Polymers 0.000 description 1

- QORWJWZARLRLPR-UHFFFAOYSA-H tricalcium bis(phosphate) Chemical compound [Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O QORWJWZARLRLPR-UHFFFAOYSA-H 0.000 description 1

- 238000009281 ultraviolet germicidal irradiation Methods 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

- 239000000037 vitreous enamel Substances 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- 230000004584 weight gain Effects 0.000 description 1

- 235000019786 weight gain Nutrition 0.000 description 1

- 239000000080 wetting agent Substances 0.000 description 1

- RUDFQVOCFDJEEF-UHFFFAOYSA-N yttrium(III) oxide Inorganic materials [O-2].[O-2].[O-2].[Y+3].[Y+3] RUDFQVOCFDJEEF-UHFFFAOYSA-N 0.000 description 1

- 229910052725 zinc Inorganic materials 0.000 description 1

- 239000011701 zinc Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B9/00—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00

- B32B9/04—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00 comprising such particular substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B41/00—After-treatment of mortars, concrete, artificial stone or ceramics; Treatment of natural stone

- C04B41/45—Coating or impregnating, e.g. injection in masonry, partial coating of green or fired ceramics, organic coating compositions for adhering together two concrete elements

- C04B41/50—Coating or impregnating, e.g. injection in masonry, partial coating of green or fired ceramics, organic coating compositions for adhering together two concrete elements with inorganic materials

- C04B41/5076—Coating or impregnating, e.g. injection in masonry, partial coating of green or fired ceramics, organic coating compositions for adhering together two concrete elements with inorganic materials with masses bonded by inorganic cements

- C04B41/5092—Phosphate cements

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/044—Forming conductive coatings; Forming coatings having anti-static properties

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/046—Forming abrasion-resistant coatings; Forming surface-hardening coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/048—Forming gas barrier coatings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/06—Coating with compositions not containing macromolecular substances

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/02—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition

- C23C18/12—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material

- C23C18/1204—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material inorganic material, e.g. non-oxide and non-metallic such as sulfides, nitrides based compounds

- C23C18/1208—Oxides, e.g. ceramics

- C23C18/1216—Metal oxides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C18/00—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating

- C23C18/02—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition

- C23C18/12—Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating; Contact plating by thermal decomposition characterised by the deposition of inorganic material other than metallic material

- C23C18/1229—Composition of the substrate

- C23C18/1245—Inorganic substrates other than metallic

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/02—Coating starting from inorganic powder by application of pressure only

- C23C24/04—Impact or kinetic deposition of particles

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C4/00—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge

- C23C4/04—Coating by spraying the coating material in the molten state, e.g. by flame, plasma or electric discharge characterised by the coating material

- C23C4/06—Metallic material

- C23C4/073—Metallic material containing MCrAl or MCrAlY alloys, where M is nickel, cobalt or iron, with or without non-metal elements

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/20—Filters

- G02B5/208—Filters for use with infrared or ultraviolet radiation, e.g. for separating visible light from infrared and/or ultraviolet radiation

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2369/00—Characterised by the use of polycarbonates; Derivatives of polycarbonates

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Materials Engineering (AREA)

- Ceramic Engineering (AREA)

- Metallurgy (AREA)

- Mechanical Engineering (AREA)

- Inorganic Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Thermal Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Toxicology (AREA)

- Plasma & Fusion (AREA)

- Structural Engineering (AREA)

- Paints Or Removers (AREA)

- Laminated Bodies (AREA)

- Sealing Material Composition (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US61592004P | 2004-10-05 | 2004-10-05 | |

| US61598604P | 2004-10-05 | 2004-10-05 | |

| US60/615,920 | 2004-10-05 | ||

| US60/615,986 | 2004-10-05 | ||

| PCT/US2005/036167 WO2006042116A2 (en) | 2004-10-05 | 2005-10-05 | Aluminum phosphate compositions, coatings and related composites |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008516015A JP2008516015A (ja) | 2008-05-15 |

| JP2008516015A5 JP2008516015A5 (enExample) | 2008-11-27 |

| JP5117857B2 true JP5117857B2 (ja) | 2013-01-16 |

Family

ID=36148945

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007534922A Expired - Fee Related JP5117857B2 (ja) | 2004-10-05 | 2005-10-05 | リン酸アルミニウム組成物、コーティング及び関連複合体 |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP1802455A2 (enExample) |

| JP (1) | JP5117857B2 (enExample) |

| KR (1) | KR20070100238A (enExample) |

| WO (1) | WO2006042116A2 (enExample) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8999488B2 (en) | 2007-01-22 | 2015-04-07 | Canon Kabushiki Kaisha | Optical member and method of manufacturing the same |

| JP4857290B2 (ja) * | 2007-01-22 | 2012-01-18 | キヤノン株式会社 | 光学部材及び光学部材の製造方法 |

| JP5320980B2 (ja) * | 2008-10-27 | 2013-10-23 | 東洋製罐株式会社 | ガスバリア材 |

| ES2602778T3 (es) * | 2009-12-23 | 2017-02-22 | Silicalia S.L. | Composición de recubrimiento |

| JP4961054B2 (ja) | 2010-03-30 | 2012-06-27 | 株式会社クラレ | 複合構造体、それを用いた包装材料および成形品、複合構造体の製造方法、ならびにコーティング液 |

| JP2011247918A (ja) * | 2010-05-24 | 2011-12-08 | Kri Inc | 低屈折率膜及び反射防止膜 |

| IN2014CN03175A (enExample) * | 2011-10-05 | 2015-07-03 | Kuraray Co | |

| CN103958184B (zh) * | 2011-10-05 | 2016-02-24 | 株式会社可乐丽 | 复合结构体、使用其的包装材料和成形品、以及它们的制造方法和涂布液 |

| JP5908918B2 (ja) * | 2011-10-05 | 2016-04-26 | 株式会社クラレ | 複合構造体およびそれを用いた製品、ならびに複合構造体の製造方法 |

| JP2013258366A (ja) * | 2012-06-14 | 2013-12-26 | Kuraray Co Ltd | 太陽電池を保護するための保護シートおよびその製造方法、ならびにそれを用いた太陽電池 |

| US10290756B2 (en) | 2012-06-14 | 2019-05-14 | Kuraray Co., Ltd. | Multilayer structure, device using the same, method for producing the multilayer structure, and method for producing the device |

| KR101280681B1 (ko) * | 2012-09-05 | 2013-07-01 | 주학식 | 이종재질의 고 기능성 박막소재 및 그 제조방법 |

| AU2015233424B2 (en) | 2014-03-18 | 2019-05-16 | Kuraray Co., Ltd. | Multilayer structure and method for producing same, packaging material and product which use same, electronic-device protective sheet, and coating liquid |

| JP6428098B2 (ja) * | 2014-09-26 | 2018-11-28 | 凸版印刷株式会社 | 防湿シート |

| JP6428097B2 (ja) * | 2014-09-26 | 2018-11-28 | 凸版印刷株式会社 | 化粧板用裏面防湿シート |

| JP6508970B2 (ja) * | 2015-02-23 | 2019-05-08 | 株式会社クラレ | 多層構造体およびそれを用いた包装材 |

| CN115141519B (zh) * | 2021-09-08 | 2023-10-31 | 武汉苏泊尔炊具有限公司 | 用于不粘涂层的复合材料及其制备方法和锅具 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IN158643B (enExample) * | 1982-05-12 | 1986-12-27 | Westinghouse Electric Corp | |

| KR20010100204A (ko) * | 2000-03-16 | 2001-11-14 | 이구택 | 절연피막 형성용 피복조성물 및 이를 이용한 무방향성전기강판의 절연피막 형성방법 |

| US6461415B1 (en) * | 2000-08-23 | 2002-10-08 | Applied Thin Films, Inc. | High temperature amorphous composition based on aluminum phosphate |

| TW513855B (en) * | 2001-01-15 | 2002-12-11 | Matsushita Electric Industrial Co Ltd | Saw device and method for manufacturing the device |

| US7678465B2 (en) * | 2002-07-24 | 2010-03-16 | Applied Thin Films, Inc. | Aluminum phosphate compounds, compositions, materials and related metal coatings |

| WO2004016548A2 (en) * | 2002-08-14 | 2004-02-26 | Applied Thin Films, Inc. | Aluminum phosphate compounds, compositions, materials and related composites. |

-

2005

- 2005-10-05 WO PCT/US2005/036167 patent/WO2006042116A2/en not_active Ceased

- 2005-10-05 JP JP2007534922A patent/JP5117857B2/ja not_active Expired - Fee Related

- 2005-10-05 KR KR1020077010192A patent/KR20070100238A/ko not_active Withdrawn

- 2005-10-05 EP EP05812559A patent/EP1802455A2/en not_active Withdrawn

Also Published As

| Publication number | Publication date |

|---|---|

| WO2006042116A3 (en) | 2006-12-21 |

| KR20070100238A (ko) | 2007-10-10 |

| EP1802455A2 (en) | 2007-07-04 |

| WO2006042116A2 (en) | 2006-04-20 |

| JP2008516015A (ja) | 2008-05-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8021758B2 (en) | Aluminum phosphate compounds, coatings, related composites and applications | |

| JP5117857B2 (ja) | リン酸アルミニウム組成物、コーティング及び関連複合体 | |

| US12163052B2 (en) | Anti-fingerprint coatings | |

| US11292288B2 (en) | Superhydrophobic transparent glass (STG) thin film articles | |

| Dey et al. | Cleaning and anti-reflective (AR) hydrophobic coating of glass surface: a review from materials science perspective | |

| EP1997565B1 (de) | Artikel mit plasmapolymerer Beschichtung und Verfahren zu dessen Herstellung | |

| TWI472641B (zh) | 基材之高疏水性表面的處理方法 | |

| EP1835002B1 (en) | Non-stick ceramic coating composition and process | |

| US9169565B2 (en) | Metallic substrates comprising a deformable glass-type coating | |

| US20180171469A1 (en) | Transparent omniphobic thin film articles | |

| US20100173167A1 (en) | Method for producing thin layers and corresponding layer | |

| US20130183487A1 (en) | Glass or glass-ceramic composite material and method for producing same | |

| EP1336592A1 (en) | Anti-fogging coating material, anti-fogging coating, and anti-fogging optical member | |

| CN101193744A (zh) | 磷酸铝组合物、涂层和相关的复合材料 | |

| WO2009125202A1 (en) | Polymer films | |

| KR101275782B1 (ko) | 무기 도료 조성물 및 이를 제조하는 방법 | |

| KR100891891B1 (ko) | 박리층을 갖는 성형용 금형 또는 전주용 모형 및 그들의제조 방법 | |

| Ko et al. | The enhanced abrasion resistance of an anti-fingerprint coating on chrome-plated brass substrate by integrating sputtering and atmospheric pressure plasma jet technologies | |

| DK2379657T3 (en) | Alkali resistant, abrasion resistant and dishwasher safe coating on a substrate | |

| KR100941954B1 (ko) | 비점착성 코팅 조성물,그 코팅방법,그로 코팅된 패널 및가열조리기기 | |

| Gopal et al. | Autochthonous self-assembly of nature's nanomaterials: green, parsimonious and antibacterial carbon nanofilms on glass | |

| Papadopoulos et al. | A versatile approach towards development of easy-to-clean transparent nanocoating systems with pronounced anti-static properties for various substrates. | |

| JP4292992B2 (ja) | 光触媒膜形成用組成物および光触媒膜付き基材 | |

| JP2013180927A (ja) | 撥水性アルミナゾル、撥水性アルミナ膜及びその製造方法 | |

| WO2018054299A1 (en) | A coating liquid, coating composition and the substrate coated with the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20081003 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20081003 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110922 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110927 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120626 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120919 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20121016 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121018 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 Ref document number: 5117857 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151026 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |