JP5096362B2 - 汚染制御のための実装マット - Google Patents

汚染制御のための実装マット Download PDFInfo

- Publication number

- JP5096362B2 JP5096362B2 JP2008545750A JP2008545750A JP5096362B2 JP 5096362 B2 JP5096362 B2 JP 5096362B2 JP 2008545750 A JP2008545750 A JP 2008545750A JP 2008545750 A JP2008545750 A JP 2008545750A JP 5096362 B2 JP5096362 B2 JP 5096362B2

- Authority

- JP

- Japan

- Prior art keywords

- fibers

- pollution control

- mat

- fiber

- mixture

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000835 fiber Substances 0.000 claims abstract description 210

- 239000000203 mixture Substances 0.000 claims abstract description 44

- 239000003365 glass fiber Substances 0.000 claims description 32

- 229910052782 aluminium Inorganic materials 0.000 claims description 16

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 16

- 239000011521 glass Substances 0.000 claims description 14

- HCWCAKKEBCNQJP-UHFFFAOYSA-N magnesium orthosilicate Chemical compound [Mg+2].[Mg+2].[O-][Si]([O-])([O-])[O-] HCWCAKKEBCNQJP-UHFFFAOYSA-N 0.000 claims description 14

- 239000000391 magnesium silicate Substances 0.000 claims description 14

- 229910052919 magnesium silicate Inorganic materials 0.000 claims description 14

- 235000019792 magnesium silicate Nutrition 0.000 claims description 14

- 238000011109 contamination Methods 0.000 claims description 5

- 239000005368 silicate glass Substances 0.000 claims description 5

- SNAAJJQQZSMGQD-UHFFFAOYSA-N aluminum magnesium Chemical group [Mg].[Al] SNAAJJQQZSMGQD-UHFFFAOYSA-N 0.000 claims 1

- 238000000034 method Methods 0.000 description 29

- 239000007789 gas Substances 0.000 description 27

- 229910052751 metal Inorganic materials 0.000 description 18

- 239000002184 metal Substances 0.000 description 18

- 230000003197 catalytic effect Effects 0.000 description 17

- 239000000919 ceramic Substances 0.000 description 13

- 238000012360 testing method Methods 0.000 description 12

- 238000005520 cutting process Methods 0.000 description 11

- 239000003054 catalyst Substances 0.000 description 10

- 238000012669 compression test Methods 0.000 description 10

- 239000000463 material Substances 0.000 description 10

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 9

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 9

- YKTSYUJCYHOUJP-UHFFFAOYSA-N [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] Chemical compound [O--].[Al+3].[Al+3].[O-][Si]([O-])([O-])[O-] YKTSYUJCYHOUJP-UHFFFAOYSA-N 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 7

- 210000004027 cell Anatomy 0.000 description 7

- 239000012784 inorganic fiber Substances 0.000 description 7

- 238000005259 measurement Methods 0.000 description 7

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 6

- 230000006835 compression Effects 0.000 description 6

- 238000007906 compression Methods 0.000 description 6

- 238000009751 slip forming Methods 0.000 description 6

- 239000011230 binding agent Substances 0.000 description 5

- 239000000395 magnesium oxide Substances 0.000 description 5

- 238000012545 processing Methods 0.000 description 5

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 4

- 229910004298 SiO 2 Inorganic materials 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000003068 static effect Effects 0.000 description 4

- 238000010998 test method Methods 0.000 description 4

- 238000003915 air pollution Methods 0.000 description 3

- 239000000292 calcium oxide Substances 0.000 description 3

- ODINCKMPIJJUCX-UHFFFAOYSA-N calcium oxide Inorganic materials [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 3

- 230000035515 penetration Effects 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 2

- 229910052581 Si3N4 Inorganic materials 0.000 description 2

- 229910002091 carbon monoxide Inorganic materials 0.000 description 2

- 229910002106 crystalline ceramic Inorganic materials 0.000 description 2

- 239000011222 crystalline ceramic Substances 0.000 description 2

- JSKIRARMQDRGJZ-UHFFFAOYSA-N dimagnesium dioxido-bis[(1-oxido-3-oxo-2,4,6,8,9-pentaoxa-1,3-disila-5,7-dialuminabicyclo[3.3.1]nonan-7-yl)oxy]silane Chemical compound [Mg++].[Mg++].[O-][Si]([O-])(O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2)O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2 JSKIRARMQDRGJZ-UHFFFAOYSA-N 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 229930195733 hydrocarbon Natural products 0.000 description 2

- 150000002430 hydrocarbons Chemical class 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 230000014759 maintenance of location Effects 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 2

- 238000004806 packaging method and process Methods 0.000 description 2

- 238000012856 packing Methods 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- 239000004071 soot Substances 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 1

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- TZONKZYJDZZXHR-UHFFFAOYSA-L [Cl-].[Cl-].CCCCCCCCCCCCc1cc(C[N+](C)(C)C)c(C)c(C[N+](C)(C)C)c1 Chemical compound [Cl-].[Cl-].CCCCCCCCCCCCc1cc(C[N+](C)(C)C)c(C)c(C[N+](C)(C)C)c1 TZONKZYJDZZXHR-UHFFFAOYSA-L 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- 229910052810 boron oxide Inorganic materials 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- BRPQOXSCLDDYGP-UHFFFAOYSA-N calcium oxide Chemical compound [O-2].[Ca+2] BRPQOXSCLDDYGP-UHFFFAOYSA-N 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 238000009960 carding Methods 0.000 description 1

- 210000002421 cell wall Anatomy 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229910052878 cordierite Inorganic materials 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- JKWMSGQKBLHBQQ-UHFFFAOYSA-N diboron trioxide Chemical compound O=BOB=O JKWMSGQKBLHBQQ-UHFFFAOYSA-N 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000003344 environmental pollutant Substances 0.000 description 1

- 239000011152 fibreglass Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 230000036449 good health Effects 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 239000011777 magnesium Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 1

- 229910044991 metal oxide Inorganic materials 0.000 description 1

- 150000004706 metal oxides Chemical class 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 231100000719 pollutant Toxicity 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- CHWRSCGUEQEHOH-UHFFFAOYSA-N potassium oxide Chemical compound [O-2].[K+].[K+] CHWRSCGUEQEHOH-UHFFFAOYSA-N 0.000 description 1

- 229910001950 potassium oxide Inorganic materials 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000029058 respiratory gaseous exchange Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 150000004760 silicates Chemical class 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- 239000011734 sodium Substances 0.000 description 1

- 229910001948 sodium oxide Inorganic materials 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000005303 weighing Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4382—Stretched reticular film fibres; Composite fibres; Mixed fibres; Ultrafine fibres; Fibres for artificial leather

- D04H1/43835—Mixed fibres, e.g. at least two chemically different fibres or fibre blends

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4382—Stretched reticular film fibres; Composite fibres; Mixed fibres; Ultrafine fibres; Fibres for artificial leather

- D04H1/43838—Ultrafine fibres, e.g. microfibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/44—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling

- D04H1/46—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H13/00—Other non-woven fabrics

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H5/00—Non woven fabrics formed of mixtures of relatively short fibres and yarns or like filamentary material of substantial length

- D04H5/02—Non woven fabrics formed of mixtures of relatively short fibres and yarns or like filamentary material of substantial length strengthened or consolidated by mechanical methods, e.g. needling

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H5/00—Non woven fabrics formed of mixtures of relatively short fibres and yarns or like filamentary material of substantial length

- D04H5/12—Glass fibres

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2839—Arrangements for mounting catalyst support in housing, e.g. with means for compensating thermal expansion or vibration

- F01N3/2853—Arrangements for mounting catalyst support in housing, e.g. with means for compensating thermal expansion or vibration using mats or gaskets between catalyst body and housing

- F01N3/2864—Arrangements for mounting catalyst support in housing, e.g. with means for compensating thermal expansion or vibration using mats or gaskets between catalyst body and housing the mats or gaskets comprising two or more insulation layers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2839—Arrangements for mounting catalyst support in housing, e.g. with means for compensating thermal expansion or vibration

- F01N3/2853—Arrangements for mounting catalyst support in housing, e.g. with means for compensating thermal expansion or vibration using mats or gaskets between catalyst body and housing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1052—Methods of surface bonding and/or assembly therefor with cutting, punching, tearing or severing

- Y10T156/1062—Prior to assembly

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/26—Web or sheet containing structurally defined element or component, the element or component having a specified physical dimension

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Inorganic Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Toxicology (AREA)

- Health & Medical Sciences (AREA)

- Exhaust Gas After Treatment (AREA)

- Nonwoven Fabrics (AREA)

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Mattresses And Other Support Structures For Chairs And Beds (AREA)

- Electrical Discharge Machining, Electrochemical Machining, And Combined Machining (AREA)

- Surgical Instruments (AREA)

- Cleaning Or Drying Semiconductors (AREA)

Description

平均直径約10μm及び長さ36mmのR−ガラス繊維(RC−10P109)(フランス、チャンベリセデクスのセントゴバインヴィトロテックスフランス社(Saint-Gobain Vetrotex France SA, Chambery Cedex, France)から得られる)が使われる。

繊維長の測定

繊維長の測定は、12.7mm未満の長さを有する繊維の量を決めるために、実施例で準備されたマットからの試料について実施される。

静的圧縮試験は、圧縮に対する抵抗性を決めるために実施例で準備されたマットについての周囲条件で実施される。試験装置は、互いに向かって進むことができる2つのアンビルを、それらの間に置かれたマット試料を圧迫するように、備える。使われた特殊な装置は、材料試験システム(Material Test System)モデルRT/30(米国、ミネソタ州エデンプレイリー、MTSアライアンス(商標)(MTS Allience, Eden Prairie MN, USA)から得られる)である。装置は、マット試料の圧縮に対する抵抗性を測定するために5kNのロードセルと、及び圧縮の様々なステージでの試料の厚さを測定する高さ測定装置とが取り付けられる。

平均直径約10μm及び長さ36mmのR−ガラスP109繊維は、フランス、チャンベリセデクス、セントゴバインヴィトロテックスフランス社(Saint-Gobain Vetrotex France SA, Chambery Cedex, France)から得られる。繊維は、実質的に塊りの無いものである。

実施例2は、ピンを装備したテーカインロールを各々有するラロッシュの前開繊機及び精密開繊機が使われたことを除き、実施例1に記述された方法によって準備される。

実施例3は、第一開繊機における間隙が2mm、第二開繊機の間隙が3mmであることを除いて、実施例2に記述された方法によって準備される。

実施例4は、開繊機が、80重量%の直径約10μm、長さ36mm(1.5インチ)に細断された、R−ガラス繊維(R−ガラス分散性チョップトストランド、セントゴバインヴィトロテックスフランス社、シャンベリセデックス、フランス(Saint-Gobain Vetrotex France SA, Chambery Cedex, France)から得られる)及び20重量%の直径約10μm、長さ12mm(0.5インチ)に細断されたR−繊維(同じ供給元から得られる)からなる繊維混合物を供給されたことを除いて実施例2で記述された方法で準備される。

実施例5は、繊維が第1及び第2開繊機を通って処理される前に、第3開繊機を通って積極的に前開繊されたこと、第1開繊機の間隙が3mmであり、第2開繊機の間隙が4mmであったこと、を除いて実施例2に記述された方法によって準備される。第3開繊機は、1.0mmの間隙でセットされ、また開繊機2(ロロシュ社、クールスラヴィレ、フランス(Laroche S.A., Cours la Ville, France)から市販)と同じ製造者によって製造されているが、開繊機2に見られるピンの数の2倍を使う。

比較例1は、第1開繊機の間隙が3mm、第2開繊機の間隙が4mmであることを除いて実施例3に記述された方法によって準備される。

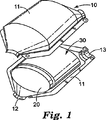

単に本発明の説明及びより良い理解の目的のために、並びに、その上いかなる方法でも本発明を限定する意図無しに図面が提供される。

Claims (7)

- ケーシング内に配置された汚染制御要素を備え、前記ケーシングと前記汚染制御要素との間に実装マットが配置されている汚染制御装置であって、前記実装マットが、無機長繊維及び無機短繊維の混合物を含む複数の繊維を有する層を備え、前記混合物が前記層中の複数の繊維の少なくとも50重量%を構成しており、前記短繊維が13mm以下の長さを有し、前記長繊維が少なくとも20mmの長さを有し、前記短繊維の量が長繊維及び短繊維の前記混合物の総重量を基にして少なくとも3重量%である、汚染制御装置。

- 長繊維及び短繊維の前記混合物がガラス長繊維及びガラス短繊維の混合物である、請求項1に記載の汚染制御装置。

- 前記層の総重量を基にして長繊維及び短繊維の前記混合物の少なくとも90重量%が、ケイ酸マグネシウム・アルミニウムガラス繊維である、請求項1又は2に記載の汚染制御装置。

- 前記短繊維及び長繊維が、長繊維及び短繊維の前記混合物を有する前記層の繊維の少なくとも80重量%を構成する、請求項1〜3のいずれか1項に記載の汚染制御装置。

- 前記マットが、2層以上のチョップドケイ酸マグネシウム・アルミニウムガラス繊維の層を含み、その少なくとも1つの層が前記ガラス長繊維及び前記ガラス短繊維の混合物を含む、請求項1〜4のいずれか1項に記載の汚染制御装置。

- 前記汚染制御要素がディーゼル汚染制御要素である、請求項1〜5のいずれか1項に記載の汚染制御装置。

- 前記実装マットの実装密度が0.2〜0.7g/cm 3 の範囲である、請求項1〜6のいずれか1項に記載の汚染制御装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0525375.2 | 2005-12-14 | ||

| GBGB0525375.2A GB0525375D0 (en) | 2005-12-14 | 2005-12-14 | Mounting mat for a pollution control device |

| PCT/US2006/047428 WO2007070531A2 (en) | 2005-12-14 | 2006-12-13 | Mounting mat for a pollution control device |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009520121A JP2009520121A (ja) | 2009-05-21 |

| JP2009520121A5 JP2009520121A5 (ja) | 2010-01-28 |

| JP5096362B2 true JP5096362B2 (ja) | 2012-12-12 |

Family

ID=35736050

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008545750A Expired - Fee Related JP5096362B2 (ja) | 2005-12-14 | 2006-12-13 | 汚染制御のための実装マット |

Country Status (11)

| Country | Link |

|---|---|

| US (3) | US9765458B2 (ja) |

| EP (1) | EP1960578B1 (ja) |

| JP (1) | JP5096362B2 (ja) |

| KR (1) | KR101367058B1 (ja) |

| CN (1) | CN101331255B (ja) |

| AT (1) | ATE458078T1 (ja) |

| BR (1) | BRPI0619832A2 (ja) |

| CA (1) | CA2634002A1 (ja) |

| DE (1) | DE602006012362D1 (ja) |

| GB (1) | GB0525375D0 (ja) |

| WO (1) | WO2007070531A2 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB0525375D0 (en) * | 2005-12-14 | 2006-01-18 | 3M Innovative Properties Co | Mounting mat for a pollution control device |

| KR101548395B1 (ko) * | 2007-10-09 | 2015-08-28 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 오염 제어 요소를 장착하기 위한 장착 매트의 제조 방법 |

| DE102009014435A1 (de) * | 2009-03-26 | 2010-10-14 | J. Eberspächer GmbH & Co. KG | Abgasbehandlungseinrichtung |

| EP2419613B1 (en) * | 2009-04-17 | 2016-08-17 | Unifrax I LLC | Exhaust gas treatment device |

| US8071040B2 (en) * | 2009-09-23 | 2011-12-06 | Unifax I LLC | Low shear mounting mat for pollution control devices |

| WO2011130048A2 (en) * | 2010-04-13 | 2011-10-20 | 3M Innovative Properties Company | Inorganic fiber webs and methods of making and using |

| ES2655838T3 (es) | 2012-04-04 | 2018-02-21 | Ucomposites A/S | Procedimiento de conversión de un material de tela de fibra de vidrio y productos obtenidos por el procedimiento |

| WO2014068528A1 (en) | 2012-11-02 | 2014-05-08 | Unifrax I Llc | Treatment of tough inorganic fibers and their use in a mounting mat for exhaust gas treatment device |

| JP5598622B1 (ja) * | 2014-03-10 | 2014-10-01 | 日東紡績株式会社 | ガラスチョップドストランドマット、ガラスチョップドストランドマットロール、ガラスチョップドストランドマットの製造方法及び自動車成形天井材 |

| US10632718B2 (en) | 2014-09-30 | 2020-04-28 | The Boeing Company | Filament network for a composite structure |

| WO2022200867A1 (en) | 2021-03-22 | 2022-09-29 | 3M Innovative Properties Company | Edge-sealed porous substrate diagnostic devices and methods of making same |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4011651A (en) * | 1973-03-01 | 1977-03-15 | Imperial Chemical Industries Limited | Fibre masses |

| US3916057A (en) * | 1973-08-31 | 1975-10-28 | Minnesota Mining & Mfg | Intumescent sheet material |

| US4181514A (en) * | 1978-02-14 | 1980-01-01 | Huyck Corporation | Stitch knitted filters for high temperature fluids and method of making them |

| JPS5571684A (en) * | 1978-11-24 | 1980-05-29 | Isolite Babcock Refractories | Ceramic fiber felt |

| JPS6333991Y2 (ja) * | 1979-06-12 | 1988-09-08 | ||

| US4305992A (en) * | 1979-11-28 | 1981-12-15 | Minnesota Mining And Manufacturing Company | Intumescent sheet material |

| US4929429A (en) * | 1988-02-11 | 1990-05-29 | Minnesota Mining And Manufacturing Company | Catalytic converter |

| US5028397A (en) * | 1988-02-11 | 1991-07-02 | Minnesota Mining And Manufacturing Company | Catalytic converter |

| US5151253A (en) * | 1991-04-18 | 1992-09-29 | Minnesota Mining And Manufacturing Company | Catalytic converter having a monolith mounting of which is comprised of partially dehydrated vermiculite flakes |

| US5145811A (en) * | 1991-07-10 | 1992-09-08 | The Carborundum Company | Inorganic ceramic papers |

| US5250269A (en) * | 1992-05-21 | 1993-10-05 | Minnesota Mining And Manufacturing Company | Catalytic converter having a metallic monolith mounted by a heat-insulating mat of refractory ceramic fibers |

| CA2152085C (en) * | 1993-01-07 | 2004-04-27 | John J. Rogers | Flexible nonwoven mat |

| US5290522A (en) * | 1993-01-07 | 1994-03-01 | Minnesota Mining And Manufacturing Company | Catalytic converter mounting mat |

| JPH06299846A (ja) * | 1993-04-16 | 1994-10-25 | Asahi Glass Co Ltd | 可撓性熱膨張性シート |

| WO1994024425A1 (en) * | 1993-04-22 | 1994-10-27 | The Carborundum Company | Mounting mat for fragile structures such as catalytic converters |

| KR100414539B1 (ko) * | 1995-04-13 | 2004-05-07 | 미쓰비시 가가꾸 가부시키가이샤 | 모노리스지지재의제조방법 |

| US5736109A (en) * | 1995-06-30 | 1998-04-07 | Minnesota Mining And Manufacturing Company | Intumescent sheet material and paste with organic binder |

| US6051193A (en) * | 1997-02-06 | 2000-04-18 | 3M Innovative Properties Company | Multilayer intumescent sheet |

| ES2237962T3 (es) * | 1998-12-08 | 2005-08-01 | Unifrax Corporation | Estera de fibras inorganicas no intumiscentes amorfa para dispositivos de tratamiento de gases de escape a baja temperatura. |

| CA2371116C (en) * | 1999-06-08 | 2007-09-25 | 3M Innovative Properties Company | High temperature mat for a pollution control device |

| JP2002047070A (ja) | 2000-07-31 | 2002-02-12 | Ibiden Co Ltd | セラミック構造体 |

| WO2003050397A2 (en) * | 2001-12-07 | 2003-06-19 | Dan T. Moore Company | Insulated exhaust manifold having internal catalyst support body |

| EP1388649B1 (en) | 2002-07-31 | 2008-12-31 | 3M Innovative Properties Company | Mat for mounting a pollution control monolith in a pollution control device for the treatment of exhaust gas of a diesel engine powered machine |

| GB0229380D0 (en) | 2002-12-17 | 2003-01-22 | Saffil Ltd | Mats |

| DE60303560T2 (de) * | 2003-06-10 | 2006-12-14 | 3M Innovative Properties Co., St. Paul | Lagerungsmatte für für katalytischen Umwandler |

| GB0525375D0 (en) * | 2005-12-14 | 2006-01-18 | 3M Innovative Properties Co | Mounting mat for a pollution control device |

| JP6299846B2 (ja) | 2016-11-17 | 2018-03-28 | 株式会社セガゲームス | 情報処理装置 |

-

2005

- 2005-12-14 GB GBGB0525375.2A patent/GB0525375D0/en not_active Ceased

-

2006

- 2006-12-13 KR KR1020087014208A patent/KR101367058B1/ko active IP Right Grant

- 2006-12-13 BR BRPI0619832-5A patent/BRPI0619832A2/pt not_active IP Right Cessation

- 2006-12-13 JP JP2008545750A patent/JP5096362B2/ja not_active Expired - Fee Related

- 2006-12-13 CN CN2006800473475A patent/CN101331255B/zh active Active

- 2006-12-13 CA CA002634002A patent/CA2634002A1/en not_active Abandoned

- 2006-12-13 AT AT06847578T patent/ATE458078T1/de not_active IP Right Cessation

- 2006-12-13 DE DE602006012362T patent/DE602006012362D1/de active Active

- 2006-12-13 EP EP06847578A patent/EP1960578B1/en active Active

- 2006-12-13 US US12/097,167 patent/US9765458B2/en active Active

- 2006-12-13 WO PCT/US2006/047428 patent/WO2007070531A2/en active Application Filing

-

2017

- 2017-08-16 US US15/678,454 patent/US10662560B2/en active Active

-

2020

- 2020-03-05 US US16/809,690 patent/US11293125B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US10662560B2 (en) | 2020-05-26 |

| WO2007070531A2 (en) | 2007-06-21 |

| ATE458078T1 (de) | 2010-03-15 |

| GB0525375D0 (en) | 2006-01-18 |

| US9765458B2 (en) | 2017-09-19 |

| US11293125B2 (en) | 2022-04-05 |

| KR20080076941A (ko) | 2008-08-20 |

| CA2634002A1 (en) | 2007-06-21 |

| US20170342613A1 (en) | 2017-11-30 |

| DE602006012362D1 (de) | 2010-04-01 |

| US20200199796A1 (en) | 2020-06-25 |

| US20090208732A1 (en) | 2009-08-20 |

| EP1960578B1 (en) | 2010-02-17 |

| EP1960578A2 (en) | 2008-08-27 |

| CN101331255B (zh) | 2011-06-22 |

| CN101331255A (zh) | 2008-12-24 |

| KR101367058B1 (ko) | 2014-02-24 |

| BRPI0619832A2 (pt) | 2011-10-18 |

| JP2009520121A (ja) | 2009-05-21 |

| WO2007070531A3 (en) | 2007-08-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5096362B2 (ja) | 汚染制御のための実装マット | |

| EP1388649B1 (en) | Mat for mounting a pollution control monolith in a pollution control device for the treatment of exhaust gas of a diesel engine powered machine | |

| JP4550806B2 (ja) | 成形プリフォーム及び排気系部品の製造方法 | |

| US7704459B2 (en) | Mat for mounting a pollution control element in a pollution control device for the treatment of exhaust gas | |

| EP2350367B1 (en) | Mounting mat and pollution control device with the same | |

| CN102264967B (zh) | 安装垫和使用该安装垫的污染控制设备 | |

| BRPI0619832B1 (pt) | Esteira de montagem para um dispositivo de controle de poluição, dito dispositivo de controle de poluição e método para tratamento do gás de escape de um motor a diesel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091203 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20091203 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120228 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120510 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120821 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120920 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5096362 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150928 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |