JP5000212B2 - フレッチングを最小限に抑えるためのチタン処理方法 - Google Patents

フレッチングを最小限に抑えるためのチタン処理方法 Download PDFInfo

- Publication number

- JP5000212B2 JP5000212B2 JP2006177521A JP2006177521A JP5000212B2 JP 5000212 B2 JP5000212 B2 JP 5000212B2 JP 2006177521 A JP2006177521 A JP 2006177521A JP 2006177521 A JP2006177521 A JP 2006177521A JP 5000212 B2 JP5000212 B2 JP 5000212B2

- Authority

- JP

- Japan

- Prior art keywords

- titanium

- carbon

- dovetail

- compressor disk

- carburized

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C8/00—Solid state diffusion of only non-metal elements into metallic material surfaces; Chemical surface treatment of metallic material by reaction of the surface with a reactive gas, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals

- C23C8/06—Solid state diffusion of only non-metal elements into metallic material surfaces; Chemical surface treatment of metallic material by reaction of the surface with a reactive gas, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals using gases

- C23C8/08—Solid state diffusion of only non-metal elements into metallic material surfaces; Chemical surface treatment of metallic material by reaction of the surface with a reactive gas, leaving reaction products of surface material in the coating, e.g. conversion coatings, passivation of metals using gases only one element being applied

- C23C8/20—Carburising

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Solid-Phase Diffusion Into Metallic Material Surfaces (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Description

101 エーロフォイル

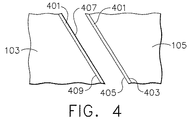

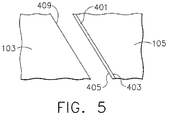

103 ダブテイル

105 ダブテイルスロット

107 圧縮機ディスク

301 領域

401 浸炭区域

403 表面

405 表面

407 表面

409 表面

601 潤滑剤被膜

603 表面

Claims (8)

- チタン含有基板を表面処理するための方法であって、

チタン含有表面を有する基板を準備する段階と、

前記チタン中に炭素を拡散させるのに十分な高さで且つ538℃未満の温度に前記基板を加熱する段階と、

前記基板中に炭素を拡散させて1種以上の炭化物及び格子間炭素を含む表面層を形成するのに十分な時間、炭素含有ガスに前記表面を接触させる段階(ただし、プラズマ浸炭処理を含むものを除く。)と

を含む方法。 - 前記基板が、Ti−6−4、Ti−17、Ti−4−4−2、Ti−6−2−4−2、Ti−8−1−1及びチタン含有超合金からなる群から選択されるチタン含有合金である、請求項1記載の方法。

- 前記基板を、前記炭素含有ガスに接触させる前に清浄にすることをさらに含む、請求項1又は請求項2に記載の方法。

- 前記炭素含有ガスが、メタン、プロパン、エチレンガス、アセチレン、二酸化炭素、一酸化炭素及びこれらの組合せからなる群から選択されるガスを含む、請求項1乃至請求項3のいずれか1項に記載の方法。

- 前記炭素含有ガスが、アルゴン、ヘリウム又は水素を含む群から選択される非反応性ガスをさらに含む、請求項4記載の方法。

- 前記接触段階が1500時間以下で行われる、請求項1乃至請求項5のいずれか1項記載の方法。

- 前記基板が400℃に加熱される、請求項1乃至請求項請求項6のいずれか1項に記載の方法。

- 前記表面層の深さが0.0254cm(0.01インチ)以下である、請求項1乃至請求項7のいずれか1項に記載の方法。

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US69475905P | 2005-06-28 | 2005-06-28 | |

| US60/694,759 | 2005-06-28 | ||

| US11/247,874 US20060289088A1 (en) | 2005-06-28 | 2005-10-11 | Titanium treatment to minimize fretting |

| US11/247,874 | 2005-10-11 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007009329A JP2007009329A (ja) | 2007-01-18 |

| JP2007009329A5 JP2007009329A5 (ja) | 2009-08-13 |

| JP5000212B2 true JP5000212B2 (ja) | 2012-08-15 |

Family

ID=37075834

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006177521A Expired - Fee Related JP5000212B2 (ja) | 2005-06-28 | 2006-06-28 | フレッチングを最小限に抑えるためのチタン処理方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US20060289088A1 (ja) |

| EP (1) | EP1739203A1 (ja) |

| JP (1) | JP5000212B2 (ja) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4024554B2 (ja) * | 2001-02-27 | 2007-12-19 | 松下電器産業株式会社 | 燃料電池発電システム |

| US7506440B2 (en) * | 2005-06-28 | 2009-03-24 | General Electric Company | Titanium treatment to minimize fretting |

| US8608592B2 (en) * | 2007-05-16 | 2013-12-17 | Taylor Made Golf Company, Inc. | Coated golf club head/component |

| DE102010004000A1 (de) * | 2009-02-23 | 2010-09-02 | BLüCHER GMBH | Textilmaterial mit erhöhter mechanischer Stabilität, insbesondere mit erhöhter Stich- und/oder Schußfestigkeit |

| US20130261034A1 (en) * | 2009-07-17 | 2013-10-03 | General Electric Company | Coating for turbomachinery |

| CN102703852B (zh) * | 2012-06-15 | 2014-03-12 | 西北有色金属研究院 | 一种两相钛合金表面复合无氢氧碳共渗的方法 |

| WO2014137438A1 (en) * | 2013-03-07 | 2014-09-12 | United Technologies Corporation | Aluminum fan blades with root wear mitigation |

| FR3005433B1 (fr) * | 2013-05-07 | 2015-06-26 | Eads Europ Aeronautic Defence | Assemblage mecanique a tenue amelioree en fatigue-frottement sous micro-deplacements |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3628921A (en) * | 1969-08-18 | 1971-12-21 | Parker Pen Co | Corrosion resistant binder for tungsten carbide materials and titanium carbide materials |

| DE2929634C3 (de) * | 1979-07-21 | 1982-05-19 | MTU Motoren- und Turbinen-Union München GmbH, 8000 München | Verfahren zur Herstellung von Turboschaufeln aus Titan bzw. Titanbasislegierung mit einer harten Oberfläche |

| US4943485A (en) * | 1981-11-27 | 1990-07-24 | S R I International | Process for applying hard coatings and the like to metals and resulting product |

| US4704336A (en) * | 1984-03-12 | 1987-11-03 | General Electric Company | Solid particle erosion resistant coating utilizing titanium carbide |

| JPS61291959A (ja) * | 1985-06-20 | 1986-12-22 | Mitsubishi Heavy Ind Ltd | チタン合金製エンジンバルブの製造法 |

| US5074970A (en) * | 1989-07-03 | 1991-12-24 | Kostas Routsis | Method for applying an abrasive layer to titanium alloy compressor airfoils |

| US5315822A (en) * | 1991-12-20 | 1994-05-31 | United Technologies Corporation | Gas turbine elements rearing coke inhibiting coatings of titanium compounds |

| JP3149577B2 (ja) * | 1992-10-21 | 2001-03-26 | 大同特殊鋼株式会社 | Ti−Al系金属間化合物の表面処理方法 |

| JPH0790541A (ja) * | 1993-09-13 | 1995-04-04 | Demutetsuku Kk | ガス複合浸透改質方法及び装置 |

| DE59406283D1 (de) * | 1994-08-17 | 1998-07-23 | Asea Brown Boveri | Verfahren zur Herstellung einer Turbinenschaufel aus einer (alpha-Beta)-Titan-Basislegierung |

| US5687900A (en) * | 1995-03-28 | 1997-11-18 | Mcdonnell Douglas Corporation | Structural panel having a predetermined shape and an associated method for superplastically forming and diffusion bonding the structural panel |

| US5910376A (en) * | 1996-12-31 | 1999-06-08 | General Electric Company | Hardfacing of gamma titanium aluminides |

| US5891267A (en) * | 1997-01-16 | 1999-04-06 | General Electric Company | Thermal barrier coating system and method therefor |

| US6190133B1 (en) * | 1998-08-14 | 2001-02-20 | Allison Engine Company | High stiffness airoil and method of manufacture |

| GB9821748D0 (en) * | 1998-10-07 | 1998-12-02 | Rolls Royce Plc | A titanium article having a protective coating and a method of applying a protective coating to a titanium article |

| GB9824611D0 (en) * | 1998-11-11 | 1999-01-06 | Rolls Royce Plc | A beta titanium alloy |

| JP4185633B2 (ja) * | 1999-08-10 | 2008-11-26 | フジオーゼックス株式会社 | チタン合金製エンジンバルブ及びその表面処理方法 |

| US7291229B2 (en) * | 2000-07-12 | 2007-11-06 | Osaka Prefecture | Method of surface treatment of titanium metal |

| JP4603198B2 (ja) * | 2001-06-14 | 2010-12-22 | 株式会社田中 | チタン合金部品の疲労特性改善方法とそれを用いたチタン合金部品 |

| JP2003041359A (ja) * | 2001-07-30 | 2003-02-13 | Tanaka:Kk | チタン合金部品の疲労特性改善方法とそれを用いたチタン合金部品 |

| JP3936892B2 (ja) * | 2002-06-07 | 2007-06-27 | 株式会社エスディーシー | プラズマ浸炭処理方法および同処理装置 |

| DE10305912B4 (de) * | 2003-02-13 | 2014-01-30 | Alstom Technology Ltd. | Hybrid- Schaufel für thermische Turbomaschinen |

| JP2005312619A (ja) * | 2004-04-28 | 2005-11-10 | Bridgestone Sports Co Ltd | ゴルフクラブヘッド |

-

2005

- 2005-10-11 US US11/247,874 patent/US20060289088A1/en not_active Abandoned

-

2006

- 2006-06-26 EP EP06253302A patent/EP1739203A1/en not_active Ceased

- 2006-06-28 JP JP2006177521A patent/JP5000212B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP1739203A1 (en) | 2007-01-03 |

| US20060289088A1 (en) | 2006-12-28 |

| JP2007009329A (ja) | 2007-01-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5000212B2 (ja) | フレッチングを最小限に抑えるためのチタン処理方法 | |

| JP5122768B2 (ja) | フレッチングを最小限に抑えるためのチタン処理 | |

| US6605160B2 (en) | Repair of coatings and surfaces using reactive metals coating processes | |

| JP4322980B2 (ja) | ガス・タービン・エンジンのシール機構 | |

| US20050129511A1 (en) | Turbine blade tip with optimized abrasive | |

| Leyens et al. | Oxide scale formation on an MCrAlY coating in various H2-H2O atmospheres | |

| RU2436866C2 (ru) | Жаростойкий компонент | |

| US6532657B1 (en) | Pre-service oxidation of gas turbine disks and seals | |

| JP2007298035A (ja) | ガスタービンエンジンコンポーネント用コーティング、シールアッセンブリおよびコーティング方法 | |

| KR20220035921A (ko) | 구성품의 선택 영역 상에 크로뮴 확산 코팅을 형성하는 방법 | |

| JP5246745B2 (ja) | 拡散アルミナイド被覆ニッケル基超合金の基材安定化法 | |

| JP5426088B2 (ja) | ニッケル基超合金を安定化させるための浸炭プロセス | |

| US6878041B2 (en) | Method for removing a metallic layer of a layer-system | |

| US20060057416A1 (en) | Article having a surface protected by a silicon-containing diffusion coating | |

| Garg et al. | Low‐Temperature Chemical Vapor Deposition Tungsten Carbide Coatings for Wear/Erosion Resistance | |

| JP2005120478A (ja) | 選択的領域気相アルミナイズ方法 | |

| JP2007009316A (ja) | 耐摩耗性鋼製部品およびその製造方法 | |

| EP2781561B1 (en) | Treated coated article and process of treating a coated article | |

| JP2008275035A (ja) | 蒸気タービン用蒸気弁 | |

| EP3153486A1 (en) | Method for coating removal | |

| EP1522607B1 (en) | Method for fabricating a coated superalloy stabilized against the formation of secondary reaction zone | |

| JP2876206B1 (ja) | 浸炭及びメタルダスティングの抑制・防止方法 | |

| JP4494995B2 (ja) | 金属材表面処理方法 | |

| Kempster et al. | A novel method for refurbishing used hot section gas turbine blades | |

| EP1076108A1 (en) | Process for treating the surface of a component, made from a Ni based superalloy, to be coated |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090625 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090625 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090625 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110915 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110927 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111222 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111228 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120327 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120417 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120516 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150525 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |