JP4936051B2 - モールドモータの製造方法 - Google Patents

モールドモータの製造方法 Download PDFInfo

- Publication number

- JP4936051B2 JP4936051B2 JP2006242543A JP2006242543A JP4936051B2 JP 4936051 B2 JP4936051 B2 JP 4936051B2 JP 2006242543 A JP2006242543 A JP 2006242543A JP 2006242543 A JP2006242543 A JP 2006242543A JP 4936051 B2 JP4936051 B2 JP 4936051B2

- Authority

- JP

- Japan

- Prior art keywords

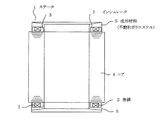

- molding

- molding die

- stator

- mold

- molding material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Manufacture Of Motors, Generators (AREA)

- Iron Core Of Rotating Electric Machines (AREA)

- Insulation, Fastening Of Motor, Generator Windings (AREA)

- Motor Or Generator Frames (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006242543A JP4936051B2 (ja) | 2006-02-14 | 2006-09-07 | モールドモータの製造方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006035966 | 2006-02-14 | ||

| JP2006035966 | 2006-02-14 | ||

| JP2006242543A JP4936051B2 (ja) | 2006-02-14 | 2006-09-07 | モールドモータの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2007252176A JP2007252176A (ja) | 2007-09-27 |

| JP2007252176A5 JP2007252176A5 (enExample) | 2009-08-13 |

| JP4936051B2 true JP4936051B2 (ja) | 2012-05-23 |

Family

ID=38595886

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006242543A Expired - Fee Related JP4936051B2 (ja) | 2006-02-14 | 2006-09-07 | モールドモータの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4936051B2 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5216399B2 (ja) * | 2008-04-18 | 2013-06-19 | アスモ株式会社 | モータ構造 |

| JP5505661B2 (ja) * | 2012-01-31 | 2014-05-28 | 株式会社富士通ゼネラル | 電動機の製造方法 |

| WO2018123576A1 (ja) * | 2016-12-26 | 2018-07-05 | パナソニックIpマネジメント株式会社 | モータ |

| JP6943743B2 (ja) * | 2017-12-05 | 2021-10-06 | トヨタ自動車株式会社 | 電動機用ステータの製造方法 |

| CN109149886B (zh) * | 2018-08-15 | 2019-11-22 | 合肥德通电驱动系统有限公司 | 一种电机外壳的全方位喷漆工艺 |

| CN112242766A (zh) * | 2019-07-18 | 2021-01-19 | 日本电产芝浦(浙江)有限公司 | 壳体、马达以及马达壳体的制造方法 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0615650A (ja) * | 1992-07-01 | 1994-01-25 | Sumitomo Rubber Ind Ltd | エラストマー物品の加硫用金型 |

| JP3113753B2 (ja) * | 1993-01-28 | 2000-12-04 | 東芝キヤリア株式会社 | 密閉形圧縮機 |

| JPH089601A (ja) * | 1994-06-22 | 1996-01-12 | Mitsubishi Electric Corp | モールドモータの固定子の製造装置及び該製造方法並びに弾性体及び圧縮部材を有する金型 |

| JPH1095904A (ja) * | 1996-09-25 | 1998-04-14 | Matsushita Electric Ind Co Ltd | モールド材、およびモールドモータ |

| JP2002115655A (ja) * | 2000-10-12 | 2002-04-19 | Matsushita Electric Ind Co Ltd | 電動機、全密閉型冷凍圧縮機および冷凍サイクル |

| JP2003340829A (ja) * | 2002-05-24 | 2003-12-02 | Maxell Hi Tec Ltd | 成型用金型 |

-

2006

- 2006-09-07 JP JP2006242543A patent/JP4936051B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007252176A (ja) | 2007-09-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6588296B2 (ja) | 金属部品と樹脂の接合方法及び金属部品と樹脂の一体成形品 | |

| DE112011101876T5 (de) | Struktur eines aus faserverstärktem Verbundmaterial hergestellten Bauteils und Herstellungsverfahren für das Bauteil | |

| JP5768811B2 (ja) | 射出成形体の製造方法 | |

| CN101450543A (zh) | 镁合金复合件及其制备方法 | |

| KR101784371B1 (ko) | 3d 프린터를 이용한 금형 코어 제작방법 | |

| JP4936051B2 (ja) | モールドモータの製造方法 | |

| CN104379324A (zh) | 打印封装 | |

| JPH07148743A (ja) | テクスチャー化した物品の製造方法とその装置 | |

| CN101189785B (zh) | 磁悬浮式铁道用地面线圈装置及其制造方法 | |

| JP2009219235A (ja) | 分割固定子、及び分割固定子製造方法 | |

| CN104835995B (zh) | 温控板,温控板的使用和加工温控板的方法 | |

| US11548232B2 (en) | Method of manufacturing isotropic parts utilizing additive manufacturing methods | |

| US20080087793A1 (en) | Mold for producing an article | |

| KR102179841B1 (ko) | 생형 주형 및 그 제조 방법, 및 철계 주물의 제조 방법 | |

| CN109070397B (zh) | 用于制造包括条纹沟槽的空气动力学元件的方法和模具 | |

| US20090026659A1 (en) | Hybrid Mandrels | |

| KR20200039414A (ko) | 알루미늄 파이프가 인서트되는 고압주조 금형 및 그 제조방법 | |

| JP2007252176A5 (enExample) | ||

| CN107266695B (zh) | 在添加形成的聚合物基底上具有耐久金属表面的工艺装置以及形成此种工艺装置的方法 | |

| WO2017180585A1 (en) | Systems and methods for manufacturing hybrid polymer mold tooling | |

| JP4368799B2 (ja) | 複合射出成形方法並びに金型 | |

| US7393203B2 (en) | Mandrel, method of use thereof and production method thereof | |

| WO2015039996A1 (de) | Magnetspule, verfahren und werkzeug zum herstellen einer magnetspule sowie verwendung der magnetspule | |

| CN107377944B (zh) | 镶铸用构件 | |

| KR101374290B1 (ko) | 파이프 성형 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090625 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090625 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111025 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20111026 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111209 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120126 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120208 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150302 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |