JP4732685B2 - 物品をコーティングする装置 - Google Patents

物品をコーティングする装置 Download PDFInfo

- Publication number

- JP4732685B2 JP4732685B2 JP2003519960A JP2003519960A JP4732685B2 JP 4732685 B2 JP4732685 B2 JP 4732685B2 JP 2003519960 A JP2003519960 A JP 2003519960A JP 2003519960 A JP2003519960 A JP 2003519960A JP 4732685 B2 JP4732685 B2 JP 4732685B2

- Authority

- JP

- Japan

- Prior art keywords

- coating

- conductor

- rim

- waveguide

- chambers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000576 coating method Methods 0.000 title claims abstract description 87

- 239000011248 coating agent Substances 0.000 title claims abstract description 85

- 239000004020 conductor Substances 0.000 claims description 85

- 229910052751 metal Inorganic materials 0.000 claims description 9

- 239000002184 metal Substances 0.000 claims description 9

- 239000000758 substrate Substances 0.000 claims description 6

- 230000005670 electromagnetic radiation Effects 0.000 claims description 2

- 238000001514 detection method Methods 0.000 claims 1

- 230000005855 radiation Effects 0.000 claims 1

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 210000002381 plasma Anatomy 0.000 abstract 1

- 230000008859 change Effects 0.000 description 5

- 238000010586 diagram Methods 0.000 description 5

- 238000000034 method Methods 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 239000003708 ampul Substances 0.000 description 3

- 230000006837 decompression Effects 0.000 description 3

- 230000005672 electromagnetic field Effects 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000005265 energy consumption Methods 0.000 description 2

- 239000011521 glass Substances 0.000 description 2

- 239000011810 insulating material Substances 0.000 description 2

- 238000010884 ion-beam technique Methods 0.000 description 2

- 230000008901 benefit Effects 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- UQEAIHBTYFGYIE-UHFFFAOYSA-N hexamethyldisiloxane Chemical compound C[Si](C)(C)O[Si](C)(C)C UQEAIHBTYFGYIE-UHFFFAOYSA-N 0.000 description 1

- 238000001764 infiltration Methods 0.000 description 1

- 230000008595 infiltration Effects 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000012806 monitoring device Methods 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 239000002243 precursor Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- XJDNKRIXUMDJCW-UHFFFAOYSA-J titanium tetrachloride Chemical compound Cl[Ti](Cl)(Cl)Cl XJDNKRIXUMDJCW-UHFFFAOYSA-J 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32192—Microwave generated discharge

- H01J37/32211—Means for coupling power to the plasma

- H01J37/32229—Waveguides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/50—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges

- C23C16/511—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges using microwave discharges

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32009—Arrangements for generation of plasma specially adapted for examination or treatment of objects, e.g. plasma sources

- H01J37/32192—Microwave generated discharge

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Vapour Deposition (AREA)

- Plasma Technology (AREA)

- Road Signs Or Road Markings (AREA)

Description

Claims (20)

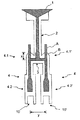

- 物品をコーティングする装置であって、

単一のマイクロ波源、および

2つ以上のコーティング室(10、10’)を有し、

前記コーティング室(10、10’)がすべて単一のマイクロ波源に接続され、

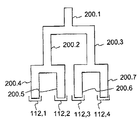

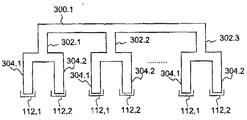

前記個々のコーティング室(10、10’)にプラズマを発生させるためにマイクロ波エネルギーを分割するための、同軸導体構造体又は導波管構造体からなるインピーダンス構造体を有し、

前記同軸導体構造体又は前記導波管構造体が、ウェブ(3)および2つのリム(4、4’)を含むH字形導体構造体を備え、

前記H字形導体構造体が少なくとも2つのコーティング室(10、10’)の上流に接続され、

前記ウェブ(3)が入力導体(2)を介して前記マイクロ波源に接続され、

前記H字形導体構造体の各リム(4、4’)が、対応する前記コーティング室(10、10’)から離隔している部分(4.1、4.1’)および該コーティング室(10、10’)の1つに面する部分(4.2、4.2’)を有し、

前記対応するコーティング室(10、10’)から離隔している前記リム部の電気長が調整可能である装置。 - 前記導波管構造体が、マイクロ波エネルギーを分割する少なくとも1つの部品からなる請求項1に記載の装置。

- 前記導波管構造体が矩形導波管を含む請求項1又は2に記載の装置。

- 前記導波管構造体が円形導波管を含む請求項1又は2に記載の装置。

- 前記同軸導体構造体又は前記導波管構造体が、前記コーティング室それぞれにマイクロ波エネルギーを導入する誘電体窓を備える、請求項1ないし4のいずれか1項に記載の装置。

- 前記同軸導体構造体が、マイクロ波エネルギーを前記個々のコーティング室(10、10’)に導入するために、金属内部導体(A)、および外部導体として金属表面により境界を画された誘電体(B)を備える、請求項1に記載の装置。

- 前記リム(4、4’)のコーティング室から離隔している部分(4.1、4.1’)の電気長を変えるスリーブ(5、5’)又は前記リム(4、4’)のコーティング室の1つに面する部分(4.2、4.2’)の電気長を変えるねじ(6、6’)が設けられた請求項1又は6に記載の装置。

- 前記入力導体(2)が前記マイクロ波源と前記H字形導体構造体の分岐点との間に接続部を形成する、請求項1に記載の装置。

- 前記入力導体(2)の電気長も調整可能である請求項8に記載の装置。

- 前記スリーブ(5、5’)が、前記金属内部導体(A)を囲む変位可能スリーブから形成される請求項7に記載の装置。

- 前記ねじ(6、6’)が、前記金属内部導体(A)にねじ込むことができるねじから形成される請求項7に記載の装置。

- 前記ウェブ(3)が追加のリム(7)に接続される請求項1に記載の装置。

- 前記追加のリム(7)が前記2つのリム(4、4’)間で前記ウェブ(3)の中央に接続される請求項12に記載の装置。

- 前記追加のリム(7)の電気長も調整可能である請求項12又は13に記載の装置。

- 前記コーティング室(10、10’)が互いに離れて配置され、互いに遮蔽されている請求項1ないし14のいずれか1項に記載の装置。

- コーティングされる物品はそれぞれ前記個々のコーティング室(10、10’)に収容されるか、あるいは前記コーティング室(10、10’)はそれぞれ物品により形成される請求項1ないし15のいずれか1項に記載の装置。

- 前記個々のコーティング室が、別個の真空供給デバイスおよびガス供給デバイスを割り当てられる請求項1ないし16のいずれか1項に記載の装置。

- 前記コーティング室はそれぞれ、前記プラズマまたはコーティングされるべき基材から発生する熱放射および/または電磁放射を記録する別個の検知ユニットを割り当てられる請求項1ないし17のいずれか1項に記載の装置。

- パルス状マイクロ波源が設けられた請求項1ないし18のいずれか1項に記載の装置。

- 前記同軸導体構造体又は前記導波管構造体が剛性導体からなる請求項1ないし19のいずれか1項に記載の装置。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10138693.1 | 2001-08-07 | ||

| DE10138693A DE10138693A1 (de) | 2001-08-07 | 2001-08-07 | Vorrichtung zum Beschichten von Gegenständen |

| PCT/EP2002/008852 WO2003015122A1 (de) | 2001-08-07 | 2002-08-07 | Vorrichtung zum beschichten von gegenständen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004538367A JP2004538367A (ja) | 2004-12-24 |

| JP2004538367A5 JP2004538367A5 (ja) | 2005-12-22 |

| JP4732685B2 true JP4732685B2 (ja) | 2011-07-27 |

Family

ID=7694632

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003519960A Expired - Lifetime JP4732685B2 (ja) | 2001-08-07 | 2002-08-07 | 物品をコーティングする装置 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7434537B2 (ja) |

| EP (1) | EP1415321B1 (ja) |

| JP (1) | JP4732685B2 (ja) |

| CN (1) | CN1328751C (ja) |

| AT (1) | ATE295612T1 (ja) |

| DE (2) | DE10138693A1 (ja) |

| WO (1) | WO2003015122A1 (ja) |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10358329B4 (de) * | 2003-12-12 | 2007-08-02 | R3T Gmbh Rapid Reactive Radicals Technology | Vorrichtung zur Erzeugung angeregter und/oder ionisierter Teilchen in einem Plasma und Verfahren zur Erzeugung ionisierter Teilchen |

| US7791280B2 (en) * | 2005-10-27 | 2010-09-07 | Luxim Corporation | Plasma lamp using a shaped waveguide body |

| US7825669B2 (en) * | 2007-03-29 | 2010-11-02 | Hamilton Sundstrand Corporation | Microwave position sensing for a turbo machine |

| KR101088876B1 (ko) | 2007-06-11 | 2011-12-07 | 고쿠리츠다이가쿠호진 도호쿠다이가쿠 | 플라즈마 처리 장치, 급전 장치 및 플라즈마 처리 장치의 사용 방법 |

| US20110114600A1 (en) * | 2008-06-11 | 2011-05-19 | Tokyo Electron Limited | Plasma processing apparatus and plasma processing method |

| JP5324137B2 (ja) * | 2008-06-11 | 2013-10-23 | 東京エレクトロン株式会社 | プラズマ処理装置及びプラズマ処理方法 |

| JP5324138B2 (ja) * | 2008-06-11 | 2013-10-23 | 東京エレクトロン株式会社 | プラズマ処理装置及びプラズマ処理方法 |

| WO2010067590A1 (ja) * | 2008-12-11 | 2010-06-17 | 東洋製罐株式会社 | マイクロ波プラズマ処理装置 |

| JP5222744B2 (ja) * | 2009-01-21 | 2013-06-26 | 国立大学法人東北大学 | プラズマ処理装置 |

| JP2012089334A (ja) | 2010-10-19 | 2012-05-10 | Tokyo Electron Ltd | マイクロ波プラズマ源およびプラズマ処理装置 |

| GB201021865D0 (en) | 2010-12-23 | 2011-02-02 | Element Six Ltd | A microwave plasma reactor for manufacturing synthetic diamond material |

| GB201021913D0 (en) | 2010-12-23 | 2011-02-02 | Element Six Ltd | Microwave plasma reactors and substrates for synthetic diamond manufacture |

| GB201021860D0 (en) | 2010-12-23 | 2011-02-02 | Element Six Ltd | A microwave plasma reactor for diamond synthesis |

| GB2497880B (en) | 2010-12-23 | 2015-05-27 | Element Six Ltd | Controlling doping of synthetic diamond material |

| GB201021870D0 (en) | 2010-12-23 | 2011-02-02 | Element Six Ltd | A microwave plasma reactor for manufacturing synthetic diamond material |

| GB201021855D0 (en) * | 2010-12-23 | 2011-02-02 | Element Six Ltd | Microwave power delivery system for plasma reactors |

| GB201021853D0 (en) | 2010-12-23 | 2011-02-02 | Element Six Ltd | A microwave plasma reactor for manufacturing synthetic diamond material |

| CN105244251B (zh) * | 2015-11-03 | 2017-11-17 | 长飞光纤光缆股份有限公司 | 一种大功率等离子体微波谐振腔 |

| CN105502918B (zh) * | 2015-12-25 | 2019-01-25 | 长飞光纤光缆股份有限公司 | 一种双腔型等离子体微波谐振腔 |

| CN106229595A (zh) * | 2016-08-30 | 2016-12-14 | 广东通宇通讯股份有限公司 | 功分器及其组件 |

| BR112019025450A2 (pt) * | 2017-05-30 | 2020-06-16 | Ellume Limited | Agregados de nanopartículas |

| EP4063334A1 (en) | 2021-03-25 | 2022-09-28 | Schott Ag | Coated glass element |

| CN115124259A (zh) | 2021-03-25 | 2022-09-30 | 肖特股份有限公司 | 涂层玻璃元件 |

| WO2022200623A1 (en) | 2021-03-25 | 2022-09-29 | Schott Ag | Pharmaceutical container |

| EP4067319A3 (en) | 2021-03-25 | 2022-10-26 | Schott Ag | Coated glass element |

| JP2022151858A (ja) | 2021-03-25 | 2022-10-07 | ショット シュヴァイツ アー・ゲー | 品質評価のための試験方法および被覆された容器 |

| KR102765720B1 (ko) * | 2021-10-20 | 2025-02-14 | 세메스 주식회사 | 기판 처리 장치 및 기판 처리 장치의 운용 방법 |

| KR102752563B1 (ko) * | 2022-06-14 | 2025-01-10 | 세메스 주식회사 | 마이크로웨이브 공급 장치, 이를 포함하는 시스템 및 반도체 소자 제조 방법 |

| EP4339171A1 (en) | 2022-09-13 | 2024-03-20 | Schott Ag | Treatment of a glass container |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5888086A (ja) | 1981-11-20 | 1983-05-26 | Sanki Eng Co Ltd | 廃棄物加熱処理装置 |

| JPS61220486A (ja) | 1985-03-27 | 1986-09-30 | Mitsubishi Electric Corp | レ−ザ発振装置 |

| JPH0616496B2 (ja) * | 1986-09-24 | 1994-03-02 | 日本電気株式会社 | 励起種cvd装置 |

| DE3711184A1 (de) * | 1987-04-02 | 1988-10-20 | Leybold Ag | Vorrichtung zur einbringung von mikrowellenenergie mit einem offenen mikrowellenleiter |

| EP0288065B1 (en) * | 1987-04-22 | 1993-10-06 | Idemitsu Petrochemical Co. Ltd. | Method for synthesis of diamond |

| DE68926923T2 (de) * | 1988-03-16 | 1996-12-19 | Hitachi Ltd | Mikrowellenionenquelle |

| JPH02148715A (ja) * | 1988-11-29 | 1990-06-07 | Canon Inc | 半導体デバイスの連続形成装置 |

| US5202095A (en) * | 1988-12-27 | 1993-04-13 | Matsushita Electric Industrial Co., Ltd. | Microwave plasma processor |

| US5236511A (en) * | 1990-03-16 | 1993-08-17 | Schott Glaswerke | Plasma CVD process for coating a dome-shaped substrate |

| US5103182A (en) * | 1990-04-02 | 1992-04-07 | Texas Instruments Incorporated | Electromagnetic wave measurement of conductive layers of a semiconductor wafer during processing in a fabrication chamber |

| DE4120176C1 (ja) * | 1991-06-19 | 1992-02-27 | Schott Glaswerke, 6500 Mainz, De | |

| DE4136297A1 (de) * | 1991-11-04 | 1993-05-06 | Plasma Electronic Gmbh, 7024 Filderstadt, De | Vorrichtung zur lokalen erzeugung eines plasmas in einer behandlungskammer mittels mikrowellenanregung |

| US5311103A (en) * | 1992-06-01 | 1994-05-10 | Board Of Trustees Operating Michigan State University | Apparatus for the coating of material on a substrate using a microwave or UHF plasma |

| DE69318480T2 (de) * | 1992-06-23 | 1998-09-17 | Nippon Telegraph & Telephone | Plasmabearbeitungsgerät |

| US5387288A (en) * | 1993-05-14 | 1995-02-07 | Modular Process Technology Corp. | Apparatus for depositing diamond and refractory materials comprising rotating antenna |

| DE19628949B4 (de) * | 1995-02-02 | 2008-12-04 | Muegge Electronic Gmbh | Vorrichtung zur Erzeugung von Plasma |

| DE19503205C1 (de) | 1995-02-02 | 1996-07-11 | Muegge Electronic Gmbh | Vorrichtung zur Erzeugung von Plasma |

| DE19608949A1 (de) * | 1996-03-08 | 1997-09-11 | Ralf Dr Spitzl | Vorrichtung zur Erzeugung von leistungsfähigen Mikrowellenplasmen |

| US5874706A (en) * | 1996-09-26 | 1999-02-23 | Tokyo Electron Limited | Microwave plasma processing apparatus using a hybrid microwave having two different modes of oscillation or branched microwaves forming a concentric electric field |

| US6186090B1 (en) * | 1999-03-04 | 2001-02-13 | Energy Conversion Devices, Inc. | Apparatus for the simultaneous deposition by physical vapor deposition and chemical vapor deposition and method therefor |

| DE19916478A1 (de) * | 1999-04-13 | 2000-10-19 | Ruediger Haaga Gmbh | Verfahren zum Evakuieren eines Plasmasterilisations-Reaktors |

| JP3792089B2 (ja) | 2000-01-14 | 2006-06-28 | シャープ株式会社 | プラズマプロセス装置 |

-

2001

- 2001-08-07 DE DE10138693A patent/DE10138693A1/de not_active Withdrawn

-

2002

- 2002-08-07 US US10/486,140 patent/US7434537B2/en not_active Expired - Lifetime

- 2002-08-07 DE DE50203097T patent/DE50203097D1/de not_active Expired - Lifetime

- 2002-08-07 CN CNB028154231A patent/CN1328751C/zh not_active Expired - Lifetime

- 2002-08-07 JP JP2003519960A patent/JP4732685B2/ja not_active Expired - Lifetime

- 2002-08-07 AT AT02767344T patent/ATE295612T1/de not_active IP Right Cessation

- 2002-08-07 WO PCT/EP2002/008852 patent/WO2003015122A1/de not_active Ceased

- 2002-08-07 EP EP02767344A patent/EP1415321B1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1415321B1 (de) | 2005-05-11 |

| ATE295612T1 (de) | 2005-05-15 |

| DE10138693A1 (de) | 2003-07-10 |

| US7434537B2 (en) | 2008-10-14 |

| JP2004538367A (ja) | 2004-12-24 |

| DE50203097D1 (de) | 2005-06-16 |

| WO2003015122A1 (de) | 2003-02-20 |

| CN1539155A (zh) | 2004-10-20 |

| EP1415321A1 (de) | 2004-05-06 |

| US20050005853A1 (en) | 2005-01-13 |

| CN1328751C (zh) | 2007-07-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4732685B2 (ja) | 物品をコーティングする装置 | |

| US11721532B2 (en) | Modular microwave source with local lorentz force | |

| TWI719290B (zh) | 使用模組化微波源的電漿處理工具 | |

| JP4116454B2 (ja) | 誘電性物体のプラズマ処理のための装置 | |

| US20200381217A1 (en) | Modular microwave plasma source | |

| US6396214B1 (en) | Device for producing a free cold plasma jet | |

| KR102029579B1 (ko) | 플라즈마 처리 장치 및 제어 방법 | |

| CN108735568B (zh) | 等离子体处理装置和控制方法 | |

| CN110391125B (zh) | 具有集成气体分配的模块化高频源 | |

| JP2004538367A5 (ja) | ||

| JP2002275635A (ja) | マイクロ波プラズマ処理方法及び装置 | |

| US10720311B2 (en) | Phased array modular high-frequency source | |

| JP2007231386A (ja) | プラズマを使用した容器処理装置 | |

| KR20250050833A (ko) | 모듈형 고주파 공급원 | |

| JP6501493B2 (ja) | プラズマ処理装置 | |

| US20070095281A1 (en) | System and method for power function ramping of microwave liner discharge sources | |

| US20090152243A1 (en) | Plasma processing apparatus and method thereof | |

| US10290471B2 (en) | Device for generating plasma by means of microwaves | |

| WO2016104205A1 (ja) | プラズマ処理装置及びプラズマ処理方法 | |

| WO2022044864A1 (ja) | プラズマ処理装置、プラズマ処理方法、および誘電体窓 | |

| US20060254521A1 (en) | Electron cyclotron resonance (ecr) plasma source having a linear plasma discharge opening | |

| CN120188256A (zh) | 具有多个发射器和吸收器的微波等离子体反应器以及使用这种微波等离子体反应器对工件进行等离子体加工的方法 | |

| JP2006089846A (ja) | マイクロ波処理装置、マイクロ波供給・処理システム及びマイクロ波処理方法 | |

| JP2007204773A (ja) | プラズマを使用した容器処理装置 | |

| JP2008106332A (ja) | プラズマcvdによる容器処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041019 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041019 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050831 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20051018 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20051205 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20071121 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20071205 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080305 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080312 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080404 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080411 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20080502 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20080513 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080605 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20081008 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090205 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20090226 |

|

| A912 | Re-examination (zenchi) completed and case transferred to appeal board |

Free format text: JAPANESE INTERMEDIATE CODE: A912 Effective date: 20090417 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110302 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20110421 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140428 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4732685 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |