JP4494792B2 - 支持体上へのコロナによる化学蒸着 - Google Patents

支持体上へのコロナによる化学蒸着 Download PDFInfo

- Publication number

- JP4494792B2 JP4494792B2 JP2003566273A JP2003566273A JP4494792B2 JP 4494792 B2 JP4494792 B2 JP 4494792B2 JP 2003566273 A JP2003566273 A JP 2003566273A JP 2003566273 A JP2003566273 A JP 2003566273A JP 4494792 B2 JP4494792 B2 JP 4494792B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- support

- electrode

- coating

- working gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45563—Gas nozzles

- C23C16/45565—Shower nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/62—Plasma-deposition of organic layers

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/40—Oxides

- C23C16/401—Oxides containing silicon

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/50—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges

- C23C16/503—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges using DC or AC discharges

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/50—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges

- C23C16/505—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges using radio frequency discharges

- C23C16/509—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating using electric discharges using radio frequency discharges using internal electrodes

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/54—Apparatus specially adapted for continuous coating

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Inorganic Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Organic Insulating Materials (AREA)

- Manufacturing Of Printed Wiring (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

- Surface Treatment Of Optical Elements (AREA)

- Polymerisation Methods In General (AREA)

- Other Resins Obtained By Reactions Not Involving Carbon-To-Carbon Unsaturated Bonds (AREA)

Description

1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;そして

2)バランスガス及び作動ガス並びに場合によっては作動ガス用のキャリアガスの混合物を、支持体上に光学的に透明な堆積を形成するのに充分な流量及び割合で電極及びコロナ放電中に流す

工程を含んでなる、支持体上への光学的に透明な堆積を調製する方法

を提供することによって、従来技術の不完全な点に取り組む。

1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;

2)支持体上にプラズマ重合堆積を形成するように、バランスガス及び作動ガス並びに、場合によっては、作動ガス用のキャリアガスの混合物を、電極及びコロナ放電中に流す工程を含んでなり、

総ガス混合物が、少なくとも1つの出口を通る速度が0.1m/s以上1000m/s以下であるような流量を有し且つ総ガス混合物に基づく作動ガスの濃度が5ppm以上500ppm以下である支持体上へ堆積を調製する方法である。

1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)移動支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;そして

2)支持体上にプラズマ重合被覆を形成するように、バランスガス及び作動ガス並びに、場合によっては、作動ガス用のキャリアガスの混合物を、電極及びコロナ放電中に流す工程を含んでなり、

バランスガスが少なくとも1つの出口を通る速度が10m/s以上200m/s以下であるような流量を有し、総ガス混合物に基づく作動ガスの濃度が5ppm以上200ppm以下であり、且つ光学的に透明な被覆が少なくとも98%の光学的透明度及び2%以下の曇り価を有する、移動する支持体上への光学的に透明な被覆を連続的に調製する方法である。

実施例1:支持体上への光学的に透明な被覆の調製方法

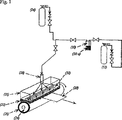

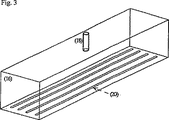

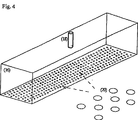

実質的に図1に示したような設備を用いて、被覆を調製する。対電極及び電源装置(30kHzに固定)は、Corotec Industries,Farmington,CTから入手した。1個の入口及び図3に示したようなスリットの形状の4つの出口を有する長さ5.5”×幅3”×高さ2”の電極(14cm×7.5cm×5cm)を設計する。スリットはそれぞれ幅が1mmであり、電極の長さ全体に伸び;各スリットの間には1.5cmの間隔があいている。いずれの実施例においても同一の装置を用いる。

実施例2:耐溶剤性を有する支持体の調製方法

支持体、作動ガス、作動ガス用キャリアガス、バランスガス及びバランスガス流量はまた、同じである。TMDSOの調整流量は50sccm(45ppm)である。出力密度は15W/cm2である。10秒間の堆積時間後に、得られた被覆は組成がSiOxCyHzで、厚さが150nmである。未被覆支持体及び被覆支持体を、ASTM 543に従って、10分間のアセトン浸漬に供する。未被覆支持体は乳白色であり且つひびが入っているのに対して、被覆支持体はほとんど影響されないことがわかる。

実施例3:表面エネルギーの増大した支持体の調製方法

支持体は20g/m2のポロプロピレン不織布である。作動ガス、作動ガス用キャリア、バランスガス及びバランスガス流量は、前記実施例と同じである。TMDSOの調整流量は35sccm(30ppm)であり、出力密度は5W/cm2であり、堆積時間は7秒間である。表面エネルギーは未処理支持体に関しては35ダイン/cm、処理支持体に関しては52ダイン/cmであることがわかる。

実施例4:気体遮断性被覆の調製

2種の異なる作動ガスを用いて、Lexanポリカーボネートフィルム上に2つの層を堆積させる。作動ガス用のキャリアガス、バランスガス及びバランスガス流量は、前記実施例と同じである。第1層は、流量65sccm(60ppm)に保持された作動ガスとしてのTMDSOを用いて形成されたSiOxCyHzの組成を有する接着層である。出力密度は10W/cm2に設定し、堆積時間は10秒である。第2層は、流量15sccm(13ppm)に保持された作動ガスとしてのテトラエチルオルトシリケート(TEOS)を用いて形成されたSiOxの組成を有する遮断層である。出力密度は15W/cm2に設定し、堆積時間は25秒間である。被覆支持体及び未被覆支持体の酸素の気体透過度(O2GTR)をASTM D 3985に従って測定する。O2GTRは、未被覆支持体に関しては32mL/100in2・日・atmO2、被覆支持体に関しては0.05mL/100in2・日・atmO2である。

以下に、本発明の態様を列挙する。

態様1.1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;そして

2)バランスガス及び作動ガス並びに、場合によっては、作動ガス用のキャリアガスの混合物を、支持体上に光学的に透明な堆積を形成するのに充分な流量及び割合で電極及びコロナ放電中に流す工程

を含んでなる支持体上へ光学的に透明な堆積を調製する方法。

態様2.前記方法が連続法で且つ対電極が移動する支持体を支持する態様1に記載の方法。

態様3.前記対電極が回転ドラムであり、且つドラム若しくは電極又はドラムと電極の両方に誘電スリーブを装着する態様1又は2のいずれか1項に記載の方法。

態様4.前記作動ガスが有機シロキサンであり且つ前記バランスガスが空気、酸素、窒素、ヘリウム、アルゴン又はこれらの組合せである態様1〜3のいずれか1項に記載の方法。

態様5.前記電極の少なくとも1つの出口が複数の孔又はスリットであり;総ガスの流量が孔又はスリットを通過するバランスガスの速度が0.1m/s以上で且つ1000m/s以下となるような流量であり;コロナ放電に入る作動ガスの濃度が、総ガス混合物に基づき、1ppm以上で且つ2000ppm以下であり;且つ作動ガスがテトラメチルジシロキサン、ヘキサメチルジシロキサン、オクタメチルトリシロキサン、テトラエチルオルトシリケート又はこれらの組合せである態様1〜4のいずれか1項に記載の方法。

態様6.前記堆積が少なくとも98%の光学的透明度及び2%以下の曇り価を有する被覆である態様5に記載の方法。

態様7.前記支持体が、プラズマ重合堆積後に、未処理支持体に比較して、増大した表面エネルギーを有する態様5に記載の方法。

態様8.前記堆積層が支持体を耐薬品性にする被覆を構成する態様5に記載の方法。

態様9.前記堆積層が、未処理支持体に比較して、増大した気体遮断性を有する被覆を構成する態様5に記載の方法。

態様10.1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)移動支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;

2)支持体上にプラズマ重合被覆を形成するように、バランスガス及び作動ガス並びに、場合によっては、作動ガス用のキャリアガスの混合物を、電極及びコロナ放電中に流す工程を含んでなり、

前記総ガスが少なくとも1つの出口を通る速度が10m/s以上200m/s以下であるような流量を有し、総ガス混合物に基づく作動ガスの濃度が5ppm以上200ppm以下であり、且つ光学的に透明な被覆が少なくとも98%の光学的透明度及び2%以下の曇り価を有する、移動する支持体上へ光学的に透明な被覆を連続的に調製する方法。

Claims (6)

- 1)a)少なくとも1つの入口及び少なくとも1つの出口を有する電極とb)移動する支持体を支持する対電極との間の領域にコロナ放電を発生せしめ;そして

2)空気、酸素、窒素、ヘリウム、アルゴン又はこれらの組合せから選ばれるバランスガス及び有機シロキサンである作動ガス並びに、場合によっては、作動ガス用の不活性キャリアガスの混合物を、支持体上にプラズマ重合被覆を形成するように、電極及びコロナ放電中に流す工程

を含んでなり、バランスガスが少なくとも1つの出口を通過する速度が10m/s以上で且つ200m/s以下であり、総ガス混合物に基づく作動ガスの濃度が5ppm以上200ppm以下であり、且つ光学的に透明な被覆が少なくとも98%の光学的透明度及び2%以下の曇り価を有する、移動する支持体上へ光学的に透明な被覆を調製する連続的方法。 - 前記対電極が回転ドラムであり、且つドラム若しくは電極又はドラムと電極の両方に誘電スリーブを装着する請求項1に記載の方法。

- 前記電極の少なくとも1つの出口が複数の孔又はスリットであり且つ作動ガスがテトラメチルジシロキサン、ヘキサメチルジシロキサン、オクタメチルトリシロキサン、テトラエチルオルトシリケート又はこれらの組合せである請求項1又は2に記載の方法。

- 前記支持体が、プラズマ重合堆積後に、未処理支持体に比較して、増大した表面エネルギーを有する請求項1〜3のいずれか1項に記載の方法。

- 前記堆積層が支持体を耐薬品性にする被覆を構成する請求項1〜4のいずれか1項に記載の方法。

- 前記被覆が、未処理支持体に比較して、増大した気体遮断性を有する被覆を構成する請求項1〜5のいずれか1項に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US35490502P | 2002-02-05 | 2002-02-05 | |

| US40864002P | 2002-09-06 | 2002-09-06 | |

| PCT/US2003/003057 WO2003066932A1 (en) | 2002-02-05 | 2003-02-03 | Corona-generated chemical vapor deposition on a substrate |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005533174A JP2005533174A (ja) | 2005-11-04 |

| JP2005533174A5 JP2005533174A5 (ja) | 2005-12-22 |

| JP4494792B2 true JP4494792B2 (ja) | 2010-06-30 |

Family

ID=27737478

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003566273A Expired - Lifetime JP4494792B2 (ja) | 2002-02-05 | 2003-02-03 | 支持体上へのコロナによる化学蒸着 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US6815014B2 (ja) |

| EP (1) | EP1472387B1 (ja) |

| JP (1) | JP4494792B2 (ja) |

| CN (1) | CN100432289C (ja) |

| AT (1) | ATE402277T1 (ja) |

| AU (1) | AU2003207794A1 (ja) |

| DE (1) | DE60322347D1 (ja) |

| WO (1) | WO2003066932A1 (ja) |

Families Citing this family (40)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8586149B2 (en) | 2003-06-18 | 2013-11-19 | Ford Global Technologies, Llc | Environmentally friendly reactive fixture to allow localized surface engineering for improved adhesion to coated and non-coated substrates |

| EP1663518A2 (en) * | 2003-09-09 | 2006-06-07 | Dow Global Technologies Inc. | Glow discharge-generated chemical vapor deposition |

| DE102004029466A1 (de) * | 2004-06-18 | 2006-01-05 | Leybold Optics Gmbh | Medieninjektor |

| BRPI0515714A (pt) * | 2004-09-27 | 2008-07-29 | Dow Global Technologies Inc | processo para preparar um revestimento em múltiplas camadas na superfìcie de um substrato polimérico orgánico por meio de uma deposição por plasma à pressão atmosférica |

| US20080107820A1 (en) * | 2004-10-29 | 2008-05-08 | Gabelnick Aaron M | Deposition Rate Plasma Enhanced Chemical Vapor Process |

| WO2006049794A2 (en) * | 2004-10-29 | 2006-05-11 | Dow Global Technologies Inc. | Abrasion resistant coatings by plasma enhanced chemical vapor deposition |

| CA2622429A1 (en) * | 2005-09-20 | 2007-03-29 | Dow Global Technologies Inc. | Process for plasma assisted coating a nanocomposite object |

| US7517561B2 (en) | 2005-09-21 | 2009-04-14 | Ford Global Technologies, Llc | Method of coating a substrate for adhesive bonding |

| TWI275658B (en) * | 2006-09-13 | 2007-03-11 | Ind Tech Res Inst | Method of improving surface frame resistance of a substrate |

| TW200814170A (en) * | 2006-09-13 | 2008-03-16 | Ind Tech Res Inst | Method of adjusting surface characteristic of a substrate |

| WO2009017964A1 (en) * | 2007-07-30 | 2009-02-05 | Dow Global Technologies Inc. | Atmospheric pressure plasma enhanced chemical vapor deposition process |

| KR100962044B1 (ko) * | 2007-12-06 | 2010-06-08 | 성균관대학교산학협력단 | 저유전 플라즈마 중합체 박막 및 그 제조 방법 |

| EP2251455B1 (en) | 2009-05-13 | 2017-09-06 | SiO2 Medical Products, Inc. | PECVD coating using an organosilicon precursor |

| EP2396451B1 (en) * | 2009-02-12 | 2012-11-07 | Fujifilm Manufacturing Europe BV | Two layer barrier on polymeric substrate |

| US7985188B2 (en) | 2009-05-13 | 2011-07-26 | Cv Holdings Llc | Vessel, coating, inspection and processing apparatus |

| DE102009030303A1 (de) * | 2009-06-24 | 2010-12-30 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur Herstellung von Antireflexschicht-bildenden Beschichtungen sowie Antireflexbeschichtungen |

| US9458536B2 (en) | 2009-07-02 | 2016-10-04 | Sio2 Medical Products, Inc. | PECVD coating methods for capped syringes, cartridges and other articles |

| US9488927B2 (en) | 2010-04-30 | 2016-11-08 | Hewlett-Packard Development Company, L.P. | Printing systems and methods of using such printing systems |

| US11624115B2 (en) | 2010-05-12 | 2023-04-11 | Sio2 Medical Products, Inc. | Syringe with PECVD lubrication |

| US9878101B2 (en) | 2010-11-12 | 2018-01-30 | Sio2 Medical Products, Inc. | Cyclic olefin polymer vessels and vessel coating methods |

| US9272095B2 (en) | 2011-04-01 | 2016-03-01 | Sio2 Medical Products, Inc. | Vessels, contact surfaces, and coating and inspection apparatus and methods |

| EP2589366A1 (de) * | 2011-11-07 | 2013-05-08 | IDT Biologika GmbH | Biologisch abbaubare Folienverpackung für orale Biologika |

| US11116695B2 (en) | 2011-11-11 | 2021-09-14 | Sio2 Medical Products, Inc. | Blood sample collection tube |

| WO2013071138A1 (en) | 2011-11-11 | 2013-05-16 | Sio2 Medical Products, Inc. | PASSIVATION, pH PROTECTIVE OR LUBRICITY COATING FOR PHARMACEUTICAL PACKAGE, COATING PROCESS AND APPARATUS |

| US8945418B2 (en) * | 2011-11-16 | 2015-02-03 | The United States Of America, As Represented By The Secretary Of The Navy | Melt stabilization and vapor-phase synthesis of cesium germanium halides |

| EP2846755A1 (en) | 2012-05-09 | 2015-03-18 | SiO2 Medical Products, Inc. | Saccharide protective coating for pharmaceutical package |

| US20150297800A1 (en) | 2012-07-03 | 2015-10-22 | Sio2 Medical Products, Inc. | SiOx BARRIER FOR PHARMACEUTICAL PACKAGE AND COATING PROCESS |

| US9664626B2 (en) | 2012-11-01 | 2017-05-30 | Sio2 Medical Products, Inc. | Coating inspection method |

| WO2014078666A1 (en) | 2012-11-16 | 2014-05-22 | Sio2 Medical Products, Inc. | Method and apparatus for detecting rapid barrier coating integrity characteristics |

| US9764093B2 (en) | 2012-11-30 | 2017-09-19 | Sio2 Medical Products, Inc. | Controlling the uniformity of PECVD deposition |

| WO2014085348A2 (en) | 2012-11-30 | 2014-06-05 | Sio2 Medical Products, Inc. | Controlling the uniformity of pecvd deposition on medical syringes, cartridges, and the like |

| US9662450B2 (en) | 2013-03-01 | 2017-05-30 | Sio2 Medical Products, Inc. | Plasma or CVD pre-treatment for lubricated pharmaceutical package, coating process and apparatus |

| KR102167557B1 (ko) | 2013-03-11 | 2020-10-20 | 에스아이오2 메디컬 프로덕츠, 인크. | 코팅된 패키징 |

| US9937099B2 (en) | 2013-03-11 | 2018-04-10 | Sio2 Medical Products, Inc. | Trilayer coated pharmaceutical packaging with low oxygen transmission rate |

| EP2971227B1 (en) | 2013-03-15 | 2017-11-15 | Si02 Medical Products, Inc. | Coating method. |

| EP2896502B1 (en) * | 2014-01-16 | 2017-03-08 | ThyssenKrupp Steel Europe AG | Composite sheet and method of manufacturing |

| US11066745B2 (en) | 2014-03-28 | 2021-07-20 | Sio2 Medical Products, Inc. | Antistatic coatings for plastic vessels |

| WO2017031354A2 (en) | 2015-08-18 | 2017-02-23 | Sio2 Medical Products, Inc. | Pharmaceutical and other packaging with low oxygen transmission rate |

| DE102019124489B3 (de) * | 2019-09-12 | 2020-11-12 | VON ARDENNE Asset GmbH & Co. KG | Vakuumanordnungen, Verfahren und Verwendung einer Elektrode im Vakuum |

| US12129078B2 (en) * | 2021-03-04 | 2024-10-29 | Yeti Coolers, Llc | Surface coating of drinkware |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US424103A (en) * | 1890-03-25 | Steam-generator | ||

| DE3705482A1 (de) * | 1987-02-20 | 1988-09-01 | Hoechst Ag | Verfahren und anordnung zur oberflaechenvorbehandlung von kunststoff mittels einer elektrischen koronaentladung |

| GB8713986D0 (en) | 1987-06-16 | 1987-07-22 | Shell Int Research | Apparatus for plasma surface treating |

| NL8701530A (nl) | 1987-06-30 | 1989-01-16 | Stichting Fund Ond Material | Werkwijze voor het behandelen van oppervlakken van substraten met behulp van een plasma en reactor voor het uitvoeren van die werkwijze. |

| US4894352A (en) | 1988-10-26 | 1990-01-16 | Texas Instruments Inc. | Deposition of silicon-containing films using organosilicon compounds and nitrogen trifluoride |

| US5176938A (en) | 1988-11-23 | 1993-01-05 | Plasmacarb Inc. | Process for surface treatment of pulverulent material |

| US5194291A (en) * | 1991-04-22 | 1993-03-16 | General Atomics | Corona discharge treatment |

| DE4225106C2 (de) | 1992-07-30 | 1995-10-05 | Heraeus Kulzer Gmbh | Verfahren und Vorrichtung zur Herstellung eines Metall-Kunststoff-Verbundes |

| KR960000190B1 (ko) * | 1992-11-09 | 1996-01-03 | 엘지전자주식회사 | 반도체 제조방법 및 그 장치 |

| FR2704558B1 (fr) | 1993-04-29 | 1995-06-23 | Air Liquide | Procede et dispositif pour creer un depot d'oxyde de silicium sur un substrat solide en defilement. |

| US5456972A (en) | 1993-05-28 | 1995-10-10 | The University Of Tennessee Research Corporation | Method and apparatus for glow discharge plasma treatment of polymer materials at atmospheric pressure |

| US6083355A (en) | 1997-07-14 | 2000-07-04 | The University Of Tennessee Research Corporation | Electrodes for plasma treater systems |

| US6106659A (en) | 1997-07-14 | 2000-08-22 | The University Of Tennessee Research Corporation | Treater systems and methods for generating moderate-to-high-pressure plasma discharges for treating materials and related treated materials |

| CA2295729A1 (en) * | 1997-07-14 | 1999-01-28 | John Lynch | Plasma treater systems and treatment methods |

| US6082292A (en) | 1999-01-05 | 2000-07-04 | Wisconsin Alumni Research Foundation | Sealing roller system for surface treatment gas reactors |

| US6118218A (en) | 1999-02-01 | 2000-09-12 | Sigma Technologies International, Inc. | Steady-state glow-discharge plasma at atmospheric pressure |

| US20020129902A1 (en) * | 1999-05-14 | 2002-09-19 | Babayan Steven E. | Low-temperature compatible wide-pressure-range plasma flow device |

-

2003

- 2003-02-03 JP JP2003566273A patent/JP4494792B2/ja not_active Expired - Lifetime

- 2003-02-03 WO PCT/US2003/003057 patent/WO2003066932A1/en not_active Ceased

- 2003-02-03 CN CNB038033178A patent/CN100432289C/zh not_active Expired - Fee Related

- 2003-02-03 EP EP03706031A patent/EP1472387B1/en not_active Expired - Lifetime

- 2003-02-03 AT AT03706031T patent/ATE402277T1/de not_active IP Right Cessation

- 2003-02-03 DE DE60322347T patent/DE60322347D1/de not_active Expired - Lifetime

- 2003-02-03 US US10/357,019 patent/US6815014B2/en not_active Expired - Lifetime

- 2003-02-03 AU AU2003207794A patent/AU2003207794A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| HK1072279A1 (en) | 2005-08-19 |

| ATE402277T1 (de) | 2008-08-15 |

| AU2003207794A1 (en) | 2003-09-02 |

| DE60322347D1 (de) | 2008-09-04 |

| JP2005533174A (ja) | 2005-11-04 |

| EP1472387A1 (en) | 2004-11-03 |

| EP1472387B1 (en) | 2008-07-23 |

| CN100432289C (zh) | 2008-11-12 |

| WO2003066932A1 (en) | 2003-08-14 |

| CN1628187A (zh) | 2005-06-15 |

| US6815014B2 (en) | 2004-11-09 |

| US20040091637A1 (en) | 2004-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4494792B2 (ja) | 支持体上へのコロナによる化学蒸着 | |

| US5224441A (en) | Apparatus for rapid plasma treatments and method | |

| JP5170268B2 (ja) | 透明ガスバリア性フィルムの製造方法 | |

| US20080095954A1 (en) | Multilayer Coatings By Plasma Enhanced Chemical Vapor Deposition | |

| JP2008516089A (ja) | プラズマコーティング方法 | |

| US20080107820A1 (en) | Deposition Rate Plasma Enhanced Chemical Vapor Process | |

| US20060222779A1 (en) | Glow discharge-generated chemical vapor deposition | |

| US20030049468A1 (en) | Cascade arc plasma and abrasion resistant coatings made therefrom | |

| JP6717371B2 (ja) | 光照射装置および光照射方法 | |

| WO2006075490A1 (ja) | 透明ガスバリアフィルム | |

| JP6341207B2 (ja) | ガスバリアーフィルムの製造装置 | |

| WO2015025782A1 (ja) | ガスバリアーフィルムの製造装置及びガスバリアーフィルムの製造方法 | |

| HK1072279B (en) | Corona-generated chemical vapor deposition on a substrate |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060202 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090512 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090812 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100309 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100408 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130416 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130416 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140416 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |