JP4185604B2 - Sample analysis method, sample preparation method and apparatus therefor - Google Patents

Sample analysis method, sample preparation method and apparatus therefor Download PDFInfo

- Publication number

- JP4185604B2 JP4185604B2 JP32772898A JP32772898A JP4185604B2 JP 4185604 B2 JP4185604 B2 JP 4185604B2 JP 32772898 A JP32772898 A JP 32772898A JP 32772898 A JP32772898 A JP 32772898A JP 4185604 B2 JP4185604 B2 JP 4185604B2

- Authority

- JP

- Japan

- Prior art keywords

- sample

- thin

- tem

- electron microscope

- holder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Analysing Materials By The Use Of Radiation (AREA)

- Sampling And Sample Adjustment (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、透過型電子顕微鏡(TEM)や走査型透過電子顕微鏡(STEM)で観察する薄片試料における注目部の断面を観察するための試料作製方法、また、注目部を解析するための試料解析方法、さらには上記試料作製または解析方法を実現させる装置に関する。

【0002】

【従来の技術】

TEMは、電子が透過しうる薄さ、例えば0.05から0.4μm程度の薄片試料に、電子線を照射して透過した電子線を拡大して形成されるTEM像を観察する顕微鏡であり、STEMは上述の薄片試料上を集束した電子線を走査して透過した電子線を検出器に導入してSTEM像を得る顕微鏡である。いずれも薄片試料に電子線を透過させるため、薄片試料の厚さ方向に積算した形状情報が得られるが、高分解能で観察できるため、半導体を始め多くの分野での材料評価に用いられている。

【0003】

半導体装置の製造において、ある製造プロセスで検出された異物、形状不良、断線、短絡などの不良部は、即刻、解析してその発生原因を究明して対策を打たなければ不良素子が大量に生産され、製造会社にとっては収益に多大なる影響を与えてしまう。このため、半導体装置の製造歩留り向上のためには不良部解析が必須である。不良部解析法のうち形状観察についてはTEMやSTEMが大きな役割を果たしており、また、TEMやSTEMに分析機能を装備することで高分解能の元素分析も可能となり、半導体の解析には不可欠なものとなっている。

【0004】

TEMやSTEMによる解析(以下、観察や元素分析、計測を代表させて解析と略記する)では、半導体ウェーハやチップなど試料の表面に対して水平方向の試料(以下、平面試料と略記)と断面方向の試料(以下、断面試料と略記)についての観察が行なわれる。

【0005】

断面試料については、機械的に断面を露出させて研磨とイオンシニングによって断面方向の薄片加工を行なう方法が行なわれてきた。最近では、集束イオンビーム(以下、FIBと略記)を用いて、所望の領域を精度よく断面薄片試料に加工する方法が行なわれるようになってきた。

【0006】

まず、研磨を用いた試料作製方法について図2で説明する。同図aのように、ウェーハなどの試料20に対して観察したい領域に目印を付け、ダイアモンドペンなどで傷付け劈開するかダイシングソーによって、例えば切断線に沿って、短冊状ペレット21に切り出す(図b)。次に、作製するTEM試料の中央部が観察領域となるようにするため、2枚の短冊状ペレット21の表面22同士を向かい合うように接着剤23で貼って、貼合わせ試料24を作る(図c)。この貼合わせ試料24をダイシングソーなどでスライスし、スライス試料25を切り出す(図d)。このスライス試料25の大きさは、3×3×0.5mm程度である。さらに、このスライス試料25の断面を研磨盤上で薄く研磨し、厚さ20μm程度の研磨試料25'を作製し、これをTEM試料ステージに搭載する単孔メッシュ26に貼り付け(図e)、この研磨試料25'の両面からにアルゴンなどのイオンビーム27の照射による(図f)イオンシニングを行い中央部を薄くしていく(図g)。中央部に穴が開くか開かない程度の薄さになった時にイオンビーム27の照射を止め、100nm程度もしくはそれ以下に薄くなった薄片部28(図h中の円内)をTEM観察領域としている。

【0007】

また、FIBによる断面TEM試料の作製方法については、例えば、E.C.G.Kirkらが、論文集Microscopy of Semiconducting Materials 1989,Institute of Physics Series No.100.,p.501−506(公知例1)に記載している。

【0008】

以下、図3を用いてFIBによる断面TEM試料の作製例を説明する。ウェーハなど試料20の観察すべき領域の近傍にレーザまたはFIBで目印を付け、図aに示すようにウェーハをダイシングを行って(破線が切断線)短冊状ペレット21を切り出し、さらに観察すべき注目部を含むペレット21'に切断する(図b)。このペレットの大きさは、おおよそ2×0.1×0.5mmである。このペレット21'を一部に切り欠き29'を有する円形の薄い金属片からなるTEM試料ホルダ29に接着剤で貼り付ける(図c)。

【0009】

このペレット21'を固定したTEM試料ホルダ29をFIB装置内に導入し、表面22の一部にFIB18を照射して薄片部28'が残るように加工する。観察領域である薄片部28'の厚さが100nm程度の壁になるように凹部22'が形成されるように加工(この加工方法を以下、薄壁加工と言う)してTEM試料となる(図e)。TEMにおいては、電子線65は薄片部28'に垂直に入射する。

【0010】

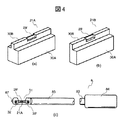

FIB加工されたTEM試料の形状例を図4aと図4bに示す。断面形状は図aの凸形状や図bのL字形状など種々変形もあるが、基本とするところは、ある程度機械的強度を有した下部30AとFIB加工領域を少なくするためにできるだけ薄く機械加工を施した上部30Bとを有する短冊状試験片21A、21Bにおいて、その所望の一部を電子が透過できるようにFIBによって薄片部28'に加工したことにある。最後に、薄壁加工を終えた試料を試料ホルダごとTEMステージに載置し、TEM装置に導入することで、試料の断面TEM観察ができる。このような短冊状試験片21A、21Bは、図4cに示すTEM試料ステージ6に搭載することでFIB加工とTEM観察ができる。

【0011】

試料ステージ6は、円柱部83と、試料ステージ6を持ったり操作するためのグリップ84と、短冊状試験片21Aを保持するための固定具32、32'と、最先端には試料ステージ6の荷重を支えたり、振動を軽減したり、回転軸のブレを防ぐための小突起87などから構成されている。また、切り欠き31を有して軸回転可能なため、薄片部28'をFIBで加工した後90°回転してTEM観察することができる。なお、この小突起87を支える支持部が試料ステージ6の軸とほぼ同軸に試料室内にあるが図示は省略するとともに、試料ステージ6の円柱部83が長いため図では途中を省略している。電子線は薄片部28'にほぼ垂直に入射する。この方法によって、μmレベルの位置出しが可能になり、特定領域のある方向からの断面をTEM観察できる。

【0012】

なお、FIB装置については、例えばL.R.Harriottが論文集Nuclear Instruments and Methods in Physics Research B55(1991)p.802−p.810(公知例2)に"The technology of finely focused ion beams"と題する論文に詳述している。FIBは、液体金属イオン源から放出したイオンをアパチャおよび静電レンズによって直径数10nmまで集束したイオンビームで、このFIBを偏向電極で試料表面の所定領域を偏向走査して照射することで、試料表面を走査形状に従ってスパッタリングし、凹部形成などの加工ができる。さらには、FIB装置にガス供給部を装着し、デポジション用ガスや反応性ガスを導入しつつFIB走査することで、走査領域にガス成分のデポジション膜を形成することができたり、高速にエッチングすることなどができる。

【0013】

一方、平面試料の作製法に関する典型的な従来方法を図5を用いて説明する。試料はウェーハ状試料で、解析領域はウェーハのある特定領域で表面から約1μmの深さにある0.5μm平方の領域とする。まず、図aのようにウェーハ20をダイヤモンドカッタやダイシンソーなどを利用して所望の解析部を含んで例えば10mm×10mm程度の大きさの試験片21に切断する(図b)。図aの破線は切断線である。

【0014】

研磨用治具(図示せず)には、切断片21のうち所望の観察領域を含む1mm平方程度の切断小片21B(図c)にしてから、その表面を接着面にして接着固定する。研磨治具には種々の形態があるが、基本的にはマイクロメータヘッドなどμmオーダの寸法が計れる機器が設置された研磨治具を用いて、試料の平面性を調節しながら研磨盤に押し当てて研磨する。研磨材や、研磨盤の回転速度などを調整しながらウェーハ裏面から切断小片21Bを研磨して、厚さ10μm程度の研磨試料21Cができる(図d)。

【0015】

この研磨試料21Cをさらに薄くするため、単孔メッシュ26Aに固定し(図e)、さらに単孔メッシュ26Aを回転させながら図fのように表裏面からのアルゴンイオン27を斜め照射してシニングする。最終的に図gのように中央周辺の100nm程度以下に薄くなった薄膜部28をTEM試料とする。

【0016】

この薄片試料28をメッシュ26Aと共にTEMステージに装着してTEM解析を実行する。平面TEM試料の観察は、数100μm平方の広領域を一度に観察できるため、例えば、材料に点在する結晶欠陥の分布を調査するなどには非常に効果的である。

【0017】

平面試料の作製方法については、例えば、論文集「ウルトラマイクロスコピー」52巻、(1993年)127頁〜140頁(Ultramicroscopy,52(1993)127〜140)においてH.Cervaらが"Specific preparation procedures forn failure analysis of(sub)micron areas in silicon devices"(公知例3)と題して詳述している。

【0018】

また、TEM試料作製に関してはウェーハを割断することなく実現する方法がある。上記公知例2による断面試料作製方法では、ウエハを割断し、所望の解析領域を含む短冊状ペレットを作製し、FIB加工しなければならない。これに対して、ウェーハなど元の試料を割断することなく上記試料の一部分を分離してTEM試料にする方法について、特開平5-52721号公報「試料の分離方法及びこの分離方法で得た分離試料の分析方法」(公知例4)に開示されている。この方法は、ウェーハなど試料から所望の解析領域を含む微小試料片を、FIB加工と微小試料の搬送手段を駆使して分離する方法である。この方法で分離した微小試料を各種解析装置に導入することで、ウエハ等の元の試料を割断することなく不良部を解析することができる。

【0019】

図6を用いて説明する。まず、試料20の表面に対しFIB16を垂直入射、矩形走査させることにより、試料20の表面に所要の深さの角穴33Aを形成する(図a)。次に、試料20の表面に対するFIB16の軸が約70°に傾斜するように試料20を傾斜させ、底穴33Bを形成する。試料20の傾斜角の変更は、試料ステージ(図示せず)によって行なう(図b)。試料20の姿勢をFIB16が再び垂直入射できるように設置し、切り欠き溝33Cを形成する(図c)。

【0020】

マニピュレータ(図示せず)を駆動し、マニピュレータ先端のプローブ34の先端を、試料20を分離する部分に接触させる(図d)。デポジション用ガスノズル35から堆積性ガス36を供給し、FIB16をプローブ34の先端部を含む領域に局所的に照射し、デポジション膜37を形成する。接触状態にある試料20の分離部分とプローブ34の先端はデポジション膜37で接続される(図e)。FIB16で残りの部分を切り欠き加工し(図f)、試料30から六面体の分離試料38を切り出すことができる。切り出された分離試料38はプローブ34で支持された状態になる(図g)。このようにしてウェーハを割断することなく微小試料を摘出することができる。

【0021】

さらに、ウェーハを割断せずにTEM試料を作製する別の方法として、FIBとプローブを用いた微小試料を摘出する方法がある。L. A. Giannuzzi,J.L.Drown,S.R.Brown,R.B.Irwin,and F.A.Stevieが、“Materials Research Society,Symposium Proceedings,vol.480 Specimen Preparation for Transmission Electron Microscopy 4"において、“Focused Ion Beam Milling and Micromanipulation Lift Out for Site Specific Cross Section TEM Specimen Preparation"(公知例5)と題する論文にて示している。これは、試料基板に対して所望の観察部をFIBによって薄片加工して試料基板と分離した状態で、上記試料基板を大気中に取り出し、光学顕微鏡下で針状のプローブを先の上記薄片試料に接近させ、薄片試料を静電気力によって吸着させ、TEM観察用のメッシュに移設させる方法である。

【0022】

さらに、F.Shaapur,T.Stark,T.Woodward.,and R.J.Grahamも、公知例5と同じ文献のp.173−180に“Evaluation of a new strategy for transverse TEM specimen preparation by focused Ion Beam Thinning"(公知例6)と題した論文を示している。この方法も、公知例5と同様の方法を用いる。

【0023】

【発明が解決しようとする課題】

通常、TEMやSTEMで得られる像は、薄片試料を通過した像であるため、薄片試料の厚さ方向の情報が重なって見える。このため、薄片試料の厚さ方向の形状を正確に解析することは困難である。特に、最近の半導体装置の構造物は0.2μm程度の薄片試料内に入ってしまうほど微細化している。例えば、プラグの最小のものは直径0.1μm程度で厚さ0.2μmの薄片試料に入ってしまう。また、一旦、薄片試料を作製してしまうと、視角を変えて直角方向から観察できないため、厚さ方向の形状を把握できず、結局、TEM像からはこのプラグ形状を正確には解釈できない結果に終わる。さらにEDXなどの元素分析手段を用いて薄片の2次元的分布が明らかになっても、先のプラグの立体的元素分布まで把握することはできない。

【0024】

そこで、TEM観察用の薄片試料について、平面的に観察した同じ観察箇所について、この薄片試料の断面方向からも観察できる方法が実現すれば、上記のような薄片試料内の構造体を立体的に把握する上で非常に有効となる。そこで、薄片試料の断面試料を作製する簡便で確実な方法、そのための装置、さらにはそのような平面および断面試料を用いた試料解析方法を実現することが非常に重要となる。

【0025】

薄い試料や研磨などで作製された薄片から断面試料を現状の技術で作製するときは、図7aのような注目部41を含む薄片試料40に対して、両側をエポキシなどの硬化性材料42A、42Bで被い(包埋し)固化して包埋試料43とする(図b)。その後、図cのように、元の薄片試料40に対して垂直方向に包埋試料43を切断し、そのスライス試料44の両面を研磨して厚さ0.1から0.2μm程度の断面薄片試料44'を作製する。さらにイオンシニングした後、図dのように断面薄片試料44'に対して電子線65をほぼ垂直入射させて注目部41の断面を観察することができる。

【0026】

この方法では断面薄片試料44'も0.1から0.2μm程度の薄さに加工せねばならず、図aのように薄片TEM観察で検出した所望の注目部41が非常に小さく0.1μm程度のものであると、注目部41を断面薄片試料44'を内に納めることがほとんど不可能に近い。つまり、位置制御性がない。また、包埋や薄片加工や研磨、イオンシニングなど手間と時間を非常に要する。従って、長時間かけて研磨を行なっても、断面薄片に所望の注目部が含まれておらず、注目部を視点を90°変えて観察して解析するという初期の目的が全く達成できないことがほとんどで、成功率が非常に低いという難点を有している。

【0027】

公知例2では、断面薄片を従来の研磨方法に比べて、加工精度を高く、短時間に作製することができるという利点を有している。しかし、図4aのような従来のTEM試料を一旦作製すると、薄片部28'の断面をTEM観察できるように加工するためには、薄片部の両側(上部30B)を削除しなければTEM観察できない。特に、長手方向に2mmから3mmもある試料21Aを、薄片部28'の両側を数100μmにまで薄く加工するには膨大な時間を要し、ダイシングなど機械加工を追加する方法をとるときは、貴重な薄片部28'を破損させてしまうという致命的な問題をも引き起こし、これら従来方式の適用は実用的ではなかった。

【0028】

公知例4では試料を試料ステージに一度セットすれば、微小試料の分離まで人間が直接手作業を行う必要はないし、ウェーハを無為に切断する必要もないという特徴を有している。しかし、この手法では分離された試料片はプローブに支持された状態であるため、この薄片部の断面を形成するためにはプローブを複雑に位置制御しなければならない。また、形成した断面を観察するためにプローブをTEMに導入することが、観察面とプローブの位置関係や角度の関係で制限を受けて容易ではない。さらには底穴33Bを形成する際、試料ステージを70°も大きく傾斜させなければならず、大口径ウェーハを載置する試料ステージでは構造上、精度上実用的ではない。

【0029】

また、公知例5、6では、試料基板から注目部の薄片を静電気力で取り出すことができるが、摘出した薄片試料はメッシュに接着剤によって貼りつけているため、再加工できないという欠点を有している。つまり、TEM観察した薄片試料について断面を観察するための加工ができない。また、これらの方法では、摘出試料を光学顕微鏡下でメッシュに貼りつける作業であるため、薄片試料の観察部が不運にもメッシュと重なってしまい観察できないという問題点も有している。さらに、公知例5、6にも著者自ら記載されているように、試料をプローブとの静電気力によって吸着させるため、吸着の信頼性がないという欠点も有している。

【0030】

このように、従来技術が多くあるにも係らず、薄片試料の断面を観察するための簡便で確実な試料作製方法がなく、断面方向から容易に観察できないのが現状であった。

【0031】

そこで、上述の従来技術の諸問題に鑑み、本発明の第1の目的は、薄片試料の注目部を観察や分析などの解析を水平方向と断面方向からTEMやSTEMで行なうための試料解析方法を提供することにあり、また第2の目的は、TEMやSTEMで観察する薄片試料における注目部の断面を観察するための試料作製方法を提供することにあり、さらには、第3の目的として、上記第1の目的もしくは上記第2の目的を実現するための試料作製装置を提供することにある。

【0032】

【課題を解決するための手段】

上記第1の目的は、以下の構成からなる試料解析方法により実現される。

【0033】

(1)薄片試料を透過型電子顕微鏡(以下、TEM)もしくは走査型透過電子顕微鏡(以下、STEM)によって観察する平面観察工程と、上記薄片試料から所望の注目部を含む微小薄片試料を取り出す摘出工程と、上記微小薄片試料を上記薄片試料の表面に対して垂直方向の断面試料に加工する断面薄片加工工程と、上記微小断面試料をTEMまたはSTEMによって観察する断面観察工程を少なくとも含む方法によって、上記注目部を平面方向と断面方向から解析する試料解析方法。

【0034】

(2)試料を薄片試料に加工する薄片加工工程と、上記薄片試料をTEMまたはSTEMによって観察する平面観察工程と、上記薄片試料から所望の注目部を含む微小薄片試料を取り出す摘出工程と、上記微小薄片試料を試料ホルダに固着させる固着工程と、上記薄片試料の表面に対して垂直方向の断面試料に加工する断面薄片加工工程と、上記微小断面試料をTEMまたはSTEMによって観察する断面観察工程とを含む方法によって、上記注目部を平面方向と断面方向から解析する試料解析方法。

【0035】

(3)サイドエントリ型の試料ステージに搭載した薄片試料をTEMまたはSTEMによって観察する平面観察工程と、上記薄片試料を加工する試料作製装置に搭載して上記薄片試料から所望の注目部を含む微小薄片試料を取り出す摘出工程と、上記試料ステージに予め搭載した試料ホルダ上に上記微小薄片試料を固定する固着工程と、上記薄片試料の表面に対して垂直な断面薄片試料を上記試料ホルダ上で作製する断面薄片加工工程と、上記試料ステージを上記TEMまたはSTEMに導入して上記断面薄片試料を観察する断面観察工程を含む試料解析方法。

【0036】

(4)特に上記(1)から(3)のいずれかの試料解析方法の断面薄片加工工程を集束イオンビームの照射によって行なうか、

(5)上記(2)または(3)の試料解析方法における摘出工程および上記固着工程を集束イオンビームの照射によって行なう。

【0037】

(6)以上の方法において、薄片試料の注目部の平面方向のTEM観察もしくはSTEM観察による画像情報と、上記薄片試料の注目部の断面方向のTEM観察もしくはSTEM観察による画像情報とによって、上記注目部の疑似立体的形状を把握する試料解析方法。

【0038】

(7)以上の方法において、薄片試料の注目部のTEM分析もしくはSTEM分析による分析情報と、上記薄片試料の注目部の断面方向のTEM分析もしくはSTEM分析による分析情報とによって、上記注目部の疑似立体的元素構成を把握する試料解析方法。

【0039】

上記第2の目的である試料作製は、以下の構成からなる方法により実現される。

【0040】

(8)TEMまたはSTEMによって観察もしくは分析する薄片試料から注目部を含む微小薄片試料を摘出して、上記注目部を上記薄片試料の表面に平行な方向から観察できるように上記微小薄片試料を上記薄片試料面の方向に電子が透過しうる薄さに加工を施す試料作製方法。

【0041】

(9)電子が透過しうる薄さの薄片試料から注目部を含む微小薄片試料を取り出す摘出工程と、摘出した上記微小薄片試料を別部材に固着させる固着工程と、さらに上記薄片試料の一部に加工を施して電子が透過しうる薄さの断面薄片試料を作製する試料作製方法。

【0042】

(10)目的とする試料を電子が透過しうる薄さの薄片試料に加工する薄片加工工程と、上記薄片試料をTEMまたはSTEMによって観察する平面TEM観察工程と、上記薄片試料から所望の注目部を含む微小薄片試料を取り出す摘出工程と、上記微小薄片試料を試料ホルダに固着させる固着工程と、上記微小薄片試料の注目部を含み上記微小薄片試料の面に対して略垂直で、電子が透過しうる薄さの断面薄片試料に加工する断面加工工程とを含む試料作製方法。

【0043】

(11)サイドエントリ型の試料ステージに搭載したTEM観察用の薄片試料のうち注目部を含んだ一部分の微小薄片試料を取り出す摘出工程と、上記試料ステージに予め搭載した試料ホルダ上に上記微小薄片試料を固着させる固着工程と、上記微小薄片試料のうち注目部を含み上記微小薄片試料の面に対して略垂直で、電子が透過しうる薄さの断面薄片試料に加工する断面加工工程とを含む試料作製方法。

【0044】

(12)上記(9)または(11)における薄片試料および微小薄片試料への加工が、少なくとも集束イオンビームによる加工を含む試料作製方法。

【0045】

(13)上記(9)から(12)のいずれかにおける薄片試料および上記断面薄片試料が、特に、TEMもしくはSTEMによる観察もしくは分析のための薄片試料である試料作製方法。

【0046】

(14)上記(9)から(13)のいずれかにおける摘出工程が、上記注目部を含む領域に保護膜を形成する過程と、上記保護膜を含んだ領域の周辺に集束イオンビームを照射して上記薄片試料の一部で保持された片持ち梁試料に加工する過程と、上記片持ち梁試料に搬送手段を固定する過程と、上記片持ち梁試料を上記薄片試料から分離する過程とを少なくとも含む試料作成方法。

【0047】

(15)上記(9)から(13)のいずれかにおける上記固着工程、もしくは(14)の片持ち梁試料に搬送手段を固定する過程が、集束イオンビームとデポジションガスによる局所デポジション膜による接着である試料作製方法。

【0048】

(16)上記(9)から(13)のいずれかにおける摘出工程が、TEMもしくはSTEM観察で得た上記薄片試料のTEMもしくはSTEM画像と、集束イオンビームの照射によって得た上記薄片試料の二次電子画像とを重ね合せて、上記注目部の位置を特定する過程を含む試料作製方法。

【0049】

(17)上記(9)から(13)のいずれかにおける摘出工程が、上記注目部を含む上記薄片試料のTEMもしくはSTEM画像を記憶する過程と、上記TEM像もしくはSTEM像の特徴的パターンを輪郭線にする計算処理過程と、集束イオンビームの照射によって得た上記薄片試料の表面の二次電子画像と上記輪郭線を重ね合せて、上記所望の注目部の存在位置関係を特定する過程とを含む試料作製方法。

【0050】

上記第3の目的は、以下の構成を有する装置とすることで実現される。

【0051】

(18)薄片試料の所望の領域に集束イオンビームを照射する集束イオンビーム照射部と、上記集束イオンビームの照射によって上記試料から発生する二次粒子を検出する二次粒子検出器と、上記集束イオンビームの照射領域にデポジション膜を形成するデポジション用ガス供給源と、上記薄片試料を載置し試料ステージと、上記薄片試料の一部を分離した微小薄片試料を別の部材に移し変える移送部と、上記微小薄片試料を載置する試料ホルダを保持する試料ホルダ保持部とを有した試料作製装置。

【0052】

(19)上記(18)の試料ステージは、TEM用メッシュを固定するメッシュホルダを取り付けるメッシュホルダ固定部を有する構造である試料作製装置、または、(20)上記(18)の試料ステージは、メッシュホルダ固定部と上記試料ホルダ保持部とを有するサイドエントリ型試料ステージである試料作製装置。

【0053】

(21)上記(20)の試料の固定部は、薄片試料を搭載するTEM用メッシュを固定するメッシュホルダを取り付ける固定部である試料作製装置。

【0054】

(22)上記(18)から(21)のいずれかにおいて、特に、上記試料ホルダにおける微小試料を栽置する面と上記メッシュの面とが平行な位置関係にある試料作製装置。

【0055】

(23)上記(20)におけるサイドエントリ型試料ステージは、TEMまたはSTEMのうちの少なくとも一方、および、上記試料作製装置とに共通して抜き差しできる構造である試料作製装置。

【0056】

(24)上記(18)において、TEMもしくはSTEMによるTEM画像情報を受け取る計算処理部を有しているか、または、

(25)上記(18)において、ネットワークを介してコンピュータに蓄えたTEMもしくはSTEMによる画像情報を受け取る計算処理部を有しているか、または、

(26)上記(18)において、少なくともTEM画像情報と上記集束イオンビームの照射による二次粒子画像情報を保存すると共に、少なくとも上記TEM画像情報と上記二次粒子像情報を重ね合せた合成像を作成する計算処理部と、少なくとも上記TEM画像情報または上記二次粒子画像情報または両者の合成像のうちの少なくとも何れかを表示する画像表示部とを有する試料作製装置。

【0057】

また、上記第3の目的である試料作製装置は、

(27)試料作製装置と、TEMまたはSTEMと、コンピュータと、上記試料作製装置と上記TEMまたはSTEMと上記コンピュータの相互を接続するネットワークとを含む試料作製システムであってもよい。

【0058】

さらに、上記第3の目的である試料作製装置を実現させるための試料ホルダとしては、

(28)薄片試料の所望の一部を分離した微小薄片試料を固定するTEMまたはSTEMのための試料ホルダで、特に、角柱形状もしくは円弧部を有する形状であるか、または、

(29)上記(28)における角柱形状の断面が特に、凸状またはL字状もしくは矩型であるか、または、

(30)上記(28)または(29)における微小薄片試料を固定する箇所が、上記試料ホルダの長手方向のほぼ中央部に設けた凹部であるか、または、

(31)上記(30)において、特に、上記凹部の底部に上記凹部の深さより低く、上記試料ホルダの幅より薄い支持台を上記微小薄片試料を固定するために設置した試料ホルダが好適な形態である。

【0059】

また、上記第3の目的を達成するための試料の形態としては、

(32)TEMまたはSTEMによって少なくとも垂直な2方向から観察もしくは分析すべき試料が、高さ0.4μm以下、幅0.4μm以下、長さ1μm以上の四角柱を含む形状に加工した試料でることが好適である。

【0060】

【発明の実施の形態】

本発明による試料解析方法の実施の形態は、電子が透過しうる薄さの薄片試料の所望の領域をTEMもしくはSTEMによって観察もしくは分析した後、さらに、上記薄片試料の所望の箇所を断面薄片に加工してTEMまたはSTEMで観察もしくは分析する方法である。

【0061】

以下、本発明の具体的実施例を示し、さらには、本発明による試料作製方法、試料作製装置の実施例について図9から図16を用いて説明するが、ここでは、まず用語を統一するために図8を用いて説明しておく。

【0062】

図8aのように少なくとも一部にTEM観察できる程度の薄片部45を有する試料や、研磨やイオンシニングなど加工、未加工に関係なく図8bのように全面にわたって薄板状の試料を薄片試料46と称する。薄片試料46は元試料の基準面に平行な平面TEM試料や、垂直な断面TEM試料を指す。薄片部45や薄片試料46の断面を観察するために、図8cのように薄片部45の一部を抜き取ることを摘出と言う。

【0063】

ここで、符号Dは薄片試料46の平面観察時の電子線の入射方向で、薄片試料の厚さEはおよそ0.05μmから0.4μmであることが望ましい。また。摘出した試料を微小薄片試料47という(図8d)。ここで断面観察方向はFまたはF'を指すが、観察断面に平行な幅が薄いほど加工時間は短くて済む。この微小薄片試料47の少なくとも一部の幅を電子線が通過するほど細く加工した試料を断面薄片試料48と名付ける。符号D'は断面薄片試料46の断面観察時の電子線の入射方向で、この時の試料の幅E'はおよそ0.05μmから0.4μmであることが望ましい。

【0064】

<実施例1>

本発明のうち試料解析方法について例を挙げて図9と図10を用いて説明する。本実施例は、製造プロセスを完了した半導体装置について電気的検査を行なった結果、動作不良部を検出し、この不良部について平面TEM観察を行ない、観察で発見した欠陥をさらに断面方向(平面TEM試料の側面方向)から観察する例を取り上げて説明する。以下、試料解析方法の手順を明確にするためいくつかの工程に分割して説明する。

【0065】

(1)平面TEM用薄片加工

まず、半導体装置について、プローバなど電気的検査装置によって動作不良部(以下、総称して注目部という)の座標情報を記憶する。座標情報の記憶は、チップに予め設置したチップマークを基準にして不良箇所の座標情報として計算処理装置に記憶しておく。この座標情報をもとにチップ(約8mm×15mm)のうち、注目部を含んで1mm平方程度の大きさの小片を機械的に切りだして図4のような従来技術を用いてチップ裏面からの研磨とイオンシニングによって、注目部の厚さが0.1μm程度になるまで薄片化して平面TEM試料とする。この薄片試料をメッシュに貼り付けてTEMステージに搭載する。TEMステージの構造に関しては本発明の重要な部分であるため後の実施例で詳述する。

【0066】

(2)平面TEM観察

TEMステージをTEMもしくはSTEMに導入して観察を行なう。TEM観察方法は公知でここでは詳細説明はしない。観察によって先に記憶した不良部の座標情報を基にTEMで同じ座標領域を観察した結果、視野には長さ3nm程度の微小な線状欠陥が見つかったとする。平面TEM観察で得られたTEM画像情報を低倍率から高倍率までTEMの計算処理部に記憶する。計算処理部では必要に応じてTEM画像情報を処理して、注目部とその他特徴ある構造や形態を輪郭線表示するようにもできる。さらには、取得したTEM画像は拡大縮小、表裏反転や左右反転などの処理もでき記憶することができる。

【0067】

(3)微小薄片試料の摘出

この工程は、試料ステージを試料作製装置に設置して、上述の薄片試料から注目部を含む微小薄片試料を摘出する操作である。この工程を図9を用いて説明する。

【0068】

図9aはメッシュなどに固定された薄片試料50を示す。但し、メッシュは図示せず。厚さはおよそ0.1μmで、大きさは1mm平方程度であるが特に限定しない。まず、薄片試料50から注目部を含む微小薄片試料を摘出する際、注目部を正確に把握しなければならない。特に、薄片試料の表面に目印になるような特異パターンがないとSIM像(FIB走査によって得られた二次電子像、Secondary Ion Microscopy:以下、SIM像)から注目部の位置特定は非常に困難となる。SIM像では試料の表面形状は観察できるが、TEMで観察できた内部欠陥などは観察できないため、内部欠陥を含む注目部分を摘出しようとしても、SIM像からは正確な加工位置が判断つかないからである。そこで、上記TEM画像を基に加工位置を判断する次の方法を採用した。

【0069】

ここで、加工位置の決定方法について図16を用いて説明しておく。図16aはTEM像である。観察視野110には注目する内部欠陥111、表面異物112、112'、さらに点状欠陥113や線状欠陥114の存在が確認できる。このTEM画像情報を一旦計算処理機に記憶しておく。

【0070】

図16bはSIM像である。SIM像視野115はTEM像視野110より広い。SIM像は試料表面の形態が観察できるため、TEM像で観察できた表面異物112。112'の他に別の表面異物116、117、118、119も観察できる。このSIM画像情報も計算処理機に記憶する。上記の計算処理機は、先のTEM画像情報を記憶した計算処理機と同一である必要はなく、必要に応じてお互いの画像情報を特定の計算処理機に呼び出して編集、解析できればよい。ここでは先に記憶したTEM画像情報をネットワークで別の計算処理機に呼び出しで観察倍率、視野の向き、不要なバックグラウンド信号の除去、注目する内部欠陥の強調、表面異物の輪郭の強調処理などを計算処理機で行なって、TEM視野、SIM視野の両方にある表面異物112、112'を基準にSIM像視野115に重ねあわせる。

【0071】

図16cはSIM像と処理したTEM像を重ねた合成像120である。この合成像120において符号110'が処理したTEM像で、この合成像からSIM像では認識できなかった注目する内部欠陥111や点状欠陥113や線状欠陥114の位置関係を確認することができ、内部欠陥111をその側面からTEM観察するために必要な摘出領域121が決定できる。

【0072】

なお、上記画像処理において、TEM画像やSIM像には試料や画像を区別するために、例えば、識別番号122a、122b、122cや記号を画像情報として記入するようにし、さらに、以降の工程で摘出した微小薄片試料にも対応する識別番号や記号をFIBによって記入しておくことによって、SIM像やTEM処理画像、試料の管理が確実になる。

【0073】

このようにして得た合成画像120を基に、注目部の位置が認識できるマーキングを施す。

【0074】

図9bはマーク51の付け方の例を示しており、例えば観察断面を形成する両端にFIB52やレーザ加工等で施す。マーク51'は、さらに精密な位置合わせを実現するために線幅の細いマークである。本例では、観察領域を挟んで10μmと1μm間隔で線分マーク51を4個、FIB52の照射によって施す。

【0075】

次に、図9cに示すように上記2個のマーク51を結ぶ線分を被うように試料保護のための保護膜53を形成する。保護膜53はデポジション用ガスを供給しつつFIB52を矩型に走査することで走査領域に金属膜を形成することができる。本例では、幅約2μm、長さ14μm、高さ1μm程度のタングステン膜を形成した。ただし、保護膜53はタングステンに限ることはなく、炭素膜やプラチナ膜など、他の材料でもよい。

【0076】

次に試料の分離工程に入る。図9dのように、保護膜53を囲むように、コの字状にFIBによって切り込み54を入れることで、カンチレバー状構造55ができる。一例として寸法は、おおよそ幅4μm、長さ18μm、試料厚さ0.1μmとした。

【0077】

次に、図9eのようにカンチレバー状構造55先端部にプローブ56を接触させる。プローブは微小試料の移送手段(図示せず)の先端に固定したもので、移送手段の駆動部(図示せず)には、不注意なプローブの押し付けによるカンチレバー状構造55やプローブ56の破損を避けるために、プローブ56が試料に接触した時点で駆動を停止させる機能を有している。プローブ56をカンチレバー状構造55に固定するために、プローブ56先端を含む約2μm平方の領域にデポジション膜57を形成する。デポジション膜57は保護膜53と同じ方法で形成し、同じ成分である。こうにしてプローブ56とカンチレバー状構造(摘出すべき試料)55とが接続できる(図9f)。

【0078】

その後、図9gのようにカンチレバー状構造55の支持部58にFIB52を照射してスパッタ加工して、カンチレバー状構造55が切断される。切断後、プローブ56を徐々に上昇させると、図9hのように微小薄片試料59として元の薄片試料50から分離、摘出できる。

【0079】

(4)微小薄片試料の固定

この工程は摘出した微小薄片試料59を試料ホルダに固定する操作である。図10を用いて説明する。微小薄片試料59の薄片試料から試料ホルダ60への移動は、プローブ56を薄片試料から上昇させた状態で停止させて試料ステージを移動させることにより微小薄片試料を相対的に移動させ、図10iのように試料ホルダ60が微小薄片試料59の真下に来たとき試料ステージを停止させる。次いで、図10jのようにプローブ56を降下させて試料ホルダ60に接着させる。微小薄片試料59が試料ホルダ60に接触した時、プローブ56の降下は自動停止できる。

【0080】

次に、微小薄片試料59を試料ホルダ60に固定するためにデポジション用ガスを導入しつつ図10kのようにFIB52をデポジション膜61の一部が微小薄片試料59面に、一部は試料ホルダ60に付着するよう走査させた。本実施例でのデポジション膜61は、微小薄片試料59の長手方向の端辺に2μm平方程度に形成した。その後、プローブ56と微小薄片試料59を分離するためにデポジション膜57にFIB52'を照射する。

【0081】

デポジション膜57の除去後、プローブ56を試料ホルダ60から遠避ける。そこで、図10lのように、微小薄片試料を試料ホルダに確実に固定するために、微小薄片試料59の長手方向の他端辺に2μm平方程度のデポジション膜61'を形成する。

【0082】

(5)断面加工

これまでの操作により、注目部を含む微小薄片試料が試料ホルダに固定できた。次に、図10mのように固定された微小薄片試料59に対してFIB52を照射して、試料ホルダ60とともに側面を削除して凹部62を形成する。本例では凹部62の間口は約10μm、奥行約2μm、深さは約3μmとした。さらに、反対側面も削除して、中央部に厚さが約0.1μmの薄壁ができるように凹部形状62'に加工する(図10n)。

【0083】

図10oが完成した薄片試料の断面試料で、中央の薄壁部63の上部が微小薄片試料59の断面試料64で、実際、TEMもしくはSTEMで観察するのはこの部分で、高さ約0.1μm、幅約0.1μm、長さ約10μmの細線状になっている。参考のために、TEM観察時の入射する電子線65は、その方向を矢印で示したように、微小薄片試料59の表面にほぼ平行に入射する。

【0084】

このように、図9と図10で示した手順によって、薄片試料の断面を観察するための試料が作成できる。本方法によると、これらの工程がすべて真空雰囲気中で行なうため、不要な微粉末を付着されることが殆どなく、高精度に位置出しできる。

【0085】

(6)断面TEM観察

試料作製装置内で作製した上記断面薄片試料は試料ステージから取り外すことなく、試料ステージをTEMに差し入れる。この時、電子線経路と断面が垂直に交わるようにTEMステージを回転させることでTEM観察できる。その後のTEM観察技術についてはよく知られているのでここでは省略する。

【0086】

上記の試料作製手順は、TEM試料に限らず、EDX(電子線X線回折分析法)による元素分析や観察手法に用いることも可能である。

【0087】

(7)立体形状把握

上記(2)の工程で得られた平面TEM像と(6)の工程で得られた断面TEM像とを複合的に解釈して注目部の立体構造を推測することができる。このように、平面のみ、もしくは断面のみのTEM観察では解釈のつきにくい試料であっても、同一箇所を90°異なった方向から観察することによって、試料構造の正確な解釈ができるようになった。

【0088】

<実施例2>

本実施例は、本発明による試料作製装置に関し、図1の概略構成図を用いて説明する。

【0089】

試料作製装置1は、半導体チップや薄片試料、断面試料などの試料2の加工や観察をするFIB照射系3、このFIB照射によって照射部から放出する二次電子や二次イオンを検出する二次粒子検出器4、FIB照射領域にデポジション膜を形成するための材料ガスを供給するデポジションガス源5、試料2を載置する試料ステージ6、試料の一部を摘出した微小薄片試料を固定する試料ホルダ7、試料ホルダ7を保持する固定具8、微小薄片試料を試料ホルダに移し変える移送部9などを少なくとも有した構成である。

【0090】

さらに、試料ステージ6の位置を制御するためのステージ制御部10、移送部9を試料ステージ6と独立に駆動するための移送手段制御部11、計算処理部15、試料ホルダ7や試料2や移送部9などを表示する画像表示部16、FIB照射系2のFIB制御部13なども含む。

【0091】

上記計算処理部15は、ステージ制御部10、移送手段制御部11、二次粒子検出器制御部12、デポジションガス源制御部13、FIB制御部14、などを制御し、さらにはSIM画像情報やTEMからの画像情報の記憶や処理もできる。また、画像表示部16はSIM像の他に、TEM画像やTEM画像を処理した画像も表示でき、さらには、計算処理部15で処理してSIM像とTEM画像を重ねて表示することができる。TEMの画像情報はTEMに備えられた計算処理部19からネットワーク19‘を介して転送することも可能であるし、記憶媒体によって計算処理部15に導入してもよい。

【0092】

さらには、メインコンピュータを中心にしたネットワーク化され、メインコンピュータのデータベースに試料作製装置やTEMによる試料の形状や元素情報データをネットワークを経由して登録する機能を有している。これにより、SIM画像やTEM画像、さらには画像を処理した処理画像を一元管理することができると共に、試料作製装置やTEM、さらには他の計算処理部がネットワークを介してメインコンピュータのデータベースから画像情報などを呼び出すことができる。このため、試料作製装置やTEMに隣接した所で、画像合成や処理をする必要はなく、作業環境の異なる場所で、さらには、異なる情報を盛り込んで計算処理することができる。

【0093】

FIB照射系3は、液体金属イオン源、ビーム制限アパチャ、集束レンズ、対物レンズなどから構成され、上記イオン源から放出させたイオンを、数10nmから数μm径のFIB17とする。このFIB17を偏向器を用いて試料2上で走査させ、走査形状に対応したμmからサブμmレベルの加工を行う。ここでの加工とは、スパッタリングによる凹部形成や、FIBアシストデポジションによる凸部形成、もしくはそれらを組み合わせて試料形状を変形させる操作を指す。FIB照射によって形成するデポジション膜は、移送手段9の先端にあるプローブ56と試料2を接続したり、微小薄片試料を試料ホルダ7に固定するために使用する。ここで用いた試料ホルダは、本発明の試料作製装置において重要な構成品であるため、実施例3で詳細に説明する。

【0094】

試料ステージ6はサイドエントリ方式である。サイドエントリ式の試料ステージ6は試料室17の真空を開放することなく試料室17に挿入、設置できる。また、抜き出したい時も、試料室17の真空を破ることなく引き抜くことができる。本試料ステージ6は薄片試料2とこの薄片試料2から摘出した微小薄片試料を搭載できる構造であることが特徴である。

【0095】

なお、試料ステージ6の抜き挿し時の真空保持などの原理は、従来、走査型電子顕微鏡や透過型電子顕微鏡に用いられているサイドエントリ型ステージおよびその挿入口の原理とおなじである。しかし、薄片試料と微小薄片試料の両者について加工を施すため、試料ステージの軸方向にが少なくとも2箇所停止でき、それぞれの停止位置で試料の加工、観察をすることができる点で、従来のサイドエントリ型ステージと異なる。また、ここで用いた試料ステージ6については本発明による試料作成装置における重要な構成品であるため、詳細な構造については実施例3において詳述する。

【0096】

微小試料の移送部9はXYZの3軸に動く粗動機構部とZ方向に微動する微動機構から構成され、いずれも移送機構制御部11によって動作する。先端には微小薄片を摘出するためのプローブ56が設置されている。

【0097】

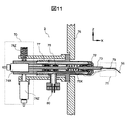

図11上記は移送部9をさらに詳しく説明するための図であり、粗動部70と微動部71から構成された例である。粗動部70は球体部72を支点として支柱73が3個のエンコーダ74X、74Y(図示せず)、74ZによってXYZ方向に移動できる。粗動ストローク、移動分解能はエンコーダの性能によるが、10mmのストローク、1μmの分解能はある。エンコーダによる力に抗する力はバネ75aなどによるが、ここでは詳細を省略する。粗動部70の駆動系は試料室壁76の横ポートを介して大気側にあり、真空はベローズ77、Oリング78によって遮断されている。

【0098】

微動部71はZ軸のみでバイモルフ圧電素子79を採用し、サブミクロンの移動分解能が得られる。バイモルフ圧電素子79の先端は直径30μm程度で、先端曲率半径は0.1μm程度に先鋭化した針状のタングステン製のプローブ56を固定した。バイモルフ圧電素子79は、数10V程度まで徐々に電圧を与えることでプローブ56先端はZ方向に微動できる。プローブ56との導通、および、バイモルフ圧電素子79への印加電圧は端子80を通じて行なう。

【0099】

このようなプローブ56を備えた移送部9およびFIB加工によって、薄片試料50の所望の箇所にサブμmレベルの正確さで接触して図9のように微小薄片試料59を摘出することができ、また、摘出した微小薄片試料59を正確に試料ホルダ60に固定することができる。

【0100】

上述の構成の試料作製装置1によって、TEM観察用の薄片試料50からさらに断面方向の微小な薄片試料を作製することができる。また、このような薄片試料から薄片断面試料の作製が実現することで、試料のサブμmレベルの注目部について2方向からの詳細な観察が可能となり、疑似的な立体評価ができるようになった。

【0101】

FIB照射部3の構成例については公知例2などに記載されている。さらにデポジション用ガス供給部5を装着し、ガスを先端のノズル5'から試料に導入しつつFIB走査することで走査領域にガス成分のデポジション膜を形成することができる。このデポジション膜は試料の表面保護等の役割を果たす。

【0102】

<実施例3>

本実施例は、本発明による試料作製装置における試料ステージ6の例に関し、試料室の真空度を悪化させることなく真空容器壁面から抜き挿しできるサイドエントリ式の試料ステージで、特に、TEMと試料作製装置に兼用の試料ステージであることが特徴である。

【0103】

本発明による試料ステージ6と従来のサイドエントリ式TEMステージやFIBステージとの大きな相違点は、TEM観察用の薄片試料を固定したメッシュもしくはメッシュホルダと、微小薄片試料を固定できる試料ホルダ7が搭載できる構造としたことである。TEM観察を終えた時、この試料ステージ6をTEMから引き抜いて試料作製装置に移し替え、試料作製装置で試料の加工が完了すれば再度TEMに導入して観察することができる。

【0104】

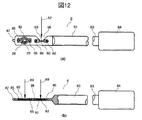

以下、図12を用いて説明する。図12aは試料ステージ6をFIB光学軸に垂直な方向から見た図で、図12bはイオン源側から見た図(図12(a)を90°軸回転させた状態)を示し、TEM観察時の電子線の通過方向は紙面に平行となる。

【0105】

試料ステージ6の概略構成については図4cで説明したが、本実施例で用いた試料ステージ6の特徴的なところは、薄片試料25'が設置されたメッシュ26を固定したメッシュホルダ82を搭載するためのメッシュホルダ設置部85と、その先端にTEM観察によって検出した注目部を摘出した微小試料を固定する試料ホルダ60を設置する試料ホルダ設置部86とを備えている点にある。なお、この小突起87を支える支持部が試料ステージ6の軸とほぼ同軸にあるが図示は省略している。

【0106】

メッシュホルダ82や試料ホルダ60はそれぞれの設置部85、86に固定される。試料ホルダ60における微小薄片試料59の設置面はメッシュ19面と平行な関係にある。また、試料ステージ6はステージ制御装置10(図1参照)によって3次元(X,Y,Z)方向移動および回転制御ができる。このように、本試料ステージ6は薄片試料25'を載置するメッシュホルダ82と摘出した微小薄片試料21を固定する試料ホルダ7が同一の試料ステージ6上に搭載できるサイドエントリ構造であることが最大の特徴である。また、試料ステージ6には、微小薄片試料59へのFIB52の入射を阻害しないように試料ホルダ7の上部88が開放状態であり、この試料ステージ6はTEMと試料作製装置の両方に搭載可能である。

【0107】

図12aの状態から90°軸回転させてTEMに導入する状態が図12bであり、電子線の入射方向を矢印89、89'で示した。このため、試料作製装置内で加工した観察試料を試料ステージの挿入口から抜き挿しするだけで、直ちにTEM観察することができ、しかも摘出前の薄片試料25'と加工後の微小薄片試料21もTEM観察できることも大きな特徴である。このような構造により、TEM観察用の薄片試料から摘出した微小薄片試料を別の特殊な試料加工装置や緊張と熟練を要する手作業を施すことなく、分析や観察に適した試料形状に加工して、試料ステージを抜き挿しするだけで、直ちに分析や観察作業に移ることができるようになった。

【0108】

さらに、図12には図示できなかったが、試料ステージ6にはメッシュホルダ82の回転機構を有しており、TEM観察しながら薄片試料25'を面内回転できる。この構造により、薄片試料25'の所望の注目部の向きを試料ステージ6の軸に平行に設定することができ、移送手段(図1参照)に回転等の複雑な動きをさせることなく、容易に薄片試料25'から摘出した微小薄片試料21を試料ホルダ60に移設できる。

【0109】

試料ステージ6は、試料ステージ挿入口からの導入の際、メッシュホルダ固定部および試料ホルダのそれぞれほぼ中央で一旦停止できる構造である。停止状態を試料ホルダ(摘出試料)からメッシュホルダ(薄片試料)に、またはその逆の操作を行なうには、試料ステージをわずかに押し込むか引き出せばよい。これにより試料ステージを設置する際、メッシュホルダまたは試料ホルダのいずれかが必ず視野に入る。このようにして、それぞれの停止位置でFIB照射やTEM観察など、目的とする領域を素早く視野中央に移動させることができる。また、中央部からずれている場合には、試料ステージ制御装置によってX,Y移動させて探索することができる。

【0110】

なお、試料ステージをメッシュホルダで停止させるか、試料ホルダで停止させるかの機構は公知の技術により容易に達成することができる。例えば、試料室の壁面側に設けた基準面と試料ステージの基準部との間隔の計測手段を設置しておくことで、試料ステージを所望の位置で停止させることができる。

【0111】

本方法では、元の薄片試料から観察試料を試料作製装置内で摘出できるため、従来の薄片試料の作製のような機械研磨が不要で、しかも摘出する試料がμmレベルであるため、例えば100μm平方の薄片試料から複数の微小試料を摘出して、各々の断面をTEM観察する試料を作ることができる。

【0112】

試料ホルダ60は、図9の薄片試料50から摘出した微小薄片試料59を固定して、TEM観察時に電子線が通過しやすくFIB加工するための部材である。従来のTEM観察におけるメッシュに相当する。

【0113】

本実施例で用いた試料ホルダの例について図13で説明する。図13aは試料ホルダ60の一実施例であり、凸状断面の短冊形状の、シリコンで形成された部材である。長さ約2mm、下部90の幅400μm、凸部91の幅は40μm程度である。特徴は凸部91の長手方向中央付近に沈み部92を設けて、この沈み部92の底面93に摘出した微小薄片試料59を固定する。この沈み部92は、固定した微小薄片試料59、または薄片化加工を行なった微小薄片断面試料が、試料ホルダ60の取り扱い時に破損しなように設けてある。また、固定のために微小薄片試料を沈み部92の底面93にプローブを操作してもプローブは周囲に接触することはない。沈み部92の寸法は、一例として、幅が約200μm、深さは約50μmである。

【0114】

図13bは微小薄片試料59を沈み部92の底面93のほぼ中央に設置し、薄壁加工を行なった様子を示している。その沈み部92を拡大したのが図13cである。微小薄片試料59の両側面をFIBによって削除して凹部62、62'を形成して、微小薄片試料59の一部を断面方向に薄壁加工する。TEM観察時の電子線の照射方向は図の矢印65のとおりである。ここに示した寸法は一例に過ぎないが、幅はプローブが接触しない程度でなるべく狭く、深さについても微小薄片試料59が確実に底面93に固定できる程度でなるべく深いことが望ましい。

【0115】

試料ホルダ60自体の断面は図13aの凸状に限定されることはなく、図13eのL字形状の断面で沈み部92に薄片台94を設置した形状でもよい。薄片台94は幅4μm、長さ20μm、高さ15μm程度で、プローブによる搬送とFIBアシストデポジション膜による接着を利用して設置できる。この薄片台94の上面に摘出した微小薄片試料59を固定する。この構造によってTEM観察時に、電子線65が沈み部92の底面93の凹凸の影響を受けることなく、微小薄片試料を照射、通過できる。

【0116】

さらには図13fのように半円形状の試料ホルダ60の直径方向の側面に沈み部92と薄片台94を設けた構造でも同じ効果を生む。これらの構造のポイントは微小な試料を固着させて、観察や解析の終了後、試料ホルダを保管したり再度観察を行なうなど、試料ホルダを取り扱う際に他の部材と接触などによる損傷を防ぐために、微小薄片試料の固定部を若干沈める(凹部を設けた)形状にしたことにある。また、電子線の通路を妨げないように、観察部への通路に障害物が突出しないような構造でもある。また、材質はシリコンに限定することなく、シリコンカーバイドなど導電性セラミック、モリブデン、タンタル、ニオブなどの金属などでもよい。

【0117】

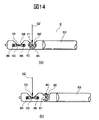

次に、図14を用いて試料ステージ6'の別の実施例を説明する。図14においては試料ステージ6'のうち特徴ある先端部のみを示し、グリップなどの記載は省略した。この試料ステージ6'は従来ダイシング装置とFIB加工によって加工した図7のTEM試料40のうち、薄片部であるTEM観察領域の断面をTEM観察することを実現する新たなサイドエントリ型試料ステージの形態である。

【0118】

構造的には、第1の試料ホルダ95と第2の試料ホルダ60を同時に搭載できるように各々の固定部を有し、さらに第1の試料ホルダ95が面内で回転できる構造が特色である。第1の試料ホルダ95は上記公知例2で説明したダイシングとFIB加工を用いて形成した断面TEM観察用試料40を設置するための治具で、一部が欠けたリングである。第2の試料ホルダ60は断面TEM観察試料40のうち断面TEM観察領域41から摘出した微小薄片試料59を固定する治具で、固定具86などによって固定される。ここで示す第2の

60は図13aで示した形状である。

【0119】

この試料ホルダ60の試料設置面(紙面に垂直)は断面TEM観察領域41の面(紙面に平行)とほぼ垂直の位置関係ある。ダイシングした短冊状試料を薄片加工するためのFIB52'が入射しやすくするためと、断面TEM観察領域41から摘出した微小薄片試料59を第2の試料ホルダ60に移送する場合に移送プローブの邪魔にならないようにそれぞれの試料ホルダ側面には切り欠き88、88'を設けた。試料ステージ6'をTEMもしくは試料作製装置のいずれかに導入すると、断面TEM観察用試料40または第2試料ホルダ60のいずれかのほぼ中央で一旦停止できる構造であるために、試料ステージ6'を設置すると、断面TEM観察領域41または微小薄片試料59のいずれかが必ず視野に入る。このようにして、それぞれの停止位置でFIB照射やTEM観察など目的とする領域を素早く視野中央に移動させることができる。また、中央部からずれている場合には、試料ステージ制御装置(図1の符号10)によってX,Y移動させて探索することができる。

【0120】

試料作製装置によって断面TEM観察用試料40の薄片加工を終えた後、試料ステージ6'を引き抜き、TEMに導入して観察領域41を観察する。TEM観察の結果、異常形態が観察されたとする。この異常形態を観察領域41面に平行な方向からその断面形状を観察するための試料を作製するために、この試料ステージ6'を試料作製装置に再度挿入して以下のような操作を行なう。

【0121】

第1の試料ホルダ95を90°回転させ、図14bのような位置関係に設定し、観察領域41から注目部41'を含む薄片を摘出する。断面TEM試料の薄片部からの微小試料の摘出方法、試料ホルダへの固定方法については後述する。摘出した微小薄片試料がプローブ先端(図示せず)に固着した状態で、一旦、試料ステージから退避させ、試料ホルダを軸中心に90°回転させる。この時、第2試料ホルダ60の試料設置面はFIB光学軸に垂直な関係になっている。そこで、プローブを第2の試料ホルダ60に接近させ、試料設置面に固定する。微小試料の固定方法も上記と同じである。プローブ切断後、微小薄片試料を薄片面に対して垂直に薄片加工する。垂直薄片加工についても上述同様である。薄片化にあたっては、試料ホルダもしくは高さ調整のための台も同時に加工しても構わない。加工終了後、試料ステージを引き抜き、TEMに導入して断面を観察することができる。

【0122】

上記のような試料ステージにより、薄片TEM試料において注目する部分の断面薄片試料を作製することができる。また、この一連の試料作製作業により平面TEM試料の断面、もしくはある方向の断面試料の側面を容易にTEM観察することができ、これまで薄片試料について、薄片に垂直な方向のみのTEM像のみから情報を得ていた微細構造や形状や欠陥について、同一試料を90°異なった方向からも観察できるため、上記微細構造や形状や欠陥を疑似的に立体解析でき、試料の構造に関して一方向からの観察だけでは明らかにならなかった新たな知見が得られるようになった。

【0123】

<実施例4>

本実施例は、本発明による試料作製方法の実施例のうち、FIBによって作製した断面TEM観察用試料をTEM観察して検出した注目部を90°観察方向を変えてさらに薄片の断面観察する例で、図15を用いて説明する。なお、試料ステージは図14に示したものであり、試料作製装置におけるFIB52'による断面薄片加工後の手順を説明する。

【0124】

(1)断面TEM観察

図15aのように従来方法で形成した断面TEM試料40のTEM観察領域41を電子線89が透過しやすいようにTEM観察領域41の向きを調整する。TEM観察領域41の厚さは0.1μm前後の薄片である。図中A部の拡大を図15bに示す。断面TEM観察の結果、注目部100をさらに詳細に観察するために、以下、注目部100を挟み、間隔約0.1μmに位置する面101、101'で切断してその断面からTEM観察するための試料作製を行なう。

【0125】

試料ステージをTEMから試料作製装置に移し替える。試料ステージの移動については、既に説明したようにサイドエントリ型ステージであるため、真空引きなどで時間をかけることなく容易にできる。試料作製装置に導入した試料ステージは、まず、微小薄片試料が摘出しやすいように、約90°回転補正して、面101、101'が摘出した微小試料を固定する試料ホルダに平行になるように設定する。(図15c参照)

(2)微小薄片試料の摘出

次に、図15dのように、注目部100を保護するためにTEM観察面41上の一部に保護膜53を形成する。また、摘出すべき薄片の周囲の一部をFIB52'によって切断するとともに、移送手段であるプローブ56の先端をTEM観察面41上の一部にデポジション膜57によって接続する。その後、さらにFIB52'の走査による切り込み54によって、TEM試料40から微小薄片試料59が分離できる。図15eは微小薄片試料59をプローブ56によって摘出した様子である。

【0126】

(3)微小薄片試料の固定

プローブ56の移動とともに試料ステージの移動によって、微小薄片試料59を試料ホルダ60の真下に位置させる。その後プローブを徐々に降下させて試料ホルダ60に接触させる。なお、試料ホルダ60の具体的形状については既に説明したので図15fでは微小薄片試料59の固定部である一部のみを図示した。次に、図15gのように試料ホルダ60と微小薄片試料59の固定はデポジション膜102によって行なう。両者の固定を行なった後、プローブを固定しているデポジション膜57をFIBによってスパッタ除去して微小薄片試料59とプローブ56を分離する。

【0127】

(4)微小薄片断面加工

次に、注目部100が残るようにFIB照射して両側を除去する。最終的に微小薄片試料59のうち、注目部100を含んで薄片幅0.1μm程度になるように加工する。このようにして、試料ホルダ60に固定された微小薄片試料59は断面観察用の薄片103となり、高さ約0.1μm、幅約0.1μm、長さ約10μmの細線状になっている。また、試料ホルダ60にはFIB走査によって凹部104、104'が形成されるが、これら凹部104、104'によってTEM観察時、電子線105は周囲の形状に影響されることなく目的とする薄片103を照射して注目部100を観察できる。

【0128】

(6)断面TEM観察

上記までの操作によって、薄片試料59の断面観察用の薄片103が完成し、この試料ステージをTEMに搭載して注目部100の観察ができる。

【0129】

(7)立体形状把握

本発明によれば、上記(1)で得られた断面TEM像と(6)で得られた90°観察方向の異なる断面TEM像とを複合的に解釈して注目部100の構造を疑似立体的に解釈することができる。このように、平面のみ、もしくは一面の断面のみのTEM観察では解釈のつきにくい試料であっても、同一箇所を90°異なった方向からもTEM観察できるようになったので、試料構造に関する知見が広がり、構造、形状により正確な解釈を下すことができるようになった。さらに、上記の試料作製手順は、TEM試料に限らず、他のEDX分析など元素分析にも用いることが可能である。

【0130】

【発明の効果】

本発明によると、薄片試料の注目部を平面方向と断面方向からTEMやSTEMで解析することができ、また、平面方向と断面方向からTEMやSTEMで解析するための試料作製することができる。さらには、上記解析やその解析を行なうための試料作製を実現するための試料作製装置を提供することができる。

【図面の簡単な説明】

【図1】本発明による試料作製装置の一実施例を示す概略構成図。

【図2】従来の研磨とイオンシニングを用いた断面試料作製方法の説明図。

【図3】従来のダイシングと集束イオンビーム加工を用いた試料作製方法の説明図。

【図4】従来のダイシングとFIB加工によるTEM試料の形状と試料ステージの説明図。

【図5】従来の研磨とイオンシニングを用いた平面試料の作製方法の説明図。

【図6】従来の微小試料を分離する方法の説明図。

【図7】従来の薄片試料の断面TEM観察を行なう試料作製方法の説明図。

【図8】本発明の一実施例による試料作製方法の説明説明図。

【図9】本発明の一実施例での微小薄片試料の摘出工程の説明図。

【図10】図9の続きの微小薄片試料の摘出工程の説明図。

【図11】本発明一実施例の試料作製装置の特に移送部の縦断面図。

【図12】本発明一実施例の試料作製装置の試料ステージ部の平面図および部分断面図。

【図13】本発明の一実施例の試料作製装置に用いた試料ホルダの実施例の説明図。

【図14】本発明の一実施例の試料作製装置の試料ステージの他の例を示す説明図。

【図15】本発明の一実施例の断面を観察するためのTEM試料作製方法の説明図。

【図16】本発明の試料作製方法おける摘出位置を決定する方法の説明図。

【符号の説明】

1…試料作製装置、2…試料、3…FIB照射部、4…二次粒子検出器、5…デポジションガス源、6,6'…試料ステージ、7,7'…試料ホルダ、8…固定具、9…移送手段、10…ステージ制御装置、11…移送手段制御装置、12…二次電子検出器制御装置、13…デポジションガス源制御装置、14…FIB制御装置、15…計算処理部、16…画像表示部、19…計算処理装置、19'…ネットワーク、45…薄片部、46…薄片試料、47…微小薄片試料、48…断面微小薄片試料、50…薄片試料、51…マーク、52…FIB、56…プローブ、59…微小薄片試料、60…試料ホルダ、64…断面試料、65…電子線、82…メッシュホルダ、89,89'…電子線、92…沈み部、94…微小台、95…第2の試料ホルダ、110…TEM像、111…内部欠陥、112,112'…表面異物、115…SIM像、120…合成像、121…摘出領域、122a,122b,122c…試料認識番号。[0001]

BACKGROUND OF THE INVENTION

The present invention provides a sample preparation method for observing a cross section of a target portion in a thin piece sample observed with a transmission electron microscope (TEM) or a scanning transmission electron microscope (STEM), and sample analysis for analyzing the target portion The present invention also relates to a method and an apparatus for realizing the sample preparation or analysis method.

[0002]

[Prior art]

The TEM is a microscope that observes a TEM image formed by magnifying the transmitted electron beam by irradiating the electron beam to a thin sample that can transmit electrons, for example, about 0.05 to 0.4 μm. It is a microscope which scans the electron beam focused on the above-mentioned thin piece sample, introduce | transduces the transmitted electron beam into a detector, and acquires a STEM image. In any case, shape information accumulated in the thickness direction of the thin sample can be obtained because the electron beam is transmitted through the thin sample, but since it can be observed with high resolution, it is used for material evaluation in many fields including semiconductors. .

[0003]

In the manufacture of semiconductor devices, defective parts such as foreign matters, shape defects, disconnections, and short circuits detected in a certain manufacturing process are analyzed immediately to find out the cause of the occurrence, and there are many defective elements unless countermeasures are taken. Produced and has a significant impact on profits for manufacturing companies. For this reason, in order to improve the manufacturing yield of the semiconductor device, the defective portion analysis is essential. Of the defect analysis methods, TEM and STEM play a major role in shape observation. In addition, TEM and STEM are equipped with analysis functions, enabling high-resolution elemental analysis and indispensable for semiconductor analysis. It has become.

[0004]

In analysis by TEM or STEM (hereinafter abbreviated as analysis, representative of observation, elemental analysis, and measurement), a sample (hereinafter abbreviated as a planar sample) and a cross section in a horizontal direction with respect to the surface of the sample such as a semiconductor wafer or chip Observation is performed on a sample in a direction (hereinafter abbreviated as a cross-sectional sample).

[0005]

For cross-sectional samples, a method has been performed in which a cross-section is mechanically exposed and thin sections are processed in the cross-sectional direction by polishing and ion thinning. Recently, a method of accurately processing a desired region into a cross-sectional slice sample using a focused ion beam (hereinafter abbreviated as FIB) has come to be performed.

[0006]

First, a sample preparation method using polishing will be described with reference to FIG. As shown in Fig. A, a mark is made on an area to be observed with respect to the

[0007]

In addition, a method for producing a cross-sectional TEM sample by FIB is described in, for example, ECG Kirk et al., In the collection of papers Microscopy of Semiconducting Materials 1989, Institute of Physics Series No. 100., p. 501-506 (Prior Art 1). Yes.

[0008]

Hereinafter, an example of manufacturing a cross-sectional TEM sample by FIB will be described with reference to FIG. Mark the area of the

[0009]

The

[0010]

Examples of the shape of the FIB-processed TEM sample are shown in FIGS. 4a and 4b. The cross-sectional shape is variously deformed, such as the convex shape in Fig. A and the L shape in Fig. B, but the basic point is to machine as thinly as possible to reduce the lower 30A and FIB machining area with some mechanical strength In the strip-

[0011]

The sample stage 6 includes a

[0012]

As for the FIB apparatus, for example, LRHarriott describes in detail a paper entitled “The technology of finely focused ion beams” in the paper “Nuclear Instruments and Methods in Physics Research B55 (1991) p.802-p.810 (known example 2)”. It is stated. FIB is an ion beam in which ions emitted from a liquid metal ion source are focused to a diameter of several tens of nanometers by an aperture and an electrostatic lens, and this FIB is irradiated by deflecting and scanning a predetermined area of the sample surface with a deflection electrode. The surface can be sputtered according to the scanning shape to form a recess. Furthermore, by installing a gas supply unit in the FIB device and performing FIB scanning while introducing deposition gas and reactive gas, a deposition film of gas components can be formed in the scanning area, or at high speed Etching can be performed.

[0013]

On the other hand, a typical conventional method relating to a method for producing a planar sample will be described with reference to FIG. The sample is a wafer-like sample, and the analysis region is a specific region of the wafer and a 0.5 μm square region at a depth of about 1 μm from the surface. First, as shown in FIG. A, the

[0014]

The polishing jig (not shown) is bonded and fixed with the cut surface 21B (FIG. C) of about 1 mm square including the desired observation area of the

[0015]

In order to make this

[0016]

The

[0017]

Regarding the method of preparing a flat sample, for example, H. Cerva et al. In “Ultramicroscopy”, Vol. 52, (1993) 127-140 (Ultramicroscopy, 52 (1993) 127-140) “Specific preparation procedures”. Forn failure analysis of (sub) micron areas in silicon devices "(known example 3) is described in detail.

[0018]

There is a method for producing a TEM sample without cleaving the wafer. In the cross-sectional sample preparation method according to the above-described known example 2, the wafer must be cut, strip-shaped pellets including a desired analysis region must be prepared, and FIB processing must be performed. On the other hand, regarding a method of separating a part of the above sample into a TEM sample without cleaving the original sample such as a wafer, Japanese Patent Application Laid-Open No. 5-52721 “Sample separation method and separation obtained by this separation method” It is disclosed in “Analysis Method of Sample” (Known Example 4). This method is a method of separating a micro sample piece including a desired analysis region from a sample such as a wafer by using FIB processing and a micro sample transport means. By introducing the micro sample separated by this method into various analysis apparatuses, it is possible to analyze the defective portion without cleaving the original sample such as a wafer.

[0019]

This will be described with reference to FIG. First, by making the

[0020]

A manipulator (not shown) is driven, and the tip of the

[0021]

Furthermore, as another method for producing a TEM sample without cleaving the wafer, there is a method of extracting a micro sample using FIB and a probe. LA Giannuzzi, JLDrown, SRBrown, RBIrwin, and FAStevie in “Materials Research Society, Symposium Proceedings, vol.480 Specimen Preparation for Transmission Electron Microscopy 4”, “Focused Ion Beam Milling and Micromanipulation Lift Out for Site Specific Cross Section TEM Specimen This is shown in a paper entitled “Preparation” (Prior Art 5). In this state, the desired observation part is processed into a thin piece by FIB and separated from the sample substrate with respect to the sample substrate, the sample substrate is taken out into the atmosphere, and the needle-like probe is placed under the optical sample under the optical sample. In this method, a thin sample is adsorbed by electrostatic force and transferred to a mesh for TEM observation.

[0022]

In addition, F. Shaapur, T. Stark, T. Woodward., And RJGraham have also described “Evaluation of a new strategy for transverse TEM specimen preparation by focused Ion Beam Thinning” (p.173-180 of the same document as in known example 5) ( It shows a paper entitled Known Example 6). Also in this method, the same method as in known example 5 is used.

[0023]

[Problems to be solved by the invention]

Normally, images obtained by TEM or STEM are images that have passed through a thin sample, so that information in the thickness direction of the thin sample appears to overlap. For this reason, it is difficult to accurately analyze the shape of the thin sample in the thickness direction. In particular, the structure of recent semiconductor devices is so fine that it enters a thin sample of about 0.2 μm. For example, the smallest plug will enter a thin sample having a diameter of about 0.1 μm and a thickness of 0.2 μm. In addition, once a thin piece sample is prepared, the shape in the thickness direction cannot be grasped because the viewing angle cannot be changed from a right angle, and the plug shape cannot be accurately interpreted from the TEM image. It ends in. Furthermore, even if the two-dimensional distribution of the flakes is clarified using elemental analysis means such as EDX, the three-dimensional element distribution of the previous plug cannot be grasped.

[0024]

Therefore, if a method capable of observing from the cross-sectional direction of the thin sample for the same observation spot observed in plan for the thin sample for TEM observation is realized, the structure in the thin sample as described above is three-dimensionally formed. It is very effective in grasping. Therefore, it is very important to realize a simple and reliable method for producing a cross-sectional sample of a thin piece sample, an apparatus therefor, and a sample analysis method using such a flat and cross-sectional sample.

[0025]

When a cross-sectional sample is produced from a thin sample or a thin piece produced by polishing or the like with the current technology, a

[0026]

In this method, the cross-sectional thin sample 44 'must also be processed to a thickness of about 0.1 to 0.2 μm, and the desired

[0027]

The known example 2 has an advantage that the cross-section flakes can be manufactured in a short time with higher processing accuracy than the conventional polishing method. However, once a conventional TEM sample as shown in FIG. 4a is produced, in order to process the cross-section of the thin piece portion 28 'so that it can be observed by TEM, TEM observation cannot be performed unless both sides (

[0028]

In the known example 4, once the sample is set on the sample stage, it is not necessary for a human to directly perform manual work until separation of a minute sample, and it is not necessary to cut the wafer unnecessarily. However, in this method, since the separated sample piece is supported by the probe, in order to form a cross section of the thin piece portion, the position of the probe must be controlled in a complicated manner. In addition, it is not easy to introduce a probe into a TEM in order to observe the formed cross section because of limitations on the positional relationship and angle relationship between the observation surface and the probe. Furthermore, when the bottom hole 33B is formed, the sample stage must be tilted as much as 70 °, and a sample stage on which a large-diameter wafer is placed is not practical in terms of structure and accuracy.

[0029]

In addition, in the known examples 5 and 6, the thin piece of the target portion can be taken out of the sample substrate by electrostatic force, but since the extracted thin piece sample is attached to the mesh with an adhesive, it cannot be reprocessed. ing. That is, the processing for observing the cross section of the thin sample observed by TEM cannot be performed. In addition, these methods have a problem that the observation part of the thin sample is unfortunately overlapped with the mesh because it is an operation of attaching the extracted sample to the mesh under an optical microscope. Further, as described in the known examples 5 and 6, the sample is adsorbed by the electrostatic force with the probe, so that there is a defect that the adsorption is not reliable.

[0030]

As described above, in spite of many conventional techniques, there is no simple and reliable sample preparation method for observing the cross section of the thin sample, and it is difficult to observe the cross section easily.

[0031]

Therefore, in view of the above-mentioned problems of the prior art, a first object of the present invention is to perform a sample analysis method for observing and analyzing a target portion of a thin sample with a TEM or STEM from a horizontal direction and a cross-sectional direction. The second purpose is to provide a sample preparation method for observing a cross section of a target portion in a thin piece sample to be observed by TEM or STEM. Further, as a third purpose, An object of the present invention is to provide a sample preparation apparatus for realizing the first object or the second object.

[0032]

[Means for Solving the Problems]

The first object is realized by a sample analysis method having the following configuration.

[0033]

(1) Planar observation process for observing a thin piece sample with a transmission electron microscope (hereinafter referred to as TEM) or a scanning transmission electron microscope (hereinafter referred to as STEM), and extracting a thin thin piece sample including a desired portion of interest from the thin piece sample By a method including at least a cross-sectional thin piece processing step of processing the micro thin sample into a cross-sectional sample perpendicular to the surface of the thin sample, and a cross-sectional observation step of observing the micro cross-sectional sample by TEM or STEM, A sample analysis method for analyzing the target portion from a plane direction and a cross-sectional direction.

[0034]

(2) A thin piece processing step for processing a sample into a thin piece sample, a planar observation step for observing the thin piece sample by TEM or STEM, an extraction step for taking out a fine thin piece sample including a desired target portion from the thin piece sample, and the above An adhering step for adhering a micro thin sample to a sample holder, a cross-sectional thin piece processing step for processing into a cross-sectional sample perpendicular to the surface of the thin sample, and a cross-sectional observation step for observing the micro cross-sectional sample by TEM or STEM The sample analysis method which analyzes the said attention part from a plane direction and a cross-sectional direction by the method of including.

[0035]

(3) Planar observation process for observing a thin piece sample mounted on a side entry type sample stage by TEM or STEM, and a microscopic part including a desired target portion from the thin piece sample mounted on a sample preparation device for processing the thin piece sample Extraction step for taking out the thin sample, fixing step for fixing the micro thin sample on the sample holder previously mounted on the sample stage, and production of a cross-sectional thin sample perpendicular to the surface of the thin sample on the sample holder A sample analysis method comprising: a cross-sectional slice processing step to perform; and a cross-section observation step of observing the cross-sectional slice sample by introducing the sample stage into the TEM or STEM.

[0036]

(4) In particular, whether the cross-section slice processing step of the sample analysis method of any one of (1) to (3) above is performed by focused ion beam irradiation,

(5) The extraction process and the fixing process in the sample analysis method of (2) or (3) are performed by irradiation with a focused ion beam.

[0037]

(6) In the above method, the above attention is obtained by the image information by TEM observation or STEM observation in the planar direction of the target portion of the thin sample and the image information by TEM observation or STEM observation of the cross section of the target portion of the thin sample. Sample analysis method to grasp the pseudo three-dimensional shape of the part.

[0038]

(7) In the above method, the information on the target portion of the flake sample is simulated by the TEM analysis or STEM analysis, and the information on the cross section of the target portion of the flake sample is analyzed by the TEM analysis or STEM analysis. A sample analysis method to grasp the three-dimensional element composition.

[0039]

The sample preparation as the second object is realized by a method having the following configuration.

[0040]

(8) Extracting the minute thin piece sample including the attention part from the thin piece sample to be observed or analyzed by TEM or STEM, and observing the attention part from a direction parallel to the surface of the thin piece sample. A sample preparation method in which processing is performed so that electrons can be transmitted in the direction of a thin sample surface.

[0041]

(9) An extraction step of taking out a minute thin piece sample including a target portion from a thin piece sample through which electrons can pass, a fixing step of fixing the extracted minute thin piece sample to another member, and a part of the thin piece sample A sample preparation method in which a cross-sectional thin sample having a thickness that allows electrons to pass through is processed.

[0042]

(10) A thin piece processing step for processing the target sample into a thin piece sample through which electrons can permeate, a flat TEM observation step for observing the thin piece sample by TEM or STEM, and a desired target portion from the thin piece sample An extraction step of taking out a minute thin piece sample containing, an adhering step of adhering the minute thin piece sample to a sample holder, an electron permeation that is substantially perpendicular to the surface of the minute thin piece sample including a target portion of the minute thin piece sample A sample preparation method including a cross-section processing step of processing into a thin-section sample having a thin cross-section.

[0043]

(11) An extraction process for extracting a part of the thin TEM sample including the target portion from the thin sample for TEM observation mounted on the side entry type sample stage, and the fine thin piece on the sample holder previously mounted on the sample stage. A fixing step for fixing the sample, and a cross-section processing step for processing into a cross-sectional thin sample of a thickness that is perpendicular to the surface of the micro thin sample and includes a target portion of the micro thin sample, and is thin enough to transmit electrons. Including a sample preparation method.

[0044]

(12) The sample preparation method, wherein the processing of the thin sample and the fine thin sample in (9) or (11) includes at least processing with a focused ion beam.

[0045]

(13) The sample preparation method in which the thin piece sample and the cross-sectional thin piece sample in any one of (9) to (12) are thin piece samples for observation or analysis by TEM or STEM.

[0046]

(14) The extraction process according to any one of (9) to (13) described above is a process in which a protective film is formed in a region including the target portion, and a focused ion beam is irradiated around the region including the protective film. The process of processing into a cantilever sample held by a part of the thin sample, the process of fixing the conveying means to the cantilever sample, and the process of separating the cantilever sample from the thin sample A sample preparation method including at least.

[0047]

(15) The fixing process in any one of (9) to (13) above, or the process of fixing the transport means to the cantilever sample in (14) is based on a local deposition film using a focused ion beam and a deposition gas. A sample preparation method that is adhesion.

[0048]

(16) The extraction process in any one of (9) to (13) above is performed by using a TEM or STEM image of the thin sample obtained by TEM or STEM observation and a secondary of the thin sample obtained by irradiation with a focused ion beam. A sample preparation method including a process of superimposing an electronic image and specifying a position of the target portion.

[0049]

(17) The extraction step in any one of (9) to (13) described above is a process of storing a TEM or STEM image of the thin sample including the target portion and a characteristic pattern of the TEM image or STEM image. A calculation process for forming a line, and a process for identifying the position of the desired target portion by superimposing the secondary electron image of the surface of the thin sample obtained by irradiation of the focused ion beam and the contour line. Including a sample preparation method.

[0050]

The third object is realized by an apparatus having the following configuration.

[0051]

(18) A focused ion beam irradiation unit that irradiates a desired region of a thin sample with a focused ion beam, a secondary particle detector that detects secondary particles generated from the sample by irradiation with the focused ion beam, and the focusing A deposition gas supply source for forming a deposition film in the ion beam irradiation region, a sample stage on which the thin sample is placed, and a minute thin sample obtained by separating a part of the thin sample are transferred to another member. A sample preparation device having a transfer unit and a sample holder holding unit for holding a sample holder on which the micro thin sample is placed.

[0052]

(19) The sample stage of (18) is a sample preparation device having a structure having a mesh holder fixing portion for attaching a mesh holder for fixing a TEM mesh, or (20) the sample stage of (18) is a mesh A sample preparation device which is a side entry type sample stage having a holder fixing portion and the sample holder holding portion.

[0053]

(21) The sample preparation device according to (20), wherein the sample fixing unit is a fixing unit for attaching a mesh holder for fixing a TEM mesh on which a thin sample is mounted.

[0054]

(22) In any one of the above (18) to (21), in particular, the sample preparation device in which the surface on which the micro sample is placed in the sample holder and the surface of the mesh are in a parallel positional relationship.

[0055]

(23) The sample preparation device in which the side entry type sample stage in (20) is a structure that can be inserted and removed in common with at least one of TEM or STEM and the sample preparation device.

[0056]

(24) In the above (18), it has a calculation processing unit for receiving TEM image information by TEM or STEM, or

(25) In the above (18), it has a calculation processing unit for receiving image information by TEM or STEM stored in a computer via a network, or

(26) In (18), at least the TEM image information and the secondary particle image information by irradiation with the focused ion beam are stored, and at least a composite image obtained by superimposing the TEM image information and the secondary particle image information is formed. A sample preparation apparatus comprising: a calculation processing unit to be created; and an image display unit that displays at least one of the TEM image information, the secondary particle image information, or a composite image of both.

[0057]

The sample preparation apparatus as the third object is as follows.

(27) The sample preparation system may include a sample preparation device, a TEM or STEM, a computer, the sample preparation device, and a network connecting the TEM or STEM and the computer.

[0058]

Furthermore, as a sample holder for realizing the sample preparation apparatus which is the third object,

(28) A sample holder for a TEM or STEM for fixing a micro thin sample obtained by separating a desired part of a thin sample, in particular, a prismatic shape or a shape having an arc portion, or

(29) The prismatic cross section in (28) above is particularly convex, L-shaped or rectangular, or

(30) The location for fixing the microlamellar sample in (28) or (29) above is a recess provided in a substantially central portion in the longitudinal direction of the sample holder, or

(31) In the above (30), in particular, a sample holder in which a support base lower than the depth of the recess and thinner than the width of the sample holder is installed at the bottom of the recess to fix the micro thin sample is preferable. It is.

[0059]

Moreover, as a form of the sample for achieving the third object,

(32) It is preferable that the sample to be observed or analyzed from at least two perpendicular directions by TEM or STEM is a sample processed into a shape including a square column having a height of 0.4 μm or less, a width of 0.4 μm or less, and a length of 1 μm or more. It is.

[0060]

DETAILED DESCRIPTION OF THE INVENTION

In the embodiment of the sample analysis method according to the present invention, after observing or analyzing a desired region of a thin sample that can transmit electrons by TEM or STEM, the desired portion of the thin sample is further converted into a cross-sectional thin piece. It is a method of processing and observing or analyzing with TEM or STEM.

[0061]

Specific examples of the present invention will be described below, and further, examples of the sample preparation method and sample preparation apparatus according to the present invention will be described with reference to FIGS. 9 to 16. Here, the terms are first unified. This will be described with reference to FIG.

[0062]

As shown in FIG. 8a, a sample having a

[0063]

Here, the symbol D is the incident direction of the electron beam when the

[0064]

<Example 1>

The sample analysis method of the present invention will be described with reference to FIGS. 9 and 10 with examples. In this example, as a result of performing electrical inspection on the semiconductor device for which the manufacturing process has been completed, a malfunctioning portion is detected, planar TEM observation is performed on the defective portion, and defects found by observation are further observed in the cross-sectional direction (planar TEM). An example of observation from the side direction of the sample will be described. Hereinafter, in order to clarify the procedure of the sample analysis method, it is divided into several steps and explained.

[0065]

(1) Thin section processing for planar TEM

First, with respect to a semiconductor device, coordinate information of a malfunctioning portion (hereinafter collectively referred to as a target portion) is stored by an electrical inspection device such as a prober. The storage of the coordinate information is stored in the calculation processing device as the coordinate information of the defective portion with reference to the chip mark previously set on the chip. Based on this coordinate information, out of the chip (about 8mm x 15mm), a small piece of about 1mm square including the target part is mechanically cut out from the back of the chip using the conventional technique as shown in Fig. 4 By flattening and ion thinning, the flattened TEM sample is made into thin pieces until the thickness of the target portion becomes about 0.1 μm. This thin sample is attached to a mesh and mounted on a TEM stage. Since the structure of the TEM stage is an important part of the present invention, it will be described in detail in a later embodiment.

[0066]

(2) Planar TEM observation

A TEM stage is introduced into a TEM or STEM for observation. The TEM observation method is known and will not be described in detail here. As a result of observing the same coordinate area with the TEM based on the coordinate information of the defective part previously stored by observation, it is assumed that a minute linear defect having a length of about 3 nm is found in the visual field. TEM image information obtained by planar TEM observation is stored in the TEM calculation processing unit from low magnification to high magnification. The calculation processing unit can process the TEM image information as necessary to display the target portion and other characteristic structures and forms in outlines. Furthermore, the acquired TEM image can be subjected to processing such as enlargement / reduction, front / back reversal and left / right reversal, and can be stored.

[0067]

(3) Extraction of small thin sample

This step is an operation of setting a sample stage in a sample preparation apparatus and extracting a minute thin piece sample including a target portion from the above thin piece sample. This process will be described with reference to FIG.

[0068]

FIG. 9a shows a

[0069]

Here, a method for determining the machining position will be described with reference to FIG. FIG. 16a is a TEM image. In the observation

[0070]

FIG. 16b is a SIM image. The

[0071]

FIG. 16c is a

[0072]

In the above image processing, in order to distinguish the sample or image from the TEM image or SIM image, for example,

[0073]

Based on the

[0074]

FIG. 9b shows an example of how to attach the

[0075]

Next, as shown in FIG. 9c, a

[0076]

Next, a sample separation step is entered. As shown in FIG. 9d, a cantilever-

[0077]

Next, the

[0078]

Thereafter, as shown in FIG. 9g, the

[0079]

(4) Fixing of small thin sample

This step is an operation of fixing the extracted minute

[0080]

Next, while introducing a deposition gas to fix the micro

[0081]

After the

[0082]

(5) Cross-section processing

By the operation so far, the micro thin sample including the target portion can be fixed to the sample holder. Next,

[0083]

FIG. 10o is a cross-sectional sample of the completed thin sample, and the upper part of the central

[0084]

In this way, a sample for observing the cross section of the thin sample can be prepared by the procedure shown in FIGS. According to this method, since all these steps are performed in a vacuum atmosphere, unnecessary fine powder is hardly attached and positioning can be performed with high accuracy.

[0085]

(6) Cross-sectional TEM observation

The sample stage is inserted into the TEM without removing the cross-sectional thin sample prepared in the sample preparation apparatus from the sample stage. At this time, TEM observation can be performed by rotating the TEM stage so that the electron beam path and the cross section intersect perpendicularly. Since the subsequent TEM observation technique is well known, it is omitted here.

[0086]

The sample preparation procedure described above is not limited to a TEM sample, and can be used for elemental analysis and observation techniques using EDX (electron beam X-ray diffraction analysis).

[0087]

(7) Grasping three-dimensional shape

The planar structure obtained in the step (2) and the cross-sectional TEM image obtained in the step (6) can be interpreted in a complex manner to estimate the three-dimensional structure of the target portion. In this way, even for a sample that is difficult to interpret by TEM observation of only a plane or a cross-section, it is now possible to accurately interpret the sample structure by observing the same part from 90 ° different directions. .

[0088]

<Example 2>

This example relates to a sample preparation apparatus according to the present invention and will be described with reference to the schematic configuration diagram of FIG.

[0089]

The

[0090]

Furthermore, a

[0091]

The

[0092]

Furthermore, it is networked around the main computer, and has a function of registering the shape of the sample and the element information data obtained by the sample preparation device and the TEM via the network in the database of the main computer. This makes it possible to centrally manage SIM images, TEM images, and processed images that have been processed, and also allows sample preparation devices, TEMs, and other calculation processing units to capture images from the main computer database via a network. Information can be called. For this reason, it is not necessary to perform image synthesis or processing at a location adjacent to the sample preparation device or TEM, and calculation processing can be performed by incorporating different information at different locations in the work environment.

[0093]

The FIB irradiation system 3 includes a liquid metal ion source, a beam limiting aperture, a focusing lens, an objective lens, and the like. The ions emitted from the ion source are

[0094]

The sample stage 6 is a side entry method. The side entry type sample stage 6 can be inserted and installed in the

[0095]

Note that the principle of holding the vacuum when the sample stage 6 is inserted and removed is the same as the principle of the side entry type stage and its insertion port conventionally used in a scanning electron microscope and a transmission electron microscope. However, since both the thin sample and the micro thin sample are processed, the axial direction of the sample stage can be stopped at least two places, and the sample can be processed and observed at each stop position. Different from the entry type stage. Since the sample stage 6 used here is an important component in the sample preparation apparatus according to the present invention, the detailed structure will be described in detail in Example 3.

[0096]

The micro

[0097]

FIG. 11 is a diagram for explaining the

[0098]

The

[0099]

By the

[0100]

With the

[0101]

A configuration example of the FIB irradiation unit 3 is described in the known example 2 and the like. Further, a deposition gas supply unit 5 is mounted, and a gas component deposition film can be formed in the scanning region by performing FIB scanning while introducing gas into the sample from the nozzle 5 ′ at the tip. This deposition film plays the role of protecting the surface of the sample.

[0102]

<Example 3>

The present embodiment relates to an example of the sample stage 6 in the sample preparation apparatus according to the present invention, and is a side entry type sample stage that can be inserted and removed from the wall surface of the vacuum vessel without deteriorating the degree of vacuum of the sample chamber. It is characterized by a sample stage that is also used as an apparatus.

[0103]

The major difference between the sample stage 6 according to the present invention and the conventional side entry type TEM stage or FIB stage is that a mesh or mesh holder to which a thin sample for TEM observation is fixed and a sample holder 7 to which a fine thin sample can be fixed are mounted. This is a possible structure. When the TEM observation is completed, the sample stage 6 is pulled out of the TEM and transferred to the sample preparation device. When the sample preparation is completed by the sample preparation device, the sample stage 6 can be introduced into the TEM again and observed.

[0104]

Hereinafter, a description will be given with reference to FIG. 12a is a view of the sample stage 6 viewed from a direction perpendicular to the FIB optical axis, and FIG. 12b is a view of the sample stage 6 as viewed from the ion source side (a state in which FIG. 12 (a) is rotated by 90 ° axis). The passing direction of the electron beam at that time is parallel to the paper surface.

[0105]

Although the schematic configuration of the sample stage 6 has been described with reference to FIG. 4c, a characteristic point of the sample stage 6 used in this embodiment is that a

[0106]

The

[0107]

FIG. 12b shows a state where the shaft is rotated 90 ° from the state shown in FIG. 12a and introduced into the TEM, and the incident direction of the electron beam is indicated by

[0108]

Furthermore, although not shown in FIG. 12, the sample stage 6 has a rotating mechanism of the

[0109]

The sample stage 6 has a structure capable of temporarily stopping at approximately the center of each of the mesh holder fixing portion and the sample holder when being introduced from the sample stage insertion port. In order to perform the operation of stopping from the sample holder (extracted sample) to the mesh holder (thin sample) or vice versa, the sample stage may be slightly pushed in or pulled out. Thus, when the sample stage is set, either the mesh holder or the sample holder always enters the field of view. In this way, the target area such as FIB irradiation or TEM observation can be quickly moved to the center of the visual field at each stop position. Further, when the position is deviated from the central portion, it can be searched by moving the X and Y by the sample stage control device.

[0110]

A mechanism for stopping the sample stage with the mesh holder or the sample holder can be easily achieved by a known technique. For example, the sample stage can be stopped at a desired position by installing a means for measuring the distance between the reference surface provided on the wall surface side of the sample chamber and the reference portion of the sample stage.

[0111]

In this method, since the observation sample can be extracted from the original thin sample in the sample preparation device, mechanical polishing like the preparation of the conventional thin sample is unnecessary, and the sample to be extracted is at the μm level. A plurality of micro samples can be extracted from the thin sample, and a sample for TEM observation of each cross section can be made.

[0112]

The

[0113]

An example of the sample holder used in this example will be described with reference to FIG. FIG. 13a shows an embodiment of the

[0114]

FIG. 13 b shows a state in which a thin

[0115]

The cross section of the

[0116]

Furthermore, the same effect can be obtained with a structure in which a sinking

[0117]

Next, another embodiment of the sample stage 6 ′ will be described with reference to FIG. In FIG. 14, only the characteristic tip portion of the sample stage 6 ′ is shown, and descriptions of grips and the like are omitted. This sample stage 6 'is a new side entry type sample stage configuration that realizes TEM observation of the cross section of the TEM observation region which is a thin piece portion of the

[0118]

Structurally, the

[0119]

The sample placement surface of the sample holder 60 (perpendicular to the paper surface) is in a substantially vertical positional relationship with the surface of the cross-sectional TEM observation region 41 (parallel to the paper surface). In order to facilitate the incidence of

[0120]

After processing the slice of the cross-sectional

[0121]

The

[0122]

By the sample stage as described above, a cross-sectional thin piece sample of a portion of interest in the thin piece TEM sample can be produced. In addition, this series of sample preparation operations enables easy TEM observation of the cross-section of a flat TEM sample or the side of a cross-sectional sample in a certain direction. Since the same sample can be observed from 90 ° different directions with respect to the microstructure, shape, and defects for which information has been obtained, the above microstructure, shape, and defects can be simulated in three dimensions, and the sample structure can be observed from one direction. New knowledge that was not clarified by observation alone can be obtained.

[0123]

<Example 4>

This example is an example of a sample preparation method according to the present invention, in which a cross section TEM observation sample prepared by FIB is observed by TEM observation and the target portion detected by changing the observation direction by 90 ° is further observed in a cross section of a thin piece This will be described with reference to FIG. Note that the sample stage is as shown in FIG. 14, and the procedure after the cross-section flake processing by the

[0124]

(1) Cross-sectional TEM observation

As shown in FIG. 15a, the orientation of the

[0125]

The sample stage is transferred from the TEM to the sample preparation device. As described above, the movement of the sample stage is a side entry type stage, so that it can be easily performed without taking time by evacuation or the like. First, the sample stage introduced into the sample preparation device is rotated approximately 90 ° so that the minute thin piece sample can be easily extracted, and the

(2) Extraction of small thin sample

Next, as shown in FIG. 15d, a

[0126]

(3) Fixing of small thin sample

By moving the sample stage together with the movement of the

[0127]

(4) Micro thin section processing

Next, both sides are removed by FIB irradiation so that the

[0128]

(6) Cross-sectional TEM observation

Through the above operation, the

[0129]

(7) Grasping three-dimensional shape

According to the present invention, the cross-sectional TEM image obtained in the above (1) and the cross-sectional TEM image obtained in (6) with different 90 ° observation directions are interpreted in a complex manner, and the structure of the

[0130]

【The invention's effect】

According to the present invention, a target portion of a thin sample can be analyzed by a TEM or STEM from a plane direction and a cross-sectional direction, and a sample can be prepared for analysis by a TEM or STEM from a plane direction and a cross-sectional direction. Furthermore, it is possible to provide a sample preparation apparatus for realizing the above analysis and sample preparation for performing the analysis.

[Brief description of the drawings]

FIG. 1 is a schematic configuration diagram showing an embodiment of a sample preparation apparatus according to the present invention.

FIG. 2 is an explanatory view of a cross-sectional sample manufacturing method using conventional polishing and ion thinning.

FIG. 3 is an explanatory diagram of a sample preparation method using conventional dicing and focused ion beam processing.

FIG. 4 is an explanatory view of the shape and sample stage of a TEM sample by conventional dicing and FIB processing.

FIG. 5 is an explanatory diagram of a method for manufacturing a planar sample using conventional polishing and ion thinning.

FIG. 6 is an explanatory diagram of a conventional method for separating a micro sample.

FIG. 7 is an explanatory view of a sample preparation method for performing cross-sectional TEM observation of a conventional thin piece sample.

FIG. 8 is an explanatory diagram for explaining a sample preparation method according to an embodiment of the present invention.

FIG. 9 is an explanatory view of a process for extracting a minute thin piece sample in one embodiment of the present invention.

FIG. 10 is an explanatory diagram of a process for extracting a minute thin piece sample continued from FIG. 9;

FIG. 11 is a longitudinal cross-sectional view of a sample preparation apparatus of an embodiment of the present invention, particularly a transfer section.

FIGS. 12A and 12B are a plan view and a partial cross-sectional view of a sample stage portion of a sample preparation apparatus according to an embodiment of the present invention. FIGS.

FIG. 13 is an explanatory diagram of an example of a sample holder used in the sample preparation device of one example of the present invention.

FIG. 14 is an explanatory view showing another example of the sample stage of the sample preparation device according to the embodiment of the present invention.

FIG. 15 is an explanatory diagram of a TEM sample manufacturing method for observing a cross section of an example of the present invention.

FIG. 16 is an explanatory diagram of a method for determining the extraction position in the sample preparation method of the present invention.

[Explanation of symbols]

1 ... Sample preparation device, 2 ... Sample, 3 ... FIB irradiation unit, 4 ... Secondary particle detector, 5 ... Deposition gas source, 6,6 '... Sample stage, 7,7' ... Sample holder, 8 ... Fixed 9 ... Transport means, 10 ... Stage control device, 11 ... Transport means control device, 12 ... Secondary electron detector control device, 13 ... Deposition gas source control device, 14 ... FIB control device, 15 ... Calculation processing unit , 16 ... Image display unit, 19 ... Computer, 19 '... Network, 45 ... Thin piece part, 46 ... Thin piece sample, 47 ... Fine thin piece sample, 48 ... Cross-section fine thin piece sample, 50 ... Thin piece sample, 51 ... Mark, 52 ... FIB, 56 ... Probe, 59 ... Small flake sample, 60 ... Sample holder, 64 ... Cross-section sample, 65 ... Electron beam, 82 ... Mesh holder, 89,89 '... Electron beam, 92 ... Sink part, 94 ... Small Table, 95 ... Second sample holder, 110 ... TEM image, 111 ... Internal defect, 112, 112 '... Surface foreign matter, 115 ... SIM image, 120 ... Composite image, 121 ... Extraction area, 122a, 122b, 122c ... Sample Recognition Identification number.

Claims (9)

透過型電子顕微鏡もしくは走査型透過電子顕微鏡で観察可能な薄片試料を載置できる試料ステージと、

前記真空試料室内の前記薄片試料に集束イオンビームを照射する照射光学系と、

前記真空試料室内にある前記薄片試料に前記集束イオンビームを照射して前記薄片試料から微小薄片試料を摘出する移送手段とを有し、

前記試料ステージは前記移送手段によって摘出された前記微小薄片試料を前記真空試料室内で載置可能な試料ホルダをさらに備え、

前記試料ステージは、前記薄片試料と前記試料ホルダを前記真空試料室内の真空を破らずに当該真空試料室から抜き挿し可能で、かつ、透過型電子顕微鏡もしくは走査型透過電子顕微鏡の真空試料室に抜き挿し可能であるサイドエントリ型試料ステージであることを特徴とする試料作製装置。And the vacuum sample chamber,

A sample stage on which a thin sample that can be observed with a transmission electron microscope or a scanning transmission electron microscope can be placed;

An irradiation optical system for irradiating the thin sample in the vacuum sample chamber with a focused ion beam;

And a transfer means to remove the micro-thin sample from the slice sample is irradiated with the focused ion beam to the thin sample in the vacuum sample chamber,

The sample stage is further provided with a can be placed sample holder in the vacuum sample chamber the micro flakes specimen that is removed by the transfer means,

The sample stage allows the thin sample and the sample holder to be inserted into and removed from the vacuum sample chamber without breaking the vacuum in the vacuum sample chamber , and is installed in a vacuum sample chamber of a transmission electron microscope or a scanning transmission electron microscope. A sample preparation apparatus, which is a side entry type sample stage that can be inserted and removed .

前記移送手段はプローブと、当該プローブを駆動する駆動手段を少なくとも備えることを特徴とする試料作製装置。 The sample preparation apparatus according to claim 1,

The sample preparation apparatus, wherein the transfer means includes at least a probe and a drive means for driving the probe .

前記試料ステージは、前記薄片試料と載置するメッシュを固定したメッシュホルダの設置部を有し、透過型電子顕微鏡もしくは走査型透過電子顕微鏡によって、前記微小薄片試料の摘出前の前記薄片試料を観察できることを特徴とする試料作製装置。 The sample preparation apparatus according to claim 1,

The sample stage has an installation part of a mesh holder that fixes the thin sample and a mesh to be placed, and observes the thin sample before extraction of the fine thin sample with a transmission electron microscope or a scanning transmission electron microscope. A sample preparation apparatus characterized by being capable of performing.