JP4135397B2 - Method and apparatus for quenching pressed parts - Google Patents

Method and apparatus for quenching pressed parts Download PDFInfo

- Publication number

- JP4135397B2 JP4135397B2 JP2002136714A JP2002136714A JP4135397B2 JP 4135397 B2 JP4135397 B2 JP 4135397B2 JP 2002136714 A JP2002136714 A JP 2002136714A JP 2002136714 A JP2002136714 A JP 2002136714A JP 4135397 B2 JP4135397 B2 JP 4135397B2

- Authority

- JP

- Japan

- Prior art keywords

- quenching

- press

- steel plate

- mold

- die

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000000171 quenching effect Effects 0.000 title claims description 75

- 238000010791 quenching Methods 0.000 title claims description 73

- 238000000034 method Methods 0.000 title claims description 28

- 229910000831 Steel Inorganic materials 0.000 claims description 104

- 239000010959 steel Substances 0.000 claims description 104

- 238000010438 heat treatment Methods 0.000 claims description 48

- 238000000465 moulding Methods 0.000 claims description 48

- 238000001816 cooling Methods 0.000 claims description 21

- 238000007493 shaping process Methods 0.000 claims description 5

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 239000000463 material Substances 0.000 description 49

- 238000012545 processing Methods 0.000 description 18

- 239000011810 insulating material Substances 0.000 description 10

- 230000009467 reduction Effects 0.000 description 9

- 230000007423 decrease Effects 0.000 description 8

- 230000000694 effects Effects 0.000 description 8

- 230000008859 change Effects 0.000 description 7

- 230000008569 process Effects 0.000 description 6

- 239000010935 stainless steel Substances 0.000 description 5

- 229910001220 stainless steel Inorganic materials 0.000 description 5

- 230000004048 modification Effects 0.000 description 4

- 238000012986 modification Methods 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 3

- 229910052799 carbon Inorganic materials 0.000 description 3

- 238000005553 drilling Methods 0.000 description 3

- 238000003825 pressing Methods 0.000 description 3

- 238000005266 casting Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000007547 defect Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 229920001971 elastomer Polymers 0.000 description 2

- 239000012212 insulator Substances 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 230000002265 prevention Effects 0.000 description 2

- 229920006311 Urethane elastomer Polymers 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000010960 cold rolled steel Substances 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Landscapes

- Heat Treatments In General, Especially Conveying And Cooling (AREA)

Description

【0001】

【発明の属する技術分野】

本発明は、加熱鋼板をプレス成形するプレス部品の焼入れ方法および焼入れ装置に関し、特に、部分的に後加工可能なプレス部品の焼入れ方法および焼入れ装置に関するものである。

【0002】

【従来の技術】

従来から鋼板(パネル材)を溶接等により組立て形成する、例えば、車体等の軽量化のために鋼板の強度を向上させる方法として、高強度鋼板(高張力鋼板)を用いる従来からの方法に代えて、加熱状態の鋼板をプレス成形により急冷・焼入れすることが提案されている。

【0003】

この成形方法は、鋼板を摂氏1000度近傍まで加熱し、プレス成形型に投入して摂氏約800度程度の鋼板をプレス成形するものである。プレス成形される鋼板は、高温のために材料強度が低下しており、成形型に沿って素直に変形し、成形品の寸法精度が向上する。また、鋼板は成形型に挟まれることで成形型に熱が奪われて急冷され焼入れされることとなり、成形品の母材強度を大幅に向上させることができる。成形品は焼入れ状態で形成されるため、スプリングバック等の寸法精度の不良等も極めて少ない。

【0004】

【発明が解決しようとする課題】

しかしながら、上記従来例の成形品は、プレス成形型による焼入れにより硬度が上昇するので以下のような問題点があった。

【0005】

即ち、成形品の表面は、急冷による焼入れにより硬度が上昇しており、剪断抵抗の増加により穴加工やトリム加工が困難となる。また、加工できた場合でも工具破損や工具摩耗の影響がある。

【0006】

また、急冷による焼入れで硬度上昇する前にピアス等の加工を行い、その後にプレス成形を行うと、成形途中に生じる材料の移動等によって穴位置にずれを生じ、その誤差により製品として成立しない恐れがある。そのため焼入れ前に加工を行ってもよい(誤差が許容される)部位は限られる。

【0007】

そこで本発明は、上記問題点に鑑みてなされたもので、部分的に後加工が可能なプレス部品の焼入れ方法および焼入れ装置を提供することを目的とする。

【0008】

【課題を解決するための手段】

第1の発明は、加熱された鋼板を成形型によりプレス成形と同時に成形型による成形品形状部位毎の冷却速度を異ならせて、焼入れ硬度を部位毎に変化させた成形品を得るプレス部品の焼入れ方法であり、前記成形型は成形面から出没可能に配置され且つ突出付勢される加熱媒体を備え、前記成形型による加熱鋼板の成形に先立って加熱媒体を加熱鋼板に接触させて接触部位の加熱鋼板の温度低下を抑制し、前記加熱鋼板が成形面により成形されるに伴い前記接触状態を維持しつつ前記加熱媒体を成形面に後退させて、加熱鋼板をプレス成形することにより、前記成形品形状部位毎の冷却速度を異ならせるようにした。

【0009】

第3の発明は、加熱された鋼板を成形型によりプレス成形と同時に成形型による成形品形状部位毎の冷却速度を異ならせて、焼入れ硬度を部位毎に変化させた成形品を得るプレス部品の焼入れ装置であり、前記成形型の成形品形状部位毎の型温度を、成形面から出没可能に配置され且つ突出付勢され、成形面に接する前に加熱鋼板に接触し、加熱鋼板が成形面により成形されるに伴い成形面に収容されるよう配置される加熱媒体の加熱により変化させて、成形品形状部位毎の冷却速度を異ならせるようにした。

【0010】

【発明の効果】

したがって、第1、3の発明では、冷却速度を部位毎に異ならせて成形品の焼入れ硬度を部位毎に選択できるため、加工が必要な部位の焼入れ硬度を低下させることでその部位の加工を容易とできる。

【0011】

また、焼入れ硬度を低下させた部位はそれだけ靭性が高くなるため、成形品の強度や靭性を部位毎の要求に対応してコントロールすることができる。

また、鋼板の冷却速度を成形型の成形品形状部位毎に予めの型温度を変化させることで異ならせるため、型温度が低い低温部は焼入れ硬度が高く、型温度が高い高温部は焼入れ硬度が低く設定できる。

そして、前記型温度を加熱媒体である発熱体により加熱することで変化させるため、発熱体の位置を変更すれば成形型の成形面を変更することなく焼入れ硬度の分布を変更することができる。

しかも、前記発熱体を成形面から出没可能且つ突出付勢し、投入されて成形面に接する前の鋼板に接触し、鋼板が成形面により成形されるに伴い成形面に収容されるよう配置したため、発熱体が鋼板に接触して鋼板の温度をより精度よく調整でき、プレス部品の材料組成のコントロールが容易に行うことができる。

【0014】

【発明の実施の形態】

以下、本発明におけるプレス部品の焼入れ方法および焼入れ装置を実現する実施の形態を各実施形態に基づいて説明する。

【0015】

図1〜図4は、プレス部品の焼入れ方法および焼入れ装置の参考例1を示し、図1は鋼板からプレス成形されたプレス部品を、図2は図1のプレス部品をプレス成形するプレス成形型を、図3は鋼板とプレス成形型とによる要部の詳細を、図4は剛性低下部の硬度の状態を夫々示す。

【0016】

図1に示すプレス部品1は、断面がハット形状をなしており、例えば、図20に示す自動車の車体構造において、エンジンコンパートメントを形成するサイドメンバSM、車室を形成するピラーPR、或いは、サイドシルアウターSO等に適用される。これらのパネル部品は、その剛性を向上させることで車体の剛性向上に比較的大きく寄与する。

【0017】

このため、このプレス部品1は、プレス成形時に、鋼板を1000℃近傍まで加熱しプレス成形型にセットした段階で800℃程度となるようにし、プレス成形により鋼板の熱を成形型により急激に奪うことで急冷する。プレス成形されたプレス部品1は、全体が焼入れされ(焼入れ部Aという)、その母材強度が大幅に上昇する。使用する鋼板の材料は、焼入れ性を向上させるため、炭素(C)量がやや多め(0.2〜0.24%程度)で、合金成分等が添加されている冷延鋼板材料、例えばSPC20CBの改良材等を使用する。

【0018】

ところで、プレス部品1中においても、設計上のレベルの強度を必要としない部位や、穴加工(ピアス)や切断加工(トリム)等の後加工を行う部位もあり、この部位では、その剛性を低下させて、穴加工や切断加工を可能とする必要がある。図1の斜線で囲んだ部位が前記剛性低下部2(即ち、この部位では焼入れ硬度を比較的低く形成する)である。以下、焼入れ部Aと剛性低下部2とを備えたプレス部品1を成形するプレス成形型について説明する。

【0019】

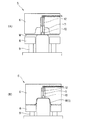

図2は、上記プレス部品1を成形するプレス成形型5の断面図を示し、ダイ6とポンチ7とブランクホルダ8を組み合わせた一般的なものである。ダイ6とポンチ7の剛性低下部2に面する表面には、幅Wdの範囲に亙って窪み6A、7Aを形成し、ダイ6およびポンチ7が成形しようとする鋼板Wに接触させないようにする。窪み6A、7Aの幅Wdは、図3に示すように、剛性低下部位2の幅Wpよりも若干大きく、即ち、鋼板W自体を通って成形型5に伝熱・吸熱されて冷却される長さXだけ大きく形成している。

【0020】

以上の構成のプレス成形型5においては、鋼板Wを1000℃近傍まで加熱し、成形型5への投入時に約800℃程度となり、高温のため材料強度が低下している状態の鋼板Wをダイ6の保持部6Bとブランクホルダ8とで挟持し、ポンチ7によりプレス成形する。鋼板Wはポンチ7とダイ6の窪み6A、7Aの部分による剛性低下部2を除く焼入れ部Aにおいては、成形型5に沿って素直に変形し、成形品1は高い寸法精度を備える。また、鋼板Wは成形型5に挟まれることで成形型5に熱が奪われて急冷され焼入れされることとなり、成形品1の母材強度を大幅に向上させることができる。成形品1は焼入れ状態で形成されるため、スプリングバック等の寸法精度の不良等も極めて少ない。

【0021】

他方、ポンチ7とダイ6の窪み6A、7Aに臨む剛性低下部2の鋼板Wは、ポンチ7とダイ6に接触しておらず、これら成形型5によっては変形および急冷されず、即ち、冷却速度が低く焼入れ硬度、即ち、強度・硬度が他の部分より低下された剛性低下部2を構成する。成形型5と鋼板WSの接触状態を示す図3によれば、ポンチ7およびダイ6と鋼板Wとは、剛性低下部2の幅Wpに境界領域の幅をXを加えた幅Wdをもってダイ6およびポンチ7の窪み6A、7Aの幅が形成されている。 図4は、窪み6A、7Aの縁からの距離(上記境界領域X)を横軸に、成形品1の硬度(HV)を縦軸にして、成形品1の硬度(ビッカース硬度HV)の変化を示すものである。これによれば、窪み6A、7Aの縁に近い5mmの位置では硬度500(HV)を超えているが、縁から15mm離れている位置では硬度420(HV)程度まで硬度が低下している。従って、成形時に焼入れ硬度を低めに抑えたい範囲WPに対して、少なくとも片側15mm以上大きな範囲Wdの窪みを確保することにより、範囲Wp内の硬度が低下できることが実験データから得られる。例えば、30mm幅の部位を低硬度にしたい場合は、最低片側15mm以上、つまり60mmの幅でプレス成形型5に窪み6A、7Aを設ける必要がある。なお、窪み6A、7Aの深さは、鋼板Wと接触しなければよいので、数mmの深さでよい。また、窪み6A、7Aの縁は、段差を持たせるのでなく、徐々に深くして境界を滑らかに繋ぐことが望ましい。

【0022】

また、プレス成形を完了してから約30秒後に、窪み6A、7Aに臨む鋼板W部分とポンチ7およびダイ6に接触する鋼板W部分の温度データをとりいくつかの値の平均値を得ると、窪み6A、7Aに臨む部位では約130℃であるのに対し成形型5への接触部分では約70℃であった。このことから、成形型5への接触部分では焼入れが進んでいるが非接触している窪み6A、7A部分においては相対的に焼入れが進んでいないことと理解できる。

【0023】

従って、加熱された鋼板Wをプレス成形型5によりプレス成形し焼入れしても、トリム加工やピアス加工を施す部位の硬度を一般部位より低くすることが可能となり、加工力を低下でき工具摩耗の防止が期待できる。

【0024】

なお、プレス成形型5によるプレス成形時において、加熱した鋼板Wが、先ず、ブランクホルダ8とダイ6のホルダ部6Bとの間で挟まれ、この両者によって急冷され焼入れされる懸念がある。この急冷を抑制するために、ブランクホルダ8とダイ6のホルダ部6Bの鋼板Wと接触する部分に断熱部材や熱伝導性の低い部材を介挿させると、その後のプレス成形される鋼板Wの硬度を増加させない意味で効果的である。また、鋼板Wに直接接触する部分に断熱部材や熱伝導性の低い部材を設けることが一番効果的であるが、耐磨耗性・耐蝕性の優れた金属を介して鋼板Wに接触させるようにしてもよい。

【0025】

また、上記参考例1においては、窪み6A、7Aにより加熱した鋼板Wに接触させないものについて説明しているが、図示しないが、例えば、窪み6A、7Aを多数のディンプルにより形成して熱の伝達面積を減少させて、成形面の他の一般断面に対して冷却速度を遅くするようにしてもよい。この場合には、剛性低下部2においてもディンプルによる断続的な成形面によりプレス成形されるため、剛性低下部2の形状精度をより一層向上できる。

【0026】

本参考例1においては、下記に記載した効果を奏することができる。

【0027】

(ア)投入された加熱鋼板Wを成形型5により成形品1形状部位毎に冷却速度を異ならせて冷却し、得られる焼入れ硬度を部位毎に変化させるため、加工が必要な部位の焼入れ硬度を低下させることで剛性低下部2を得ることができ、その部位の加工を容易とできる。

【0028】

(イ)また、焼入れ硬度を低下させた部位としての剛性低下部2はそれだけ靭性が高くなるため、成形品1の強度や靭性を部位毎の要求に対応してコントロールすることができる。

【0029】

(ウ)前記部位毎の冷却速度を成形型5の成形面形状部位と鋼板Wとの単位面積あたりの接触面積を変化させることにより異ならせるため、接触面積の多い部位は冷却速度が速いので接触面積の少ない部位に比べて焼入れ硬度を高くできる。

【0030】

(エ)前記単位面積あたりの接触面積を成形型5の対向する成形面に設ける窪み6A、7Aの有無により形成するため、成形型5の成形面に窪み6A、7Aを設けるのみで形成でき、成形型5の成形面形状のプレス部品への高精度の転写を然程必要としない部位に適用できる。

【0031】

(オ)前記単位面積あたりの接触面積を成形型5の成形面に設けた複数の窪み、即ち、ディンプルの密度により変化させる場合には、上記窪み6A、7Aによるプレス部品1よりさらに精度よく成形型5の成形面形状をプレス部品1へ高精度に転写できる。

【0032】

次に、プレス部品の焼入れ方法および焼入れ装置を実現する参考例2について説明する。

【0033】

図5は、プレス部品の焼入れ方法および焼入れ装置の参考例2を示し、ポンチ7およびダイ6に窪み6A、7Aを形成して鋼板Wに接触させないことにより剛性低下部2を形成することに代えて、ポンチ7およびダイ6の鋼板Wに接触する部位の型材を熱伝導率の低い材質の材料により構成することで剛性低下部2を形成するようにしたものである。

【0034】

図5に示すように、通常鋳物や鋼材で形成されるポンチ7の剛性低下部2に対応する範囲の型材7Cをステンレス材等の熱伝導率の低い材料により形成する。図示しないが、剛性低下部2に対応する範囲においてダイ6の型材6Cも同様にステンレス等の熱伝導率の低い材料により形成する。ステンレス等の熱伝導率の低い材料の型材7Cは、図5に示すポンチ7の例では、台形のブロック状の型材7Cをポンチ7の基本となる材質のブロックに嵌め込み(インサート構造)により固定している。ダイ6側においても、ポンチ7の熱伝導率の低い材料で形成された型材7Cに対応する範囲を含んで熱伝導率の低い材料の型材6Cをブロック状に嵌め込み(インサート構造)固定する。なお、熱伝導率の低い型材6C、7Cを配置する範囲は、剛性低下部2の範囲より、鋼板W自体で伝熱する境界領域Xの幅だけ大きく形成する。また、ブランクホルダ8およびダイ6のホルダ部6Bについては、第1実施形態で説明した構造とする。なお、熱伝導率の低い材料としてステンレスを挙げたが、他の金属、セラミック、樹脂等でも、耐熱性、耐蝕性、および、型材としての条件を満足するものであればよい。

【0035】

図6は、横軸に型材6C、7Cの熱伝導率、縦軸に硬度(HV)とし、得られる成形品の硬度変化を示したグラフである。このグラフでも判るように、型材6C、7Cの熱伝導率が高いほど成形品の硬度が上昇し、熱伝導率が低いほど成形品の硬度を低下させることができる。

【0036】

従って、このようにプレス成形型5を形成することで、熱伝導率の低い材質により形成した成形面によりプレス成形される成形品部位は、急冷されることが抑制され、焼入れ効果が緩和された剛性低下部2とする。他方、その他一般の材質の型材で形成した成形面によりプレス成形される成形品部位は、急冷され、焼入れ効果を高くしてその硬度を高くする焼入れ部Aとすることができる。

【0037】

しかも、鋼板は、通常の材質で形成された成形面にも、また、熱伝導率の低い材質で形成された成形面にも、接触して成形されるため、いずれの部分をとっても成形品の形状精度を高くできる。

【0038】

なお、上記参考例2では、熱伝導率の低い材料により型材6C、7Cの成形面を形成するものについて説明しているが、図示しないが、例えば、型材の成形面の一部を分離し、断熱材を介して固定するようにしてもよい。この場合には、断熱材により熱的に浮いているため、この部分の温度は加熱された鋼板からの入熱によりその温度を他の型材部分より高く維持することができる。

【0039】

本参考例2においては、参考例1による効果(ア)、(イ)の効果に加えて、下記に記載した効果を奏することができる。

【0040】

(カ)鋼板Wの冷却速度を成形型5の成形品形状部位毎に熱伝導の異なる材質の型材6C、7Cを使用することで異ならせるため、例えば、高い焼入れ硬度が必要な部位は鋼材や鋳物等の型材を使用し、低い焼入れ硬度でよい箇所にはステンレス等の熱伝導率の低い型材を使用することにより、焼き入れ硬度に変化を設けることができる。

【0041】

(キ)成形型5の全ての成形面が鋼板Wに接触するため、プレス部品1の形状精度を高精度とできる。

【0042】

(第3実施形態)

次に、本発明におけるプレス部品の焼入れ方法および焼入れ装置を実現する実施の形態を第1の実施形態に基づいて説明する。

【0043】

図7〜図12は、本発明におけるプレス部品の焼入れ方法および焼入れ装置の第1の実施形態を示し、鋼板に接触させない若しくは熱伝導率の低い型材で接触させることにより剛性低下部を形成することに代えて、発熱体により鋼板の温度低下を抑制することで剛性低下部を形成するようにしたものである。

【0044】

図7は、発熱体10を備えた成形型5を示し、ダイ6、ポンチ7、ブランクホルダ8およびクッション9を備えた一般的な成形型5に加えて、ダイ6の成形空間に突出した発熱体10を備えている。発熱体10は断熱材11により保持され、断熱材11はダイ6に上下方向に設けたガイド穴6D内に摺動自在に挿入され、ガイド穴6Dの底部に配置されたスプリング12等の弾性体により突出するよう付勢されている。前記発熱体10は、例えば、伝熱ヒータにより構成され、ガイド穴6Dからダイ6の側方に延びた穴6Eに通した電力線13を介して電力を供給される。発熱体10の温度は、鋼板Wの炭素量により焼入れ効果が変化するため、炭素量に応じて250℃〜900℃の間で設定する。発熱体10は弾性体12により突出付勢されており、ダイ6がポンチ7から離脱した型開き状態では、ダイ6のブランクホルダ8と共に鋼板Wを保持するホルダ部6Bより下方に突出して位置する。型締めによりダイ6がポンチ7と重なるに連れて後退され、プレス成形を完了する時にはダイ6のガイド穴6D内にその全てが後退される。

【0045】

図8(A)〜図9(B)は、本実施形態におけるプレス成形過程を示したものであり、以下に説明する。

【0046】

先ず、図8(A)に示す加熱炉15により鋼板Wが約1000℃近くに加熱され、図8(B)に示すように、型開きしたプレス成形型5内に投入され、ポンチ7若しくはブランクホルダ8上に載置される。

【0047】

次いで、図9(A)に示すように、成形型5のダイ6を下降させると、先ず、断熱材11に保持された発熱体10が鋼板Wに接触する。発熱体10は設定された温度に維持されているため、鋼板Wの発熱体10と接触する部位の温度は、発熱体10で設定された温度までポンチ7を経由して放熱され、その後は発熱体10の温度に維持される。

【0048】

次いで、鋼板Wをダイ6のホルダ部6Bとブランクホルダ8で挟み、引き続き、ダイ6が下降されることで鋼板Wは成形型5に素直に変形し、成形面から急激に冷却される。しかし、発熱体10に接触している部位の鋼板Wは発熱体10によりその温度が維持される。

【0049】

その後にダイ6を上昇させて型開きすると、ブランクホルダ8も共に上昇して成形品1とポンチ7との接触が離脱し、次いで、ブランクホルダ8と成形品1との接触が解除される。この時点においても、成形品1と発熱体10とは接触を維持し、発熱体10は成形品1を温め続ける。成形品1が成形型5から離脱すると、成形品1は空冷状態となり、徐々に冷却される。

【0050】

図10は上記成形過程における鋼板Wの温度変化を示すものであり、プレス成形型5で急冷される焼入れ部Aである一般断面部では、時点T1までは、図8(A)の加熱炉15内で加熱され、剛性低下部2を除いた部分は、時点T4において、鋼板Wがプレス成形されて成形型5により時点T5まで急冷され、時点T5から空気中で放冷される。

【0051】

他方、剛性低下部2は、鋼板Wがプレス成形により急冷される時点T4より前の時点T2から発熱体10と接触して発熱体10の温度となる時点T3まで冷却され、型開きされる時点T5より後の発熱体10が成形品1から離脱する時点T6まで発熱体10の温度に維持され、時点T6から空気中で放冷される。即ち、時点T3から時点T6までは発熱体10の温度に維持され、一気に急冷されることがない。

【0052】

図11は、以上の構成のプレス部品の焼入れ方法による成形品1の斜視図を示す。成形品1は、発熱体10を複数配置することで、図示のように、斜線図示した剛性低下部2を複数配列することができる。

【0053】

図12は、焼入れ部Aである一般断面部と剛性低下部2との硬度を比較したものであり、一般断面部での硬度が約500(HV)であるのに対し、剛性低下部2では硬度が約400(HV)と剛性が低下している。

【0054】

図13は、本実施形態の変形例を示し、発熱体10と対向するポンチ7の先端に断熱体16を埋め込んだものである。断熱体16は発熱体10と共に鋼板Wを挟み込み、ポンチ7から逃げる熱量を抑制して、剛性低下部2の冷却速度を低下させて、徐々に温度低下するようにした。この断熱材16の存在により、図10における発熱体10の温度まで低下する時点T3が遅くなり、その分だけ剛性低下部2の温度を高く維持して除冷することができる。

【0055】

なお、上記実施形態では、発熱体10がダイ6に進退自在に形成されたものについて説明しているが、図示しないが、例えば、ダイおよびまたはポンチの成形面を構成するよう断熱材を介して固定された発熱体であってもよい。この場合においても、剛性低下部は他の一般断面部と同様に温度低下するが、発熱体の温度まで低下した後はその温度を維持し、急激な冷却による焼入れを生じないようにできる。

【0056】

本実施の形態においては、参考例1における効果(ア)、(イ)に加えて、下記に記載した効果を奏することができる。

【0057】

(ク)鋼板Wの冷却速度を成形型5の成形品形状部位毎に予めの型温度を変化させることで異ならせるため、型温度が低い低温部は焼入れ硬度が高く、型温度が高い高温部は焼入れ硬度が低く設定できる。

【0058】

(ケ)前記型温度を加熱媒体である発熱体10により加熱することで変化させるため、発熱体10の位置を変更すれば成形型5の成形面を変更することなく焼入れ硬度の分布を変更することができる。

【0059】

(コ)前記発熱体10を成形面から出没可能且つ突出付勢し、投入されて成形面に接する前の鋼板Wに接触し、鋼板Wが成形面により成形されるに伴い成形面に収容されるよう配置したため、発熱体10が鋼板Wに接触して鋼板Wの温度をより精度よく調整でき、プレス部品1の材料組成のコントロールが容易に行うことができる。

【0060】

次に、プレス部品の焼入れ方法および焼入れ装置およびプレス部品を実現する参考例3について説明する。

【0061】

図14〜図19は、プレス部品の焼入れ方法および焼入れ装置の参考例3を示し、プレス成形の成形型から離脱させて別の後工程にて穴等の加工をするのに代えて、プレス成形型内で穴等の加工を行うようにしたものである。

【0062】

図14は、本参考例3におけるプレス成形型5を示し、クッションピン9に支持されたブランクホルダ8およびポンチ7で下型を形成し、ダイ6により上型を形成している点は共通するが、ダイ6が上プレート17にリテーナ18等で昇降自在となりゴムやタンカシリンダ等の圧力源19を介して支持された構成、上プレート17にダイ6を貫通して配置したピアスポンチ20の構成、および、ポンチ7にピアスポンチ20に対応して位置させてボタンダイ21を配置する構成を新規に備える。

【0063】

この場合、上プレート17がプレス機械により下降され、図15〜図17に示す作動により、鋼板Wがプレス成形され、引き続き、成形された成形品1にピアス加工がなされる。以下、詳細に説明する。

【0064】

先ず、図15に示すように、上プレート17、ダイ6、および、圧力源19が一体となって下降し、ダイ6のホルダ部6Bが鋼板Wに接触して、ブランクホルダ8との間で鋼板Wを保持する。

【0065】

更に上プレート17が下降すると、クッションピン9にかかるクッション圧は、上型の圧力源19よりも小さいため、ブランクホルダ8をダイ6により下方に押し下げつつ、図16に示すように、鋼板Wをダイ6とポンチ7との間でプレス成形する。

【0066】

上記プレス成形によりダイ6がポンチ7と鋼板Wを挟んでそれ以上の下降を阻止されるため、上プレート17は圧力源19を圧縮して、図17に示すように、ピアスポンチ20を下降させる。ピアスポンチ20はボタンダイ21との間で鋼板Wにピアス加工を行う。

【0067】

その後、上プレート17を上昇させると、ピアスポンチ20、ダイ6ともに上昇し、加工は完了する。

【0068】

上記作動では、ピアス加工時の鋼板Wの温度はポンチ7上に接触することにより低下しているが、少なくとも摂氏500℃以上あるため、ピアス加工時のせん断抵抗は小さくなる。このため、工具破損防止や工具寿命の延長を図れる。

【0069】

そして、プレス成形の後にピアス等の加工を行うことになるため、鋼板Wの材料移動は終了しており、穴位置のずれが回避でき、精度のよい穴加工が可能となる。

【0070】

図18は、ピアスポンチ20の変形例を示す。これは、ピアス加工時にパッド22によって穴明け周辺の鋼板Wを固定して、ピアスポンチ20によって精度よくピアス加工を行うために提案したものである。

【0071】

図18において、ピアスポンチ20は上プレート17に固定されるポンチリテーナ23に固定されており、ピアスポンチ20を包むように筒状のウレタンゴム等の弾性体24と弾性体24の先端に断熱材25を介してやはり筒状のパッド22を固定している。断熱材25はパッド22が高温の鋼板Wに接触する時、その熱が弾性体24に伝達されて弾性体24が溶けることを防止するために配置する。

【0072】

図19は、本参考例のプレス部品の焼入れ方法の変形例を示し、ピアスポンチの穴開けタイミングの自由度を更に改善したものである。即ち、ピアスポンチ20を作動させるために用いたリテーナ18および圧力源19に代えて、上プレート17にシリンダ等のアクチュエータ26を介してピアスポンチ20を配置するものである。なお、この場合のダイ6は上プレート17に直に固定する。

【0073】

プレス機械の上プレート17の下降に伴いダイ6はブランクホルダ8との間で鋼板Wをブランクホールドし、ポンチ7との間で鋼板Wにプレス成形を行い、上プレート17は下死点にて保持される。

【0074】

その保持されている間に、シリンダ等のアクチュエータ26によりピアスポンチ20を押し出し成形品1に穴加工を行う。

【0075】

動力源がプレス機械とは別個に設けられているため、ピアス加工のタイミングを任意に設定することができ、鋼板Wが最適と思われる温度に下降したタイミングでのピアス加工ができる。なお、本構造でも鋼板Wを押さえるパッド22を備えたピアスポンチ20とすることにより穴の形状精度が向上する。

【0076】

本参考例3においては、参考例1における効果(ア)、(イ)に加えて、下記に記載した効果を奏することができる。

【0077】

(サ)成形型5内でプレス成形され冷却・硬化する前に成形品1を加工するため、成形品1の材料が高温で材料強度が低い状態のうちに加工が行え、剪断抵抗等の加工力を低く抑えることができて加工が容易であると共に工具破損防止や工具寿命の延長につながる。

【0078】

(シ)プレス成形の後に加工を施すため、成形品1の材料は移動済みであり、加工による穴位置などのずれが回避でき、精度のよい加工が可能である。

【0079】

(ス)図14においては、前記加工装置としてのピアスポンチ20およびボタンダイ21を成形型5によるプレス成形の完了に連動して作動させるため、ダイ6が上プレート17にリテーナ18等で昇降自在となりゴムやタンカシリンダ等の圧力源19を介して支持してプレス機械に容易に適用できる。

【0080】

(セ)図19においては、前記加工装置としてのピアスポンチ20を成形型5によるプレス成形と独立して作動させるようにしたため、加工時の材料温度を任意に選ぶことができ、精度の良い穴加工が可能である。

【0081】

(ソ)図18においては、前記加工装置がボタンダイ21とピアスポンチ20で構成する穴加工である場合において、成形品1の穴開け部位の周囲をパッド22により押さえることでより精度のよい穴加工を行うことができる。なお、パッド22は断熱材25等を介した弾性体24で鋼板Wに押圧するように構成すると、弾性体24に鋼板Wの熱が伝達され難い。

【0082】

なお、上記実施形態において、プレス成形品としてハット型断面を備えるものについて説明しているが、図示しないが、コ字状断面、L字状断面、さらには、平面状断面のものであってもよく、また、剛性低下部を配置する部位がプレス部品の中央部に限定されるものでもない。

【図面の簡単な説明】

【図1】参考例1を示すプレス部品の焼入れ装置により得られたプレス部品の斜視図。

【図2】参考例1のプレス部品の焼入れ装置の断面図。

【図3】図2における焼入れ装置の要部を示す断面図。

【図4】図3における要部の硬度状態を示すグラフ。

【図5】参考例2のプレス部品の焼入れ装置の斜視図。

【図6】横軸に型材の熱伝導率を縦軸に硬度(HV)をとり得られる成形品の硬度変化を示したグラフ。

【図7】本発明の第1の実施形態のプレス部品の焼入れ装置の断面図。

【図8】第1の実施形態の作動を(A)、(B)に分けて示す工程図。

【図9】図8の工程に続く作動を(A)、(B)に分けて示す工程図。

【図10】図8、9におけるプレス部品の温度変化を示すグラフ。

【図11】第1の実施形態の焼入れ状態の一例を示す斜視図。

【図12】第1実施形態による焼入れ硬度を示すグラフ。

【図13】図8の変形例を示すプレス部品の焼入れ装置の断面図。

【図14】参考例3のプレス部品の焼入れ装置の断面図。

【図15】図14に示す焼入れ装置の作動を示す断面図。

【図16】図15に続く作動を示す断面図。

【図17】図17に続く作動を示す断面図。

【図18】ピアスポンチの変形例を示す断面図。

【図19】参考例3のプレス部品の焼入れ方法の変形例を示す断面図。

【図20】本発明によるプレス部品の適用箇所の一例を示す車体構造の斜視図。

【符号の説明】

A 焼入れ部

W 鋼板

1 プレス部品(成形品)

2 剛性低下部

5 成形型

6 ダイ

7 ポンチ

6A、7A 窪み

6C、7C 熱伝導の異なる型材

8 ブランクホルダ

10 加熱媒体としての発熱体

16 断熱材

20 加工装置としてのピアスポンチ

21 加工装置としてのボタンダイ[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a method for quenching a pressed part for press-molding a heated steel plate and a quenching apparatus.In placeIn particular, a method of quenching and quenching of press parts that can be partially post-processedIn placeIt is related.

[0002]

[Prior art]

Conventionally, steel plates (panel materials) are assembled and formed by welding or the like. For example, as a method for improving the strength of a steel plate to reduce the weight of a vehicle body or the like, a conventional method using a high-strength steel plate (high-tensile steel plate) is used. Thus, it has been proposed to rapidly cool and quench a heated steel sheet by press forming.

[0003]

In this forming method, a steel sheet is heated to around 1000 degrees Celsius, and put into a press mold to press form a steel sheet of about 800 degrees Celsius. The steel sheet to be press-formed has a low material strength due to high temperature, and deforms straight along the forming die, thereby improving the dimensional accuracy of the formed product. Further, when the steel sheet is sandwiched between the forming dies, the forming dies are deprived of heat and rapidly cooled and quenched, so that the strength of the base material of the formed product can be greatly improved. Since the molded product is formed in a quenched state, there are very few dimensional accuracy defects such as a spring back.

[0004]

[Problems to be solved by the invention]

However, the molded product of the above conventional example has the following problems because the hardness is increased by quenching with a press mold.

[0005]

That is, the hardness of the surface of the molded product is increased by quenching by rapid cooling, and drilling and trimming are difficult due to an increase in shear resistance. Moreover, even if it can process, there is an influence of tool breakage and tool wear.

[0006]

Also, if piercing or other processing is performed before the hardness is increased by quenching due to quenching, and then press molding is performed, the position of the hole may be displaced due to movement of the material that occurs during molding, and the product may not be established due to the error. There is. For this reason, the parts that may be processed before quenching (error is allowed) are limited.

[0007]

Accordingly, the present invention has been made in view of the above problems, and a quenching method and a quenching device for a pressed part that can be partially post-processed.PlaceThe purpose is to provide.

[0008]

[Means for Solving the Problems]

The first invention isThe quenching hardness was changed for each part by changing the cooling rate for each part of the molded product shape by the mold simultaneously with press forming of the heated steel plate.It is a method of quenching a pressed part to obtain a molded product,The forming die is provided with a heating medium that can be projected and retracted from the forming surface and is urged to be projected, and prior to forming the heated steel plate by the forming die, the heating medium is brought into contact with the heated steel plate and the temperature of the heated steel plate at the contact site By suppressing the decrease and pressing the heated steel sheet by retreating the heating medium to the molding surface while maintaining the contact state as the heated steel sheet is molded by the molding surface, The cooling rate of the was changed.

[0009]

According to a third aspect of the present invention, there is provided a press part for obtaining a molded product in which the quenching hardness is changed for each part by changing the cooling rate for each part of the molded product shape by the mold simultaneously with press molding of the heated steel plate. It is a quenching device, and the mold temperature for each molded product shape part of the molding die is arranged so as to be able to protrude from the molding surface and is projected and biased, and comes into contact with the heated steel plate before contacting the molding surface. By changing the heating rate of the heating medium arranged so as to be accommodated on the molding surface as it is molded, the cooling rate for each part of the molded product shape is varied.I did it.

[0010]

【The invention's effect】

Therefore,In the first and third inventionsSince the quenching hardness of the molded product can be selected for each part by changing the cooling rate for each part, the part can be easily processed by reducing the quenching hardness of the part requiring processing.

[0011]

Moreover, since the site | part which reduced quenching hardness becomes so much toughness, the intensity | strength and toughness of a molded product can be controlled corresponding to the request | requirement for every site | part.

Also, because the cooling rate of the steel sheet is varied by changing the mold temperature in advance for each part of the molded product shape, the low temperature part where the mold temperature is low has high quenching hardness, and the high temperature part where the mold temperature is high is quenching hardness. Can be set low.

And since the said mold temperature is changed by heating with the heat generating body which is a heating medium, if the position of a heat generating body is changed, distribution of quenching hardness can be changed without changing the shaping | molding surface of a shaping | molding die.

In addition, the heating element can be protruded and projected from the forming surface and is urged to project, and is brought into contact with the steel plate before being brought into contact with the forming surface, so that the steel plate is accommodated in the forming surface as it is formed by the forming surface. The heating element can contact the steel plate to adjust the temperature of the steel plate with higher accuracy, and the material composition of the pressed part can be easily controlled.

[0014]

DETAILED DESCRIPTION OF THE INVENTION

Hereinafter, a method of quenching a press part and a quenching apparatus according to the present inventionPlaceThe embodiment to be realizedeachThis will be described based on the embodiment.

[0015]

1 to 4 are,Quenching method and quenching of less partsReference example 1FIG. 1 shows a press part press-formed from a steel plate, FIG. 2 shows a press-forming die for press-forming the press part of FIG. 1, FIG. 3 shows details of the main part of the steel plate and the press-forming die, Reference numeral 4 denotes the hardness state of the rigidity-decreasing portion.

[0016]

The

[0017]

For this reason, the

[0018]

By the way, there are parts in the

[0019]

FIG. 2 shows a cross-sectional view of a

[0020]

In the

[0021]

On the other hand, the steel plate W of the rigidity-reduced

[0022]

In addition, about 30 seconds after the press forming is completed, the temperature data of the steel plate W portion facing the

[0023]

Therefore, even if the heated steel sheet W is press-molded by the

[0024]

In addition, at the time of press molding by the

[0025]

Also, aboveReference example 1However, although not illustrated, for example, the

[0026]

Reference Example 1Can produce the effects described below.

[0027]

(A) The charged heated steel sheet W is cooled by the

[0028]

(A) Moreover, since the

[0029]

(C) Since the cooling rate for each part is made different by changing the contact area per unit area between the forming surface shape part of the

[0030]

(D) Since the contact area per unit area is formed by the presence or absence of

[0031]

(E) When the contact area per unit area is changed by a plurality of depressions provided on the molding surface of the

[0032]

next,Quenching method and quenching of less partsPlaceRealizeAbout Reference Example 2explain.

[0033]

FIG.,Quenching method and quenching of less partsReference example 2Instead of forming the

[0034]

As shown in FIG. 5, a

[0035]

FIG. 6 is a graph showing the change in hardness of the obtained molded product with the horizontal axis representing the thermal conductivity of the

[0036]

Therefore, by forming the

[0037]

Moreover, since the steel sheet is formed in contact with both a molding surface formed of a normal material and a molding surface formed of a material with low thermal conductivity, any part of the molded product can be taken. Shape accuracy can be increased.

[0038]

The aboveReference example 2Explains the formation of the molding surfaces of the

[0039]

BookReference example 2InReference example 1In addition to the effects (a) and (b), the effects described below can be achieved.

[0040]

(F) Since the cooling rate of the steel plate W is made different by using the

[0041]

(G) Since all the forming surfaces of the forming

[0042]

(Third embodiment)

Next, a method for quenching a pressed part and a quenching apparatus according to the present inventionPlaceThe embodiment to be realized1This will be described based on the embodiment.

[0043]

7 to 12 show a method of quenching a press part and a quenching apparatus according to the present invention.SetFirst1In this embodiment, instead of forming a reduced-rigidity part by not contacting the steel sheet or by using a mold material having low thermal conductivity, the reduced-temperature part is formed by suppressing the temperature decrease of the steel sheet by a heating element. It is what you do.

[0044]

FIG. 7 shows a

[0045]

FIG. 8A to FIG. 9B show the press molding process in the present embodiment, which will be described below.

[0046]

First, the steel sheet W is heated to about 1000 ° C. by the

[0047]

Next, as shown in FIG. 9A, when the

[0048]

Next, the steel plate W is sandwiched between the

[0049]

Thereafter, when the

[0050]

FIG. 10 shows the temperature change of the steel sheet W in the forming process.ShowIn the general cross-section portion that is the quenching portion A that is quenched by the

[0051]

On the other hand, when the steel sheet W is cooled from the time T2 before the time T4 when the steel sheet W is rapidly cooled by press forming to the time T3 when the temperature of the

[0052]

FIG. 11 shows a perspective view of the molded

[0053]

FIG. 12 is a comparison of the hardness of the general cross-sectional portion that is the quenched portion A and the rigidity reduced

[0054]

FIG. 13 shows a modification of the present embodiment, in which a

[0055]

In addition, although the said embodiment demonstrated what the

[0056]

In this embodiment,Reference example 1In addition to the effects (a) and (b), the effects described below can be achieved.

[0057]

(H) Since the cooling rate of the steel sheet W is varied by changing the mold temperature in advance for each part of the molded product shape of the

[0058]

(K) Since the mold temperature is changed by heating with the

[0059]

(E) The

[0060]

next,To realize a quenching method, quenching equipment and press parts for less partsAbout Reference Example 3explain.

[0061]

14 to 19 are,Method and apparatus for quenching less partsReference example 3In this case, the holes are processed in the press mold instead of being separated from the press mold and processed in another post-process.

[0062]

Figure 14 shows the bookReference example 3The die 6 is the same as that shown in FIG. 1, in which the lower die is formed by the

[0063]

In this case, the

[0064]

First, as shown in FIG. 15, the

[0065]

When the

[0066]

Since the

[0067]

Thereafter, when the

[0068]

In the above operation, the temperature of the steel plate W at the time of piercing is lowered by contact with the

[0069]

Then, since processing such as piercing is performed after press forming, the material movement of the steel plate W has been completed, the displacement of the hole position can be avoided, and accurate hole processing becomes possible.

[0070]

FIG. 18 shows a modification of the

[0071]

In FIG. 18, the

[0072]

19 shows the bookReference exampleThe modified example of the quenching method of press parts of this is shown, and the freedom degree of the piercing | piercing punching timing is further improved. That is, instead of the

[0073]

As the

[0074]

While being held, the piercing

[0075]

Since the power source is provided separately from the press machine, the timing of piercing can be arbitrarily set, and piercing can be performed at the timing when the steel plate W is lowered to a temperature considered to be optimal. Even in this structure, the hole shape accuracy is improved by using the

[0076]

In this reference example 3,Reference example 1In addition to the effects (a) and (b), the effects described below can be achieved.

[0077]

(S) Since the molded

[0078]

(F) Since the processing is performed after the press molding, the material of the molded

[0079]

(S) In FIG. 14, since the

[0080]

(C) In FIG. 19, since the

[0081]

(E) In FIG. 18, when the processing device is a hole processing constituted by the button die 21 and the

[0082]

In addition, in the said embodiment, although what has a hat-shaped cross section is demonstrated as a press-molded article, although it is not illustrated, even if it is a thing of a U-shaped cross section, an L-shaped cross section, and a planar cross section. In addition, the portion where the rigidity reduction portion is disposed is not limited to the central portion of the press part.

[Brief description of the drawings]

[Figure 1]Reference example 1The perspective view of the press part obtained by the quenching apparatus of the press part which shows.

[Figure 2]Reference example 1Sectional drawing of the quenching apparatus of press parts of.

3 is a cross-sectional view showing a main part of the quenching apparatus in FIG. 2;

4 is a graph showing the hardness state of the main part in FIG. 3;

[Figure 5]Reference example 2The perspective view of the quenching apparatus of press parts of.

FIG. 6 is a graph showing the change in hardness of a molded product obtained by taking the thermal conductivity of the mold on the horizontal axis and the hardness (HV) on the vertical axis.

FIG. 7 shows the first of the present invention.1Sectional drawing of the quenching apparatus of the press parts of embodiment of this.

FIG. 81The process figure which divides and shows the action | operation of embodiment of (A) and (B).

FIG. 9 is a process chart showing the operation following the process of FIG. 8 separately in (A) and (B).

FIG. 10 is a graph showing a temperature change of the pressed part in FIGS.

FIG. 111The perspective view which shows an example of the hardening state of embodiment of this.

FIG. 121The graph which shows the quenching hardness by embodiment.

13 is a cross-sectional view of a press part hardening apparatus showing a modification of FIG.

FIG. 14Reference example 3Sectional drawing of the quenching apparatus of press parts of.

15 is a cross-sectional view showing the operation of the quenching apparatus shown in FIG.

16 is a cross-sectional view showing the operation following FIG.

17 is a cross-sectional view showing the operation following FIG.

FIG. 18 is a cross-sectional view showing a modified example of the pierce punch.

FIG. 19Reference example 3Sectional drawing which shows the modification of the hardening method of the press parts of.

FIG. 20 is a perspective view of a vehicle body structure showing an example of an application location of a pressed part according to the present invention.

[Explanation of symbols]

A quenching part

W steel plate

1 Press parts (molded products)

2 Stiffness reduction part

5 Mold

6 die

7 Punch

6A, 7A hollow

6C, 7C Mold materials with different heat conduction

8 Blank holder

10 Heating element as heating medium

16 Insulation

20 Piercing punch as a processing device

21 Button die as processing equipment

Claims (4)

前記成形型は成形面から出没可能に配置され且つ突出付勢される加熱媒体を備え、

前記成形型による加熱鋼板の成形に先立って加熱媒体を加熱鋼板に接触させて接触部位の加熱鋼板の温度低下を抑制し、

前記加熱鋼板が成形面により成形されるに伴い前記接触状態を維持しつつ前記加熱媒体を成形面に後退させて、加熱鋼板をプレス成形することにより、

前記成形品形状部位毎の冷却速度を異ならせるようにしたことを特徴とするプレス部品の焼入れ方法。In the quenching method of the press part to obtain a molded product in which the quenching hardness is changed for each part by changing the cooling rate for each part of the molded product shape by the mold simultaneously with the press molding of the heated steel plate,

The mold is provided with a heating medium that can be projected and retracted from the molding surface and is biased to protrude.

Prior to the formation of the heated steel sheet by the forming mold, the heating medium is brought into contact with the heated steel sheet to suppress the temperature drop of the heated steel sheet at the contact site,

As the heated steel sheet is formed by the forming surface, the heating medium is retracted to the forming surface while maintaining the contact state, and the heated steel sheet is press formed.

A method for quenching a pressed part, characterized in that the cooling rate for each part of the molded product shape is varied .

前記成形型の成形品形状部位毎の型温度を、成形面から出没可能に配置され且つ突出付勢され、成形面に接する前に加熱鋼板に接触し、加熱鋼板が成形面により成形されるに伴い成形面に収容されるよう配置される加熱媒体の加熱により変化させて、成形品形状部位毎の冷却速度を異ならせることを特徴とするプレス部品の焼入れ装置。 In the quenching apparatus for press parts to obtain a molded product in which the quenching hardness is changed for each part by changing the cooling rate for each part of the molded product shape by the molding die at the same time as the press molding of the heated steel plate with the molding die,

The mold temperature of each molded product shape part of the mold is arranged so as to be able to protrude and project from the molding surface and is urged to protrude and contact the heated steel plate before coming into contact with the molding surface, so that the heated steel plate is molded by the molding surface. with varied by heating of the heating medium is arranged to be accommodated in the molding surface, hardening apparatus features and to pulp-less components to varying the cooling rate of the molded article each shaping site.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002136714A JP4135397B2 (en) | 2002-05-13 | 2002-05-13 | Method and apparatus for quenching pressed parts |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002136714A JP4135397B2 (en) | 2002-05-13 | 2002-05-13 | Method and apparatus for quenching pressed parts |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2003328031A JP2003328031A (en) | 2003-11-19 |

| JP4135397B2 true JP4135397B2 (en) | 2008-08-20 |

Family

ID=29698663

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002136714A Expired - Fee Related JP4135397B2 (en) | 2002-05-13 | 2002-05-13 | Method and apparatus for quenching pressed parts |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4135397B2 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20230030351A (en) * | 2021-08-25 | 2023-03-06 | 현대제철 주식회사 | Mold for hot stamping and manufacturing method of hot stamping component |

Families Citing this family (53)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005138111A (en) * | 2003-11-04 | 2005-06-02 | Nippon Steel Corp | Steel plate hot press forming method and apparatus |

| JP4625263B2 (en) * | 2004-03-12 | 2011-02-02 | 新日本製鐵株式会社 | Hot forming method |

| JP4494834B2 (en) * | 2004-03-16 | 2010-06-30 | 新日本製鐵株式会社 | Hot forming method |

| JP4837259B2 (en) * | 2004-03-24 | 2011-12-14 | 新日本製鐵株式会社 | Hot forming method and high strength hot formed parts with excellent strength after forming |

| JP2005297042A (en) * | 2004-04-15 | 2005-10-27 | Nippon Steel Corp | Deep drawing method in hot forming |

| DE102004038626B3 (en) | 2004-08-09 | 2006-02-02 | Voestalpine Motion Gmbh | Method for producing hardened components from sheet steel |

| JP4317506B2 (en) * | 2004-09-15 | 2009-08-19 | 新日本製鐵株式会社 | Manufacturing method of high strength parts |

| KR101136560B1 (en) | 2004-09-15 | 2012-04-17 | 신닛뽄세이테쯔 카부시키카이샤 | Process for producing high-strength part |

| SE528130C2 (en) | 2004-10-04 | 2006-09-12 | Gestamp Hardtech Ab | Ways to heat mold and harden a sheet metal |

| JP2006104527A (en) * | 2004-10-06 | 2006-04-20 | Nippon Steel Corp | Manufacturing method of high-strength parts and high-strength parts |

| JP4724406B2 (en) * | 2004-11-04 | 2011-07-13 | 新日本製鐵株式会社 | Method for producing hot-pressed high-strength steel members with low residual stress |

| JP4542439B2 (en) * | 2005-01-21 | 2010-09-15 | 新日本製鐵株式会社 | Method and apparatus for hot press forming metal plate material |

| JP2006326620A (en) * | 2005-05-25 | 2006-12-07 | Toa Kogyo Kk | Press forming device, and press forming method |

| DE102005032113B3 (en) * | 2005-07-07 | 2007-02-08 | Schwartz, Eva | Thermal deformation and partial hardening apparatus, e.g. for automobile components, comprises mold of at least two parts, each formed from segments adjustable to different temperatures |

| US20080295563A1 (en) * | 2006-01-18 | 2008-12-04 | Mehmet Terziakin | Method for Delaying of Cooling and Hardening of Desired Zones of a Sheet During a Hot Metal Stamping Process |

| JP5137323B2 (en) * | 2006-04-26 | 2013-02-06 | 新日鐵住金株式会社 | Bumper reinforcing member manufacturing method |

| FR2927828B1 (en) * | 2008-02-26 | 2011-02-18 | Thyssenkrupp Sofedit | METHOD OF FORMING FROM FLAN IN SOFT MATERIAL WITH DIFFERENTIAL COOLING |

| WO2009123538A1 (en) * | 2008-04-03 | 2009-10-08 | Gestam Hardtech Ab | Method of manufacturing a press-formed sheet-metal product |

| DE112009000981T5 (en) * | 2008-04-25 | 2011-03-24 | Aleris Aluminium Duffel Bvba | Method for producing an aluminum alloy component |

| JP5119475B2 (en) * | 2008-05-14 | 2013-01-16 | 新日鐵住金株式会社 | Center pillar reinforcing member and manufacturing method thereof |

| WO2010011103A2 (en) * | 2008-07-25 | 2010-01-28 | 현대제철 주식회사 | Press-cure mold cooling device |

| JP4825882B2 (en) | 2009-02-03 | 2011-11-30 | トヨタ自動車株式会社 | High-strength quenched molded body and method for producing the same |

| DE102009043926A1 (en) * | 2009-09-01 | 2011-03-10 | Thyssenkrupp Steel Europe Ag | Method and device for producing a metal component |

| KR101125387B1 (en) * | 2009-12-03 | 2012-03-27 | 현대자동차주식회사 | Partial-strengthening hot-stamping method for improving impact resistance of vehicle parts |

| KR101171450B1 (en) | 2009-12-29 | 2012-08-06 | 주식회사 포스코 | Method for hot press forming of coated steel and hot press formed prodicts using the same |

| JP5359925B2 (en) * | 2010-02-23 | 2013-12-04 | 新日鐵住金株式会社 | Manufacturing method of energy absorbing member having strength difference in member |

| JP5508059B2 (en) * | 2010-02-26 | 2014-05-28 | アイシン高丘株式会社 | Combined press machine |

| DE102010012831B4 (en) * | 2010-03-25 | 2023-02-16 | Benteler Automobiltechnik Gmbh | transmission tunnel |

| DE102010012830B4 (en) | 2010-03-25 | 2017-06-08 | Benteler Automobiltechnik Gmbh | Method for producing a motor vehicle component and body component |

| JP5740099B2 (en) * | 2010-04-23 | 2015-06-24 | 東プレ株式会社 | Manufacturing method of hot press products |

| DE102010048209C5 (en) | 2010-10-15 | 2016-05-25 | Benteler Automobiltechnik Gmbh | Method for producing a hot-formed press-hardened metal component |

| US20160067760A1 (en) | 2010-12-22 | 2016-03-10 | Nippon Steel & Sumitomo Metal Corporation | Surface layer grain refining hot-shearing method and workpiece obtained by surface layer grain refining hot-shearing |

| KR101253838B1 (en) * | 2010-12-27 | 2013-04-12 | 주식회사 포스코 | Method for Manufacturing a Multi Physical Property Part |

| EP2682199B1 (en) * | 2011-03-03 | 2018-07-25 | Nippon Steel & Sumitomo Metal Corporation | Method for bending sheet metal and product of sheet metal |

| JP5768663B2 (en) * | 2011-11-01 | 2015-08-26 | 新日鐵住金株式会社 | Hot shearing method |

| JP5902939B2 (en) * | 2011-12-13 | 2016-04-13 | 株式会社神戸製鋼所 | Manufacturing method of hot press-formed product |

| JP5786728B2 (en) * | 2012-01-23 | 2015-09-30 | Jfeスチール株式会社 | Press forming method and apparatus |

| WO2016021261A1 (en) * | 2014-08-04 | 2016-02-11 | 本田技研工業株式会社 | Vehicle body structure |

| JP2017001601A (en) | 2015-06-15 | 2017-01-05 | 本田技研工業株式会社 | Side frame for vehicle body |

| JP6724452B2 (en) * | 2016-03-18 | 2020-07-15 | 日本製鉄株式会社 | Quenched steel pipe member and method for manufacturing quenched steel pipe member |

| RU2019104106A (en) * | 2016-08-09 | 2020-09-15 | Аутотек Инжиниринг, C.Л. | CENTERING AND SELECTED HEATING OF BLANKS |

| DE102017201674B3 (en) | 2017-02-02 | 2018-03-29 | Ford Global Technologies, Llc | Method for producing a press-hardened component and press mold |

| US10486215B2 (en) | 2017-06-16 | 2019-11-26 | Ford Motor Company | Apparatus and method for piercing and trimming hot stamped parts |

| WO2019069938A1 (en) | 2017-10-02 | 2019-04-11 | 新日鐵住金株式会社 | Hot-stamp molded article, hot-stamp steel sheet, and methods for producing these |

| CA3088954C (en) * | 2018-03-09 | 2023-07-04 | Sumitomo Heavy Industries, Ltd. | Molding device, molding method, and metal pipe |

| JP7155986B2 (en) * | 2018-12-13 | 2022-10-19 | トヨタ自動車株式会社 | Steel plate member and its manufacturing method |

| CN113490759B (en) | 2019-04-01 | 2022-10-04 | 日本制铁株式会社 | Hot stamped product and method for producing the same |

| JP7151878B2 (en) | 2019-04-01 | 2022-10-12 | 日本製鉄株式会社 | HOT STAMP MOLDED PRODUCT, HOT STAMP STEEL STEEL, AND METHOD OF MANUFACTURING THEM |

| JP7294062B2 (en) * | 2019-10-30 | 2023-06-20 | マツダ株式会社 | Manufacturing method for light metal castings |

| CN111390033A (en) * | 2020-03-24 | 2020-07-10 | 首钢集团有限公司 | Device and method for preparing thermoforming parts |

| EP4129519A4 (en) * | 2020-04-03 | 2023-09-20 | Nippon Steel Corporation | Hot press device and method for manufacturing hot press molded article |

| CN114260650B (en) * | 2021-12-17 | 2023-11-03 | 江西洪都航空工业集团有限责任公司 | Sheet metal forming method for airplane homodromous bent narrow-long-mouth part |

| CN117960900A (en) * | 2024-03-27 | 2024-05-03 | 无锡朗贤轻量化科技股份有限公司 | Thermoforming sectional strengthening process and mould for thermoforming high-strength steel |

-

2002

- 2002-05-13 JP JP2002136714A patent/JP4135397B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20230030351A (en) * | 2021-08-25 | 2023-03-06 | 현대제철 주식회사 | Mold for hot stamping and manufacturing method of hot stamping component |

| KR102513575B1 (en) * | 2021-08-25 | 2023-03-24 | 현대제철 주식회사 | Mold for hot stamping and manufacturing method of hot stamping component |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003328031A (en) | 2003-11-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4135397B2 (en) | Method and apparatus for quenching pressed parts | |

| CN103056212B (en) | For sheet material hot forming and the mould of cutting and method | |

| JP6157845B2 (en) | Hot stamping molding apparatus and method | |

| US8261591B2 (en) | Apparatus for hot-forming, press-quenching, and cutting semifinished hardenable-steel workpiece | |

| US20080295563A1 (en) | Method for Delaying of Cooling and Hardening of Desired Zones of a Sheet During a Hot Metal Stamping Process | |

| US8578750B2 (en) | Method and tool for hot forming a metal workpiece | |

| JP6314926B2 (en) | Press machine | |

| KR101438453B1 (en) | Hot stamping method and mold device for forming and trimming of blank | |

| CN105107939A (en) | Continuous hot stamping device and technology | |

| JP6314925B2 (en) | Press machine | |

| KR20130108899A (en) | Hot stamping device | |

| CN108472909B (en) | stamping die | |

| JP2014018801A (en) | Hole piercing method, method for manufacturing structure with hole, and structure with hole | |

| JP6256571B1 (en) | Press machine | |

| CN110643795A (en) | Method for die trimming hot stamped parts and parts formed thereby | |

| JP2005205416A (en) | Hot press-forming method and hot press-forming die | |

| JP6619645B2 (en) | Hot press apparatus and hot press molding method | |

| JP2010075935A (en) | Die quenched product, method and apparatus for manufacturing the same | |

| JP2017100183A (en) | Hot press apparatus and hot press molding method | |

| JP2006326620A (en) | Press forming device, and press forming method | |

| JP2017164774A (en) | Method and apparatus for manufacturing press-formed article | |

| US9616481B2 (en) | Hot stamping device | |

| JP5286522B2 (en) | Molding device for hot press and hot press molding method | |

| JP2012218018A (en) | Press working apparatus | |

| JP4845813B2 (en) | Press working equipment in die quench method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041027 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060316 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080219 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080416 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080513 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080526 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110613 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120613 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120613 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130613 Year of fee payment: 5 |

|

| LAPS | Cancellation because of no payment of annual fees |