JP4020217B2 - コーティング厚さ制御 - Google Patents

コーティング厚さ制御 Download PDFInfo

- Publication number

- JP4020217B2 JP4020217B2 JP53142198A JP53142198A JP4020217B2 JP 4020217 B2 JP4020217 B2 JP 4020217B2 JP 53142198 A JP53142198 A JP 53142198A JP 53142198 A JP53142198 A JP 53142198A JP 4020217 B2 JP4020217 B2 JP 4020217B2

- Authority

- JP

- Japan

- Prior art keywords

- opening

- air knife

- lips

- lip

- pair

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000576 coating method Methods 0.000 title claims description 60

- 239000011248 coating agent Substances 0.000 title claims description 59

- 239000000463 material Substances 0.000 claims description 42

- 239000012530 fluid Substances 0.000 claims description 22

- 238000006073 displacement reaction Methods 0.000 claims description 8

- 238000010276 construction Methods 0.000 claims 1

- 230000008859 change Effects 0.000 description 10

- 230000007547 defect Effects 0.000 description 10

- 239000002184 metal Substances 0.000 description 10

- 229910052751 metal Inorganic materials 0.000 description 10

- 238000007598 dipping method Methods 0.000 description 6

- 230000000694 effects Effects 0.000 description 5

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 4

- 239000007789 gas Substances 0.000 description 4

- 230000002829 reductive effect Effects 0.000 description 4

- 229910052725 zinc Inorganic materials 0.000 description 4

- 239000011701 zinc Substances 0.000 description 4

- 238000000034 method Methods 0.000 description 3

- 239000011253 protective coating Substances 0.000 description 3

- 238000010586 diagram Methods 0.000 description 2

- 230000003628 erosive effect Effects 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 230000007935 neutral effect Effects 0.000 description 2

- 238000007747 plating Methods 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 229910001297 Zn alloy Inorganic materials 0.000 description 1

- 238000007792 addition Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000000691 measurement method Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

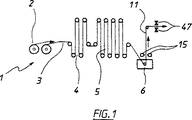

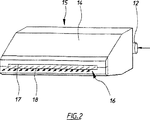

- C23C2/00—Hot-dipping or immersion processes for applying the coating material in the molten state without affecting the shape; Apparatus therefor

- C23C2/14—Removing excess of molten coatings; Controlling or regulating the coating thickness

- C23C2/16—Removing excess of molten coatings; Controlling or regulating the coating thickness using fluids under pressure, e.g. air knives

- C23C2/18—Removing excess of molten coatings from elongated material

- C23C2/20—Strips; Plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C11/00—Component parts, details or accessories not specifically provided for in groups B05C1/00 - B05C9/00

- B05C11/02—Apparatus for spreading or distributing liquids or other fluent materials already applied to a surface ; Controlling means therefor; Control of the thickness of a coating by spreading or distributing liquids or other fluent materials already applied to the coated surface

- B05C11/06—Apparatus for spreading or distributing liquids or other fluent materials already applied to a surface ; Controlling means therefor; Control of the thickness of a coating by spreading or distributing liquids or other fluent materials already applied to the coated surface with a blast of gas or vapour

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H25/00—After-treatment of paper not provided for in groups D21H17/00 - D21H23/00

- D21H25/08—Rearranging applied substances, e.g. metering, smoothing; Removing excess material

- D21H25/16—Rearranging applied substances, e.g. metering, smoothing; Removing excess material with a blast of vapour or gas, e.g. air knife

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Coating Apparatus (AREA)

- Coating With Molten Metal (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU4732 | 1991-02-22 | ||

| AUPO4732A AUPO473297A0 (en) | 1997-01-22 | 1997-01-22 | Coating thickness control |

| PCT/AU1998/000030 WO1998032890A1 (en) | 1997-01-22 | 1998-01-22 | Coating thickness control |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2001508358A JP2001508358A (ja) | 2001-06-26 |

| JP2001508358A5 JP2001508358A5 (enExample) | 2005-09-08 |

| JP4020217B2 true JP4020217B2 (ja) | 2007-12-12 |

Family

ID=3799036

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP53142198A Expired - Fee Related JP4020217B2 (ja) | 1997-01-22 | 1998-01-22 | コーティング厚さ制御 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6199301B1 (enExample) |

| JP (1) | JP4020217B2 (enExample) |

| AU (1) | AUPO473297A0 (enExample) |

| DE (1) | DE19881989B4 (enExample) |

| GB (1) | GB2336377B (enExample) |

| WO (1) | WO1998032890A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8429834B2 (en) | 2009-03-06 | 2013-04-30 | Mitsubishi-Hitachi Metals Machinery, Inc. | Gas wiping apparatus |

Families Citing this family (42)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6749390B2 (en) | 1997-12-15 | 2004-06-15 | Semitool, Inc. | Integrated tools with transfer devices for handling microelectronic workpieces |

| US6752584B2 (en) | 1996-07-15 | 2004-06-22 | Semitool, Inc. | Transfer devices for handling microelectronic workpieces within an environment of a processing machine and methods of manufacturing and using such devices in the processing of microelectronic workpieces |

| US6749391B2 (en) | 1996-07-15 | 2004-06-15 | Semitool, Inc. | Microelectronic workpiece transfer devices and methods of using such devices in the processing of microelectronic workpieces |

| US6921467B2 (en) * | 1996-07-15 | 2005-07-26 | Semitool, Inc. | Processing tools, components of processing tools, and method of making and using same for electrochemical processing of microelectronic workpieces |

| US6565729B2 (en) * | 1998-03-20 | 2003-05-20 | Semitool, Inc. | Method for electrochemically depositing metal on a semiconductor workpiece |

| TW593731B (en) * | 1998-03-20 | 2004-06-21 | Semitool Inc | Apparatus for applying a metal structure to a workpiece |

| US6497801B1 (en) * | 1998-07-10 | 2002-12-24 | Semitool Inc | Electroplating apparatus with segmented anode array |

| US7020537B2 (en) * | 1999-04-13 | 2006-03-28 | Semitool, Inc. | Tuning electrodes used in a reactor for electrochemically processing a microelectronic workpiece |

| US6368475B1 (en) * | 2000-03-21 | 2002-04-09 | Semitool, Inc. | Apparatus for electrochemically processing a microelectronic workpiece |

| WO2000061837A1 (en) | 1999-04-13 | 2000-10-19 | Semitool, Inc. | Workpiece processor having processing chamber with improved processing fluid flow |

| US7351314B2 (en) | 2003-12-05 | 2008-04-01 | Semitool, Inc. | Chambers, systems, and methods for electrochemically processing microfeature workpieces |

| US6916412B2 (en) * | 1999-04-13 | 2005-07-12 | Semitool, Inc. | Adaptable electrochemical processing chamber |

| US7264698B2 (en) | 1999-04-13 | 2007-09-04 | Semitool, Inc. | Apparatus and methods for electrochemical processing of microelectronic workpieces |

| US20030038035A1 (en) * | 2001-05-30 | 2003-02-27 | Wilson Gregory J. | Methods and systems for controlling current in electrochemical processing of microelectronic workpieces |

| US7351315B2 (en) | 2003-12-05 | 2008-04-01 | Semitool, Inc. | Chambers, systems, and methods for electrochemically processing microfeature workpieces |

| US7189318B2 (en) * | 1999-04-13 | 2007-03-13 | Semitool, Inc. | Tuning electrodes used in a reactor for electrochemically processing a microelectronic workpiece |

| US7438788B2 (en) | 1999-04-13 | 2008-10-21 | Semitool, Inc. | Apparatus and methods for electrochemical processing of microelectronic workpieces |

| US7585398B2 (en) * | 1999-04-13 | 2009-09-08 | Semitool, Inc. | Chambers, systems, and methods for electrochemically processing microfeature workpieces |

| US7160421B2 (en) | 1999-04-13 | 2007-01-09 | Semitool, Inc. | Turning electrodes used in a reactor for electrochemically processing a microelectronic workpiece |

| US6623609B2 (en) | 1999-07-12 | 2003-09-23 | Semitool, Inc. | Lift and rotate assembly for use in a workpiece processing station and a method of attaching the same |

| AU2001259504A1 (en) * | 2000-05-24 | 2001-12-03 | Semitool, Inc. | Tuning electrodes used in a reactor for electrochemically processing a microelectronic workpiece |

| WO2002004887A1 (en) * | 2000-07-08 | 2002-01-17 | Semitool, Inc. | Methods and apparatus for processing microelectronic workpieces using metrology |

| KR20030018175A (ko) * | 2001-08-27 | 2003-03-06 | 주식회사 포스코 | 에어나이프 노즐과 강판사이의 간격측정장치 |

| AU2002343330A1 (en) | 2001-08-31 | 2003-03-10 | Semitool, Inc. | Apparatus and methods for electrochemical processing of microelectronic workpieces |

| US6630360B2 (en) | 2002-01-10 | 2003-10-07 | Advanced Micro Devices, Inc. | Advanced process control (APC) of copper thickness for chemical mechanical planarization (CMP) optimization |

| US6991710B2 (en) * | 2002-02-22 | 2006-01-31 | Semitool, Inc. | Apparatus for manually and automatically processing microelectronic workpieces |

| US20030159921A1 (en) * | 2002-02-22 | 2003-08-28 | Randy Harris | Apparatus with processing stations for manually and automatically processing microelectronic workpieces |

| US6893505B2 (en) * | 2002-05-08 | 2005-05-17 | Semitool, Inc. | Apparatus and method for regulating fluid flows, such as flows of electrochemical processing fluids |

| US20040031167A1 (en) * | 2002-06-13 | 2004-02-19 | Stein Nathan D. | Single wafer method and apparatus for drying semiconductor substrates using an inert gas air-knife |

| US7114903B2 (en) * | 2002-07-16 | 2006-10-03 | Semitool, Inc. | Apparatuses and method for transferring and/or pre-processing microelectronic workpieces |

| KR20040048263A (ko) * | 2002-12-02 | 2004-06-07 | 주식회사 포스코 | 폭방향 에어 송풍량이 조절이 가능한 에어나이프 장치 |

| US20050092611A1 (en) * | 2003-11-03 | 2005-05-05 | Semitool, Inc. | Bath and method for high rate copper deposition |

| KR100903180B1 (ko) * | 2006-05-22 | 2009-06-17 | 주식회사 엘지화학 | 리튬이온 폴리머 전지용 분리막의 코팅량 조절방법 |

| WO2007142396A1 (en) * | 2006-06-05 | 2007-12-13 | Posco | Gas wiping apparatus |

| CN1928147B (zh) * | 2006-09-12 | 2012-09-19 | 攀钢集团攀枝花钢铁研究院 | 用于控制镀锌层厚度的气刀 |

| EP2140944A1 (en) * | 2008-07-03 | 2010-01-06 | Linde AG | Adjustable baffles for gas wiping |

| DE102008058513B4 (de) * | 2008-11-21 | 2011-03-10 | Berger, Bernd, Dr.-Ing. | Vorrichtung zum Entfernen von Flüssigkeit von der Oberfläche eines bewegten Bandes und Bandbearbeitungsanlage mit solch einer Vorrichtung |

| JP5602371B2 (ja) * | 2009-03-06 | 2014-10-08 | 三菱日立製鉄機械株式会社 | ガスワイピング装置 |

| KR101125649B1 (ko) * | 2010-05-24 | 2012-03-27 | 삼성에스디아이 주식회사 | 활물질 코팅 장치 및 이를 이용한 코팅 방법 |

| JP5857577B2 (ja) * | 2011-09-22 | 2016-02-10 | 日本電気株式会社 | 塗工ダイヘッド |

| CN103510032B (zh) * | 2012-06-20 | 2015-12-02 | 鞍钢股份有限公司 | 冷轧热镀锌镀层均匀度的偏差值控制方法 |

| KR102362174B1 (ko) | 2018-10-01 | 2022-02-10 | 주식회사 엘지에너지솔루션 | 슬롯 다이 코터의 상부 토출구와 하부 토출구 간의 거리를 조절하는 슬롯 다이 코터 조정 장치 및 이를 포함하는 전극 활물질 코팅 시스템 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2568492A (en) * | 1949-04-16 | 1951-09-18 | Gen Aniline & Film Corp | Adjustable nozzle |

| US3272176A (en) * | 1964-04-13 | 1966-09-13 | Du Pont | Air knife |

| BE758803A (fr) * | 1969-11-12 | 1971-04-16 | Jones & Laughlin Steel Corp | Procede pour controler le revetement d'un substrat |

| FR2090313B1 (enExample) * | 1970-05-27 | 1974-04-26 | Italsider Spa | |

| US4041895A (en) * | 1975-09-29 | 1977-08-16 | Republic Steel Corporation | Coating thickness and distribution control |

| US4106429A (en) * | 1977-05-23 | 1978-08-15 | Beloit Corporation | Air knife with adjustable lip |

| US4270702A (en) * | 1978-04-26 | 1981-06-02 | Albany International Corp. | Adjustable orifice air knife |

| DD152143A1 (de) * | 1980-07-22 | 1981-11-18 | Lothar Werk | Vorrichtung zur erzeugung gleichmaessig dicker metallschichten auf feuermetallisiertem bandstahl |

| US4359964A (en) * | 1981-05-20 | 1982-11-23 | Beloit Corporation | Air knife coater with pivoted lip |

| US4697542A (en) * | 1985-05-13 | 1987-10-06 | The Kohler Coating Machinery Corporation | Adjustable nozzle for coating equipment |

| ATE45390T1 (de) * | 1986-06-12 | 1989-08-15 | Duma Konstruktionsbuero | Abblasvorrichtung zum kontinuierlichen beidseitigen beschichten von metallband. |

| DE4024229C1 (enExample) * | 1990-07-31 | 1991-07-18 | Heinrich 4100 Duisburg De Pannenbecker | |

| US5221345A (en) * | 1990-10-12 | 1993-06-22 | National Galvanizing Inc. | Method and apparatus for coating a strip |

| GB9106925D0 (en) * | 1991-04-03 | 1991-05-22 | Air Controls Installations Cha | Air knife |

| FR2690170B1 (fr) * | 1992-04-17 | 1995-03-31 | Clecim Sa | Dispositif à lame d'air de régulation d'un dépôt métallique. |

| ATE197822T1 (de) * | 1994-07-14 | 2000-12-15 | Fontaine Eng & Maschinen Gmbh | Vorrichtung und verfahren zum kontrollieren der beschichtungsgewicht eines metallüberzuges mittels blasdüsen |

| FR2726288B1 (fr) * | 1994-10-27 | 1997-01-17 | Clecim Sa | Dispositif a lame d'air pour le reglage de l'epaisseur d'un depot |

-

1997

- 1997-01-22 AU AUPO4732A patent/AUPO473297A0/en not_active Abandoned

-

1998

- 1998-01-22 JP JP53142198A patent/JP4020217B2/ja not_active Expired - Fee Related

- 1998-01-22 US US09/341,818 patent/US6199301B1/en not_active Expired - Lifetime

- 1998-01-22 GB GB9916682A patent/GB2336377B/en not_active Expired - Fee Related

- 1998-01-22 WO PCT/AU1998/000030 patent/WO1998032890A1/en not_active Ceased

- 1998-01-22 DE DE19881989T patent/DE19881989B4/de not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8429834B2 (en) | 2009-03-06 | 2013-04-30 | Mitsubishi-Hitachi Metals Machinery, Inc. | Gas wiping apparatus |

| DE102010008989B4 (de) | 2009-03-06 | 2018-07-26 | Primetals Technologies Japan, Ltd. | Gasabstreifvorrichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| GB9916682D0 (en) | 1999-09-15 |

| AUPO473297A0 (en) | 1997-02-20 |

| WO1998032890A1 (en) | 1998-07-30 |

| GB2336377B (en) | 2001-07-25 |

| GB2336377A (en) | 1999-10-20 |

| DE19881989T1 (de) | 2000-02-10 |

| US6199301B1 (en) | 2001-03-13 |

| JP2001508358A (ja) | 2001-06-26 |

| DE19881989B4 (de) | 2009-05-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4020217B2 (ja) | コーティング厚さ制御 | |

| FI91025B (fi) | Menetelmä paperin tai muun rainamateriaalin päällystemäärän poikkiprofiilin säätämiseksi ja menetelmän toteuttamiseen tarkoitettu päällystysasema | |

| US4697542A (en) | Adjustable nozzle for coating equipment | |

| GB2120132A (en) | Extrusion coating apparatus | |

| KR100758240B1 (ko) | 용융금속 도금강판의 제조방법 | |

| US6174567B1 (en) | Coating medium applicator with guide surface | |

| US6475281B1 (en) | Applicator for direct or indirect application of a liquid or pasty coating medium onto a traveling material web | |

| US6485570B2 (en) | Sink roll blade apparatus used in continuous molten metal plating apparatus and method for preventing occurrence of dents | |

| KR950011764A (ko) | 이동하는 판재나 종이의 웨브를 코우팅하는 방법 및 장치 | |

| KR101959101B1 (ko) | 공기 나이프에서 와이핑 가스 소모를 저감시키는 시스템 | |

| US4321884A (en) | Coating thickness control nozzle | |

| US5788162A (en) | Application unit for directly or indirectly applying a fluid or pasty medium to a continuous material web | |

| JP2002540937A (ja) | シート製品コータでのコーティング厚みの制御 | |

| EP0692549B1 (en) | Apparatus and method for control of metallic coating-weight by the use of gas knives | |

| JPH0640648A (ja) | 紙またはボール紙の移動中にウェブをコーティングする装置 | |

| AU721545B2 (en) | Coating thickness control | |

| US5158388A (en) | Arrangement for the jointed connection of a moveable flow control element with a support element | |

| JPH1190298A (ja) | ダイコータ | |

| JP2006055703A (ja) | カーテン塗布装置及びカーテン塗布方法 | |

| JPH0925552A (ja) | 溶融めっき鋼板の形状制御方法 | |

| JP2000005685A (ja) | ダイコータ | |

| JPH10244199A (ja) | ダイコータ | |

| JPH11207235A (ja) | ダイコータ | |

| Iwamoto et al. | A new air knife system with adjustable lip gaps for hot dip galvanizing | |

| US5419813A (en) | Paper machine headbox with adjustable lower lip |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050120 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20050120 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070213 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070510 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070828 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070919 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101005 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101005 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101005 Year of fee payment: 3 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111005 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121005 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131005 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |