JP3843274B2 - 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 - Google Patents

熱間圧延製品を減速させ、一時的に蓄積する方法と装置 Download PDFInfo

- Publication number

- JP3843274B2 JP3843274B2 JP2004144023A JP2004144023A JP3843274B2 JP 3843274 B2 JP3843274 B2 JP 3843274B2 JP 2004144023 A JP2004144023 A JP 2004144023A JP 2004144023 A JP2004144023 A JP 2004144023A JP 3843274 B2 JP3843274 B2 JP 3843274B2

- Authority

- JP

- Japan

- Prior art keywords

- product

- speed

- guide

- drum

- outlet end

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B39/00—Arrangements for moving, supporting, or positioning work, or controlling its movement, combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B39/002—Piling, unpiling, unscrambling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B41/00—Guiding, conveying, or accumulating easily-flexible work, e.g. wire, sheet metal bands, in loops or curves; Loop lifters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/02—Winding-up or coiling

- B21C47/10—Winding-up or coiling by means of a moving guide

- B21C47/14—Winding-up or coiling by means of a moving guide by means of a rotating guide, e.g. laying the material around a stationary reel or drum

- B21C47/143—Winding-up or coiling by means of a moving guide by means of a rotating guide, e.g. laying the material around a stationary reel or drum the guide being a tube

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C47/00—Winding-up, coiling or winding-off metal wire, metal band or other flexible metal material characterised by features relevant to metal processing only

- B21C47/16—Unwinding or uncoiling

- B21C47/18—Unwinding or uncoiling from reels or drums

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES OR PROFILES, OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C49/00—Devices for temporarily accumulating material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/16—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling wire rods, bars, merchant bars, rounds wire or material of like small cross-section

- B21B1/18—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling wire rods, bars, merchant bars, rounds wire or material of like small cross-section in a continuous process

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B45/00—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B45/02—Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills for lubricating, cooling, or cleaning

- B21B2045/0236—Laying heads for overlapping rings on cooling conveyor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B39/00—Arrangements for moving, supporting, or positioning work, or controlling its movement, combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills

- B21B39/14—Guiding, positioning or aligning work

- B21B39/18—Switches for directing work in metal-rolling mills or trains

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Winding, Rewinding, Material Storage Devices (AREA)

- Metal Rolling (AREA)

- Attitude Control For Articles On Conveyors (AREA)

- Replacement Of Web Rolls (AREA)

Description

Claims (9)

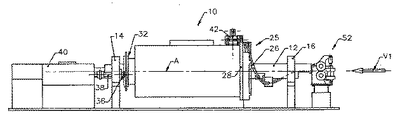

- 受け軸上を長さ方向に第一の速度V1で移動する熱間圧延製品を減速させ、一時的に蓄積する方法であって、

前記軸と一列に並び、前記製品を受ける入口端と、前記軸から半径方向に間隔を空けて設けられ、前記軸を横切る排出方向へと前記製品を方向付ける出口端を有する湾曲ガイドの中に前記製品を通すステップと、

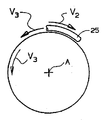

前記軸を中心として、前記排出方向と反対の方向に、前記出口端の速度がV2となる速度で前記湾曲ガイドを連続的に回転させ、前記出口端から運ばれる前記製品を、V1−V2に等しい速度V3へと減速させ、前記ガイドの曲率と前記出口端の向きが、前記出口端から運ばれる前記製品が螺旋を形成するような状態となるステップと、

前記螺旋を円柱形ドラムの上に設置し、一時的に蓄積するステップと、

前記ドラムを、前記湾曲ガイドの前記回転方向と反対の方向に速度V 3 で回転させ、これによって前記ドラムから一時的に蓄積された製品を巻き戻すステップと、

前記ドラムから巻き戻された製品を受ける第二のガイドを配置するステップと、

前記湾曲ガイドの出口端における前記製品の前端の到達時間を決定するステップと、

前記湾曲ガイドの回転速度を調整して、前記到達時間に製品の前端を前記第二のガイドに排出するために前記出口端の角度位置を第二のガイドに関して位置づけるステップと、

を含むことを特徴とする方法。 - 請求項1に記載の方法であって、

前記軸と平行に前記第二のガイドを往復的にシフトさせ、前記第二のガイドが前記ドラムから巻き戻される前記製品と位置合わせされた状態に保たれるようにするステップを含むことを特徴とする方法。 - 請求項1に記載の方法であって、

さらに、前記製品を前記軸に沿って前記湾曲ガイドの中に強制的に進めるステップを含むことを特徴とする方法。 - 軸上を長さ方向に第一の速度V1で移動する熱間圧延製品を減速させるための装置であって、

前記軸と一列に並び、前記製品を受ける入口端と、前記軸から半径方向に間隔を空けて設けられ、前記軸を横切る排出方向へと前記製品を方向付ける出口端とを有する湾曲ガイドと、

前記軸を中心として、前記排出方向と反対の方向に、前記出口端の速度がV2となる速度で前記湾曲ガイドを連続的に回転させ、前記製品が前記出口から、螺旋形状で、V1−V2に等しい速度V3で運ばれるようにする第一の駆動手段と、

前記軸を中心として回転可能であり、前記螺旋を軸方向に受けるよう配置された円柱形ドラムと、

前記ドラムを、前記湾曲ガイドの回転方向に反対の方向に、前記製品が前記第三の速度で前記ドラムから巻き戻されるような速度で回転させる第二の駆動手段と、

前記ドラムから巻き戻された前記製品を受けるための受け入れ手段と、

前記湾曲ガイドの出口端における前記製品の前端の到達時間を決定し、前記湾曲ガイドの回転速度を調整し、前記受け入れ手段に製品の前端を排出する角度位置に、前記出口端を回転して前記出口端を前記受け入れ手段に関して位置づける制御手段と、

を備えることを特徴とする装置。 - 請求項4に記載の装置であって、

前記ドラムの受け入れ端に前記湾曲ガイドの前記出口端が重なることを特徴とする装置。 - 請求項4に記載の装置であって、

前記受け入れ手段は、前記軸に平行なトラックに沿って移動可能なキャリッジと、前記キャリッジの上に設置され、前記ドラムから巻き戻された前記製品を受ける第二のガイドと、前記キャリッジを前記トラックに沿って移動させ、前記第二のガイドを巻き戻された製品と一列に並んだ状態に維持するための第三の駆動手段とを備えることを特徴とする装置。 - 請求項4に記載の装置であって、

さらに、前記製品を前記軸に沿って前記湾曲ガイドの中に強制的に進める手段を備えることを特徴とする装置。 - 請求項4または7に記載の装置であって、

さらに、前記ドラムから巻き戻される前記製品を強制的に前進させる手段を備えることを特徴とする装置。 - 受け軸上を長さ方向に第一の速度V1で移動する熱間圧延製品を減速させ、一時的に蓄積する方法であって、

前記軸と一列に並び、前記製品を受ける入口端と、前記軸から半径方向に間隔を空けて設けられ、前記軸を横切る排出方向へと前記製品を方向付ける出口端を有する湾曲ガイドの中に前記製品を通すステップと、

前記軸を中心として、前記排出方向と反対の方向に、前記出口端の速度がV2となる速度で前記湾曲ガイドを連続的に回転させ、前記出口端から運ばれる前記製品を、V1−V2に等しい速度V3へと減速させ、前記ガイドの曲率と前記出口端の向きが、前記出口端から運ばれる前記製品が螺旋を形成するような状態となるステップと、

前記螺旋を円柱形ドラムの上に設置し、一時的に蓄積するステップと、

前記ドラムを、前記湾曲ガイドの前記回転方向と反対の方向に、前記製品が前記ドラムから速度V3で巻き戻されることができる表面速度で回転させるステップと、

前記ドラムから巻き戻される前記製品を受ける第二のガイドを設置するステップと、

前記出口端における前記製品の前端の到達時間において、前記第二のガイドに関して前記湾曲ガイドの出口端を回転してその角度位置を位置づけ、製品の前端を前記第二のガイドに排出するステップと、

前記第二のガイドを、前記ドラムから巻き戻される製品と一列に並んだ状態に保つステップと、

を含むことを特徴とする方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US47026503P | 2003-05-14 | 2003-05-14 | |

| US10/832,142 US7021103B2 (en) | 2003-05-14 | 2004-04-26 | Method and apparatus for decelerating and temporarily accumulating a hot rolled product |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006136603A Division JP4868506B2 (ja) | 2003-05-14 | 2006-05-16 | 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004337982A JP2004337982A (ja) | 2004-12-02 |

| JP2004337982A5 JP2004337982A5 (ja) | 2005-05-26 |

| JP3843274B2 true JP3843274B2 (ja) | 2006-11-08 |

Family

ID=33032727

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004144023A Expired - Fee Related JP3843274B2 (ja) | 2003-05-14 | 2004-05-13 | 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 |

| JP2006136603A Expired - Fee Related JP4868506B2 (ja) | 2003-05-14 | 2006-05-16 | 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006136603A Expired - Fee Related JP4868506B2 (ja) | 2003-05-14 | 2006-05-16 | 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 |

Country Status (17)

| Country | Link |

|---|---|

| US (1) | US7021103B2 (ja) |

| EP (1) | EP1477244B1 (ja) |

| JP (2) | JP3843274B2 (ja) |

| KR (1) | KR100572643B1 (ja) |

| CN (1) | CN1287923C (ja) |

| AR (1) | AR044356A1 (ja) |

| AT (1) | ATE330727T1 (ja) |

| BR (1) | BRPI0401749B1 (ja) |

| CA (1) | CA2521460C (ja) |

| CZ (1) | CZ2005712A3 (ja) |

| DE (1) | DE602004001281T2 (ja) |

| ES (1) | ES2266954T3 (ja) |

| MX (1) | MXPA05012166A (ja) |

| MY (1) | MY136933A (ja) |

| PL (2) | PL378764A1 (ja) |

| TW (1) | TWI255742B (ja) |

| WO (1) | WO2004103594A1 (ja) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7104510B2 (en) * | 2003-11-19 | 2006-09-12 | Construction Technology, Inc. | Removable balancing assembly for rotating cylindrical structures |

| DE102005044299A1 (de) * | 2005-09-16 | 2007-03-22 | Sms Meer Gmbh | Drahtstraße |

| JP4669777B2 (ja) * | 2005-11-29 | 2011-04-13 | 株式会社日立製作所 | 連続処理設備の速度制御方法 |

| US7093472B1 (en) * | 2006-03-14 | 2006-08-22 | Morgan Construction Company | Method of continuously rolling a product exiting from an upstream roll stand at a velocity higher than the take in velocity of a downstream roll stand |

| US7207202B1 (en) | 2006-05-30 | 2007-04-24 | Morgan Construction Company | Method of subdividing and decelerating hot rolled long products |

| US7587950B2 (en) * | 2006-09-11 | 2009-09-15 | Cummins Filtration Ip Inc. | Source dilution sampling system for emissions analysis |

| US7316145B1 (en) | 2007-02-15 | 2008-01-08 | Morgan Construction Company | Multiple outlet rolling mill |

| US8024949B2 (en) * | 2008-11-17 | 2011-09-27 | Siemens Industry, Inc. | Apparatus for decelerating and temporarily accumulating hot rolled product |

| US8256257B2 (en) * | 2010-12-17 | 2012-09-04 | Siemens Industry, Inc. | Method of operating an apparatus for decelerating and temporarily accumulating hot rolled long products |

| US8997540B2 (en) | 2011-09-27 | 2015-04-07 | Primetals Technologies USA LLC | Tail end ring control in a curved guide of a coiler |

| CN104960999B (zh) * | 2015-06-01 | 2017-11-07 | 无锡华工薄板有限公司 | 钢带用螺旋活套收紧装置 |

Family Cites Families (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US351840A (en) | 1886-11-02 | lenox | ||

| BE389189A (ja) | 1931-09-24 | |||

| US3486359A (en) | 1967-11-21 | 1969-12-30 | Siegener Maschinenbau Gmbh | Rolling mill arrangement |

| DE2100088C3 (de) | 1971-01-02 | 1980-08-21 | Bindernagel, Ali, 5632 Wermelskirchen | Haspelofen für ein kontinuierliches Feineisenwalzwerk |

| BE784118A (fr) | 1971-06-05 | 1972-09-18 | Schloemann Ag | Procede de laminage de petits fers dans un laminoir a grande capacite, et laminoir a petits fers pour la mise en oeuvre du procede |

| JPS5347779B2 (ja) * | 1973-09-28 | 1978-12-23 | ||

| US3942350A (en) | 1974-04-08 | 1976-03-09 | Friedrich Kocks | Rolling mill train for the production of wire |

| JPS5345937B2 (ja) * | 1974-04-26 | 1978-12-09 | ||

| DE2458721C3 (de) | 1974-12-12 | 1978-10-19 | Philips Patentverwaltung Gmbh, 2000 Hamburg | Vorrichtung zur Herstellung von Glühlampenwendeln |

| DE2838155C3 (de) | 1978-09-01 | 1981-09-24 | Mannesmann AG, 4000 Düsseldorf | Förderer zum Transportieren von Drahtwindungen |

| US4457154A (en) | 1981-03-23 | 1984-07-03 | Mitsubishi Denki Kabushiki Kaisha | Control method for multi-strand rolling mill |

| JPS59199115A (ja) * | 1983-04-26 | 1984-11-12 | Nippon Steel Corp | 管棒の圧延巻取法 |

| JPH02235181A (ja) | 1989-03-09 | 1990-09-18 | Fuji Electric Co Ltd | 画像入力装置 |

| JPH02235518A (ja) * | 1989-03-10 | 1990-09-18 | Hitachi Cable Ltd | 線条体の送出装置および送出方法 |

| JP2906386B2 (ja) | 1991-10-28 | 1999-06-21 | 古河電気工業株式会社 | 線状体の貯線方法 |

| US5312065A (en) | 1992-02-05 | 1994-05-17 | Morgan Construction Company | Rod laying head with front and tail end ring control |

| US5307663A (en) | 1993-01-12 | 1994-05-03 | Morgan Construction Company | Multiple outlet finishing mill |

| US5595354A (en) * | 1995-06-29 | 1997-01-21 | Lucent Technologies Inc. | Apparatus for storing a variable quantity of moving strand material |

| DE69710955T2 (de) | 1996-06-26 | 2004-01-29 | Danieli Off Mecc | Wickelverfahren und Wickelvorrichtung |

| US5893288A (en) | 1997-04-25 | 1999-04-13 | Morgan Construction Company | Multiple outlet finishing mill |

| JP2002126817A (ja) | 2000-10-23 | 2002-05-08 | Sumitomo Heavy Ind Ltd | レイングヘッド |

-

2004

- 2004-04-26 US US10/832,142 patent/US7021103B2/en not_active Expired - Fee Related

- 2004-04-29 WO PCT/US2004/013386 patent/WO2004103594A1/en active IP Right Grant

- 2004-04-29 PL PL378764A patent/PL378764A1/pl not_active Application Discontinuation

- 2004-04-29 CZ CZ20050712A patent/CZ2005712A3/cs unknown

- 2004-04-29 CA CA002521460A patent/CA2521460C/en not_active Expired - Fee Related

- 2004-04-29 MX MXPA05012166A patent/MXPA05012166A/es active IP Right Grant

- 2004-05-06 EP EP04010742A patent/EP1477244B1/en not_active Expired - Lifetime

- 2004-05-06 PL PL04010742T patent/PL1477244T3/pl unknown

- 2004-05-06 DE DE602004001281T patent/DE602004001281T2/de not_active Expired - Lifetime

- 2004-05-06 AT AT04010742T patent/ATE330727T1/de active

- 2004-05-06 ES ES04010742T patent/ES2266954T3/es not_active Expired - Lifetime

- 2004-05-10 MY MYPI20041739A patent/MY136933A/en unknown

- 2004-05-13 KR KR1020040033680A patent/KR100572643B1/ko not_active IP Right Cessation

- 2004-05-13 BR BRPI0401749A patent/BRPI0401749B1/pt not_active IP Right Cessation

- 2004-05-13 JP JP2004144023A patent/JP3843274B2/ja not_active Expired - Fee Related

- 2004-05-13 TW TW093113477A patent/TWI255742B/zh not_active IP Right Cessation

- 2004-05-14 AR ARP040101673A patent/AR044356A1/es active IP Right Grant

- 2004-05-14 CN CNB2004100435387A patent/CN1287923C/zh not_active Expired - Fee Related

-

2006

- 2006-05-16 JP JP2006136603A patent/JP4868506B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| TW200502056A (en) | 2005-01-16 |

| CZ2005712A3 (cs) | 2006-02-15 |

| EP1477244A2 (en) | 2004-11-17 |

| ES2266954T3 (es) | 2007-03-01 |

| PL1477244T3 (pl) | 2006-10-31 |

| JP2006212710A (ja) | 2006-08-17 |

| CN1287923C (zh) | 2006-12-06 |

| MXPA05012166A (es) | 2006-02-10 |

| US7021103B2 (en) | 2006-04-04 |

| EP1477244B1 (en) | 2006-06-21 |

| KR100572643B1 (ko) | 2006-04-24 |

| DE602004001281T2 (de) | 2007-06-06 |

| BRPI0401749B1 (pt) | 2015-11-03 |

| AU2004240904A1 (en) | 2004-12-02 |

| DE602004001281D1 (de) | 2006-08-03 |

| JP2004337982A (ja) | 2004-12-02 |

| EP1477244A3 (en) | 2005-01-19 |

| PL378764A1 (pl) | 2006-05-15 |

| BRPI0401749A (pt) | 2005-01-18 |

| TWI255742B (en) | 2006-06-01 |

| ATE330727T1 (de) | 2006-07-15 |

| MY136933A (en) | 2008-11-28 |

| WO2004103594A1 (en) | 2004-12-02 |

| CN1550268A (zh) | 2004-12-01 |

| KR20040098561A (ko) | 2004-11-20 |

| CA2521460C (en) | 2009-06-09 |

| CA2521460A1 (en) | 2004-12-02 |

| US20040250590A1 (en) | 2004-12-16 |

| JP4868506B2 (ja) | 2012-02-01 |

| AR044356A1 (es) | 2005-09-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4868506B2 (ja) | 熱間圧延製品を減速させ、一時的に蓄積する方法と装置 | |

| JP5767246B2 (ja) | 巻取/巻戻装置および圧延ラインにおける金属製品の巻取/巻戻方法 | |

| RU2727457C1 (ru) | Комбинированная установка непрерывного литья и горячей прокатки металлических полос | |

| US4123011A (en) | Coil unwind and wind-up method and apparatus therefor | |

| JP5124558B2 (ja) | 下流の圧延スタンドに設定された速度よりも高い速度で上流の圧延スタンドから排出された製品を連続圧延する方法 | |

| JP2020509937A (ja) | 結合された連続鋳造および金属ストリップ熱間圧延プラント | |

| AU2004240904B2 (en) | Method and apparatus for decelerating and temporarily accumulating a hot rolled product | |

| WO2000044512A1 (en) | Coil-forming head | |

| RU2275261C2 (ru) | Способ и устройство для замедления движения и временного накапливания изделия горячей прокатки | |

| US7823431B2 (en) | Method and apparatus for temporarily interrupting the passage of long products between upstream and downstream paths in a rolling mill | |

| RU2285569C2 (ru) | Способ и устройство для временного прерывания прохождения удлиненных продуктов между расположенными вверх по потоку и вниз по потоку проходами в прокатном стане | |

| JP2832128B2 (ja) | 線材巻取機における先後端制御方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040927 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050830 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051129 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20060117 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060516 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20060612 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060718 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060814 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100818 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| S633 | Written request for registration of reclamation of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313633 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| R360 | Written notification for declining of transfer of rights |

Free format text: JAPANESE INTERMEDIATE CODE: R360 |

|

| R371 | Transfer withdrawn |

Free format text: JAPANESE INTERMEDIATE CODE: R371 |

|

| S633 | Written request for registration of reclamation of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313633 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110818 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120818 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120818 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130818 Year of fee payment: 7 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |