JP3786502B2 - 繊維強化複合成形体およびその製造方法 - Google Patents

繊維強化複合成形体およびその製造方法 Download PDFInfo

- Publication number

- JP3786502B2 JP3786502B2 JP16761697A JP16761697A JP3786502B2 JP 3786502 B2 JP3786502 B2 JP 3786502B2 JP 16761697 A JP16761697 A JP 16761697A JP 16761697 A JP16761697 A JP 16761697A JP 3786502 B2 JP3786502 B2 JP 3786502B2

- Authority

- JP

- Japan

- Prior art keywords

- fiber

- core

- intermediate layer

- thickness

- reinforced composite

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000003733 fiber-reinforced composite Substances 0.000 title claims description 41

- 238000004519 manufacturing process Methods 0.000 title claims description 16

- 239000000835 fiber Substances 0.000 claims description 22

- 239000003365 glass fiber Substances 0.000 claims description 19

- 229920005992 thermoplastic resin Polymers 0.000 claims description 18

- 229920005989 resin Polymers 0.000 claims description 12

- 239000011347 resin Substances 0.000 claims description 12

- 230000003014 reinforcing effect Effects 0.000 claims description 10

- 229920001187 thermosetting polymer Polymers 0.000 claims description 10

- 238000000465 moulding Methods 0.000 claims description 6

- 239000002131 composite material Substances 0.000 claims description 5

- 238000001816 cooling Methods 0.000 claims description 4

- 239000007788 liquid Substances 0.000 claims description 3

- 230000002787 reinforcement Effects 0.000 claims 1

- 239000010410 layer Substances 0.000 description 81

- 239000006185 dispersion Substances 0.000 description 25

- 238000004513 sizing Methods 0.000 description 15

- 238000000034 method Methods 0.000 description 14

- 239000011521 glass Substances 0.000 description 13

- 238000005470 impregnation Methods 0.000 description 12

- 229920006337 unsaturated polyester resin Polymers 0.000 description 12

- 230000002093 peripheral effect Effects 0.000 description 11

- 229920000122 acrylonitrile butadiene styrene Polymers 0.000 description 10

- 230000000052 comparative effect Effects 0.000 description 10

- 238000005452 bending Methods 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 7

- 230000010354 integration Effects 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 238000007493 shaping process Methods 0.000 description 5

- 238000012669 compression test Methods 0.000 description 4

- 238000011417 postcuring Methods 0.000 description 4

- 230000000704 physical effect Effects 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 239000012783 reinforcing fiber Substances 0.000 description 2

- 238000012360 testing method Methods 0.000 description 2

- 230000009466 transformation Effects 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005336 cracking Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 238000009415 formwork Methods 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 239000011796 hollow space material Substances 0.000 description 1

- 239000011229 interlayer Substances 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 150000002978 peroxides Chemical class 0.000 description 1

- 238000013001 point bending Methods 0.000 description 1

- 229920003229 poly(methyl methacrylate) Polymers 0.000 description 1

- 239000004926 polymethyl methacrylate Substances 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 229920006305 unsaturated polyester Polymers 0.000 description 1

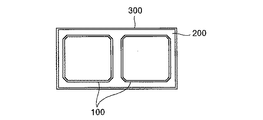

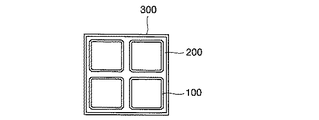

Images

Landscapes

- Rod-Shaped Construction Members (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

- Laminated Bodies (AREA)

- Moulding By Coating Moulds (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP16761697A JP3786502B2 (ja) | 1996-10-02 | 1997-06-24 | 繊維強化複合成形体およびその製造方法 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP26213396 | 1996-10-02 | ||

| JP8-262133 | 1996-10-02 | ||

| JP16761697A JP3786502B2 (ja) | 1996-10-02 | 1997-06-24 | 繊維強化複合成形体およびその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH10156982A JPH10156982A (ja) | 1998-06-16 |

| JPH10156982A5 JPH10156982A5 (enExample) | 2005-03-17 |

| JP3786502B2 true JP3786502B2 (ja) | 2006-06-14 |

Family

ID=26491606

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP16761697A Expired - Fee Related JP3786502B2 (ja) | 1996-10-02 | 1997-06-24 | 繊維強化複合成形体およびその製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3786502B2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010513755A (ja) * | 2006-12-18 | 2010-04-30 | エボニック レーム ゲゼルシャフト ミット ベシュレンクテル ハフツング | プラスチックを他の材料と組み合わせて使用した複合支持系 |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4528385B2 (ja) * | 1999-07-13 | 2010-08-18 | 宇部日東化成株式会社 | 繊維強化中空構造体及びその製造方法 |

| JP2010032168A (ja) * | 2008-07-30 | 2010-02-12 | Ryuki Engineering:Kk | 送風又は排気用のダクト |

| EP2355116A1 (en) | 2010-01-29 | 2011-08-10 | ABB Research Ltd. | An electric device and a method for manufacturing the device |

| CN103568346B (zh) * | 2012-07-18 | 2016-04-27 | 廖树汉 | 能锯钻耐冲击抗弯曲代替钢管的空心壁塑玻管 |

| JP6034174B2 (ja) * | 2012-12-17 | 2016-11-30 | 三菱樹脂株式会社 | Frp製の構造物及びこれを用いた建築土木構造物 |

| CN104401011B (zh) * | 2014-10-30 | 2017-11-07 | 中国人民解放军国防科学技术大学 | 夹芯结构复合材料及其制备方法 |

| MX2022007498A (es) * | 2019-12-16 | 2022-10-13 | Fibercore Ip Bv | Producto con un conjunto de elementos centrales o huecos y laminas interpuestas y procedimientos para formar dicho producto. |

| CN112664729A (zh) * | 2020-12-17 | 2021-04-16 | 威海纳川管材有限公司 | 一种玻璃钢柔性复合管、生产装置及生产方法 |

| CN113263723B (zh) * | 2021-04-30 | 2022-04-05 | 西安交通大学 | 可变半径的多打印头一体式桁架3d打印机及其使用方法 |

-

1997

- 1997-06-24 JP JP16761697A patent/JP3786502B2/ja not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010513755A (ja) * | 2006-12-18 | 2010-04-30 | エボニック レーム ゲゼルシャフト ミット ベシュレンクテル ハフツング | プラスチックを他の材料と組み合わせて使用した複合支持系 |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH10156982A (ja) | 1998-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6607798B1 (en) | Fiber-reinforced composite hollow structure, method for production thereof, and apparatus therefor | |

| JP5416341B2 (ja) | 丸形状繊維強化プラスチック線材の製造方法 | |

| US6592979B1 (en) | Hybrid matrix fiber composites | |

| KR102060109B1 (ko) | Pmi 발포체 코어를 사용하는 풀-코어 방법 | |

| JP3786502B2 (ja) | 繊維強化複合成形体およびその製造方法 | |

| KR102216229B1 (ko) | 폼 코어들을 갖는 샌드위치 타입의 구성의 프로파일들의 연속적인 제조 및 강성의 폼이 충전된 프로파일 | |

| CN108583485A (zh) | 一种多胞金属基碳纤维复合薄壁吸能结构及其制备工艺 | |

| WO2017181279A1 (en) | Methods for producing continuous composite sandwich structures by pultrusion | |

| CN110549653A (zh) | 一种纤维增强复合型材及其制备方法和显示设备边框 | |

| KR20210086469A (ko) | 연속섬유 복합재 제조장치 | |

| JPH0561091B2 (enExample) | ||

| JP5624871B2 (ja) | 扁平形状繊維強化プラスチック線材シートの製造方法 | |

| JP2659110B2 (ja) | 繊維強化樹脂複合管及びその製造方法 | |

| CN101637974A (zh) | 一种复合材料型材的定型装置 | |

| US20230249420A1 (en) | Method of producing fiber-reinforced molded article | |

| CN117002050A (zh) | 环向性能增强的复合材料组合型材的制作方法 | |

| KR100959389B1 (ko) | 다축 프리프레그 시트 및 그 제조방법 | |

| CN212022561U (zh) | 一种多胞金属基碳纤维复合薄壁吸能结构 | |

| JPH0834066A (ja) | 連続引抜き成形装置 | |

| JPH0834065A (ja) | Frp製中空体の引抜き成形方法 | |

| CN121157393A (zh) | 一种采用混编纱制备热塑/环氧连续纤维增强复合材料的方法 | |

| CN120966178A (zh) | 一种热塑性双稳态管及其制备方法 | |

| CN118423517A (zh) | 高刚度细长管以及成型方法 | |

| KR20050032734A (ko) | 덕트의 플랜지 성형방법 및 그 방법에 의한 덕트 | |

| CN116882069A (zh) | 轨道车辆复合材料扶手杆设计方法、扶手及轨道车辆 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040413 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040413 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20050921 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20051004 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051118 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20051213 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060125 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060221 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060320 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20090331 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100331 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100331 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| R371 | Transfer withdrawn |

Free format text: JAPANESE INTERMEDIATE CODE: R371 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| R371 | Transfer withdrawn |

Free format text: JAPANESE INTERMEDIATE CODE: R371 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110331 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120331 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130331 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130331 Year of fee payment: 7 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |