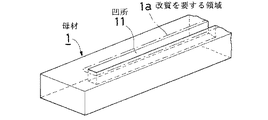

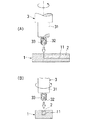

JP3775894B2 - 母材の局部的改質方法 - Google Patents

母材の局部的改質方法 Download PDFInfo

- Publication number

- JP3775894B2 JP3775894B2 JP20445097A JP20445097A JP3775894B2 JP 3775894 B2 JP3775894 B2 JP 3775894B2 JP 20445097 A JP20445097 A JP 20445097A JP 20445097 A JP20445097 A JP 20445097A JP 3775894 B2 JP3775894 B2 JP 3775894B2

- Authority

- JP

- Japan

- Prior art keywords

- base material

- reforming

- probe

- locally

- recess

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000000463 material Substances 0.000 title claims description 155

- 238000000034 method Methods 0.000 title claims description 39

- 230000004048 modification Effects 0.000 title claims description 13

- 238000012986 modification Methods 0.000 title claims description 13

- 238000002407 reforming Methods 0.000 claims description 73

- 239000000523 sample Substances 0.000 claims description 37

- 230000000051 modifying effect Effects 0.000 claims description 19

- 238000003756 stirring Methods 0.000 claims description 10

- 239000000843 powder Substances 0.000 claims description 8

- 239000007769 metal material Substances 0.000 claims description 6

- 230000002093 peripheral effect Effects 0.000 claims description 5

- 239000007790 solid phase Substances 0.000 claims description 3

- 229910052751 metal Inorganic materials 0.000 description 9

- 239000002184 metal Substances 0.000 description 9

- 238000002844 melting Methods 0.000 description 6

- 230000008018 melting Effects 0.000 description 6

- 230000004075 alteration Effects 0.000 description 5

- 238000005304 joining Methods 0.000 description 5

- 238000003466 welding Methods 0.000 description 5

- 230000006866 deterioration Effects 0.000 description 4

- 238000002156 mixing Methods 0.000 description 4

- 230000007423 decrease Effects 0.000 description 3

- 238000005243 fluidization Methods 0.000 description 3

- 239000008187 granular material Substances 0.000 description 3

- 229910000765 intermetallic Inorganic materials 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 239000002994 raw material Substances 0.000 description 3

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 238000009826 distribution Methods 0.000 description 2

- 230000006698 induction Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 238000002715 modification method Methods 0.000 description 2

- 230000000704 physical effect Effects 0.000 description 2

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 1

- 238000013019 agitation Methods 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 239000010953 base metal Substances 0.000 description 1

- 238000005219 brazing Methods 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 229910000423 chromium oxide Inorganic materials 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 230000032798 delamination Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 210000001503 joint Anatomy 0.000 description 1

- 229910052748 manganese Inorganic materials 0.000 description 1

- 239000011572 manganese Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- MTPVUVINMAGMJL-UHFFFAOYSA-N trimethyl(1,1,2,2,2-pentafluoroethyl)silane Chemical compound C[Si](C)(C)C(F)(F)C(F)(F)F MTPVUVINMAGMJL-UHFFFAOYSA-N 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/1275—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding involving metallurgical change

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K20/00—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating

- B23K20/12—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding

- B23K20/122—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding

- B23K20/128—Non-electric welding by applying impact or other pressure, with or without the application of heat, e.g. cladding or plating the heat being generated by friction; Friction welding using a non-consumable tool, e.g. friction stir welding making use of additional material

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

- Other Surface Treatments For Metallic Materials (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP20445097A JP3775894B2 (ja) | 1997-07-30 | 1997-07-30 | 母材の局部的改質方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP20445097A JP3775894B2 (ja) | 1997-07-30 | 1997-07-30 | 母材の局部的改質方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH1150266A JPH1150266A (ja) | 1999-02-23 |

| JPH1150266A5 JPH1150266A5 (enExample) | 2005-05-26 |

| JP3775894B2 true JP3775894B2 (ja) | 2006-05-17 |

Family

ID=16490736

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP20445097A Expired - Fee Related JP3775894B2 (ja) | 1997-07-30 | 1997-07-30 | 母材の局部的改質方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3775894B2 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4672202B2 (ja) * | 2001-08-01 | 2011-04-20 | マツダ株式会社 | 回転工具、当該回転工具を用いた部材の処理方法及び表面処理方法 |

| JP4335702B2 (ja) * | 2004-01-22 | 2009-09-30 | 三菱重工業株式会社 | クラッド材の製造方法 |

| TWI335251B (en) * | 2004-03-25 | 2011-01-01 | Univ Nihon | Method ana apparatus of joining metallic plates by frictional pressure welding |

| JP5052187B2 (ja) * | 2006-04-11 | 2012-10-17 | 国立大学法人大阪大学 | 金属材の製造方法および金属材 |

| JP5250410B2 (ja) * | 2008-12-26 | 2013-07-31 | 株式会社日立製作所 | 複合材料の製造方法 |

| JP5289990B2 (ja) * | 2009-01-28 | 2013-09-11 | 日立建機株式会社 | 丸軸表面の改質方法及びこれに用いる改質装置 |

| JP5618314B2 (ja) * | 2009-03-26 | 2014-11-05 | 国立大学法人大阪大学 | 金属材の製造方法及び金属材 |

| EP2745972B1 (en) | 2011-08-19 | 2021-11-10 | Nippon Light Metal Company, Ltd. | Friction stir welding method |

| CN106141422A (zh) * | 2016-08-23 | 2016-11-23 | 山东建筑大学 | 一种提高热处理强化铝合金搅拌摩擦焊接头表面抗腐蚀性的方法 |

| CN109676328B (zh) * | 2019-02-12 | 2023-11-21 | 黄山学院 | 一种斜面工件表面改性方法及装置 |

| CN109648187B (zh) * | 2019-02-12 | 2023-04-07 | 黄山学院 | 一种工具钢搅拌摩擦加工改性的方法及改性用填充板材结构 |

| CN110193658B (zh) * | 2019-06-24 | 2021-03-12 | 哈尔滨工业大学 | 一种组分可调同步送料的摩擦头及摩擦增材制造方法 |

| JP7432842B2 (ja) * | 2019-12-04 | 2024-02-19 | 日本製鉄株式会社 | 部分複合化鉄鋼材及びその製造方法 |

-

1997

- 1997-07-30 JP JP20445097A patent/JP3775894B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH1150266A (ja) | 1999-02-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3775894B2 (ja) | 母材の局部的改質方法 | |

| US7661575B2 (en) | Friction stirring-welding method | |

| JP2019081197A (ja) | 低温摩擦攪拌処理中の耐摩耗性を向上させるための装置、システム、及び方法 | |

| US6732901B2 (en) | Anvil for friction stir welding high temperature materials | |

| US20020158109A1 (en) | Method of processing metal members | |

| US6892924B2 (en) | Precessing rivet and method for friction stir riveting | |

| US6227432B1 (en) | Friction agitation jointing method of metal workpieces | |

| KR20010052329A (ko) | 마찰 스터 용접 공구 | |

| JP2003326372A (ja) | 摩擦攪拌接合用ツール | |

| EP1399286A1 (en) | Anvil for friction stir welding high temperature materials | |

| JP4592103B2 (ja) | 摩擦圧接による金属板材の接合方法及びその装置 | |

| CN112368102A (zh) | 摩擦搅拌接合用工具及摩擦搅拌接合方法 | |

| JP4412608B2 (ja) | 接合方法および接合体 | |

| JP2002283070A (ja) | 異種金属材料の摩擦撹拌接合方法 | |

| JP5953060B2 (ja) | 被加工部材の加工方法 | |

| JP2011235335A (ja) | 摩擦撹拌接合用工具 | |

| JP2000225476A (ja) | 金属製ワーク同士の摩擦撹拌接合方法 | |

| JP2023515789A (ja) | 摩擦攪拌溶接ツールおよびそれを生産するための方法 | |

| JP6192040B2 (ja) | 継手の製造方法及び複合材料の製造方法 | |

| JP2004034141A (ja) | 接合継手の製造方法、接合継手、摩擦撹拌接合法、接合装置及び平削り用バイト | |

| JP2005152971A (ja) | 摩擦攪拌接合用の金属板材表面処理方法、金属板材、塗料、接合方法、及び移動体 | |

| JP2006205190A (ja) | 異種金属材料の接合方法 | |

| JP2004042095A (ja) | 摩擦攪拌接合法とその装置 | |

| JPH11197861A (ja) | 肉盛り溶接方法 | |

| JP2003311440A (ja) | 摩擦圧接により接合された金属板及び摩擦圧接による金属板の接合方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040726 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040726 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20050912 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050927 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051125 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060214 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060221 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: R3D02 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120303 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120303 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150303 Year of fee payment: 9 |

|

| LAPS | Cancellation because of no payment of annual fees |